This document discusses evaporation effects on inkjet performance and image quality. It summarizes that as nozzles sit idle, water evaporation causes large localized viscosity variations in the inkjet ejector. This has a negative impact on jetting performance and print quality. The document then goes into detail explaining the multi-physics involved, including heat and mass convection/diffusion at the ink-air interface, and how this affects the transient viscosity fields and ultimately jetting and image quality. Models are used to predict and understand these relationships and tradeoffs between ink formulation, environmental effects, and ejector design.

![Print Physics Notes: Evaporation Effects on Inkjet Performance and Image Quality

December 2008

1

Evaporation Effects on Inkjet Performance and Print Quality

Robert W. Cornell; Print Systems Science; Lexmark International; Lexington, Kentucky

Abstract

As nozzles sit idle, water evaporation causes large, highly

localized viscosity variations in an inkjet ejector. This has long

been a topic of qualitative discussion and empirical studies. This

analysis goes to the root of the problem, covering the underlying

multi-physics at work, the mathematical solution techniques and

model validations at each step along the way.

It is shown that significant viscosity field variations occur in

the ejector on a time scale less than one second. Idle time

evaporation induced viscosity variations have a negative impact on

jetting performance and print quality. This article examines this

phenomenon quantitatively. It begins with a discussion on the

properties of moist air and continues on to the topics; heat and

mass convection/diffusion. The boundary layer equations for heat

and mass transfer in the gap between a swathing print-head and a

media surface are derived, as are the resultant convection

coefficients. It is shown that the mass convection coefficient is

inversely proportional to media gap – a result that helps explain

machine-machine idle time variation. Also, a method is presented

to predict viscosity and mass diffusivity properties for multi-

component ink- mixtures as a function of formulation, temperature

and water loss. Next an overview of the finite element method is

presented to illustrate the solution means for the field equations.

Evaporative flux exiting an inkjet ejector is then discussed from

experimental and theoretical viewpoints. It will be shown that a

heretofore undiscovered mechanism is at work during the first few

seconds of evaporation. This mechanism tends to cause the

evaporation rate from an inkjet nozzle to be self-limiting. The

experimental and simulation results agree quite well on this

phenomenon. The evaporation and mass diffusion results are then

merged with the jetting model. The temporal and spatial variations

of viscosity are accounted for, enabling the jetting model to predict

the idle time print quality defects – drop placement error and

reflective luminance variation. The predicted idle time defects are

very much on target with experimental results. Lastly, the pigment-

dye dilemma is quantitatively discussed as are the paths that some

competitors have taken to enable idle time robustness with pigment

inks.

Introduction

An uncapped, idle nozzle will suffer water loss by evaporation.

After a few seconds, or less, the remnant mixture in the nozzle

consists primarily of highly viscous co-solvents. While all inks are

affected by evaporation, the negative impact on performance is

magnified with pigment inks. HP has expressed similar thoughts

on this. “Pigment inks cannot be de-capped for more than a few

seconds without significant property changes, so Edgeline spits all

nozzles after ~800ms of idle time.” [1]

Within seconds, the physical properties of the ink change well

beyond the range needed for consistent jetting. The resulting weak

and misdirected droplets are easily visible and highly objectionable

from a print quality viewpoint. Fig.I illustrates this effect.

Figure I: Idle Time Effect

This article examines and quantifies the interrelationships

between the ejector flow features, local environmental conditions,

media gap and ink formulation choices that impact the transient

mass diffusion and viscosity fields, and ultimately – how these

affect jetting and imaging performance.

The goal of all mathematical models is to predict performance

of some variable set [ as a function of a wide variety of inputs.

In some simple cases, the model results lead to optimum,

bulletproof designs. However, like most things inkjet, there is no

“optimum” design for idle time. Rather, there exists a series of

tradeoffs where one parameter suffers at the expense of another.

That is not to say modeling is an esoteric exercise. Indeed, exactly

the opposite is the case. When a simple system is designed for

optimum performance it is often easy to do so with minimal

experimentation and computation. However, when the system

involves a complex set of field variables covering many scientific

disciplines, it may take decades of experimentation to build a

disconnected set of empirical do/don’t rules. When the modeling

approach is not easily accomplished because of complex

mathematical physics, the variables also are usually so endless that

full-factorial experiments are utterly impractical. In such cases,

taking the time to develop a mathematical model is extremely

important, and well-worth the effort, because it permits tradeoffs to

be studied without decades of empiricism. That said, the value of

the multi-physics model described herein is a means of quantifying

idle time tradeoffs between: ink formulation, environmental

effects, thermo-hydrodynamic ejector effects, jetting and image

quality.

Properties of Moist Air

Evaporation may be rate-limited by any of the following [2]:

Vapor diffusion across a stagnant, or non-receptive gas

layer above the liquid](https://image.slidesharecdn.com/2ef8fd00-29b8-44cb-9a8a-fc4d36d27b5c-160108062003/75/Evaporation-effects-on-jetting-performance-1-2048.jpg)

![Print Physics Notes: Evaporation Effects on Inkjet Performance and Image Quality

December 2008

2

A barrier that impedes molecular transport at the liquid-

vapor surface

Evaporation of a volatile species may generate

concentration gradients in the liquid such that mass

transport within the liquid is rate-limiting

Since vapor diffusion is dependent upon the gas properties existing

in the boundary layer at the liquid-air interface, a good starting

point for this analysis is psychrometrics [3].

Moist air is a binary mixture of dry air and water vapor.

Humidity ratio (W) is the mass of water vapor per unit mass of dry

air. Since it is known that dry air has a molecular weight of 29

grams/mol and water vapor has a molecular weight of 18

grams/mol, it is convenient to write the following expression for

humidity ratio.

W

W

W

W

x

x

x

x

W

1

622.0

129

18

(Eq.1)

xW = mol-fraction water vapor contained in the moist air

Relative humidity () is also conveniently related to water vapor

mol fraction:

SW

W

x

x

,

(Eq.2)

xW = mol-fraction water vapor contained within the air at Troom

Troom = room temperature

xW,S = mol-fraction water vapor at saturation at Troom

Using Dalton’s Rule, (Eqs.1-2) can be written in terms of pressure.

pressurecatmospheri

airmoistinorwater vapofpressurepartial

622.0

P

P

PP

P

W

W

W

W

(Eq.3)

Standard atmospheric pressure = 101300 (N/m2

) = 101300 (Pa)

SW

W

P

P

,

(Eq.4)

PW,S = saturated vapor pressure(TROOM , 100% relative humidity)

Then the saturated humidity ratio (WS) can be written:

SW

SW

S

PP

P

W

,

,

622.0

(Eq.5)

Pressure values may be obtained from look-up steam tables, or

they may be computed from the ideal gas law approximation of the

Clausius-Clapeyron equation, shown below.

TTbR

hfgM

PTP

11

exp)( (Eq.6)

P(T) = vapor pressure (Pascal, or N/m2

) at temperature (T)

hfg = latent heat of evaporation = 2.35 x 106

(J/Kg) for water

M = molecular weight = 0.018 (Kg/mol) for water

R = universal gas constant = 8.315 (J/mol-K)

Tb = normal boiling temperature = 373 (K) for water

T = temperature (K)

Consequently, saturated temperature values may be computed by

rearranging (Eq.6):

P

P

RTbMhfg

MhfgTb

PT

ln

)( (Eq.7)

T(P) = saturated vapor temperature (K) at vapor pressure [P(Pa)]

Eq.6 compares favorably to steam table values, as shown in Fig.1.

Figure 1: Vapor pressure versus water temperature

Example

If the room temperature is 25C, and the relative humidity is 35%;

find the saturated vapor pressure (PW,S), the partial pressure of

water vapor in the moist air (PW), the humidity ratio (W), the

saturated humidity ratio (WS) and the dew point temperature

(TDEW).

By (Eq.6) the saturated vapor pressure at 25C is:

PW,S(298K) = 3272 Pa = 24 mm-Hg

By (Eq.4) the partial pressure of water vapor at 25C and 35%

relative humidity is:

PW(298K, 0.35) = 1145 Pa = 8.6 mm-Hg

By (Eq.3) the humidity ratio of air at 25C and 35% relative

humidity is:

W = 0.007 Kg-water/Kg-dry air

By (Eq.5) the saturated humidity ratio at 25C is:

Ws = 0.0208 Kg-water/Kg-dry air

By (Eq.7) the dew point temperature at a dry bulb temperature of

25C and 35% relative humidity is:

TDEW = 281K = 8C

These values may also be extracted from a psychrometric chart

(Fig. 2-3), but for mathematical convenience it is more desirable to

use (Eq.1-7).](https://image.slidesharecdn.com/2ef8fd00-29b8-44cb-9a8a-fc4d36d27b5c-160108062003/75/Evaporation-effects-on-jetting-performance-2-2048.jpg)

![Print Physics Notes: Evaporation Effects on Inkjet Performance and Image Quality

December 2008

3

Figure 2: Psychrometric Chart

Figure 3: Psychrometric Chart-Expanded

Heat and Mass Convection

Now let us discuss the kinetics of water evaporation into moist air.

During typical evaporation, heat is transferred from the air into the

water, and mass (water vapor) is transferred from the liquid into

the air. The energy transfer process occurring at the liquid-air

interface is heat-convection and heat-conduction, while the

evaporative transfer process is mass-convection and mass-

diffusion.

Heat transfer at the vapor-liquid interface obeys the following

relationship:

Surfacey

SROOMC

y

T

kTThq

(Eq.8)

q = heat flux (W/m2

)

hC = heat transfer convection coefficient (W/m2

-C)

TROOM = room temperature (C)

TS = temperature at the liquid surface (C)

k = thermal conduction coefficient of air (W/m-C)

Similarly, mass transfer at the vapor-liquid interface is described

by:

fluxmassareaunitperunit timepertransfermass

:Where

0

A

m

y

W

DWWh

A

m

y

AIRAIRSD

(Eq.9)

hD = mass convection coefficient (Kg/m2

-s)

DAIR = water vapor-air diffusion coefficient (m2

/s)

AIR = density of air (Kg/m3

)

y = 0 is the vapor-liquid interface

Note: it is obvious from (Eq.3) and (Eq.5) that (Eq.9) can

also be written in terms of vapor pressure and pressure

gradient, as often seen in the literature.

It can be shown that the mass diffusion coefficient (hD) is related to

the heat transfer convection coefficient (hC) by [4]:

3

2

3/2

Le

DCph

h

AIR

AIR

AIRD

C

(Eq.10)

CpAIR = specific heat of air (J/Kg-C)

AIR = thermal diffusivity of air (m2

/s)

The ratio of thermal diffusivity () to mass diffusivity (D) is the

Lewis number (Le).

So if the heat transfer convection coefficient (hC) is known, the

mass convection coefficient (hD) may be computed from (Eq.10).

Unfortunately, (Eq.8-9) are deceptively simple. From a

psychrometric analysis we may know the saturated water vapor

pressure at the liquid-air interface and the partial pressure of water

vapor beyond the boundary layer in the free stream (i.e. the room).

However, without a priori knowledge of the boundary layer (y)

characteristics (Fig.4), the convection coefficients are intractable.

