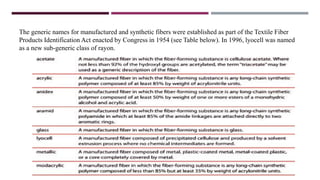

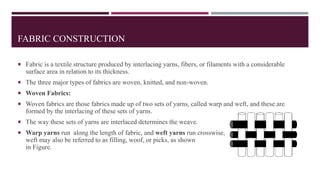

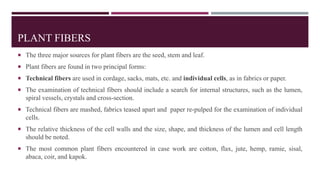

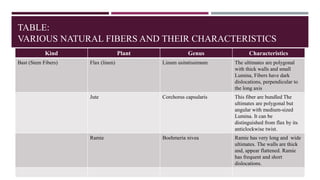

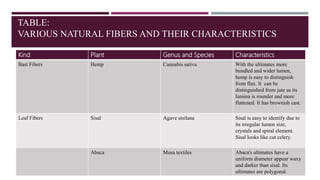

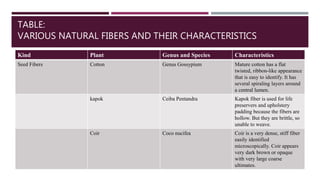

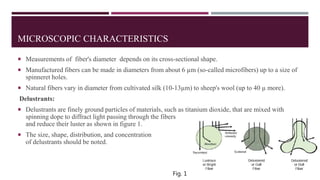

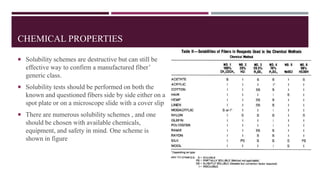

This document provides an overview of fiber analysis for forensic science. It discusses the different types of textile fibers including natural fibers from animals and plants, as well as manufactured fibers. The document outlines the characteristics and properties of fibers that are analyzed, such as fiber size, shape, color, crimp, and optical properties when viewed under microscopes. Different fabric constructions are also summarized, including woven, knitted and non-woven fabrics. The document provides context for how fiber analysis is used in criminal investigations and casework.