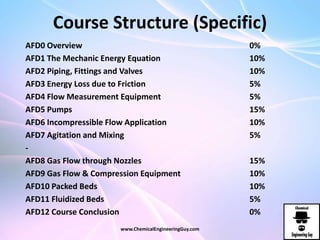

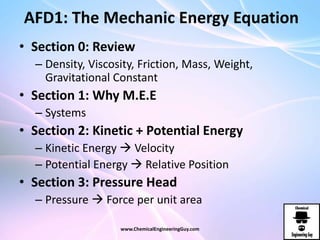

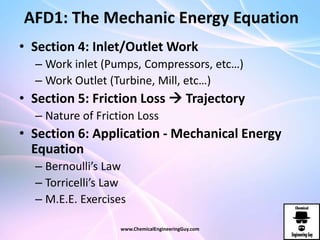

This document outlines the structure and content of an online course on applied fluid dynamics. The course is divided into two parts: Part 1 covers incompressible flow, while Part 2 will cover compressible flow. Part 1 includes lessons on the mechanic energy equation, piping systems, energy losses, flow measurement equipment, pumps, incompressible flow applications, and mixing. Each lesson provides an overview of key concepts and equations. Upon completing Part 1, students are instructed to review the material and directed to the next part of the course on the website listed.