Often this dilemma leads to an expedition into the literature –

looking for pre-solved special cases that mimic, or approximate the

nature of the boundary layer at hand, e.g. flat infinite plates,

spheres, circular tubes, etc.

For the case of an inkjet print head swathing at 30 inches per

second, a few millimeters above a media surface, it is expected that

forced convection is at work. Table 1 indicates a vast range, from

10-500 W/m2

-C, to be expected for forced air convection. Perhaps

a boundary layer analysis will yield a more narrow range for (hC)

than this.

Table 1: Approximate heat transfer convection coefficients [5]

Mode hC (W/m2

-C)

Free convection, air 5-20

Forced convection, air 10-500

Forced convection, water 100-15000

Boiling water 2500-25000

Condensing water vapor 5000-100000](https://image.slidesharecdn.com/2ef8fd00-29b8-44cb-9a8a-fc4d36d27b5c-160108062003/75/Evaporation-effects-on-jetting-performance-3-2048.jpg)

![Print Physics Notes: Evaporation Effects on Inkjet Performance and Image Quality

December 2008

4

Figure 4: Typical Evaporation Boundary Layer

Boundary Layer Analysis

The boundary layer for the case at hand is formed between a

moving nozzle plate and a fixed media surface (Fig. 5).

Figure 5: Velocity Profile Between Nozzle-Media

The velocity boundary layer of Fig.5 is the well-known

Couette flow condition. It can be shown that the velocity profile

reaches steady state within 60-70 ms, when the nozzle-media gap

is 1.65mm. At a carrier velocity of 30 in/s, steady state is achieved

in the first two inches of the print zone. Thus it may be argued that

the majority of the print zone sees the steady state velocity profile

shown in Fig.5. So the velocity profile (U) is simply:

L

y

UyU C)( (Eq.11)

Furthermore, since the carrier velocity is much less than the speed

of sound in air and the Reynolds number is on the order of 102

, we

may consider this problem domain as laminar, incompressible

flow. Then the energy equation for the condition shown in Fig.5 is:

2

2

2

0

y

U

y

T

k (Eq.12)

Integrating (Eq.12) twice and introducing the boundary condition:

[T(y = L) = TNOZ] where TNOZ is the nozzle plate temperature, leads

to an expression for temperature in the gap.

22

1

2

)(

L

y

k

U

TyT C

NOZ

(Eq.13)

= dynamic viscosity of air ~ 18.5 x 10-6

Pa-s

k = thermal conductivity of air ~ 0.0265 W/m-C

From Fourier’s Law, heat flux (q) at the nozzle surface is:

Ly

y

T

kq

(Eq.14)

Taking the derivative of (Eq.13) and solving it at (y = L) says that

heat flux at the nozzle plate is:

L

U

Lyq C

2

(Eq.15)

From Newton’s Law of Cooling:

LyTyThq C 0 (Eq.16)

Solving (Eq.13) for T(y = 0) and T(y = L) and inserting those

values into (Eq.16) and combining that with (Eq.15) leads to the

convective heat transfer coefficient for the nozzle-gap case shown

in Fig.5.

L

k

h

k

U

LyTyT

C

C

2

2

0

2

(Eq.17)

Combining (Eq.17) with (Eq.10) leads to a value to mass

convection coefficient for an inkjet print head swathing back and

forth over a media surface.

3/2

,

3/2

,

2

LeC

L

k

DC

h

h

AIRPAIRAIRAIRP

C

D

(Eq.17a)

Eq.17 returns an unexpected result (hC = 2k/L). Surprisingly, it

shows that the convective heat transfer coefficient in the nozzle-

media gap is independent of carrier velocity (UC). Instead it shows

that (hC) is a linear function of the conductive heat transfer

coefficient of air (k) and inversely proportional to the nozzle-media

gap (L). Since (Eq.17) was unexpected, an order of magnitude

analysis is called for to check on its form.

The Prandtl number (Pr) characterizes the relationship

between momentum diffusivity (i.e. kinematic viscosity ) and

thermal diffusivity ().

Pr

Physically this implies that as Pr 1.0 the momentum and

thermal boundary layers become identical. For air, the Prandtl

number is 0.71. Thus it may be argued that an order of magnitude

estimation of the temperature and momentum boundary layers are

nearly identical (for liquids the Prandtl number is much greater

than one, so this simplification would not apply).

Since the nozzle-media gap is filled with air, the

simplification applies. So, it is reasonable to state that a first order

approximation of the temperature field in the gap mimics the linear

Couette flow field. That said - it follows:

tcoefficienconvectionofionapproximatorderfirst

L

k

h

Th

L

T

k

y

T

kq

C

C

Ly](https://image.slidesharecdn.com/2ef8fd00-29b8-44cb-9a8a-fc4d36d27b5c-160108062003/75/Evaporation-effects-on-jetting-performance-4-2048.jpg)

![Print Physics Notes: Evaporation Effects on Inkjet Performance and Image Quality

December 2008

5

Note that the first order approximation and (Eq.17) have the same

form. So from two different perspectives it can be shown that the

convective heat transfer coefficient for the nozzle-media gap is

proportional to thermal conductivity and inversely proportional to

nozzle-media gap.

The thermal conductivity of air is basically constant over the

temperature range of interest, so for the special case of a swathing

inkjet print head, the convective heat transfer coefficient is:

)(W/m1.2665.1

gapmedianozzle1.65mmaFor

(m)

C)-(W/m043.02

2

Cmmh

LL

k

h

C

C

(Eq.17a)

This falls into the low range for forced air convection, as shown in

Table 1.

Eq.10 showed an inverse relationship between (hC) and (hD). This

implies that any variability in nozzle-media gap will have a direct

relationship on evaporation rate. Historically, idle time is a metric

with a lot of variability.

So an unexpected result of this boundary layer analysis is that

some of the observed idle time variability can be attributed to

machine-machine gap variation.

Before moving on, it is important to note that if idle time

evaporation was simply like water vapor coming from a pool, or a

lake, we would have the mass flux solution in hand at this point.

Recall (Eq.9), shown repeated below:

WWh

A

m

SD

(Eq.9)

From the boundary layer analysis (hD) is known. So if the water

temperature is known and the psychrometric properties of air are

known (as they usually are), the mass flux of water vapor due to

evaporation is solved directly from this equation. However, the

inkjet problem is not so simple. Presumably the pool has just one

component – water. That said, there is no concentration gradient on

the liquid side of the interface, so knowing the mass convection

coefficient and the humidity ratio difference between the surface

and the free stream – computing mass flux is just an algebra

problem. It will be shown that the limiting factor for water

evaporation from an inkjet nozzle is the concentration gradient on

the liquid side of the ink-air interface. Computing that gradient is a

calculus problem.

Heat and Mass Diffusion

For many field problems in mathematical physics (heat transfer,

mass diffusion, electric field, flow in porous media, torsion, etc.),

the partial differential equation has the following form [6]:

t

Q

z

K

zy

K

yx

K

x

zyX

= field variable of interest

KX, KY, KZ are material properties

is a storage term

Q is an internal generation term

(x,y,z) = spatial coordinates

t = time

Because the ejectors are placed side by side there is negligible heat

flux in the z-direction. Also, because the ejectors are separated by

physical flow feature walls, the diffusive mass flux between

ejectors may be ignored. These conditions reduce the heat and

mass diffusion fields, as related to inkjet, to two spatial dimensions

(x,y).

For the heat transfer problem [with internal heat generation

(Q)] the field variable is temperature (T); and the material

properties of interest are thermal conductivity (k), density () and

constant pressure specific heat (CP). For the inkjet evaporation-

mass diffusion problem, the field variable is water concentration

(cW); the material property of interest is mass diffusivity (D), and

because there is no species generation, the Q term equals zero in

the evaporation-mass diffusion problem. Considering these

physical descriptors, the partial differential equations describing

the heat and mass diffusion fields are written:

t

T

CQ

y

T

k

yx

T

k

x

P

(Eq.18)

t

c

y

c

D

yx

c

D

x

WWW

(Eq.19)

Because these equations have the same form, the same finite-

element, solution technique works for both. The heat transfer

solutions, as related to nucleation, bubble growth and jetting will

be described in a later article. This article will focus on the mass

diffusion problem (Eq.19).

For the evaporative, mass flux problem, as related to nozzle idle

time, a typical finite element mesh with initial and boundary

conditions is shown in Fig.6. Each element has an associated width

that depends upon the spatial location of the element centroid.

Element width is considered during the solution phase. Also, note

the boundary condition enforced along the wall:

0

WALLZ

W

z

c

This technique permits diffusion in the z-direction within the mesh,

but stops it at the ejector walls, as in the actual device. This is an

important point. The governing equation (Eq.19) is in just two

dimensions, but since each element in the mesh has three

dimensions associated with it, the solution to the mass diffusion

field variable (cW) does account for flow feature variations in the z-

direction. Because the mesh is 3-D the field solution is essentially

3-D within the ejector even though it was generated from a 2-D

governing equation.

Figure 6: Typical mass diffusion field with evaporative boundary condition](https://image.slidesharecdn.com/2ef8fd00-29b8-44cb-9a8a-fc4d36d27b5c-160108062003/75/Evaporation-effects-on-jetting-performance-5-2048.jpg)

![Print Physics Notes: Evaporation Effects on Inkjet Performance and Image Quality

December 2008

6

The solution technique for (Eq.19) will be discussed in a later

section. It was simply introduced at this point to show the

mathematical relationship between water concentration (cW) and

diffusivity (D). Before solving the mass diffusion field equation it

is appropriate to quantify viscosity of a multi-component ink

formulation as a function of water concentration and mass

diffusivity as a function of viscosity.

Ink Property: Viscosity

Solving the evaporation problem for an inkjet ejector presents

several dilemmas. In order to quantify how evaporation affects

jetting performance, it is required to know how evaporation

impacts ink viscosity. This is dilemma number one – predicting the

viscosity of a multi-component liquid mixture.

Unlike gases, a kinetic theory of viscosity does not exist.

Yet there is a need to predict how mixture viscosity

varies with formulation, solid loading, temperature and

various evaporation conditions and nozzle idle times.

The viscosity model described herein was created to

address this dilemma. The genesis of this model was

during the Lexmark’s short excursion into printed

electronics. At that time, it was discovered that silver ink

could be loaded up to 27 wt.% Ag and still possess

reasonably low viscosity. The viscosity model, combined

with experimental results, provided the needed teachings

to obtain a US patent on this topic (US 7,316,475).

Viscosity Model

The viscosity model is an extension of the Teja-Rice method [7]

developed at the Thermodynamic Research Center. Mixture

viscosity is computed from the thermodynamic properties of the

mixture components.

• Tb = normal boiling temperature

• Tc = critical temperature

• Pc = critical pressure

• Vc = critical volume

• Zc = critical compressibility factor

• Mw = molecular weight

• (Tref) = viscosity at reference temperature (25C)

• (Tamb) = liquid density at ambient temperature

• Vb = molar volume at the normal boiling point

• = acentric factor

Note: the thermodynamic properties for the chemicals of interest

come from the DIPPR database (licensed yearly from Brigham

Young University - $750/PC install).

