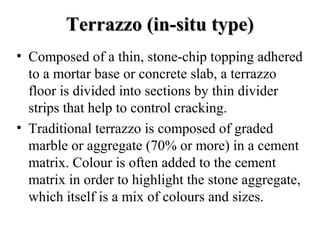

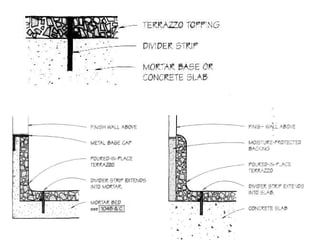

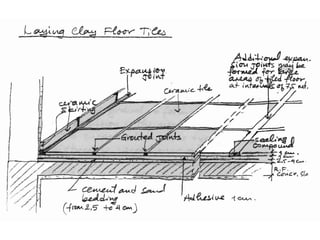

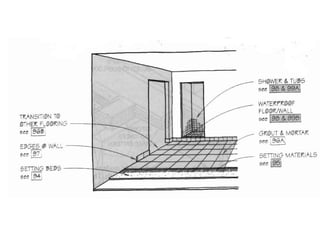

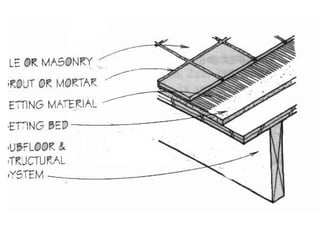

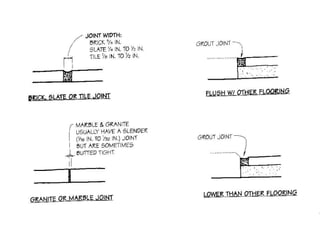

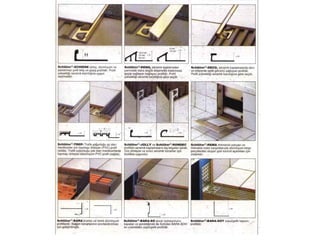

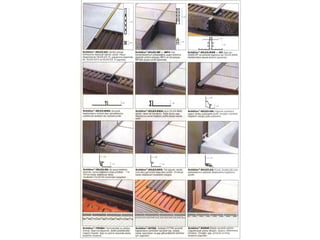

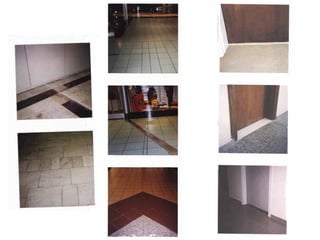

This document discusses different types of floor finishes including screeds, terrazzo, ceramic tiling, and granite or marble. It provides details on cement screeds, fiber-reinforced cement screeds, and the traditional laying process for screeds. For terrazzo floors, it describes the stone-chip topping adhered to a mortar base or concrete slab and the use of divider strips. The document outlines the process for laying ceramic tiles, including using a semi-dry cement bed and grout and including expansion joints.