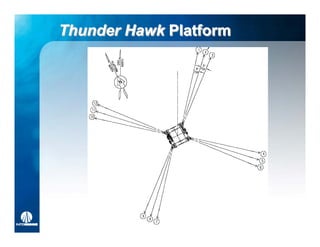

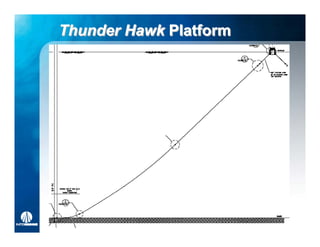

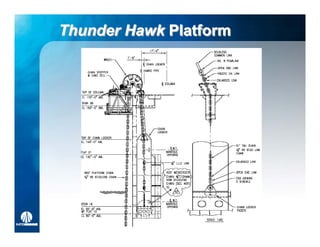

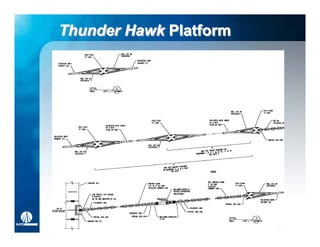

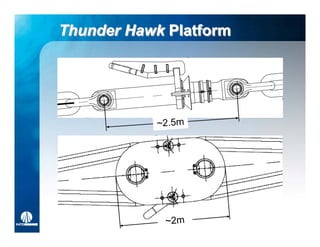

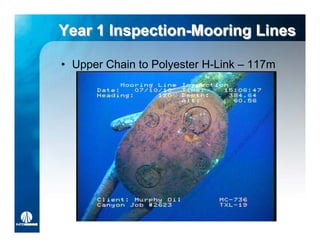

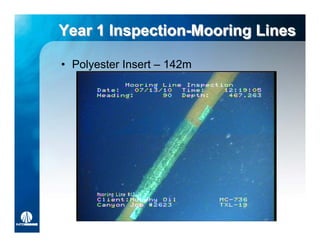

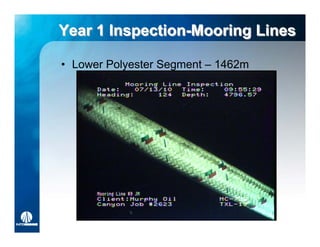

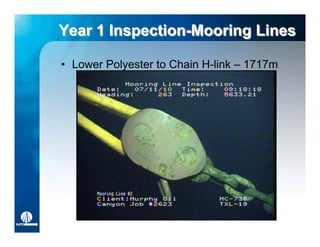

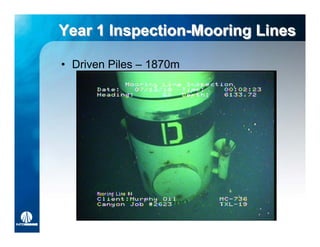

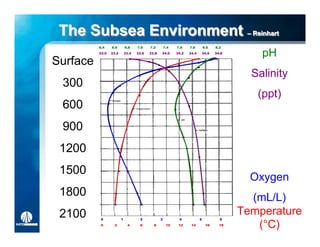

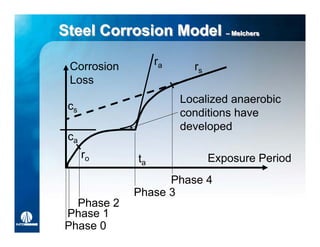

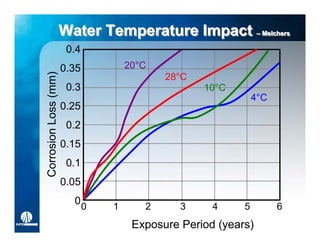

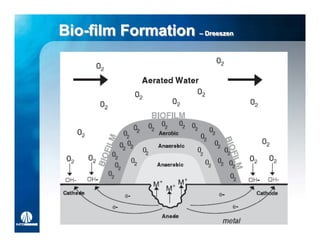

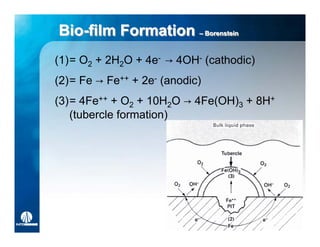

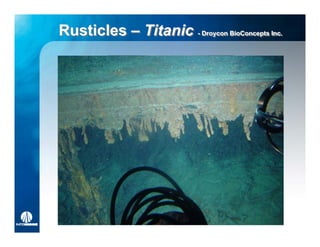

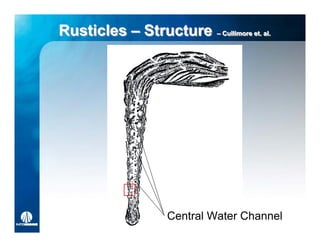

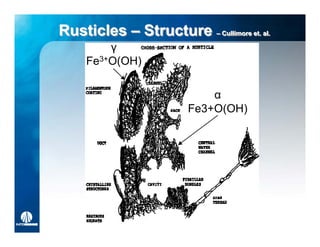

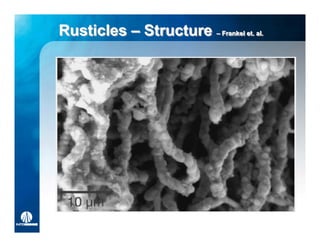

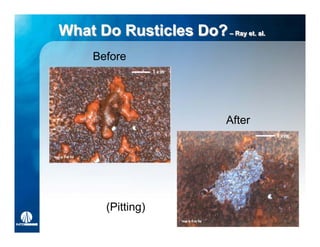

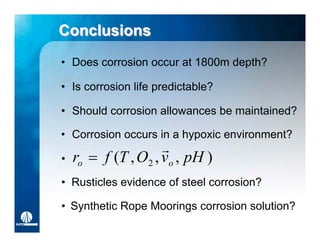

The document presents new findings on the Thunder Hawk platform's polyester and chain mooring systems, summarizing inspection results which indicate the integrity of mooring lines and hardware. It discusses factors influencing steel corrosion, including environmental conditions and bio-film formation, as well as detailing rusticle composition and structure from various shipwrecks. The conclusions raise questions about corrosion predictability and the maintenance of corrosion allowances at significant depths.