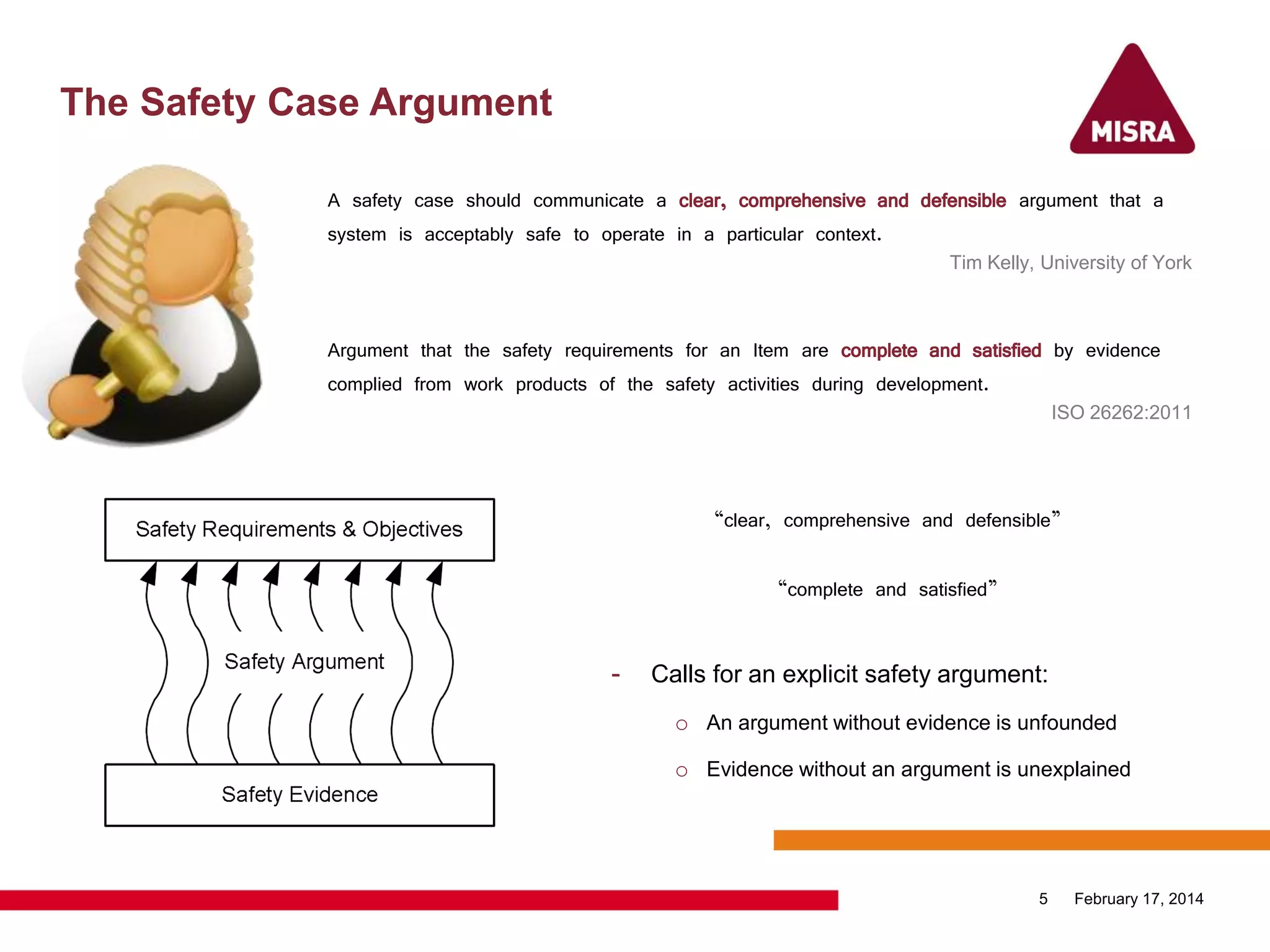

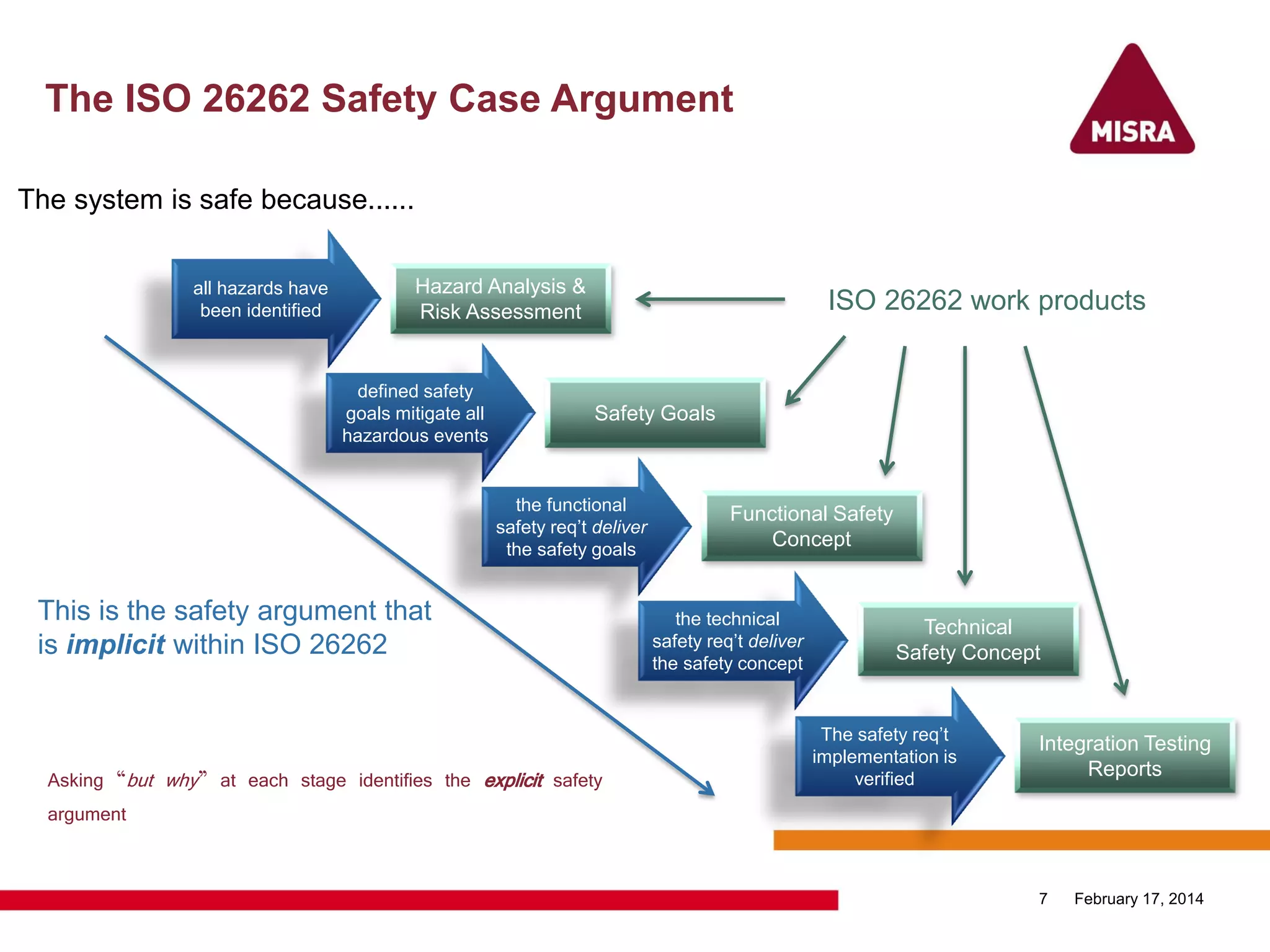

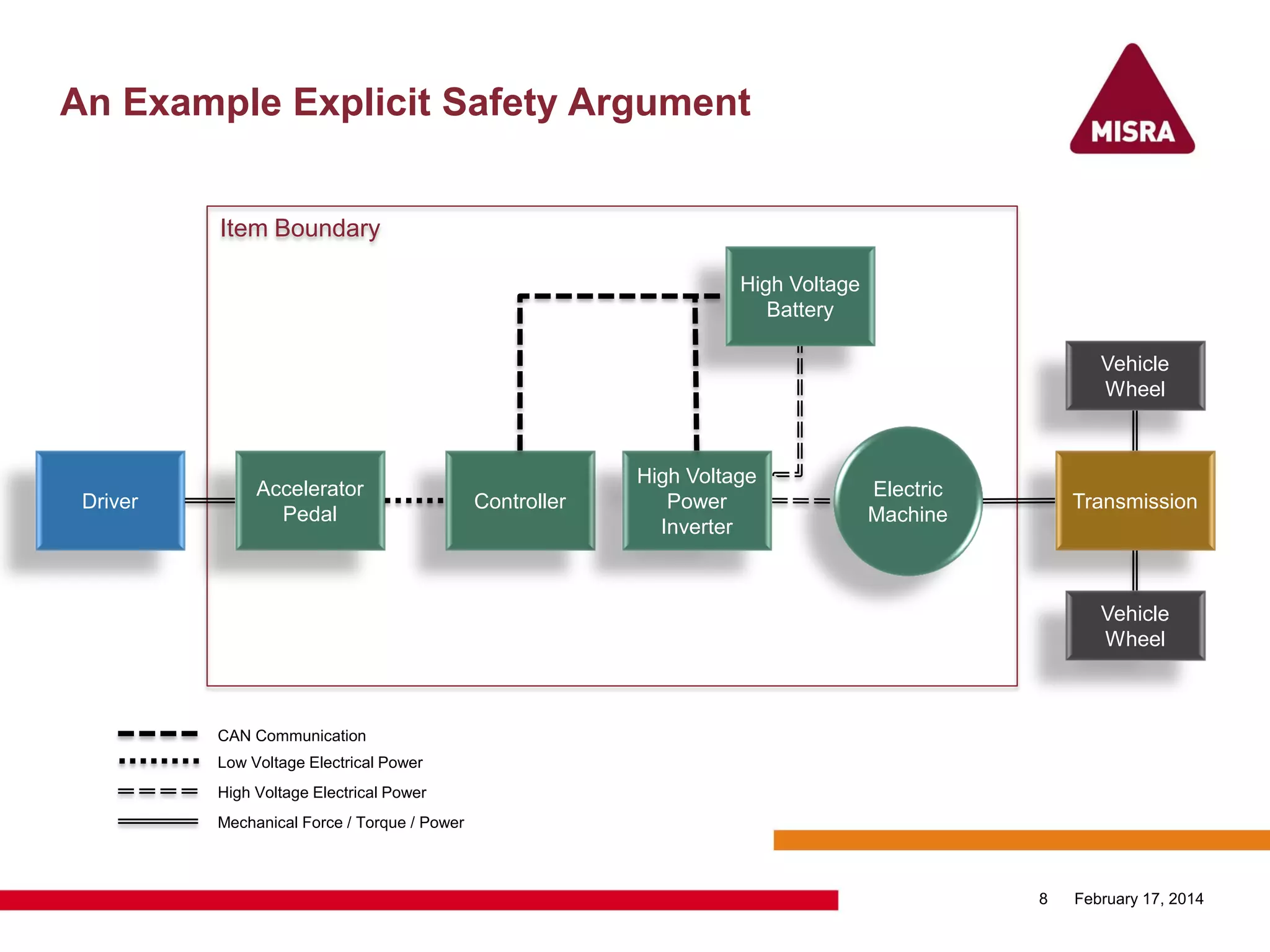

