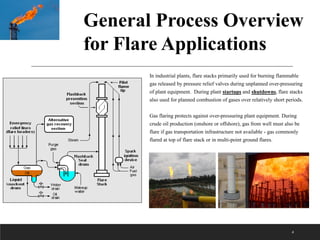

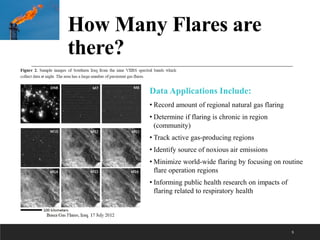

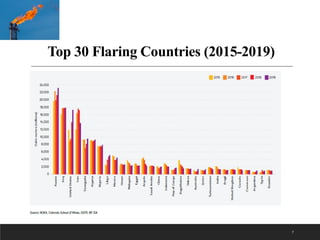

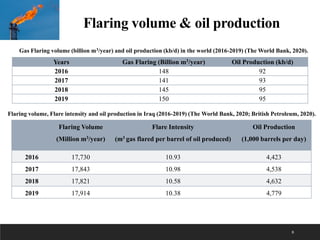

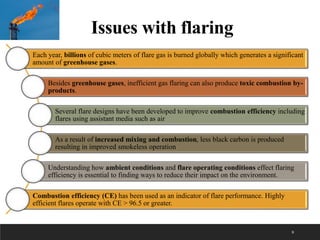

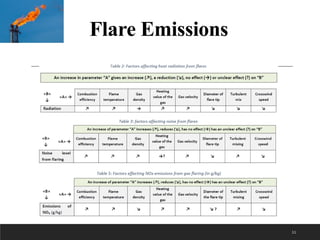

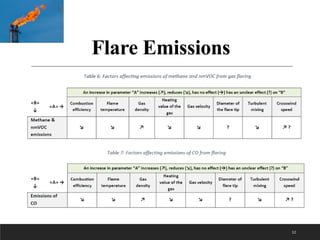

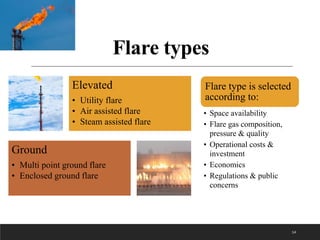

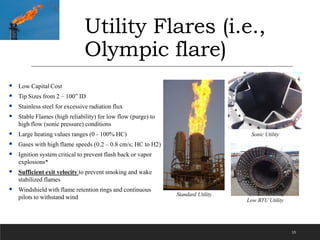

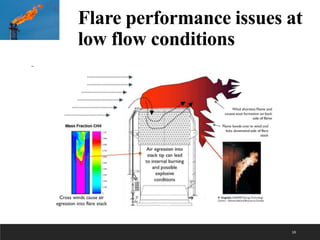

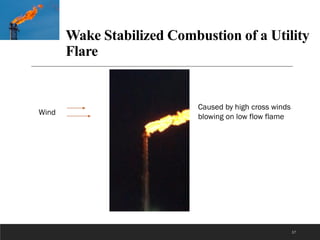

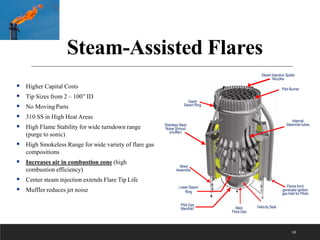

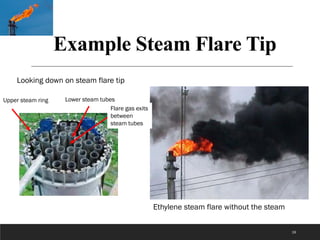

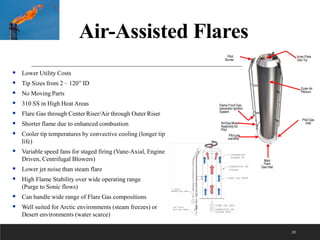

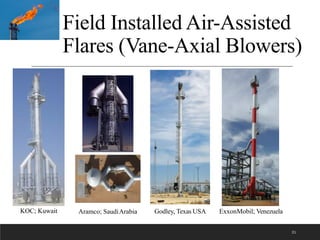

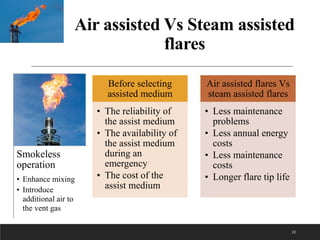

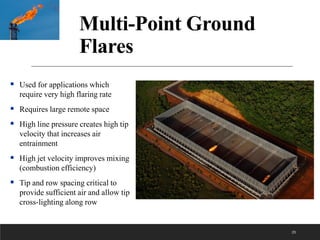

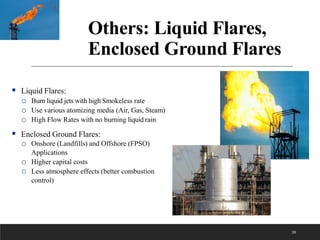

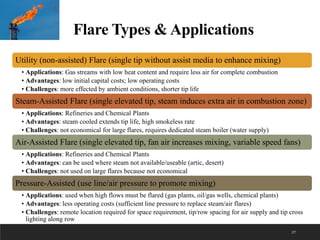

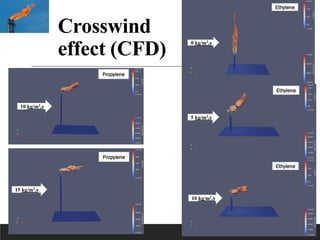

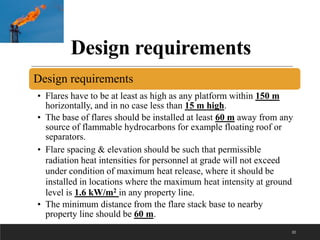

This document discusses flare technology and applications. It begins with an outline and defines a flare as safety equipment used to burn unwanted gases from oil, gas, and chemical plants. It notes that flares ensure safe combustion to prevent explosions. The document then discusses: the widespread use of flares globally; types of flares including utility, steam-assisted, air-assisted, and multi-point ground flares; factors that influence flare design and performance such as gas composition and flow rates; and issues with flaring including emissions and strategies to minimize flaring.