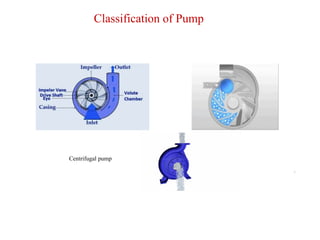

The document provides an overview of turbo machines, specifically focusing on pumps and turbines, including their classifications, components, and operational principles. It details the functioning of centrifugal pumps, the role of impellers, casings, and suction and delivery pipes, along with insights on cavitation and methods to prevent it. The document emphasizes the importance of selecting appropriate materials for impellers based on the fluid being pumped and highlights efficiency factors in pump design.