The model is best described in a series of steps.

Step 1: Describe the formulation. Identify each component and its

mass fraction.

Step 2: Compute the mol-fraction of each liquid component in the

mixture.

Step 3: Compute the viscosity of each ink component at the

temperatures of interest [(T)]. This step utilizes the Lewis-Squires

equation [7].

758.3

,2661.0

,

233

iREF

iREFi

TT

T (Eq.20)

REF,i = component-i viscosity (mPa-s) at temperature TREF,i

T = temperatures of interest = 15, 20, 25,…70 C

Note: 1 milli-Pascal (mPa-s) = 1 centipoise (cP)

Step 4: Select two reference liquids (R1, R2) from the mixture.

These are the two components with the largest mol-fraction.

Step 5: If this is a pigment ink, account for the solid particles. The

Einstein equation is only valid up to 5% volume fraction solid, so

the model make use of the Krieger-Dougherty equation [8], as it is

reportedly better for cases involving high particle packing and non-

spherical particles.

917.1

71.0

1

fp

F

v

m

fp

mm

v

MIX

P

P

i

i

i

P

P

MIX

(Eq.21)

vMIX = specific volume of the mixture

(mP, P) = particle mass fraction and density

(mi, i) = liquid component-i mass fraction, density

fP = volume fraction of the pigment particles

F = viscosity multiplication factor due to solid particles

Step 6: Compute the critical volume (VCM) of the mixture using

the quadratic mixing rule [7][9].

n

i

n

j

ijCjiCM VxxV , (Eq.22)

(xi, xj) = mol-fraction of components i, j

VC,ij = critical volume of components i, j

n = number of liquid components in the ink mixture

The inks used by Lexmark are multi-component, usually

containing five liquids (n = 5). The model’s algorithm for (Eq.22)

accounts for such mixtures. It is easy to get confused over the i’s

and j’s of (Eq.22), so let us illustrate how the algorithm works by

showing a binary mixture example (Table 2).

Table 2: Binary Mixture Example

i j xixj VC,ij

1 1 x1x1 x1

2

VC11 VC1

1 2 x1x2 x1x2 VC12 VC12

2 1 x2x1 VC21

2 2 x2x2 x2

2

VC22 VC2

8

33/1

2

3/1

1

12

CC

C

VV

V

Applying the values listed in Table 2 to (Eq.22) the critical volume

of a binary mixture may be written as:

8

2

33/1

2

3/1

1

212

2

21

2

1

CC

CCCM

VV

xxVxVxBinaryV

Step 7: Compute the critical temperature of the mixture using the

quadratic mixing rule [7][9].

CM

n

i

n

j

ijCijCji

CM

V

VTxx

T

,,

(Eq.23)

(xi, xj) = mol-fraction of components i, j](https://image.slidesharecdn.com/2ef8fd00-29b8-44cb-9a8a-fc4d36d27b5c-160108062003/75/Evaporation-effects-on-jetting-performance-6-2048.jpg)

![Print Physics Notes: Evaporation Effects on Inkjet Performance and Image Quality

December 2008

8

Figure 9: Data-Model comparison DS1-C ink viscosity versus temperature

Finally, Fig.10 illustrates the model results are well correlated over

a range of 57 test cases (the viscosity measurements and

formulations were performed by Agnes Zimmer).

Figure 10: Data-Model correlation over 57 test cases

Ink Property: Mass Diffusivity

The validity of the viscosity model has been established, and

demonstrated to be a relatively accurate means of predicting

viscosity as a function of formulation, temperature and

evaporation. Now can it be used to estimate idle time

performance? No, not just yet - to estimate idle time performance

we also need a predictive means for the evaporation rate. The

evaporation rate is dependent upon knowing the mass diffusivity of

the mixture. That is the topic of this section. It is worth noting that

this is dilemma number two. Predicting the mass diffusivity of a

multi-component liquid mixture is (and historically has been)

problematic.

Mass diffusivity in many solid materials is generally

predictable due to long range crystal order [19].

Mass diffusivity in gas is well understood due to kinetic

theory [19].

Many scientists have worked on developing a kinetic

theory for mass diffusion in liquid:

• Einstein, Stokes, Born, Deybe, Eyring

Unfortunately, much like the viscosity dilemma, kinetic

theory does not extend to mass diffusion in liquid [7]

Another complication is that commonly published mass

diffusivity values only hold for binary mixtures at

infinite dilution.

Mass diffusivity, over a wide solvent-solute range, is

published for only a few binary aqueous mixtures.

Our ink formulations are not binary, nor are they

infinitely dilute.

Molecular modeling holds the promise of solving multi-

component mixture diffusivity someday….but published

molecular modeling predictions (USA-ORNL, Spain,

Korea, Norway) show significant deviations from

experiment.

In the meantime, we must rely on semi-empirical models

to estimate mass diffusivity.

Mass Diffusivity Model

The diffusivity model makes use of the Wilke-Chang method

[7][8]. This is said to be an empirical modification of the Stokes-

Einstein relation.

6.0

8

104.7

BMIX

AMIX

AB

V

MT

D

(Eq.29)

DAB = mutual diffusion coefficient (cm2

/s) between components A

and B

TMIX = temperature (K) of the liquid mixture

MIX = viscosity (cP) of the mixture at TMIX

MA = molecular weight of water (g/mol)

VB = molar volume of the non-aqueous ink components (cm3

/mol)

= association factor of the solvent

[Wilke-Chang recommends ( = 2.6) when the solvent is water]

The Wilke-Chang method is intended for use in binary mixtures.

As mentioned earlier, ink mixtures are not binary. However, they

may be generally classified as mixtures of water (M = 18 g/mol)

and a cocktail of high molecular weight co-solvents (M ~ 100-200

g/mol). So for the purposes of this model, component-A is water

and component-B is treated as a quadratic mixture of the co-

solvents.

Note that the mass diffusion coefficient (DAB) is inversely

proportional to the mixture viscosity. This should be expected

since mass transport in liquids requires the molecules to squeeze

past each other as they move from point(x) to point(x+x). Thus it

is quite natural that there should be a connection between viscosity

and mass diffusivity. Mixture viscosity increases as evaporation

removes water (leaving a higher content of viscous glycols), and a

corresponding DAB reduction is expected.

Diffusivity Model Validation

Table 4 shows an excellent correlation between published DAB

values [10] and (Eq.29) for several binary mixtures.](https://image.slidesharecdn.com/2ef8fd00-29b8-44cb-9a8a-fc4d36d27b5c-160108062003/75/Evaporation-effects-on-jetting-performance-8-2048.jpg)

![Print Physics Notes: Evaporation Effects on Inkjet Performance and Image Quality

December 2008

9

Table 4: Computed DAB Compared to Reported Experimental

values [10]

Solute in an infinite

dilution of water

T(C)

DAB (10-5

cm2

/s)

Experimental

Value

Wilke-Chang

Equation

Acetone 25 1.28 1.28

Ethanol 25 1.24 1.41

Ethylene glycol 25 1.16 1.28

Glycerol 25 1.06 1.02

Methanol 15 1.28 1.41

1-propanol 15 0.87 0.9

Sucrose 25 0.52 0.58

Cyclohexane 20 0.84 0.83

3-methyl-1-butanol 10 0.69 0.59

Aniline 25 0.91 1.06

Eq.29 does a good job of predicting DAB for binary mixtures that

are infinitely dilute. However, it is known that DAB varies with

viscosity. So it begs the question: If it is known how viscosity

varies as a function of the mixture, can W-C be used to predict DAB

over a wide range of concentrations? This is important to know

because as water evaporates from the ink the water concentration

varies widely. Let us answer this by studying an example in the

literature.

Transport Canada funded a research project to evaluate the

effectiveness of new de-icing fluids [11]. Fundamental to solving

the problem was an understanding of diffusion characteristics of

the candidate mixtures. The University of Quebec measured

diffusion coefficients as part of the project. To validate their

diffusion measurement technique, they first calibrated it against

published values for water-EG mixtures. Their experimental results

along with the values computed with (Eq.29) are shown in Fig.11.

Figure 11: Data-Model correlation for water-EG mixtures

Fig.11 illustrates an important point - mass diffusivity is not a

constant. It varies greatly with water concentration. Any attempt to

simulate evaporation rate and idle time performance must account

for this.

Failing to account for mass diffusivity as a variable can easily

cause an order of magnitude error in the solution of (Eq.19).

Solution Procedure

The groundwork has now been laid, so it is time to apply all of the

teachings to a multi-physics solution.

Ink Formulation

Flow Feature Geometry

Ink Temperature

Water Evaporation

Mass Diffusivity

Viscosity

Ink Simulation Example

The model workspace contains thermodynamic information [Tb,

Tc, Pc, Vc, Zc, Mw,(Tref), (Tamb), Vb, ] for a wide variety of

chemicals. These thermodynamic properties are used, as described

previously, to simulate ink viscosity as a function of temperature

and water loss.

Table 5: Gen1 ink formulation

Component Wt.%

C M Y

DI water 67.79 69.54 69.21

Glycerol 12.5 6 6

Tripropylene glycol 7.5 --- ---

Triethylene glycol 5.5 7 7

1,3-Propanediol --- 8 8

Surfactant 0.75 0.9 0.8

Biocide* 0.13 0.13 0.13

Wax emulsion 0.5 0.5 0.5

Pigment** 4 6 6.5

Dispersant** 1.33 1.93 1.86

*The biocide is ignored in the model because it has a negligible

mol-fraction.

**The pigment and its encapsulating dispersant are considered

solids and are handled with the aforementioned Krieger-Dougherty

equation.

Figure 12: Data-Model correlation for Gen1-Magenta](https://image.slidesharecdn.com/2ef8fd00-29b8-44cb-9a8a-fc4d36d27b5c-160108062003/75/Evaporation-effects-on-jetting-performance-9-2048.jpg)

![Print Physics Notes: Evaporation Effects on Inkjet Performance and Image Quality

December 2008

10

Figure 13: Mass diffusivity versus viscosity Gen1-Magenta

Fig.12-13 illustrate the simulation results for Gen-1 magenta. Note

the exponential rise in viscosity as ink evaporates from the

mixture. This mimics the actual response of lab data as measured

by Shirish Mulay (Fig. 14).

Figure 14: Lab results – exponential viscosity increase with evaporation

Also note how mass diffusivity plummets as viscosity increases

(Fig 13). If the ink was pure water its diffusivity would be 300

m2

/s, and if the ink contained just 10% water, the remaining, high

viscosity components drive DAB to 8 m2

/s.

To put these values into perspective consider that the mass

diffusivity of moist air at 25C is 25,000,000 m2

/s. That said, the

limiting factor is the diffusivity in the liquid. Once a water

molecule makes it to the air-liquid interface there is no waiting line

to transport it into the free stream. In other words for the special

case of inkjet:

Evaporation of the volatile species generates concentration

gradients in the liquid such that mass transport within the

liquid is rate-limiting.

