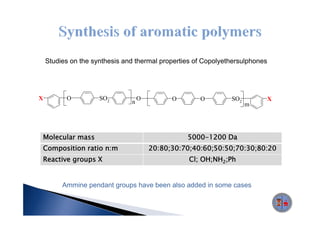

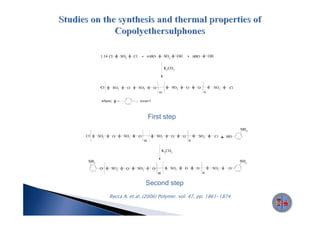

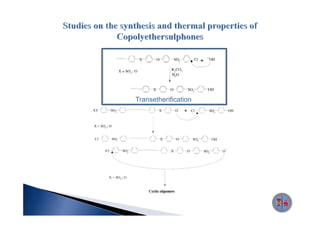

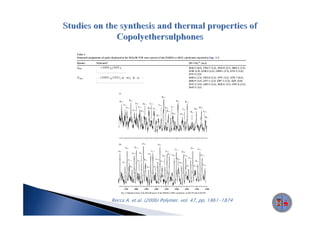

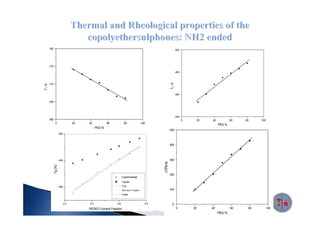

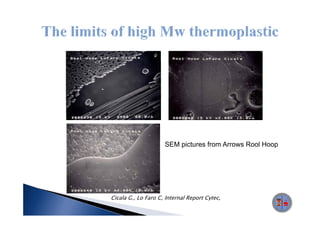

The document summarizes the research activities of Prof. A. Recca and his group at the University of Catania. Their work focuses on the synthesis and characterization of aromatic polymers, epoxy/thermoplastic blends, and RTM technology. Current projects include studies on copolyethersulphones and the development of toughened thermoset blends for aerospace composites. The group also works on new materials and processes with industrial partners. They have equipment for polymer synthesis, characterization, and composite processing like RTM.

![3

10

50:50 PES:PEES Cl Ended @290°C 4

10

3

10

G', G'' [Pa]

Pa-s]

η* [P

G

2

10

1

10

2

10

0,1

, 1 10 100

ω [rad/sec]](https://image.slidesharecdn.com/pecgroup-12537817816331-phpapp03/85/Pe-C-Group-9-320.jpg)

![DGEBA/MDEA

3

10 No Modifier

15% C1

2 15% C2

10

15% C3

15% C4

1

10

-s]

η * [Pa-

0

10

-1

10

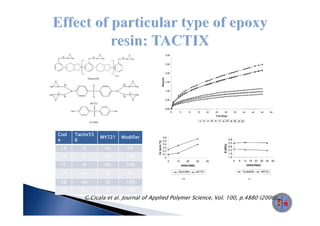

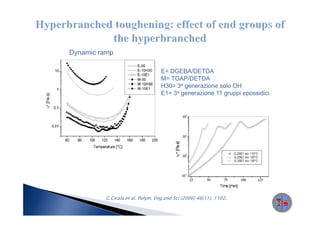

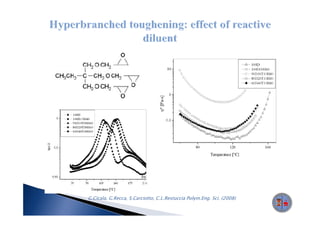

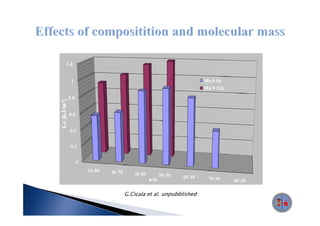

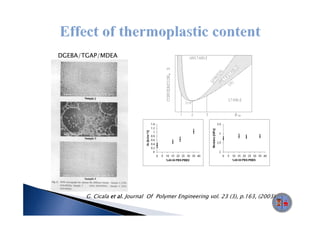

Modifier End Group Mn Gc [kJ/m2] Kc [Mpa m3/2]

-2 No Modifier ----------- ----------- 0,23

0 23 0,92

0 92

10

C1 Amine 5k 0,89 1,80

0 25 50 75 100 125 150

C2 Amine 9k 1,15 2,07

Time [min]

C3 Chlorine 10 k 0,52 1,39

C4 Hydroxyl 12 k 1,33 2,20

G.Cicala et al. Journal of Applied Polymer Science, Vol. 101, p.250 (2006)](https://image.slidesharecdn.com/pecgroup-12537817816331-phpapp03/85/Pe-C-Group-16-320.jpg)

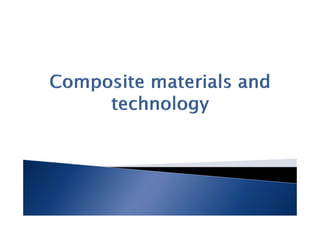

![DGEBA/DDS 10 DGEBA/MDEA

1 No Modifier

No Modifier

15% wt Modifier 15% Wt Modifier

30% wt Modifier 30% Wt Modifier

1

Tan δ

Tan δ

0.1

0.1

0.01

0.01

60 90 120 150 180 60 120 180

Temperature [°C] Temperature [°C]

G.Cicala et al. Journal of Applied Polymer Science, Vol. 94, p.361 (2004)](https://image.slidesharecdn.com/pecgroup-12537817816331-phpapp03/85/Pe-C-Group-17-320.jpg)