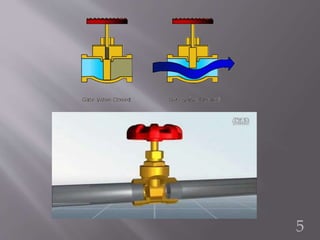

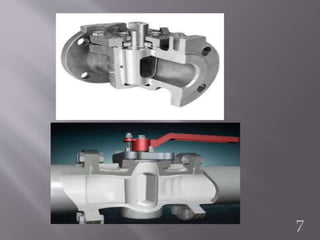

This document discusses different types of valves used in pipe systems. It describes 7 common valve types: gate valves, plug valves, globe valves, butterfly valves, diaphragm valves, check valves, and ball valves. For each type it provides a brief description of its purpose and basic functioning within pipe networks. The document aims to provide an overview of common valve types and their applications in regulating fluid flow through pipes and conduits.