Finite Element Analysis

Using the finite element method, Fick’s 2nd law can now be

solved. Recall (Eq.19) and the finite element mesh of the mass

diffusion domain.

t

c

y

c

D

yx

c

D

x

WWW

Fick’s 2nd

Law (Eq.19)

Figure 6: Typical mass diffusion field with evaporative boundary condition

The finite element method is a powerful numerical procedure

that can be applied to a wide variety of application areas. It had its

beginnings in the aerospace industry about 50 years ago, and was

primarily used for structural and solid mechanics problems. It did

not gain wide acceptance until computing power became

ubiquitous (and cheap). Today the finite element method is

commonly used to solve problems in all areas of mathematical

physics. If one can write a set of governing partial differential

equations for the phenomena, it can be solved via the finite

element method. Therefore, it is well suited to the multi-physics

problems so common in inkjet.

There are several excellent books on this topic, and they

should be studied by anyone interested in print physics modeling

[6][12][13]. This section will provide a brief overview of the

numerical procedure that is the finite element method. In this

overview the field variable will be referred to as (). This makes

the discussion generic, applying equally to heat transfer, mass

diffusion, electric field, solid mechanics, etc.

Fig.15 shows the basic 3-node triangular element. The mesh

consists of (N) such elements interconnected at the nodes. The

meshing routine is an exercise in analytical geometry. It will be

covered in a future article.

100% Water

10% Water remaining

In the mixture](https://image.slidesharecdn.com/2ef8fd00-29b8-44cb-9a8a-fc4d36d27b5c-160108062003/75/Evaporation-effects-on-jetting-performance-10-2048.jpg)

![Print Physics Notes: Evaporation Effects on Inkjet Performance and Image Quality

December 2008

11

Figure 15: Triangular finite element

Diffusive Element Equations

Over the element, variable () is given by:

yx

NNN

NNN

mji

mji

m

j

i

mji

e

,variableofvaluesnodal

functionsioninterpolat

)(

(Eq.30a)

It can be shown that the shape functions are:

yx

yx

yx

A

N

N

N

mmm

jjj

iii

e

m

j

i

)(

2

1

(Eq.30b)

Where:

areaelement

1

1

1

det2

)(

)(

e

mm

jj

ii

e

A

yx

yx

yx

A

(Eq.30c)

ijmmijjmi

jimimjmii

iiiimmimijmjmii

xxxxxx

yyyyyy

xyyxyxxyxyyx

(Eq.30d)

Since field problems like those described by (Eq.18-19) are often

gradient dependent, it is convenient to write the gradient term as:

y

xg (Eq.30e)

Taking derivatives of (Eq.30a):

m

j

i

mji

mji

m

j

i

mji

mji

A

y

N

y

N

y

N

x

N

x

N

x

N

g

2

1

In a more compact form the gradient term may be restated as:

Bg (Eq.30g)

Field problems having the form of (Eq.18-19) have a diffusive

material property associated with them:

B-Aspeciesbetweenydiffusivitmassmutual

0

0

:ydiffusivitisotropicy withdiffusivitmassFor

directionsy)(x,intyconductivithermal,

0

0

:problemferheat transFor the

AB

AB

AB

MATL

yx

y

x

MATL

D

D

D

D

KK

K

K

D

(Eq.30h)

Field problems having the form of (Eq.18-19) have diffusive-like

and convective-like properties. The diffusive-like term is handled

as:

elementtheofthickness

equationelementdiffusive

:Where

)(

)(

)()()(

e

e

D

MATL

Teee

D

thk

k

BDBAthkk

(Eq.30i)

Convective Element Equations

The convective terms occur at domain boundaries, as shown in

Fig.16. Since convection is a function of exposed area, the element

equations must take that into account.

miEXP

mjEXP

jiEXP

e

EXPconve

conv

LL

LL

LL

thkLh

k

and;

201

000

102

:m)-(iissideelementexposedtheif

and;

210

120

000

:m)-(jissideelementexposedtheif

and;

000

021

012

:j)-(iissideelementexposedtheif

6

)(

)(

(Eq.30j)

hconv = convective coefficient;

- if [ = temperature (T)]; hconv = hc of (Eq.17)

- if [ = concentration (cW)]; hconv = hD/air of (Eq.17a)

LEXP = exposed element length = Li-m in (Fig.16)](https://image.slidesharecdn.com/2ef8fd00-29b8-44cb-9a8a-fc4d36d27b5c-160108062003/75/Evaporation-effects-on-jetting-performance-11-2048.jpg)

![Print Physics Notes: Evaporation Effects on Inkjet Performance and Image Quality

December 2008

12

Figure 16: Arbitrary mesh showing a convection boundary condition

Global Matrices

The mesh consists of (NNODE) nodes and (NELE) elements. For

each element (Eq.30i) is written, and for elements that have a

convective boundary (Eq.30j) is added to it.

)()()( e

conv

e

D

e

kkk (Eq.30k)

The individual element equations are assembled into a global

matrix {K}. Since the finite element method had its roots in

structural mechanics, the {K} matrix is often referred to as the

global stiffness matrix.

Breaking up the domain into an interconnected mesh of finite

elements allows the numerical solution to take the form of

algebraic matrix equations, like (Eq.30m), instead of the often

intractable partial differential equations when applied to complex

geometries and boundary conditions.

0

FK

t

C (Eq.30m)

(Eq.18)aldifferentipartialFor the

(Eq.19)aldifferentipartialFor the1

211

121

112

12

matrixecapacitancGlobal

matrixstiffnessGlobal

:Where

)()(

)(

1

)(

P

ee

e

NNODE

e

C

Athk

c

cC

K

(Eq.30n)

For elements with a convective boundary condition:

0

1

1

2

:(Eq.19)aldifferentipartialFor

0

1

1

2

:(Eq.18)aldifferentipartialFor

matrixforceGlobal

)(

)(

)(

)(

1

)(

AIR

e

EXPDe

e

EXPCe

NNODE

e

thkLWh

f

thkLTh

f

fF

(Eq.30m)

Note (Eq.30m), as shown, is for elements with a convective

boundary along element side i-j. If the convective boundary is on

side j-m the (3 x 1) matrix is [0 1 1]T

. If convection is along side i-

m the (3 x 1) matrix is [1 1 0]T

.

Matrix Equation Solution

Eq.30m may be solved by many numerical techniques. The central

difference method is shown below.

FPS

KC

t

P

C

t

KA

OLD

2

2

(Eq.30n)

[OLD] = nodal values of the field variable at the last time step

t = time step

To account for convective and fixed boundary conditions, [A] and

[S] must be modified. There are many techniques to do this (e.g.

see Appendix 3 of reference [6]). A convenient mathematical trick

is to identify the node numbers that are affected by fixed and/or

convective conditions. Then multiply the diagonal terms of those

nodes in [A] by a very large number (e.g. 1015

). Next set the

affected nodes of [S] equal to the boundary condition value and

multiply those terms by the same very large number. The set of

equations may now be solved using various matrix reduction

techniques.

MODMODNEW SA

1

(Eq.30p)

[NEW] = nodal values of field variable at time (t+t)

[AMOD] [SMOD] are the matrices of (Eq.30n) that have been

modified for fixed and/or convective boundary conditions.

i

j

m

Li-m

j

i m

Free

Stream

Convection Boundary](https://image.slidesharecdn.com/2ef8fd00-29b8-44cb-9a8a-fc4d36d27b5c-160108062003/75/Evaporation-effects-on-jetting-performance-12-2048.jpg)

![Print Physics Notes: Evaporation Effects on Inkjet Performance and Image Quality

December 2008

13

Because the mesh usually contains thousands of nodes, matrix

inversion is an impractical means of solving (Eq.30p). Matrix

inversion is storage and CPU intensive. The LXK model uses node

renumbering to minimize the bandwidth of the [AMOD] matrix, and

since the matrix is symmetrical, only the upper, non-zero terms,

are stored and manipulated. The details of the bandwidth reduction

method and the rectangular matrix solver algorithm will be

covered in a future article.

After each time step (t), the field variables are laminated

onto a results matrix {}.

nNNODENNODENNODENNODE

n

n

n

tntttttt

,3,2,1,

,32,31,30,3

,23,21,20,2

,13,11,10,1

0 2

For each element, at each time step, there is an associated gradient

as shown in (Eq.30g). Gradients of the field variable are the prime

movers of some flux variable. Flux is the flow rate of some

physical property per unit area. The generic flux over each element

(e) is given by:

)()()()( eee

MATL

e

BDFlux

Where:

format.equationmatrixelement,finitein

:andform,equationaldifferentipartialin

)()()( eee

Bg

Grad

In particular, the energy flux in a heat transfer problem (Eq.18) is

given by:

22

)()()()(

ms

Joules

m

Watts

TBDq eee

MATL

e

(Eq.30q)

Similarly for the mass diffusion problem (Eq.19), the mass flux is

given by:

2

)()()()(

)(

ms

grams

cBDm

e

W

ee

MATL

e

e

(Eq.30r)

[DMATL] is given by (Eq.30h)

(e)

is the density of the material in the element

To determine the evaporative mass flux leaving the ejector

(Eq.30r) is summed over the elements at the nozzle exit.

Evaporative Flux Exiting an Inkjet Nozzle

The groundwork has now been laid for computing the evaporation

of water vapor from an inkjet ejector and the resultant, transient

viscosity field in the flow features. Reviewing the steps to get to

this point, it was necessary to quantify:

