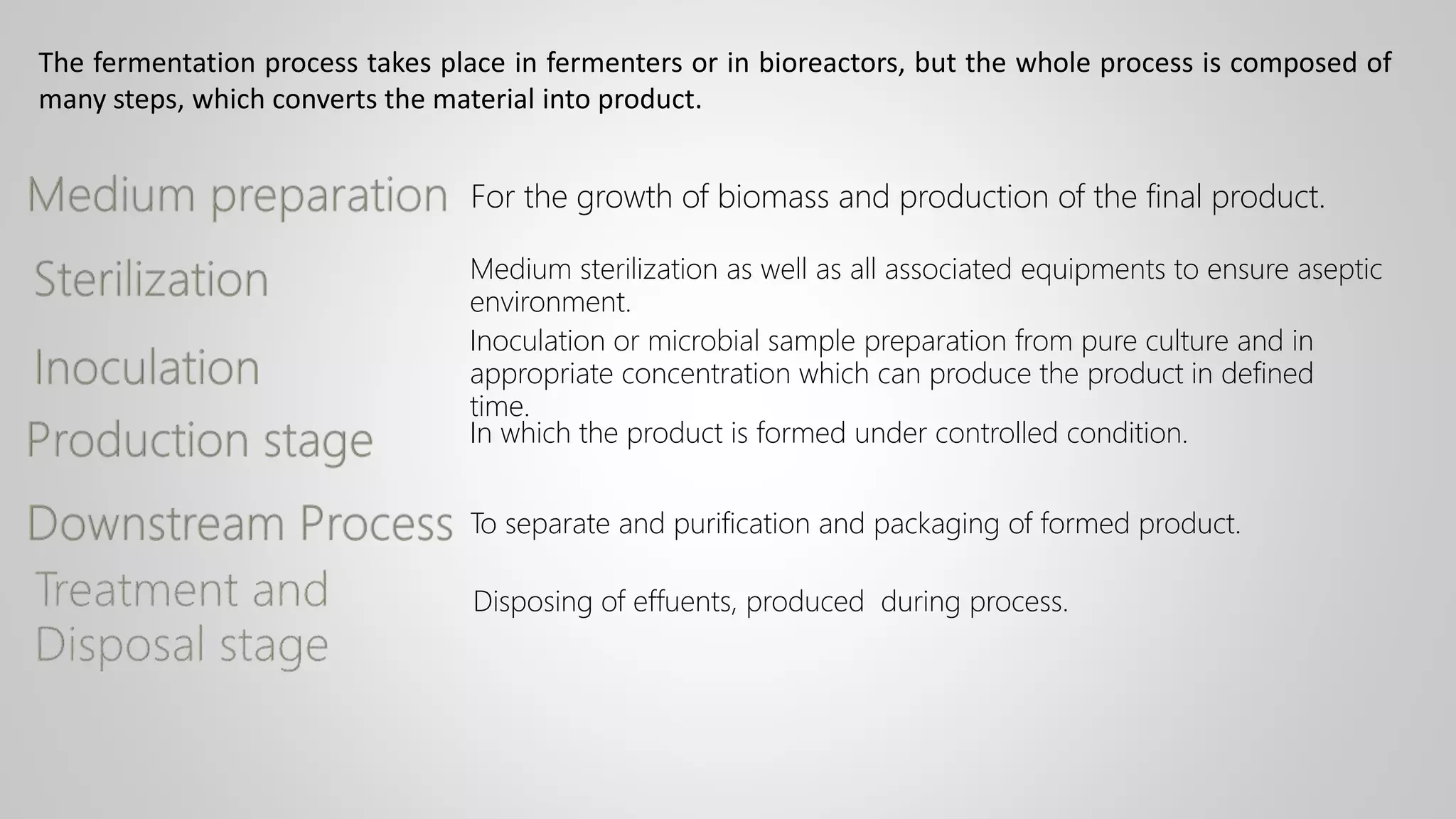

The document presents an overview of fermenters and bioreactors, highlighting their roles in facilitating biochemical reactions mediated by microbial cells. It details the fermentation process, the importance of inoculum preparation, and the various types of fermenters, such as submerged and supported growth fermenters. The document also emphasizes the controlled environmental conditions necessary for product formation and downstream processes for product isolation and purification.

![Presented By: Prashansa Tayal

M.Sc Biotechnology [3rd Sem]

Chaudhary Charan Singh University,

Meerut, U.P

. India.

Supervisor : MS. Gyanika Shukla Mam [Phd Scholar]

Dept. Of Genetics And Plant Breeding/ Dept. Of

Biotechnology.

