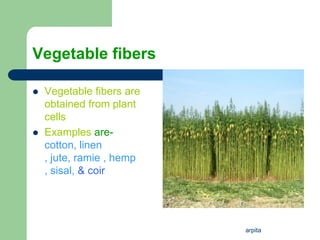

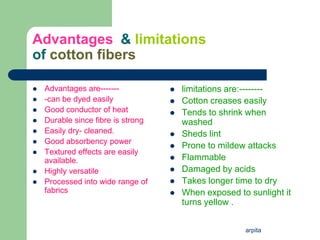

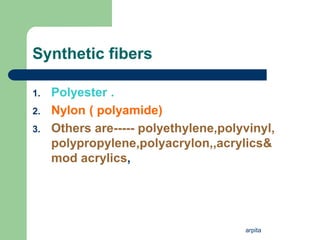

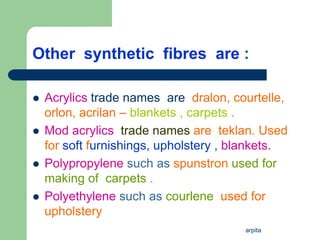

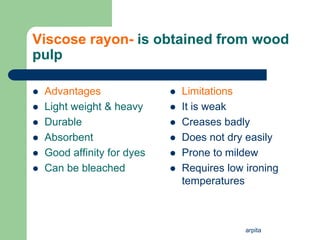

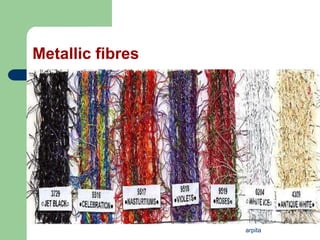

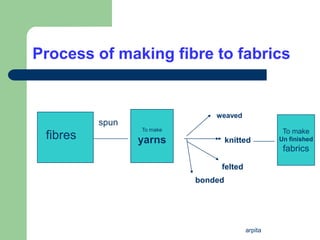

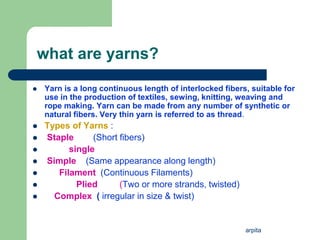

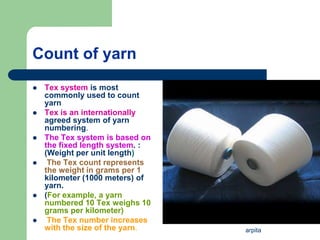

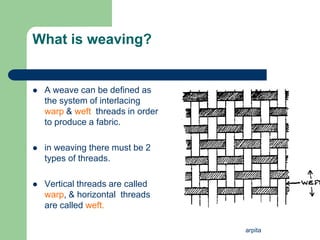

This document provides information about textile fibers and fabrics. It begins by defining what a textile is. It then classifies textile fibers into two main categories: natural fibers and man-made fibers. Several examples are provided for each type of fiber. The document also discusses the processes involved in transforming fibers into yarns and then into various types of fabrics, including weaving techniques like plain weave, satin weave, twill weave and more. Fabric treatments and care are also briefly mentioned.

![arpita

What is a textile??

A textile is a flexible material comprised of a

network of natural or artificial fibers often

referred to as thread or yarn. Yarn is

produced by spinning raw wool

fibers, linen, cotton, or other material on a

spinning wheel to produce long strands

known as yarn.[1] Textiles are formed by

weaving, knitting, crocheting, knotting, or

pressing](https://image.slidesharecdn.com/fabricfibres-140412025842-phpapp02/85/Fabric-fibres-3-320.jpg)