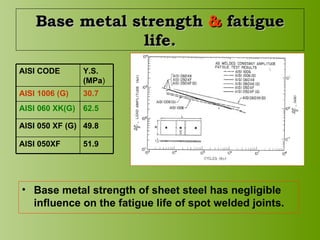

1) The document discusses improving the fatigue resistance of spot welds used in automotive applications through various methods like controlling residual stresses, increasing base metal strength, and improving steel sheet surface condition.

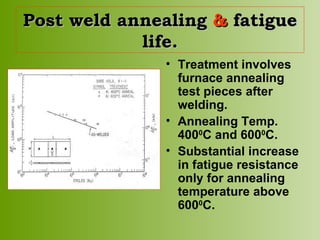

2) Key methods to control residual stresses and improve fatigue life included tensile preloading, coining, and stress relief annealing which reduce tensile stresses or induce compressive stresses.

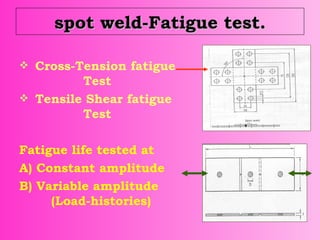

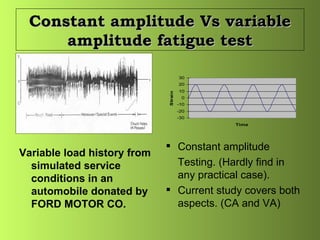

3) Fatigue testing of spot welds was done under constant and variable amplitude loading, and improvements in fatigue life from pretreatments proved stable under variable loading emulating actual vehicle use.

![Spot Welding Principle. WELDING CYCLE: Squeeze. Weld. Forge/Hold. Off. PROCESS VARIABLES : Effective current [KA] Electrode force [lbf] Weld time [cycles] Hold time [Cycles]](https://image.slidesharecdn.com/fatigue2-12809605731375-phpapp01/85/Advance-fatigue-and-fracture-analysis-of-spot-welds-4-320.jpg)