Chaudhary Charan Singh University, Meerut U.P., India .](https://image.slidesharecdn.com/fermentaion-210124072117/75/Fermentation-Technology-1-2048.jpg)

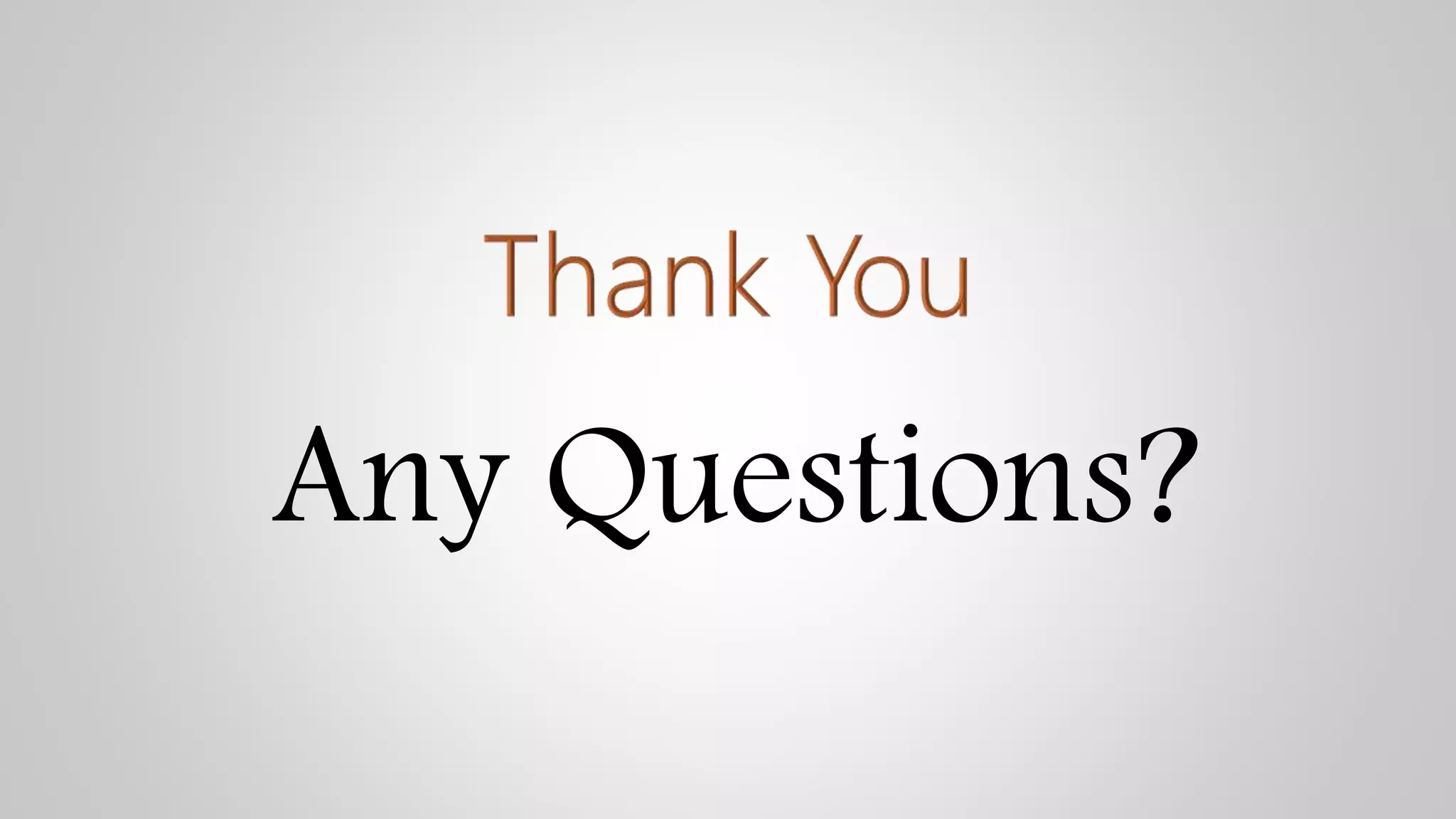

![Inoculum Development

Inoculum is the microbial seed culture, that use to perform the desired bioconversion reaction for the formation of

products.

• The inoculum should be healthy and pure.

• The inoculum should be in suitable morphologic from [vegetative forms].

• The inoculum must be free from any contamination.

• The inoculum must have appropriate metabolic capacity to form product.

Microbial

strain

Cells mix with

culture media

Cells become

in Rapid

dividing Form

{log phase of

growth}

Stored at

20⁰C And

check For

purity

Appropriat

e Dilution

to prepare

Inoculum

And ready

to Transfer

to

fermenter](https://image.slidesharecdn.com/fermentaion-210124072117/75/Fermentation-Technology-6-2048.jpg)

![TYPES OF FERMENTERS

[BIOREACTORS]](https://image.slidesharecdn.com/fermentaion-210124072117/75/Fermentation-Technology-9-2048.jpg)