- The thermodynamic properties of moist air

- Boundary layer analysis for (hC, hD) convection coefficients

- Heat and mass diffusion

- Ink viscosity simulation method

- Mass diffusivity (DAB) for multi-component ink mixture

- Finite element analysis overview

Demonstration Example

The example chosen here is the evaporation of water from a

Romulan ejector filled with Puddy2-CMY dye inks. This ink-

ejector combination was chosen because evaporation lab data

exists to check the model veracity. The CMY-flow field is shown

in Fig.17. The K1-K2 flow fields are not shown because those

nozzles were not part of this experiment (they were intentionally

covered with tape so that PM1-mono ink would not confound the

experiment with its clumping, nozzle-blocking tendency). The

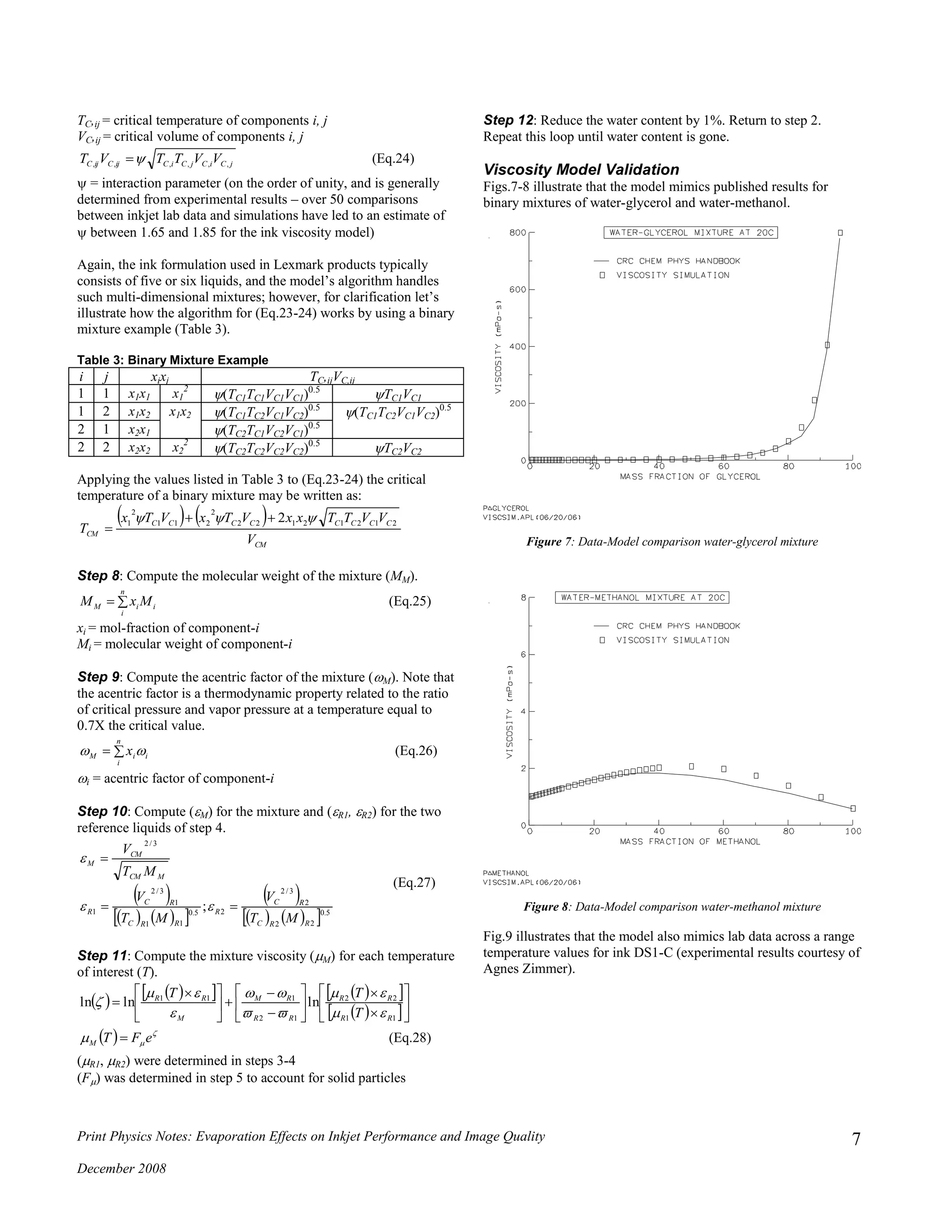

Puddy2 ink formulation is shown in Table 6. The simulated

viscosity versus temperature results are shown in Fig.18 along with

the measured values [(T) measurements courtesy of Agnes

Zimmer]. Except at very low temperatures, the model-lab data

comparisons are good for all three inks. Fig.19 shows how

viscosity is expected to vary with temperature and evaporative

mass loss.

Figure 17: Romulan-PINP color ejector

Table 6: Puddy2 ink formulation

Component Wt.%

C M Y

DI water 72.4 72.4 72.3

1,2-propanediol 7.0 --- ---

1,3-propanediol 7.0 6.0 7.0

Triethylene glycol 6.0 --- 6.0

1,2-hexanediol 3.0 3.0 3.0

trimethylolpropane --- 6.0 ---

1,5-pentanediol --- 8.0 ---

Tripropylene glycol --- --- 7.0

Silwet 0.5 0.5 0.5

Biocide 0.1 0.1 0.1

triethanolamine --- --- 0.1

Dye 4.0 4.0 4.0](https://image.slidesharecdn.com/2ef8fd00-29b8-44cb-9a8a-fc4d36d27b5c-160108062003/75/Evaporation-effects-on-jetting-performance-13-2048.jpg)

![Print Physics Notes: Evaporation Effects on Inkjet Performance and Image Quality

December 2008

15

At this point, we can infer the model treats the following correctly:

- The thermodynamic properties of moist air

- Boundary layer analysis for (hC, hD) convection coefficients

- Heat and mass diffusion

- Ink viscosity simulation method

- Mass diffusivity [DAB()] for multi-component ink mixture

- Finite element analysis of the mass diffusion domain

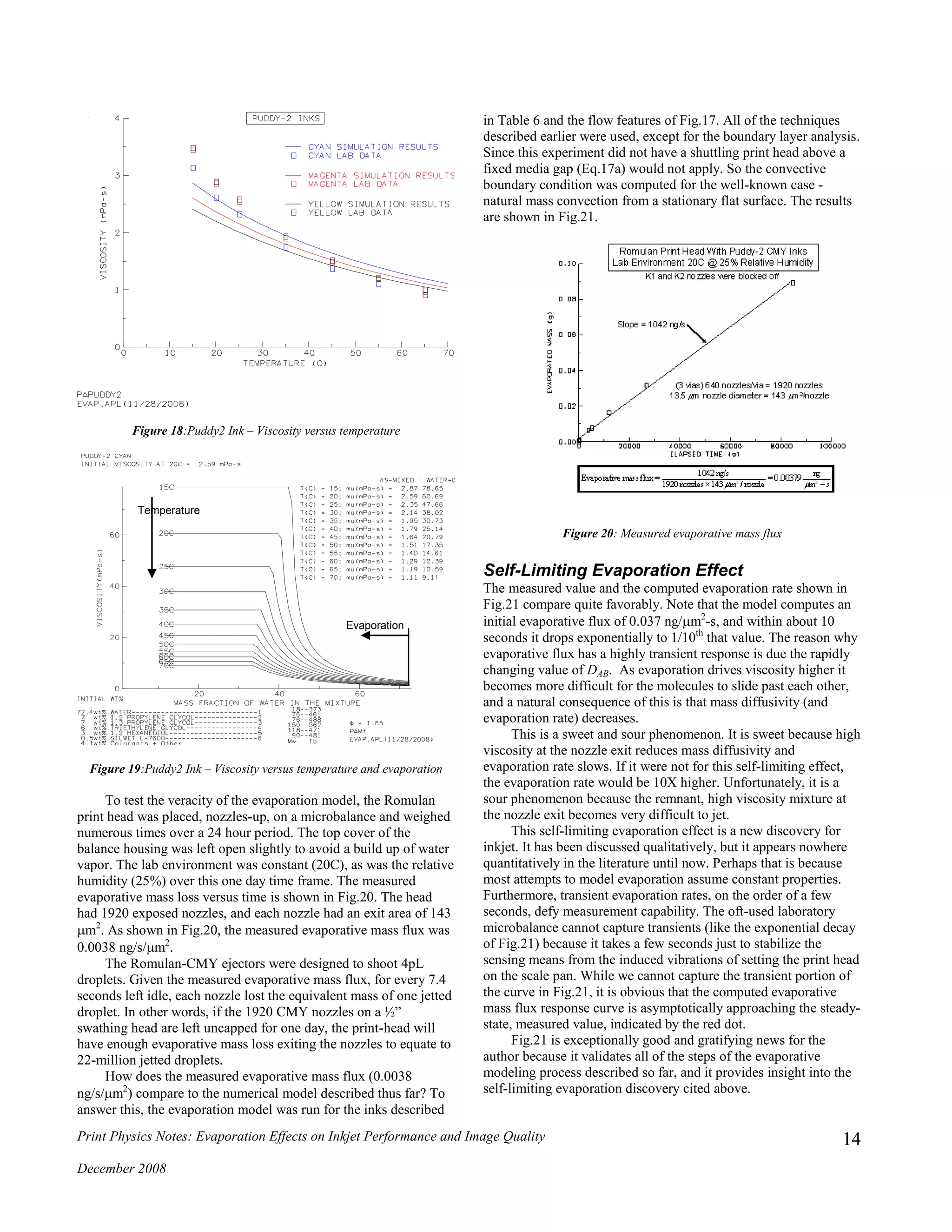

Figure 21: Evaporative mass flux-measured and simulated

Mass Diffusion Field Results

Recall the governing partial differential equation (Eq.19).

Everything is now in place to solve it for any given ejector design,

ink formulation, idle time and environmental condition.

Let us shift focus to Newman-mono. It will be beneficial to

use these teachings to quantitatively show why this ejector-ink

system is more prone to have idle time problems than Newman-

CMY (and Canon-mono).

Fig.22 shows the Newman-mono water concentration field

after just one second of idle time evaporation from a chip held at

42C in an atmosphere of 25C and 25% R.H. Also note the insert in

the upper right corner of Fig.22 showing viscosity versus nozzle

location. According to these results, liquid at the top 2 microns of

the nozzle has a viscosity of 70mPa-s after just one second of idle

time evaporation. That is an increase of 35X over the initial

mixture at 42C.

Recall the earlier comment that HP spits their Edgeline head

every 800 ms because they said substantial changes to

pigment ink properties occur within seconds. Fig.22-23

confirms - substantial changes indeed.

Figure 22: Water concentration after one second of evaporation

Figure 23: Water concentration after ten seconds of evaporation

85,000 s

Evaporative Mass Flux

Experimental Result

0.0038 ng/s-m

2

Simulated evaporative flux](https://image.slidesharecdn.com/2ef8fd00-29b8-44cb-9a8a-fc4d36d27b5c-160108062003/75/Evaporation-effects-on-jetting-performance-15-2048.jpg)

![Print Physics Notes: Evaporation Effects on Inkjet Performance and Image Quality

December 2008

17

dzP

tz

P

HYD

(Eq.31)

Where:

s/mrateflowvolumetric

)(mfactorresistancehydraulicgeometric

s)-(Paexitnozzle-heaterfromviscositydynamic

nozzle)-(heaterdirection-zin thes/m)-(Pagradientpressure

(Pa)resistancehydraulictoduedroppressure

3

4-

t

z

z

P

PHYD

FEAJET solves for volumetric flow rate by iteration. As the bubble

grows, liquid is converted to water vapor. This phase change

requires energy. The source of the phase-change energy is the

thermal boundary layer in the ink at the onset of nucleation. So

phase-change energy pulled from the thermal boundary layer tends

to cool liquid-vapor interface. Also, at nucleation the temperature

gradient in the thermal boundary layer is on the order of 300

million Kelvin per meter. This gigantic gradient effects rapid

diffusion of thermal energy into the cool region of the ink.

