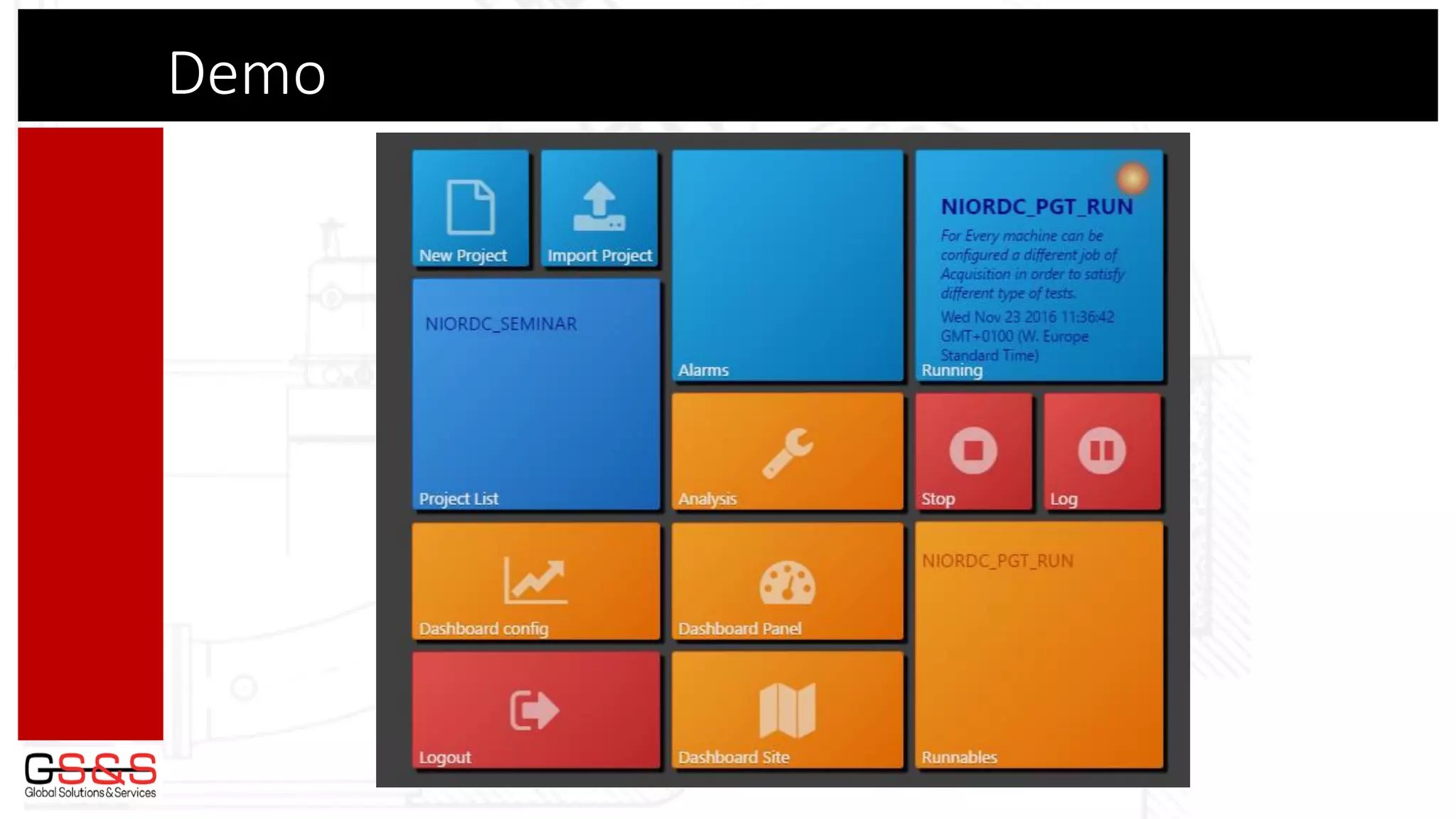

GS&S provides diagnostic and remote diagnostic services for industrial machinery using their DASBOX system. They have mechanical engineers with condition monitoring certifications who perform on-site troubleshooting, testing, and data analysis. The DASBOX gathers diagnostic data from machines via common protocols and sensors to enhance monitoring and maintenance. It has customizable configuration, reliable operation, data storage and multiple monitoring functions. GS&S uses the DASBOX and their expertise to provide remote monitoring, performance analysis, and maintenance support to optimize customers' plant operations and productivity.