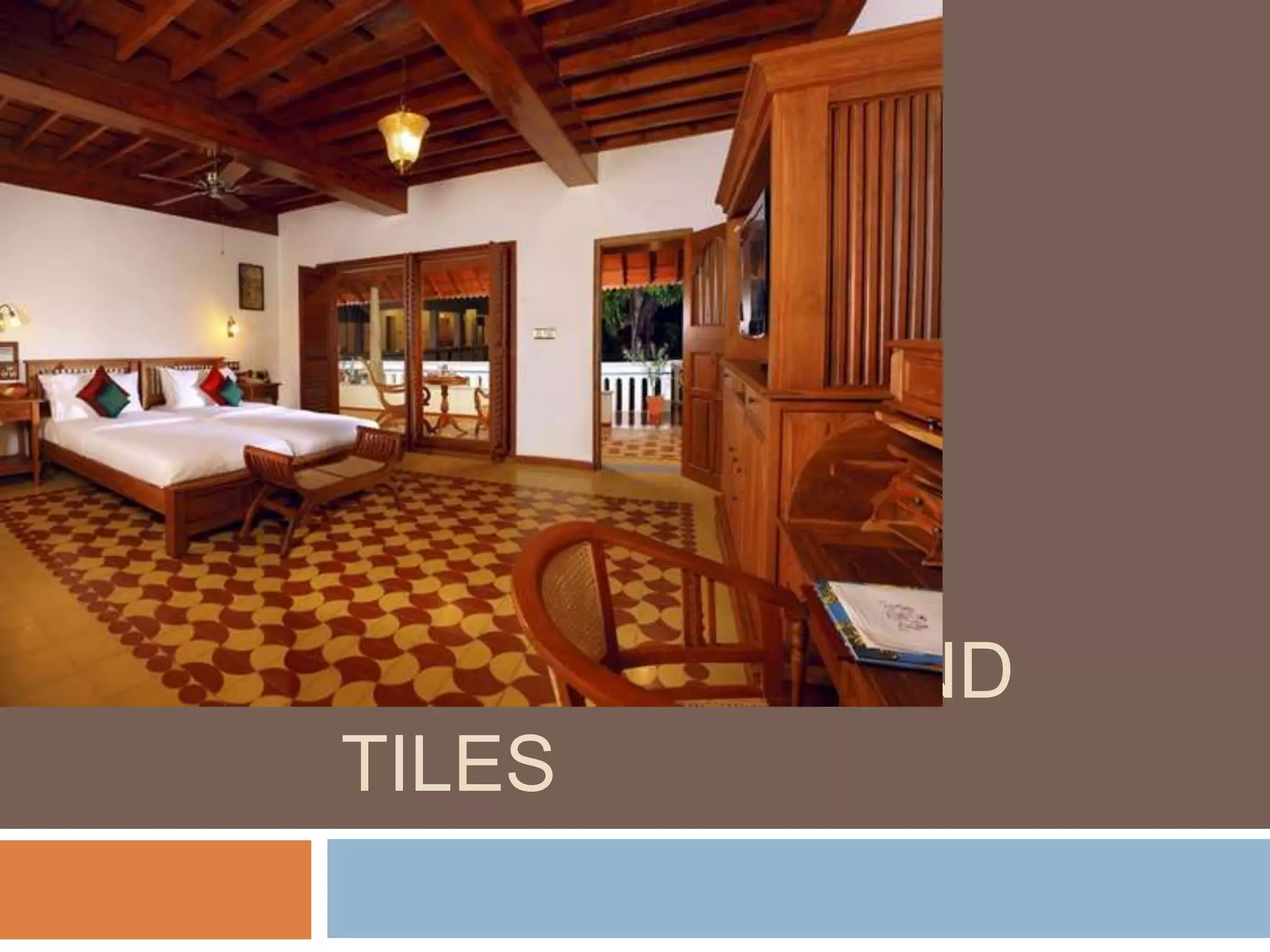

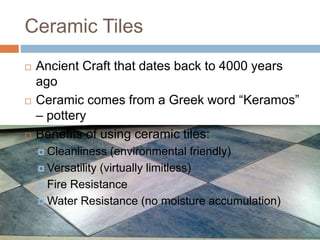

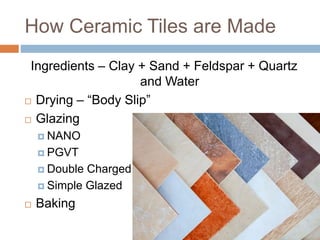

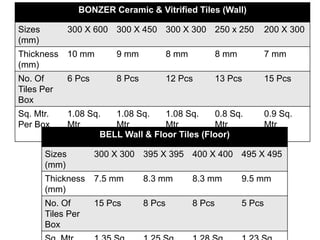

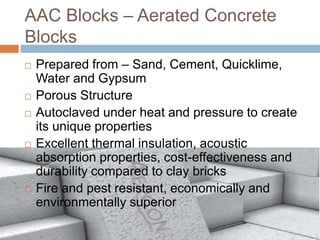

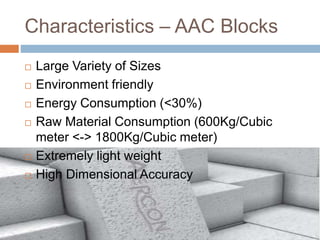

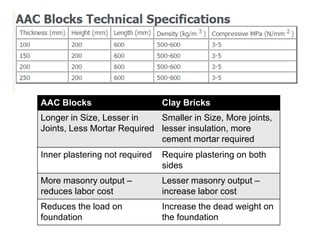

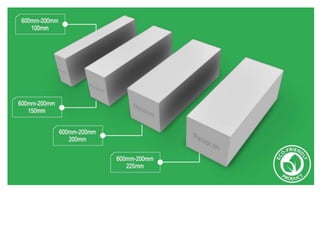

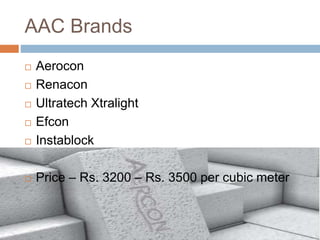

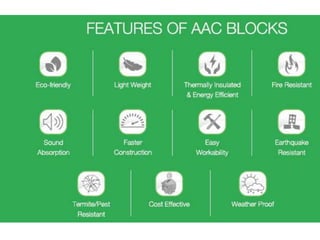

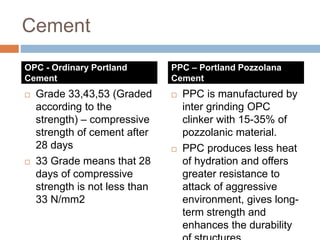

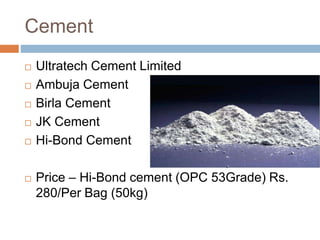

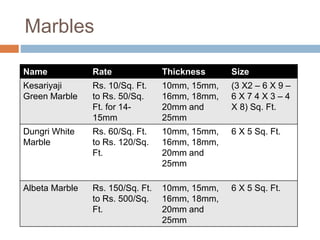

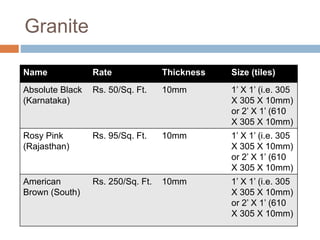

This document provides information on plastering, tiles, and construction materials. It discusses the different types of plaster like lime plaster and cement plaster. It also describes various tiles including ceramic, stone, digital and glass tiles. Ceramic tile production involves ingredients like clay, sand and feldspar that are dried, glazed and baked. The document lists tile sizes and provides specifications for wall and floor tiles. It also gives details on aerated concrete blocks, cement, marbles, granite and their characteristics, brands and pricing.