Combining the diffusion effect with the phase-change effect causes

a very rapid cooling of the ink. With the rapid cooling comes a

rapid decrease in the phase-change pressure pulse. The phase-

change pressure pulse and the resultant bubble growth act as a

virtual piston – displacing liquid in the ejector and shooting ink

onto the media. The nature of the explosive phase-change pressure

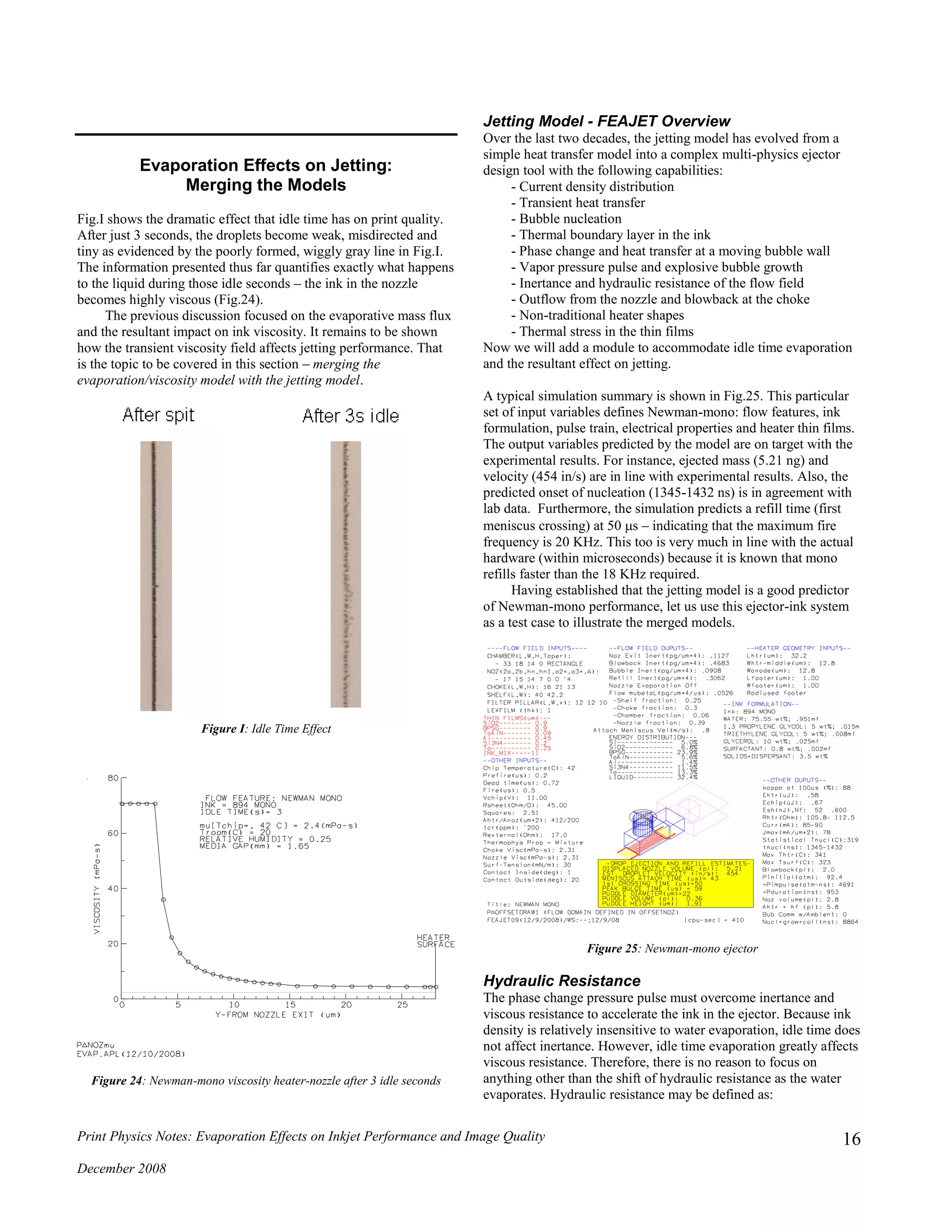

pulse is seen by comparing Fig.26a and Fig.26b. In both of these

cases the end-point is when the bubble reaches its maximum

displacement, i.e. the onset of bubble collapse. When the pressure

pulse must overcome a highly viscous flow field, the pressure

pulse is spent more quickly. For example, the 3 second idle time

case (Fig.26a) expends its pressure pulse in about 1.6 s, while the

0 second idle time pressure pulse (Fig.26b) lasts about 3.6 s.

These pressure-temperature response curves are a function of how

hard the bubble has to work to move liquid. There is a fixed

amount of available energy in the thermal boundary layer for

phase-change. So when the viscous resistance is high, the pressure

pulse is quickly dissipated.

Figure 26a: Newman-mono phase change pressure pulse after 3 seconds of

idle time evaporation

Figure 26b: Newman-mono phase change pressure pulse after 0 seconds of

idle time evaporation

Fig.26 illustrates the effect of PHYD. As for the other terms in

(Eq.31), the evaluation of dz can be problematic because, like

many MEMS flow structures, inkjet ejectors are non-circular. This

presents a problem for micro-flow fields, but a solution

methodology was derived and published in 2007 [14]. Instead of

repeating those teachings here, interested parties may consult [14].

The result for the Newman-mono flow features dz is given by:

0.00579 (m-3

) shelf region

0.00677 (m-3

) choke region

0.00133 (m-3

) chamber region

0.00884 (m-3

) nozzle region](https://image.slidesharecdn.com/2ef8fd00-29b8-44cb-9a8a-fc4d36d27b5c-160108062003/75/Evaporation-effects-on-jetting-performance-17-2048.jpg)

![Print Physics Notes: Evaporation Effects on Inkjet Performance and Image Quality

December 2008

20

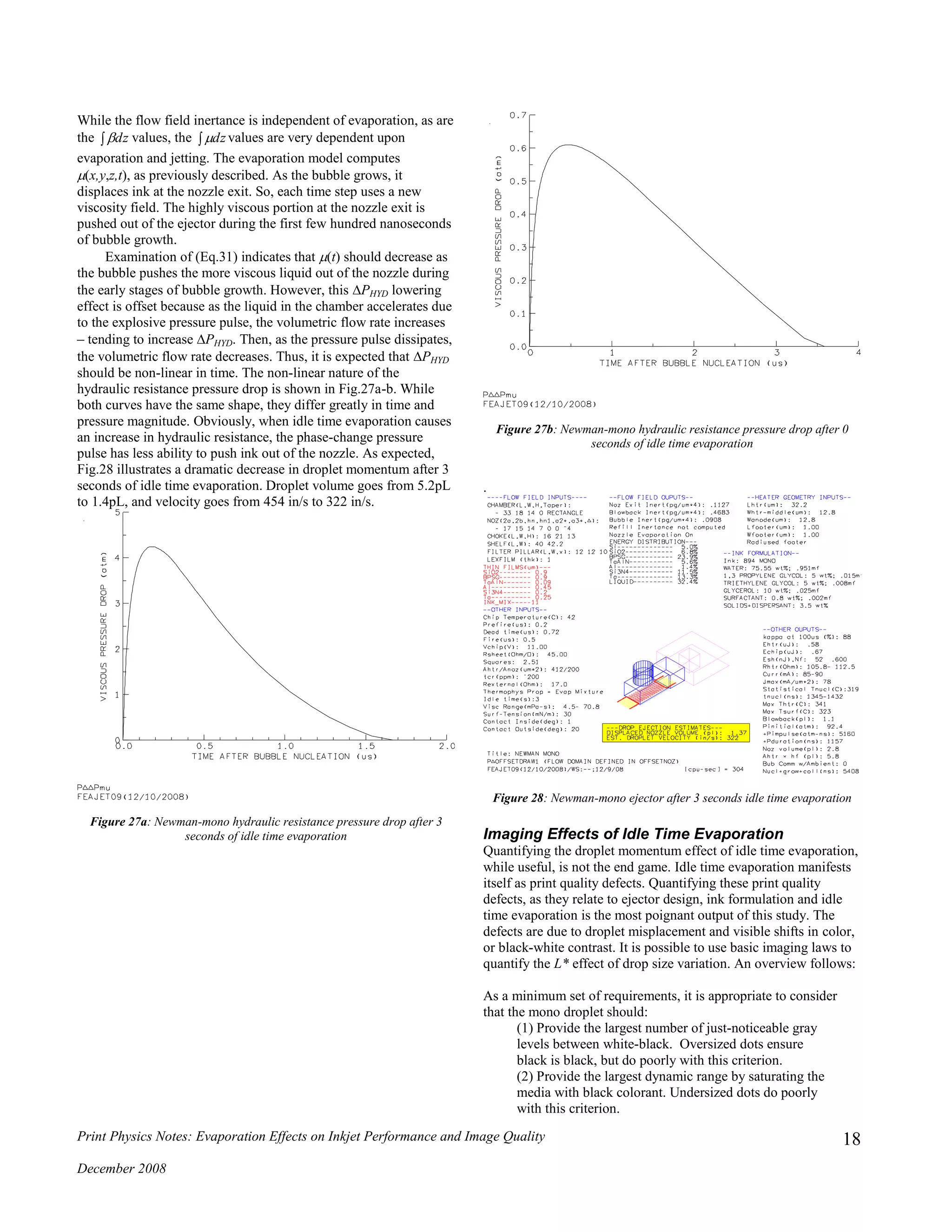

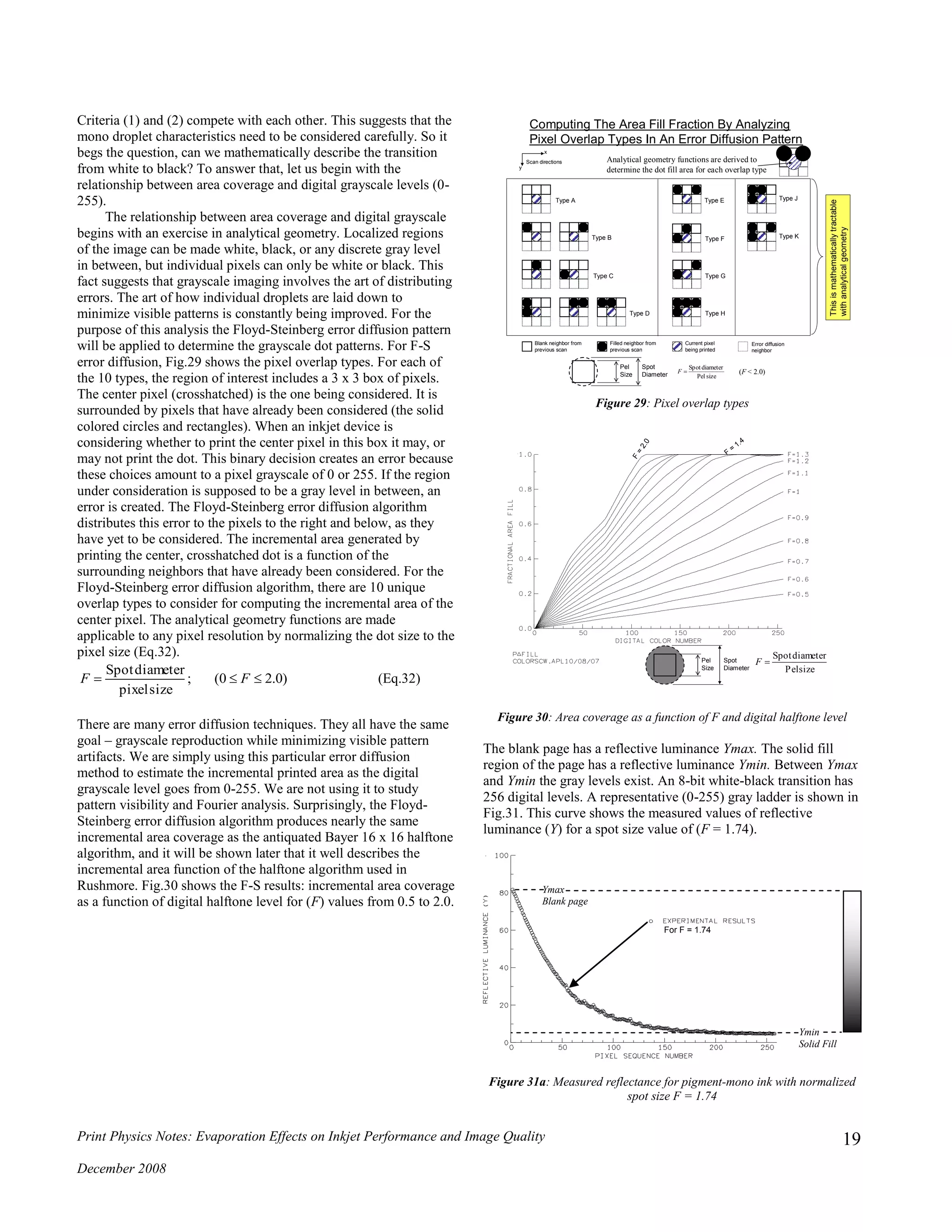

The cira-1936 Murray-Davies equation relates area coverage to

reflective luminance. Unfortunately, as shown in Fig.31b, it does a

poor job of matching the lab data over much of the experimental

space.

