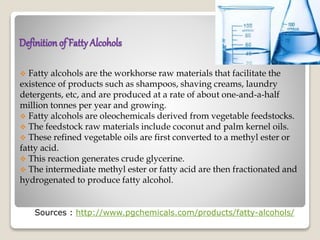

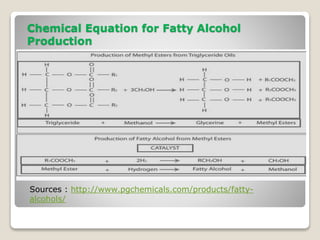

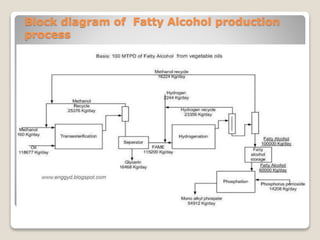

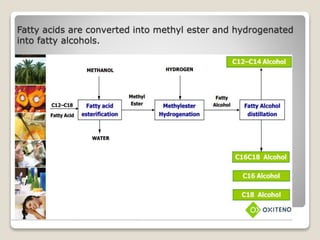

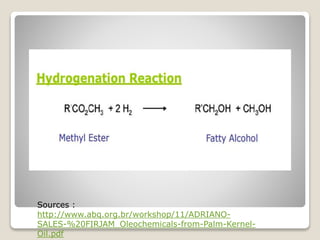

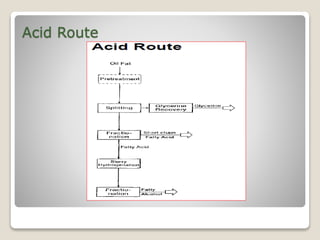

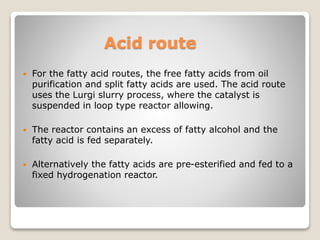

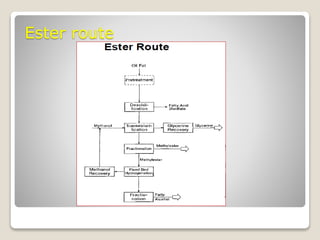

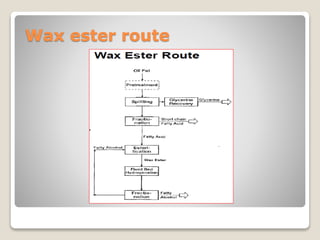

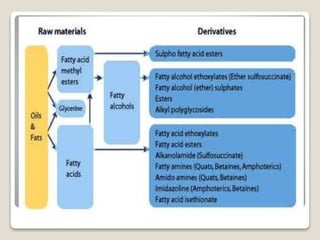

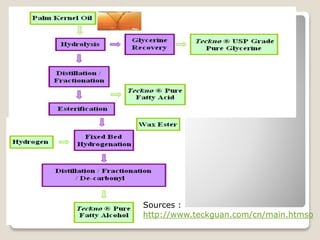

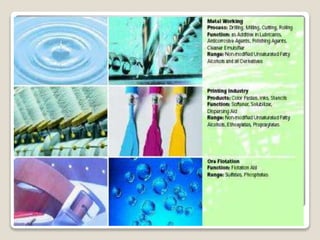

Fatty alcohols are derived from vegetable oils like coconut and palm kernel oils. They are produced through several routes including converting the oils to fatty acids or methyl esters, then hydrogenating and fractionating the results to yield fatty alcohols. Fatty alcohols have various uses as surfactants in personal care products and detergents due to their emulsifying properties. They are produced at over 1.5 million tonnes annually.