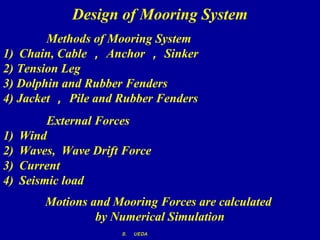

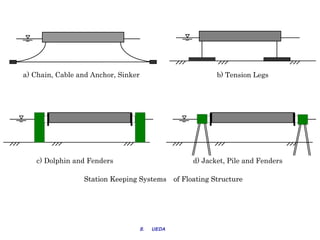

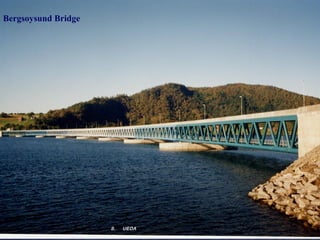

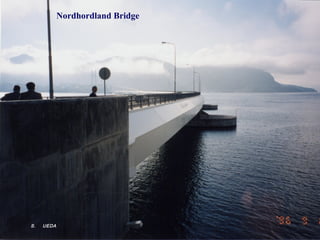

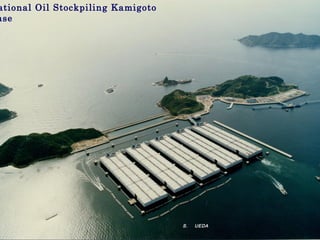

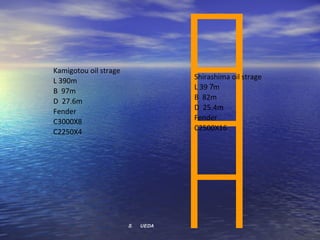

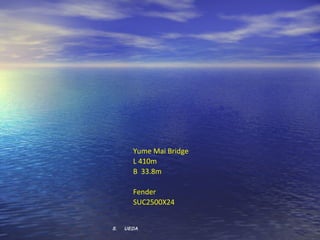

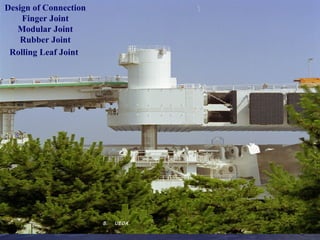

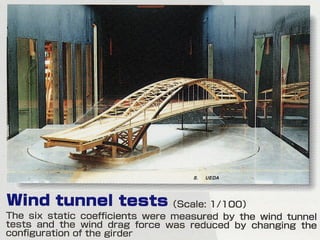

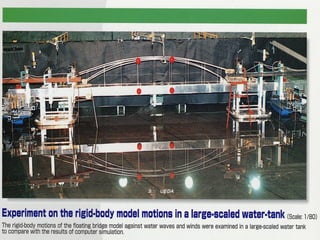

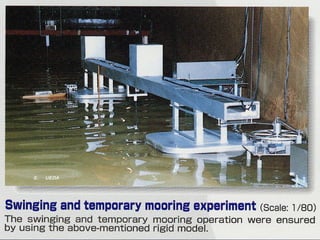

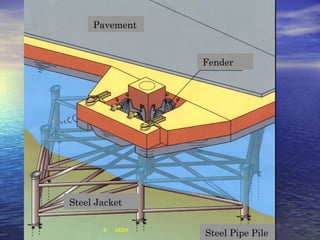

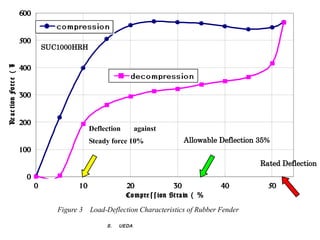

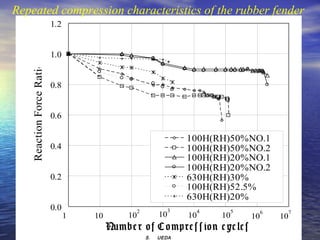

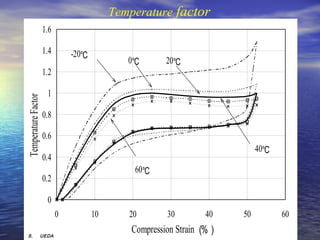

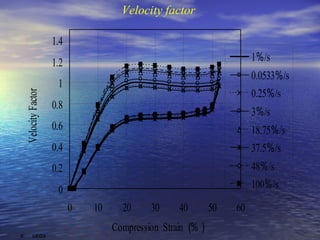

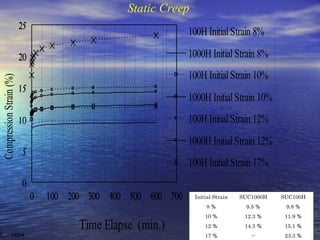

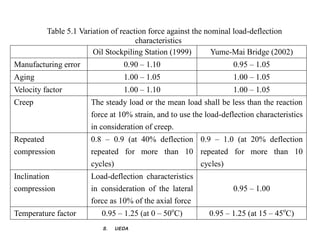

The document discusses methods for mooring floating structures in Japan, focusing on the use of rubber fenders. It describes four main mooring systems - chains/cables, tension legs, dolphins with fenders, and jackets/piles with fenders. The document then examines forces that affect floating structures like wind, waves, currents and seismic activity. It provides examples of floating structures moored using rubber fenders and discusses fender properties, performance factors, load-deflection characteristics, and variability in reactions forces over time.