Figure 31b: Measured reflectance for pigment-mono ink with normalized

spot size F = 1.74 along with values computed by Murray-Davies equation

So the obvious solution relating luminance and grayscale, based

simply upon incremental dot area coverage, is the wrong one.

However, it is interesting to note that the Murray-Davies equation

matches the experimental data in the solidly filled region, but it

does a poor job in the regime where dot coverage is low. This

observation provides a clue to the source of the discrepancy. The

discrepancy is explained by examining what happens to the light

when it enters the non-dot regions (Fig.32). Because the media

scatters light in the non-dot regions, some of the diffused light

exits in the dot regions. Thus sparsely placed dots absorb more

light than their area alone would suggest. This discovery is

attributed to Yule and Nielsen (1957) [15].

Figure 32: Internal light reflections in the non-dot regions of the media

tcoefficienNielsen-Yule

fractioncoveragearea

fillsolidofdensitydottheofdensity

paperblankofdensity

density

1011log

:isequationNielsen-YuletheofformdensityThe

10

n

c

DD

D

D

cnDD

a

Pd

P

n

dD

aP

(Eq.33)

16

100

116*

:by*familiarmorethetoconvertedthenisformereflectancThe

0.10;10

:byereflectanctoconvertedisformdensityThe

3/1

Y

L

L

RR D

DP and Dd are known from densitometry measurements (solid fill

and blank paper). Coverage area (ca) is computed by analytical

geometry. What value is to be placed upon (n)?

Physical arguments behind the derivation of (Eq.33) suggest

that n is contained within the range of 1 to 2. Furthermore, it can

be shown that as the dot coverage (ca) goes to unity, n goes to

unity. In other words, when there is little to no non-dot area there

is no need to account for the scattering effect shown in Fig.32. The

literature abounds with various means of estimating (n). Since

there is no general agreement within the image science community,

the sigmoid function proposed here (Eq.34) is both easy and

reasonable.

0.05factorsteepnessslope

ntransitiobatheofpoint-mid

)0.10(fractioncoveragearea

1.0regionsfill-solidin thefactorNielsen-Yule

2.0regionsdot-nonin thefactorNielsen-Yule

exp1

0

0

w

x

xcx

b

a

w

xx

ba

an

a

(Eq.34)

Figure 33: Sigmoid function for Yule-Nielsen factor (n)

RY

RcRR daP

100

11

R = image reflectivity

Rp = paper reflectance

Rd= dot reflectance

ca = area coverage fraction

Ymax

Blank page

Ymin

Solid Fill

F = 1.74

DotDot

Dot

Media

Light Rays

The media scatters the light entering the non-dot regions.

Some of the scattered light is absorbed by nearby dots.

The sigmoid function is used in this analysis to

determine n as a function of area coverage*

n 2

n 1](https://image.slidesharecdn.com/2ef8fd00-29b8-44cb-9a8a-fc4d36d27b5c-160108062003/75/Evaporation-effects-on-jetting-performance-20-2048.jpg)

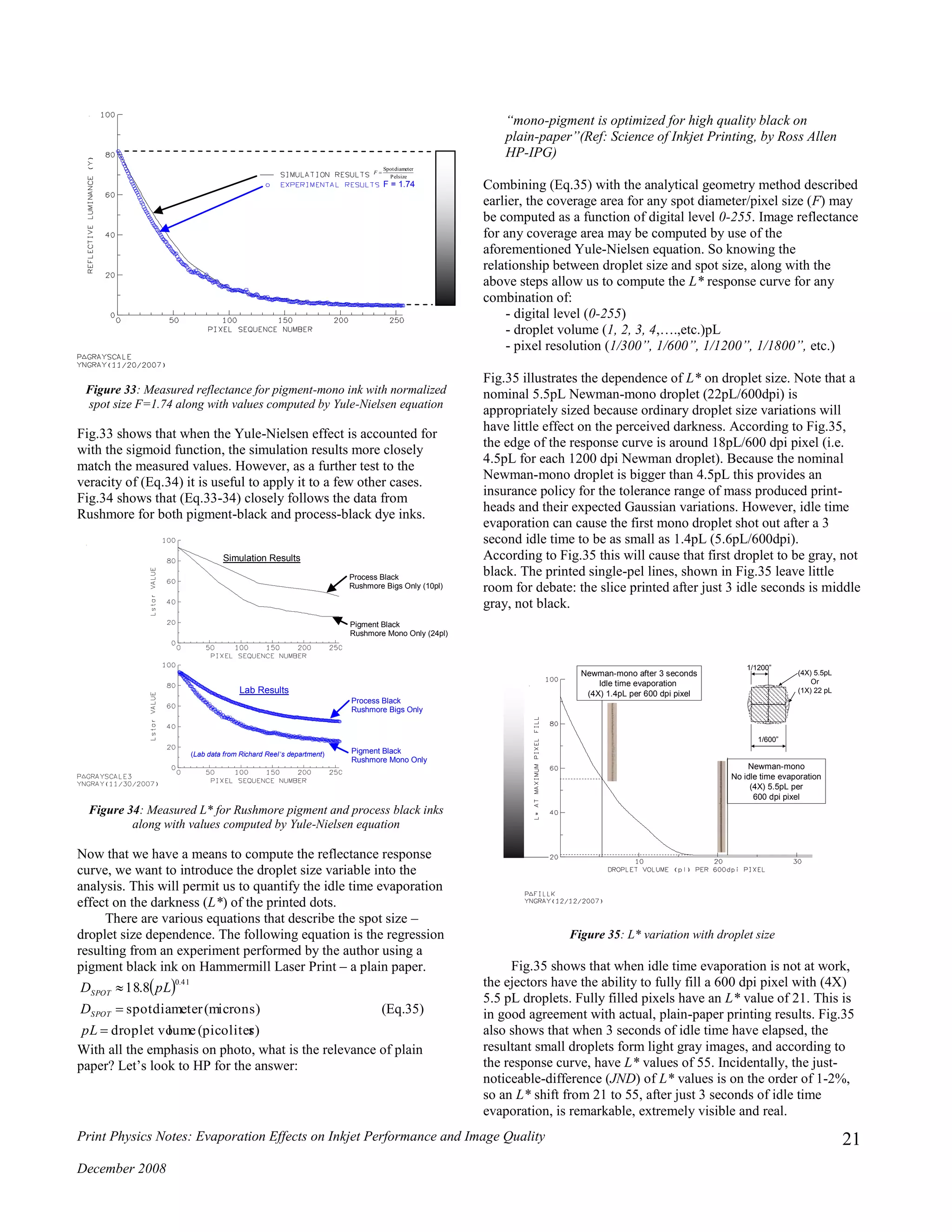

![Print Physics Notes: Evaporation Effects on Inkjet Performance and Image Quality

December 2008

24

quality. For example, to satisfy photo-centric imaging scientists,

the Gen1-pigment color formulations had between 6-6.5 wt.%

colorant to achieve the gamut obtained with 4 wt.% dye

formulations. The Gen1-pigment colors also used a polymeric

dispersant that consumed another 1.9 wt.% of the mix (typically in

the industry, pigment-dispersant ratios are about 15:4). Because the

dispersants attach themselves to the pigment particle, the charged

particle shell is physically larger than the dry pigment particle

itself. This effect is illustrated as (D) in Fig.41. That said, when

polymeric dispersants are used in conjunction with pigment

particles, they both go into the Krieger-Dougherty equation, and

the solid volume fraction increases – increasing the viscosity

multiplier of Eq.21.

Pigment Particle Kinetics

The solids account for some of the pigment-dye viscosity

difference. The other part of the issue is that the remnant co-

solvent blend used in pigment formulations are very often more

viscous than those used in the dye formulation. This slows the

pigment retreat as water evaporates – a good thing. Charged

pigment particles seek water to balance the electrostatic field

formed by the double charge layer surrounding them. When

evaporation leaves a humectant-rich, water-poor mixture in the

nozzle, the pigment particles retreat to the water-rich region of the

ink via.

Pigment retreat is a form of electro-kinetics. If a charged

particle is accelerated with respect to the surrounding fluid when

an electric field is applied, the particle kinetics are defined as

electrophoresis. If the fluid moves under the influence of an

electric field, the flow is defined as electro-osmotic. Observations

of pigment particle retreat show that the particles move thru a

stationary liquid, thus the kinetics of pigment retreat is a form of

electrophoresis. When an electric field is placed across a pigment

loaded ink, electrophoretic flow occurs. This is easily seen when

an anode-cathode probe pair is placed in the ink because pigment

particles travel towards one of the probes. The source of the

electric field in capillary electrophoresis may be anode-cathode

pairs as often used in bioMEMS applications [18] (DNA micro-

arrays, Lab-on-chip, hemoglobin electrophoresis, protein analysis,

etc.). Or, the electric field source may be due to ionic and pH

gradients that come about from evaporation driven concentration

gradients of water in the ejector.

Figure 41: Charge field around an electrophoretic particle

Fig.41 shows the double charge layer surrounding a particle. Under

the influence of an electric field, the electrophoretic velocity is

[17]:

Ev L

EP

0

(Eq.37)

vEP = electrophoretic velocity

0 = zeta potential = f(chemistry, pH, temperature)

L = dielectric constant of the liquid

= viscosity

E = electric field strength (Volt/m)

If (vEP) is large, the pigment retreat is fast, and the ejected droplets

lack colorant. Pigment retreat is a serious problem – what good is a

jettable ink formulation if the first few droplets have no colorant

due to pigment retreat. Pigment particles move more slowly thru a

high viscosity mixture. Note in (Eq.37), electrophoretic velocity is

inversely proportional to viscosity.

So there is a particle-kinetics benefit to using more viscous

co-solvents in pigment inks. If co-solvents are chosen such that

the mixture has low viscosity in the evaporated state, the idle time

jetting may be unimpeded, but the ejected droplet will have low

colorant loading because the low viscosity mixture allows rapid,

electrophoretic transport of pigment particles away from the water-

poor nozzle towards the water-rich ink via. Yet, if the co-solvents

are viscous enough to slow the pigment kinetics, they form a

highly viscous plug, a few microns long, that impedes jetting.

