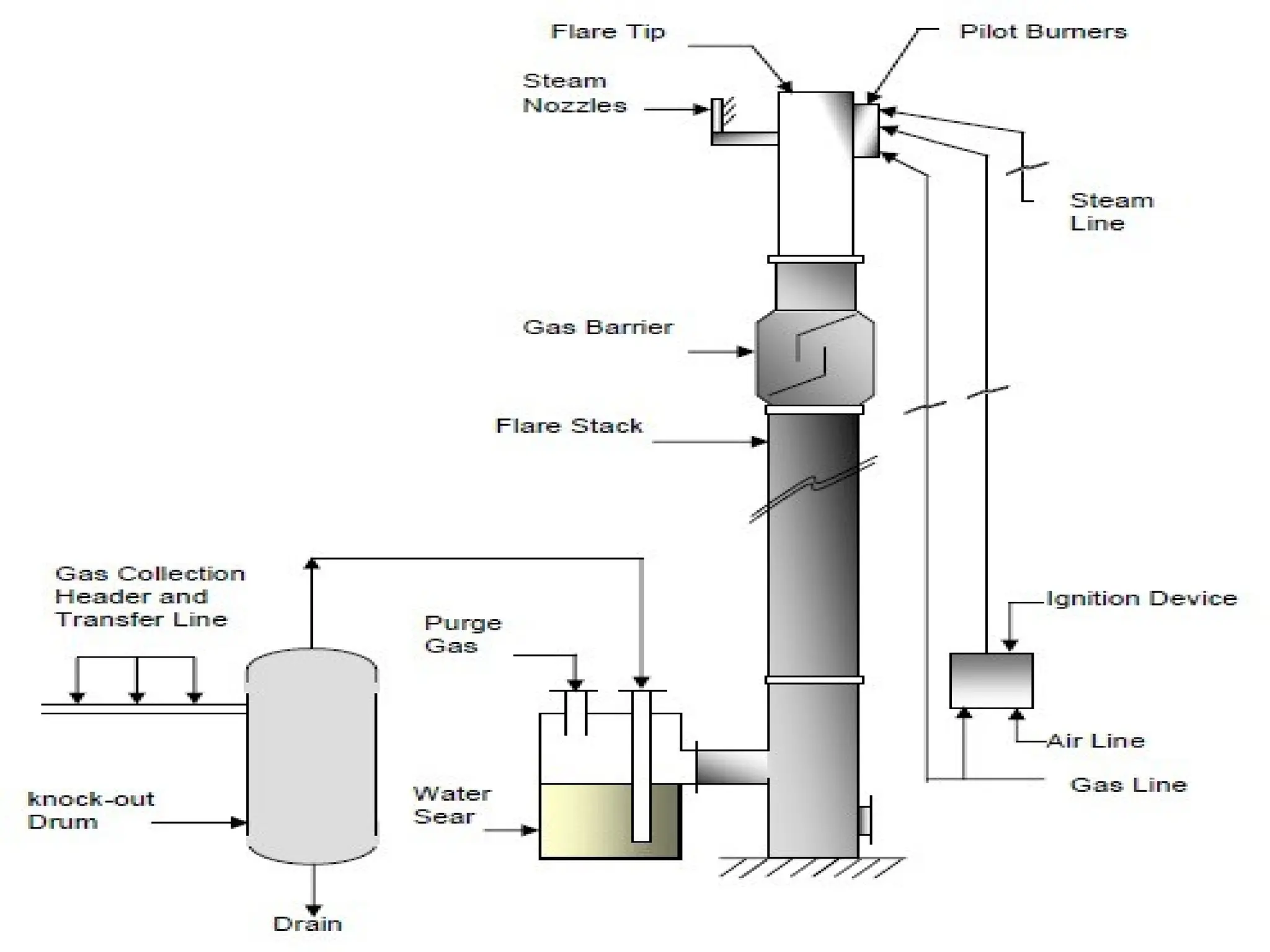

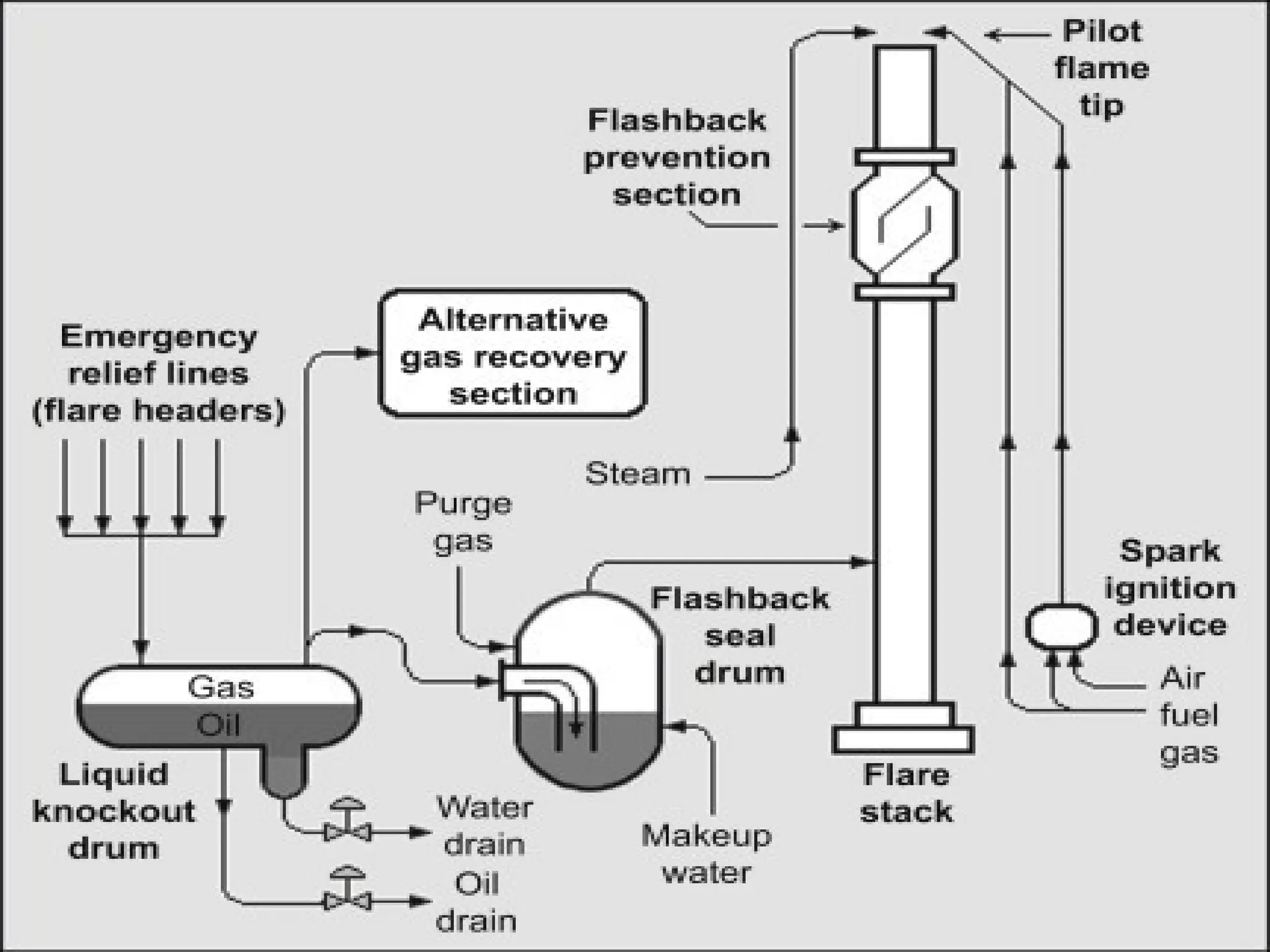

Flaring is the combustion of waste gases in industrial operations to safely relieve pressure and prevent emissions of harmful chemicals into the environment, often occurring during oil well testing, plant start-up, and shutdown. The process primarily produces water and carbon dioxide, effectively mitigating volatile organic compounds' toxicity. While alternatives like gas recovery systems are being explored, flaring remains a crucial method for safely managing excess gases in hydrocarbon and chemical processing.