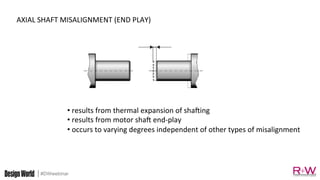

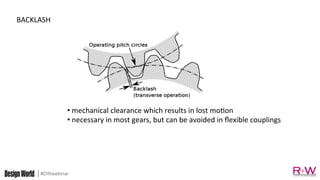

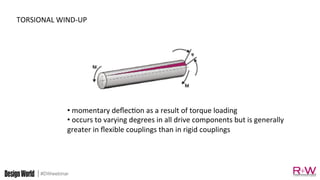

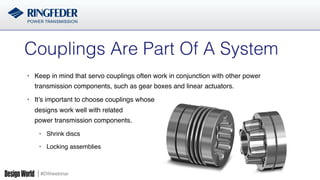

The webinar discusses the differences between flexible and rigid couplings, focusing on their applications, benefits, and limitations. It highlights the importance of addressing misalignments in shaft connections and presents specific coupling types suitable for various automation systems. The discussion also includes technical details about designing couplings for operational efficiency in high-precision environments.