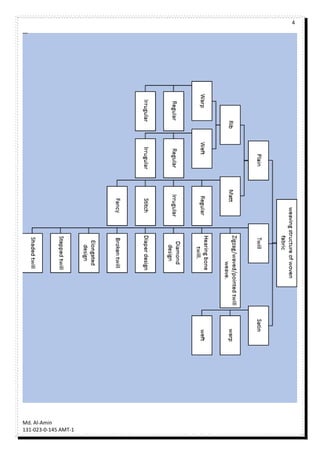

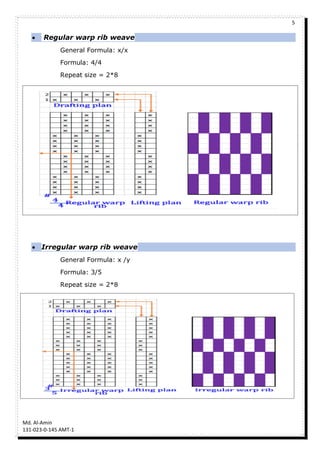

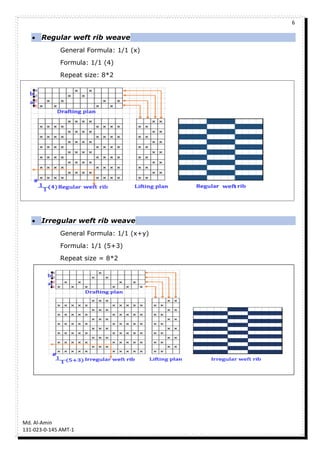

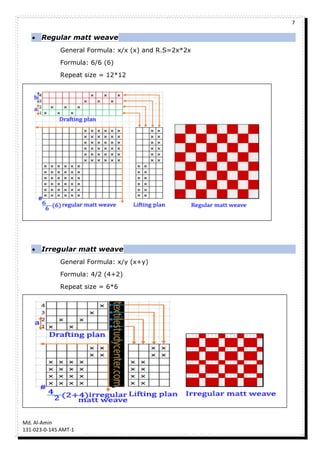

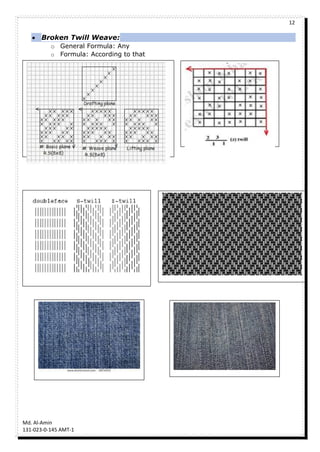

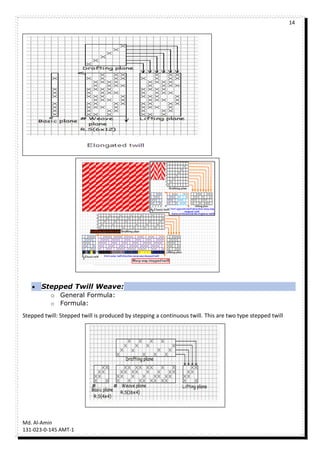

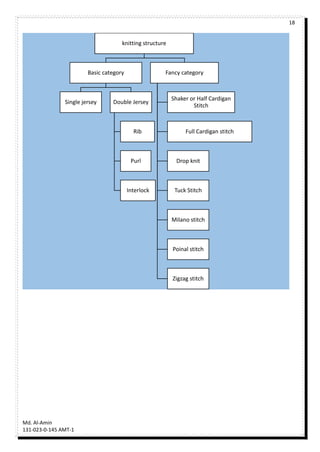

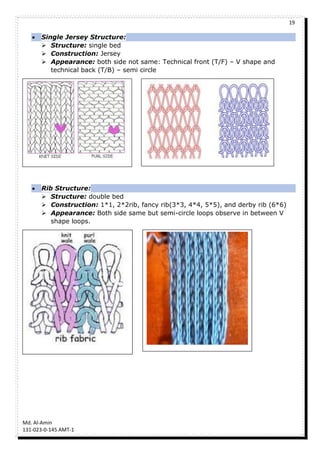

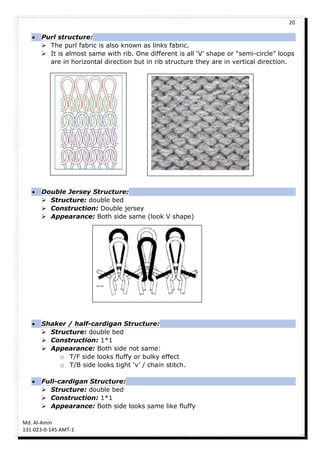

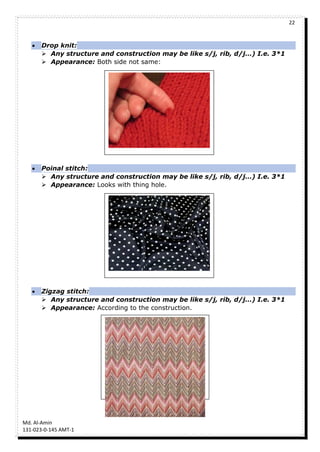

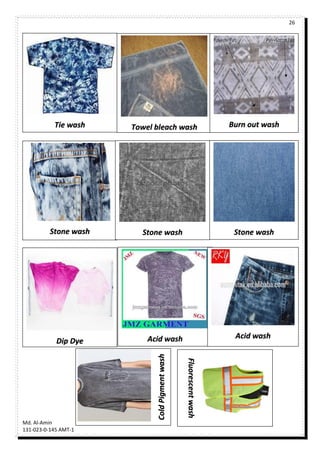

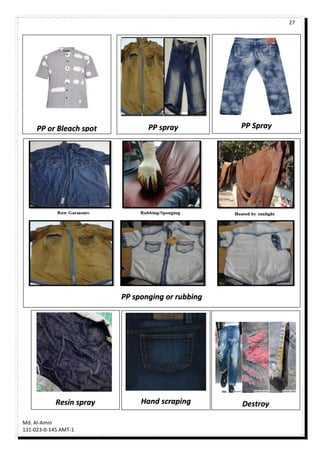

The document provides information on various weaving, knitting and fabric finishing techniques. It begins by defining fabrication and the processes of weaving and knitting. It then details various weaving structures like plain, twill, satin and their formulas. The document also discusses different knitting structures under basic and fancy categories. Finally, it lists various printing, embroidery and washing methods used in fabric finishing.