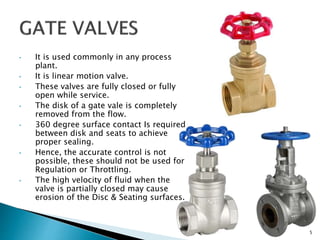

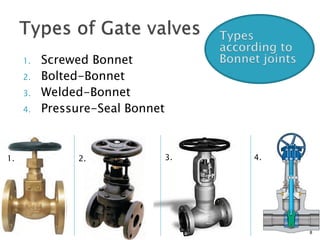

The document presents an overview of various types of valves, including gate, globe, and butterfly valves, along with their applications, advantages, and disadvantages. It also discusses pressure relief valves as safety devices for pressurized systems, and highlights the importance of properly spacing pipe supports and hangers in industrial piping or ducting systems. Key factors influencing support spacing include the diameter of the piping, system temperature, and the weight of transported liquids.