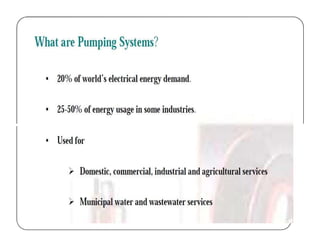

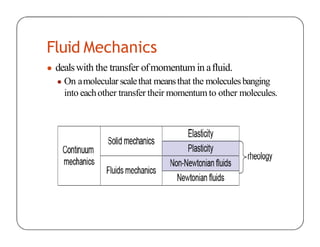

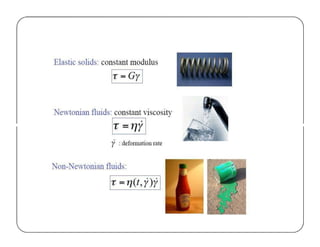

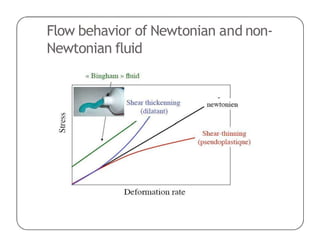

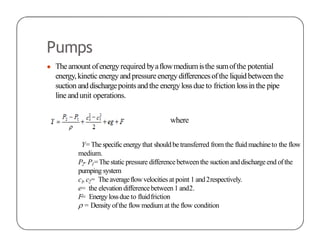

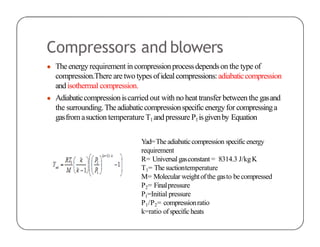

This document provides an overview of fluid machines used in chemical process industries. It defines fluid machines as devices that transfer mechanical energy to fluids to increase pressure, velocity or potential energy. Common fluid machines discussed include pumps, fans, compressors and blowers. Key concepts covered are mechanical energy and specific work of fluids, fluid flow characteristics, transport phenomena, and basic equations for determining energy requirements of pumping and compression processes.