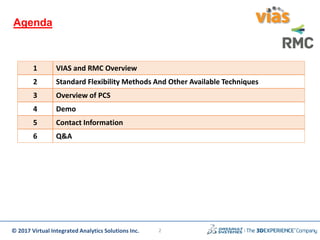

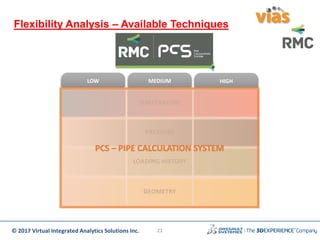

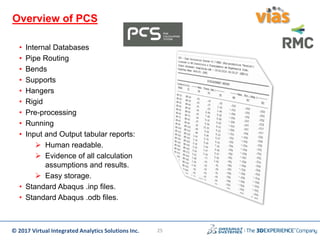

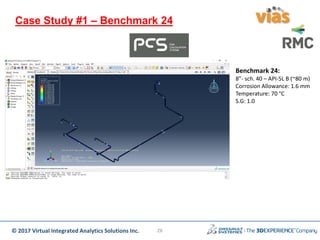

This document provides an overview of pipe stress analysis using the Pipe Calculation System (PCS). It begins with introductions of VIAS and RMC, which develop and support PCS. Standard flexibility analysis methods and their limitations are discussed. PCS is then introduced as an FEA-based alternative. The document demonstrates PCS through examples and a demo. Contact information is provided for questions.

![© 2017 Virtual Integrated Analytics Solutions Inc.

Case Study #2 – Benchmark 07

Benchmark 07:

14”/16”/18”- STD – API-5L B

(~250 m)

Corrosion Allowance: 1.6 mm

Temperature: 70 °C

S.G: 0.82

Fx [N] Fy [N] Fz [N]

PCS 58,097.0 -33,800.0 144,763.0

Caesar II (No Flg) -28,803.0 27,410.0 -80,066.0

Caesar II (2 Flg) -37,732.0 30,729.0 -101,969.0

28](https://image.slidesharecdn.com/pcswebinar-rmc-viasmarch22-2017-180802215156/85/FEA-Based-Pipe-Stress-Analysis-Introduction-To-Pipe-Calculation-System-PCS-28-320.jpg)