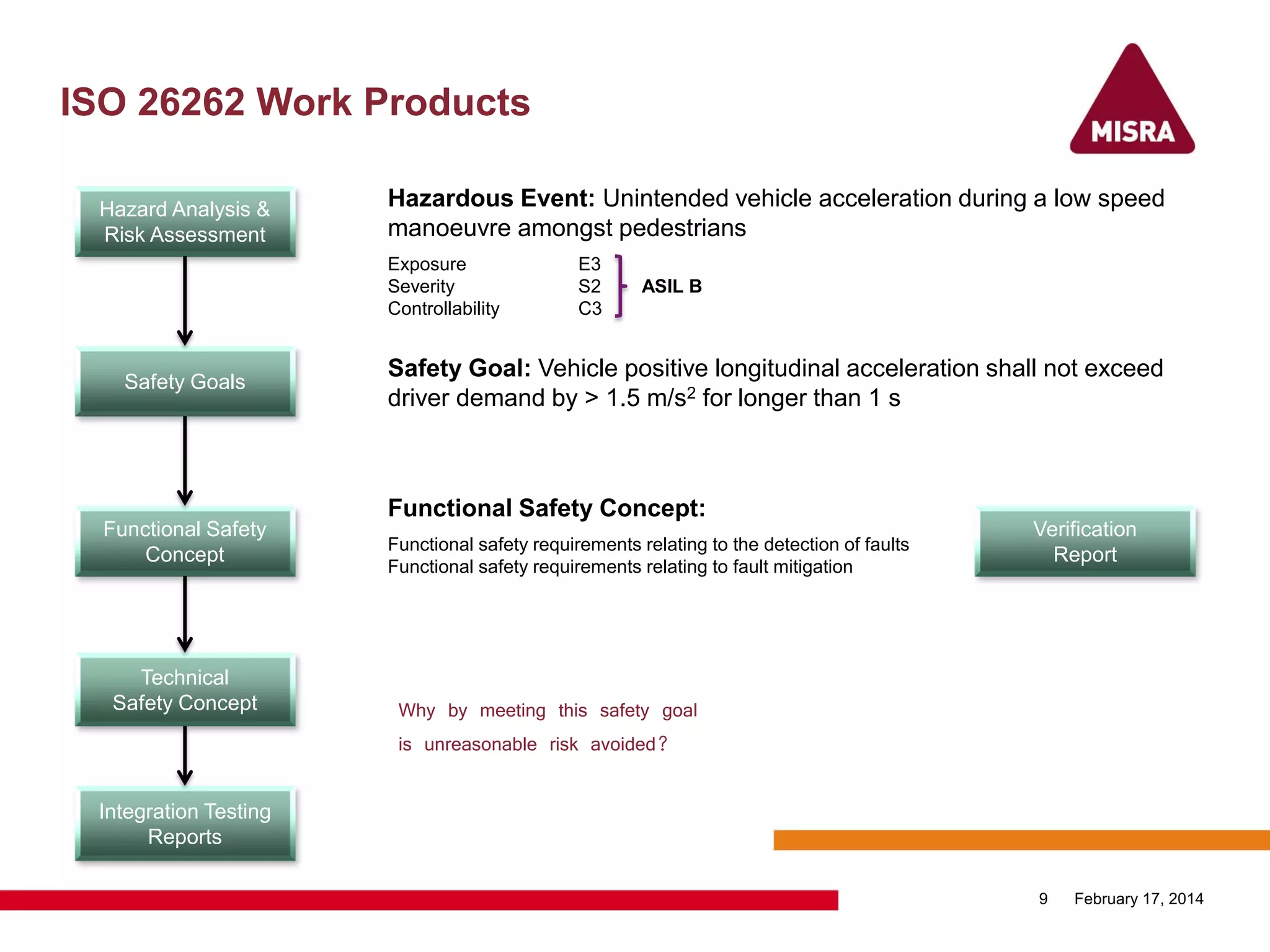

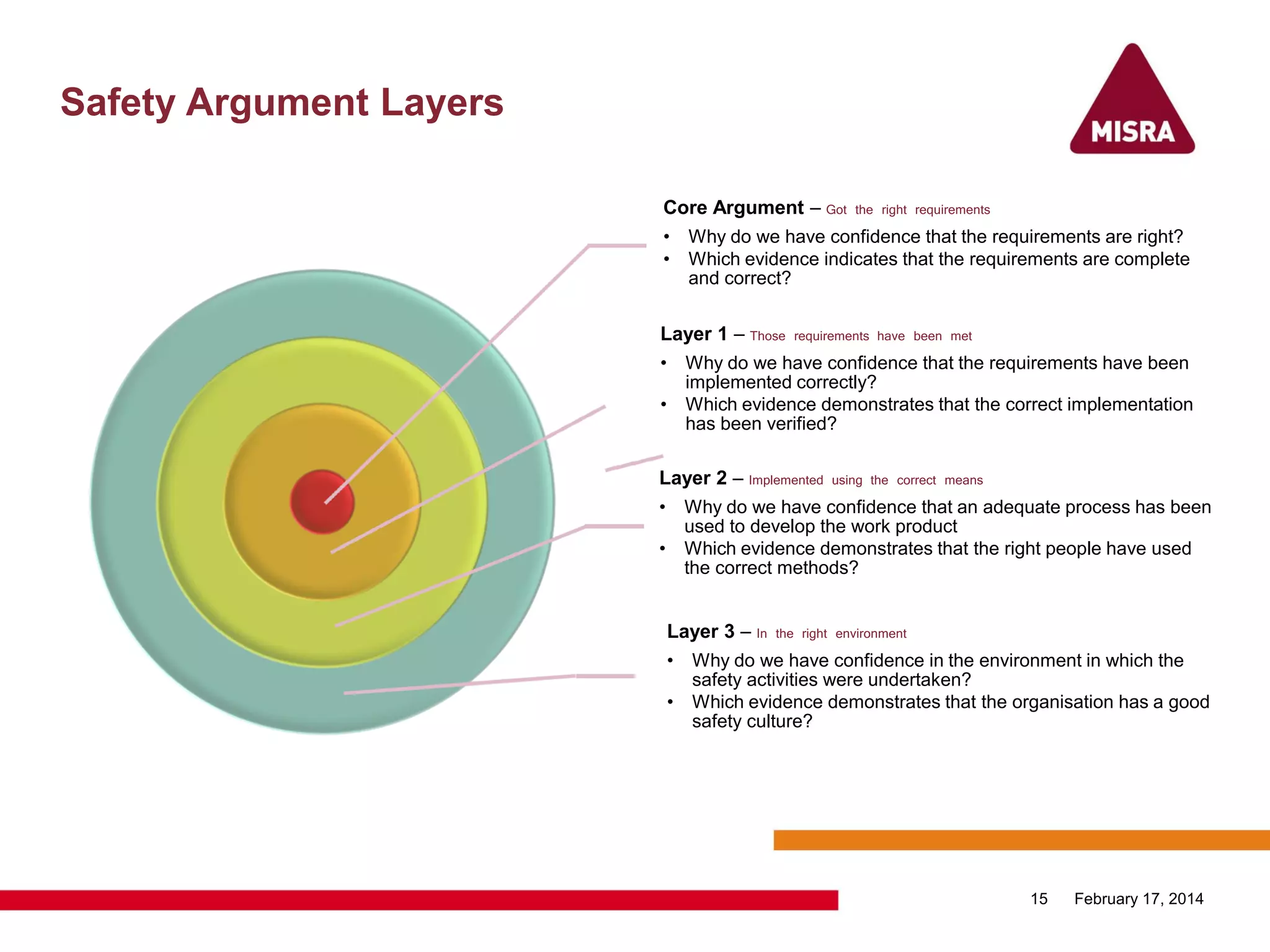

