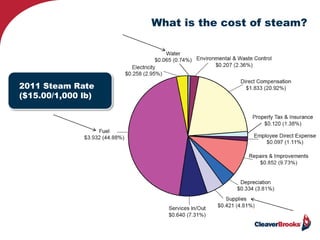

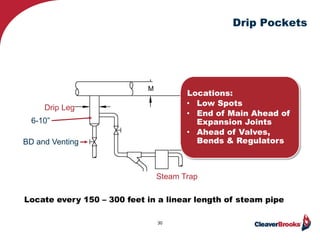

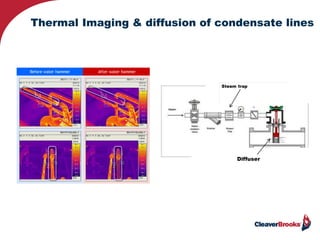

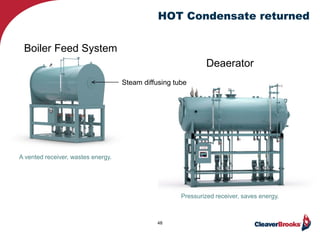

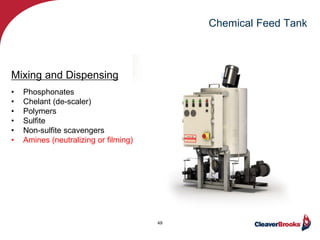

The document discusses the importance of a proper condensate return system in steam operations, highlighting its impact on operating costs, reliability, and safety. It covers various aspects such as the efficiency of steam systems, the cost of steam, and issues related to corrosion and reliability challenges. Key considerations include condensate recovery methods, the efficiency of operation, and ensuring optimal condensate delivery back to the boiler room.