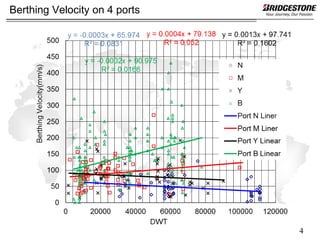

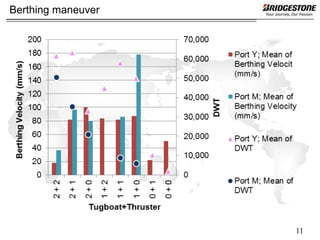

This document analyzes berthing velocities and angles at four ports to inform fender design. It finds berthing velocities vary by port and do not correlate directly to vessel size. Wind has little effect on velocities. Berthing angles are typically smaller than design specifications, but flare angles are three times larger. Larger container ships have more curved hulls at fender level, allowing energy absorption across multiple fenders during berthing. Proper measurement of temperature and strain rates is important for accurately assessing fender performance under different conditions.