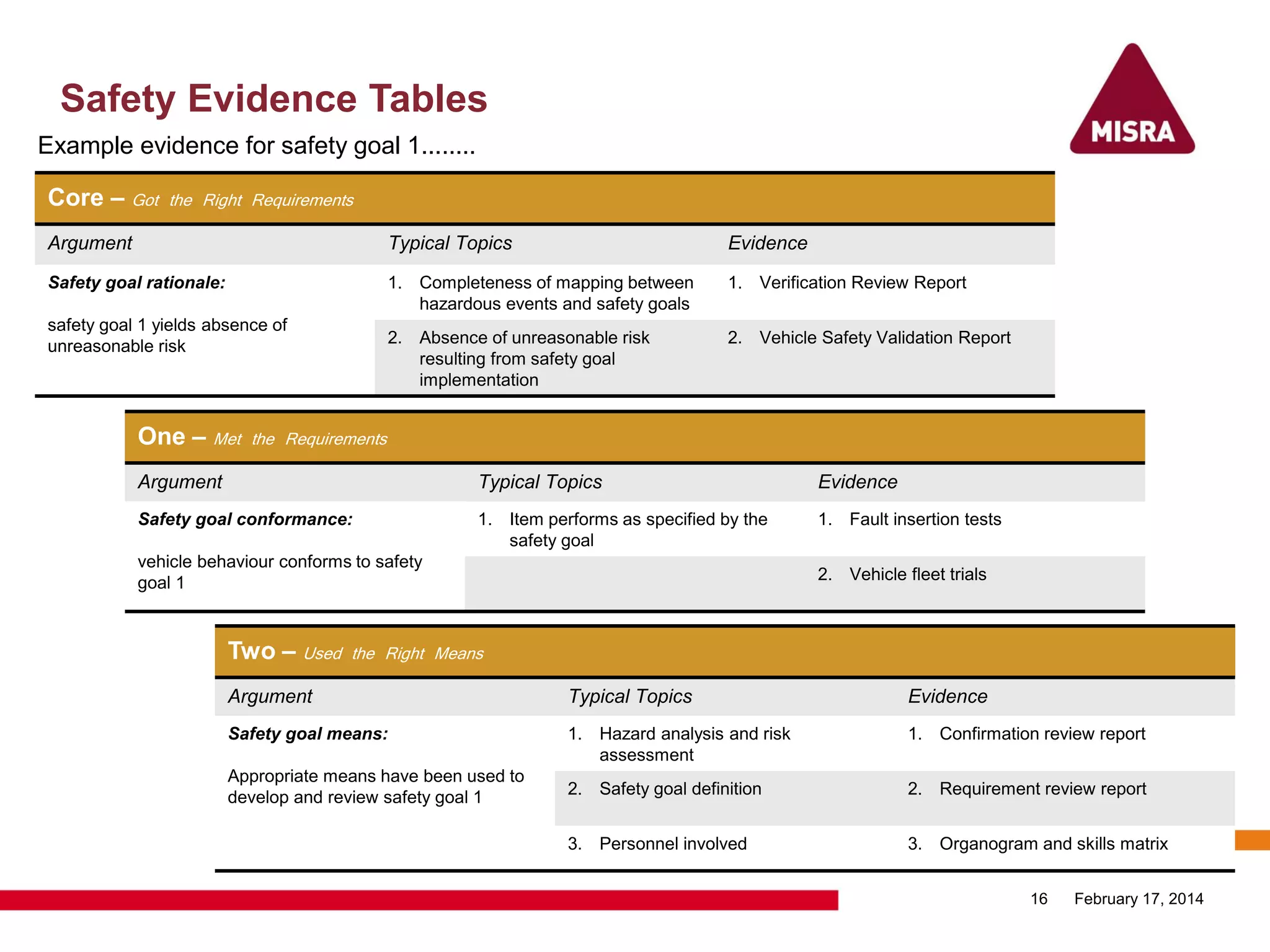

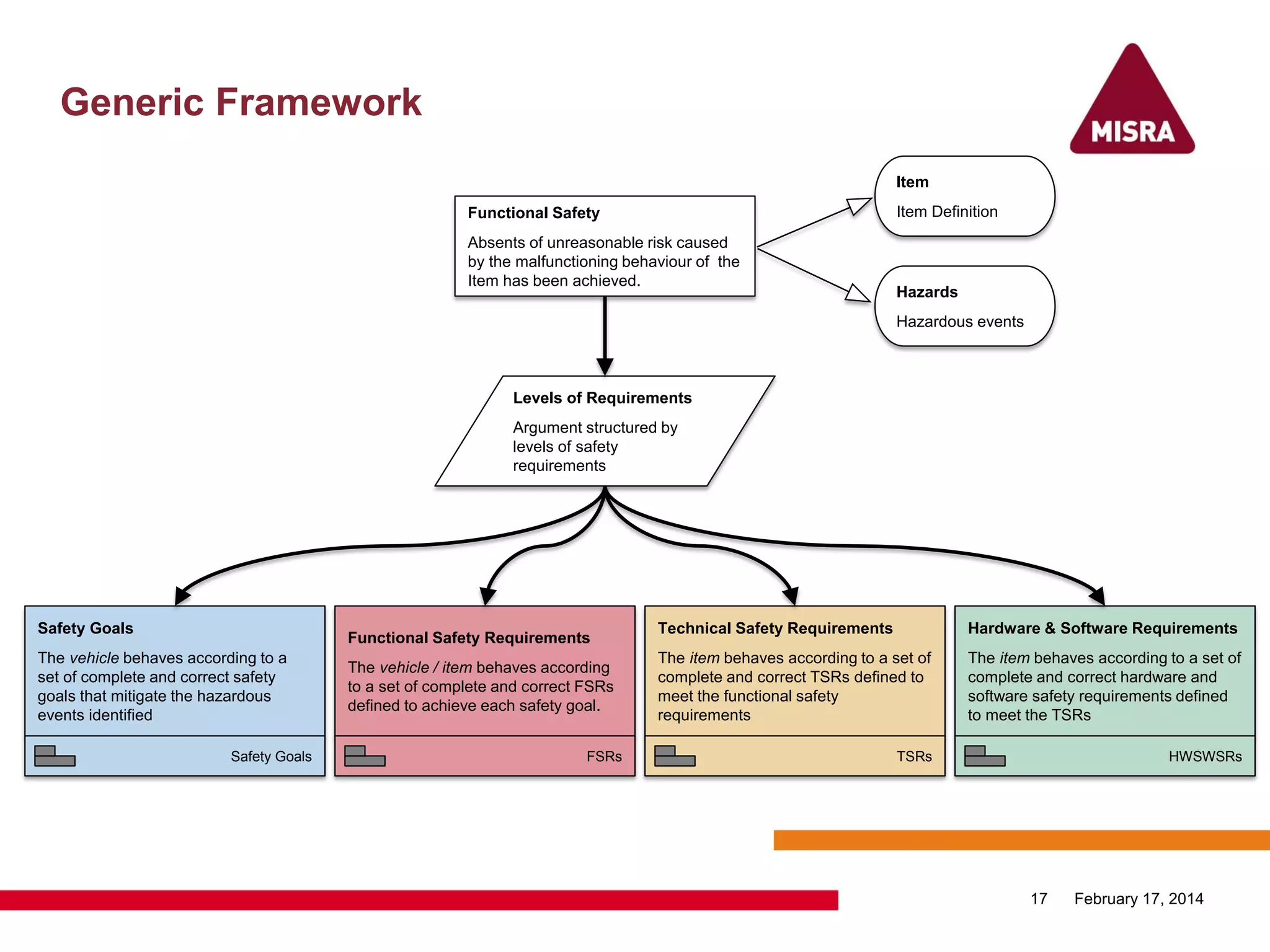

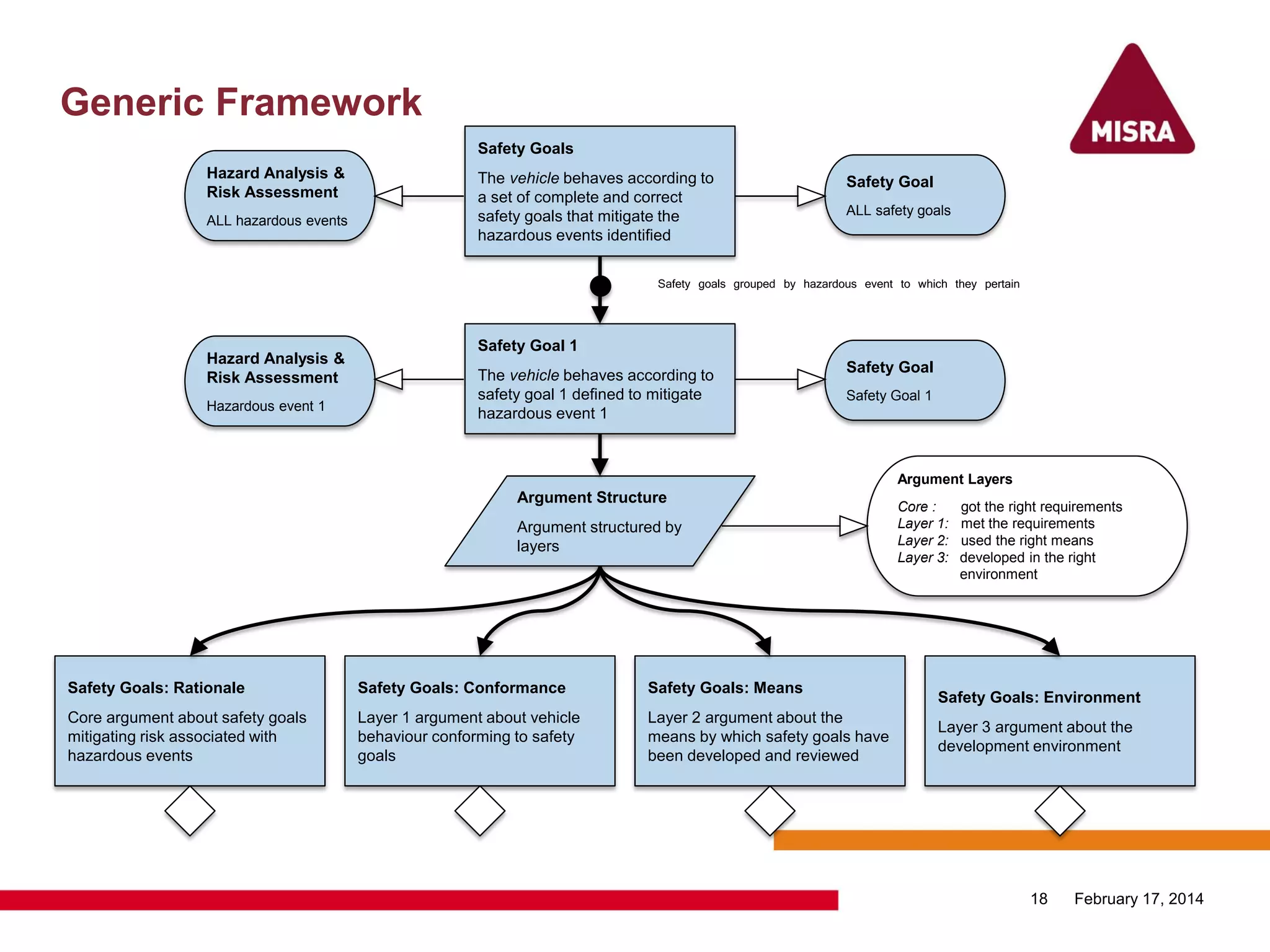

The document provides guidelines for developing safety cases to demonstrate that automotive systems are acceptably safe to operate. It discusses key concepts like argument layers and evidence tables that structure the safety argument. The guidelines are intended to help with ISO 26262 compliance by providing a common framework for explicit safety arguments, which lay out the rationale for safety requirements and evidence that the requirements are complete and implemented correctly. This approach aids communication, consistency, and third-party assessment of a system's safety.