There may be a middle ground between dye-based and

pigment-based formulations that offer the best set of tradeoffs

between image permanence, gamut, pigment retreat

(electrophoresis) and idle time jetting. If so, the viscosity response

curves will likely lie between those of Fig.19 (dye) and Fig.42

(pigment).

Figure 19:Puddy2-dye-ink – Viscosity versus temperature and evaporation](https://image.slidesharecdn.com/2ef8fd00-29b8-44cb-9a8a-fc4d36d27b5c-160108062003/75/Evaporation-effects-on-jetting-performance-24-2048.jpg)

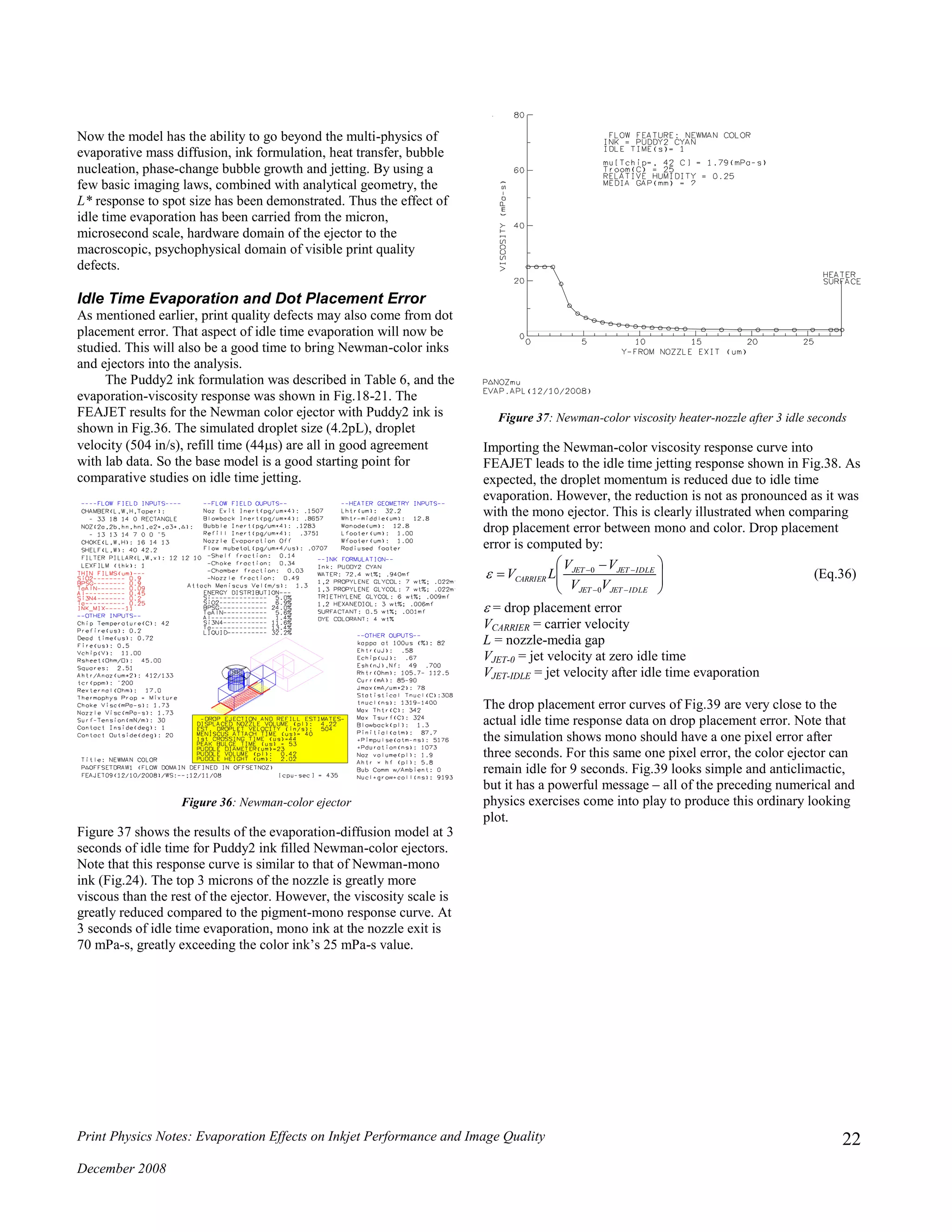

![Print Physics Notes: Evaporation Effects on Inkjet Performance and Image Quality

December 2008

25

Figure 42:894 Pigment-mono ink – Viscosity versus temperature and

evaporation

Epson Pigment-Color Ink

In Lexmark’s market segments, the nearly universal rule is that

mono ink is pigment (with droplets >> 4pL) and color is dye-based

(with droplets < 4pL). An exception to this rule is Epson. With

their piezo-electric technology they have chosen to incorporate

pigment-color inks. Let’s examine their formulation to see if they

have discovered the magic where image permanence, gamut

pigment particle kinetics and idle time jetting live happily in

unison. Tab.7 (courtesy of Agnes Zimmer) lists our best analytical

chemistry estimate of the Epson C88 Pigment-Magenta ink

formulation. Fig.43 shows the viscosity response curves of this ink.

The simulation shows that this ink has a room temperature (20C)

viscosity of 4.36cP. Epson, on their MSDS [16], reports this ink

having a viscosity less than 5cP, so the simulation results agree

with the published information. The Epson C88 pigment color

viscosity response curves look nearly identical to the Gen1-

pigment magenta results shown earlier in Fig.12. The Gen1

pigment-CMY formulations were simply horrible from an idle time

viewpoint. That said, it is clear that Epson may have a pigment ink

formulation for image permanence and probably not prone to

pigment retreat; however, the enormous viscosity in the evaporated

state means that the C88 formulation has no magical idle time

properties.

Table 7: Epson C88 pigment-magenta ink formulation

Component Wt.%

2-pyrollidone 3.2

Glycerol 12.6

Triethylene glycol mono butyl ether 2.5

Trimethyol propane 4.3

1,2-Hexanediol 2

Water 70

Colorant – dispersant load Bal (5.4)

Figure 43:Epson C88 Pigment-color ink – Viscosity versus temperature

and evaporation

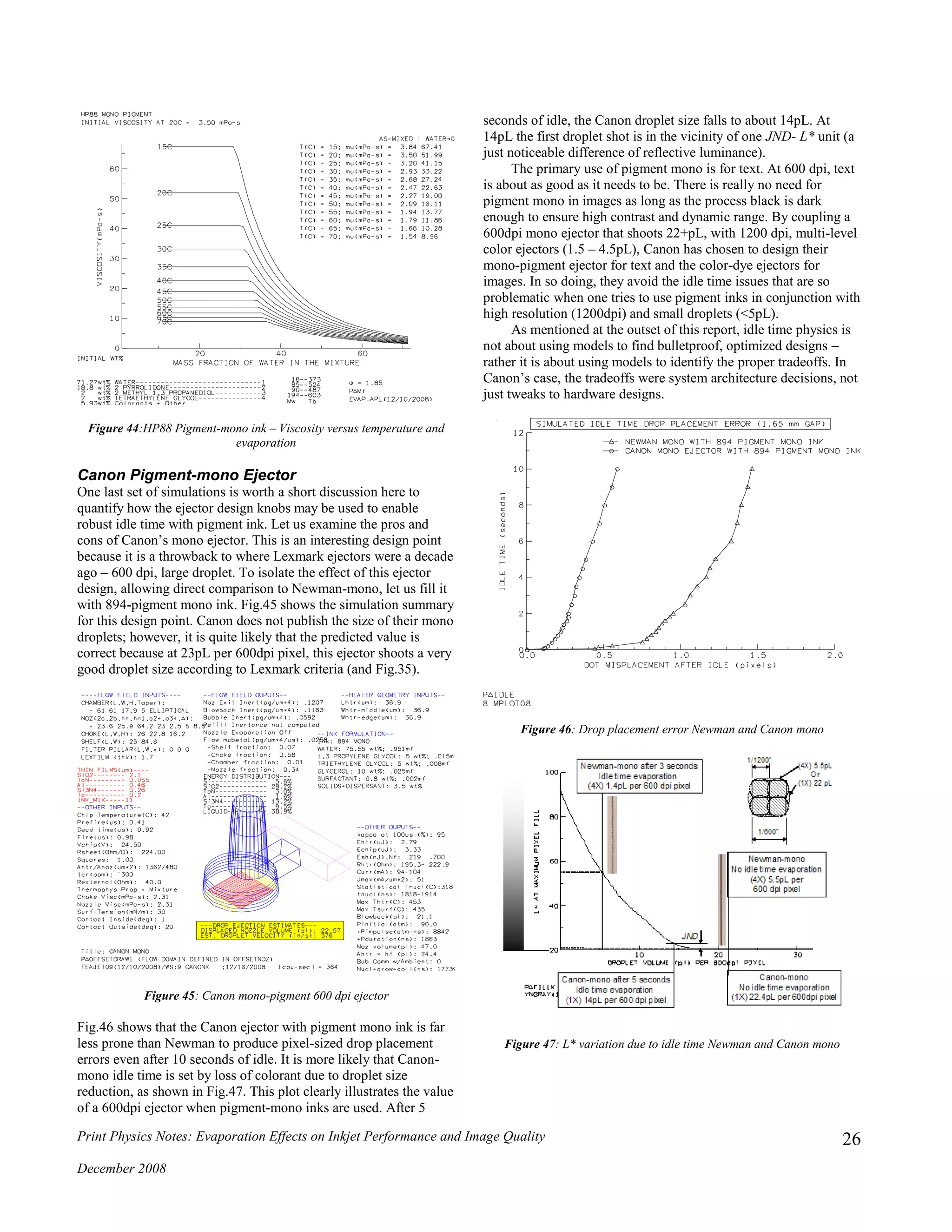

HP Pigment-Mono Ink

The mono-pigment formulation from HP is shown in Table 8

(courtesy Agnes Zimmer), and its viscosity response curves are

shown in Fig.44. According to the simulation the HP-mono ink

should have a viscosity of 3.5cP at 20C. This agrees very well with

the experimental value of 3.3cP at 22C. It is interesting to note that

the HP pigment mono formulation has much lower viscosity in the

evaporated state than all other pigment inks examined in this

document. In the evaporated state the HP pigment mono ink looks

more like Puddy2-dye inks than 894-mono pigment, Gen1-color

pigment and Epson-color pigment. This does not imply that HP has

found the magic spot where pigment inks are optimized, but it

clearly shows that they understand the issues and the importance of

not allowing the evaporated state viscosity to leap up to values

greater than dye-based inks.

Table 8: HP88 pigment-mono ink formulation

Component Wt.%

2-pyrollidone 18.8

2-methyl-1,3-propanediol 2

Tetraethylene glycol 2

Water 71.3

Colorant – dispersant load Bal (6)](https://image.slidesharecdn.com/2ef8fd00-29b8-44cb-9a8a-fc4d36d27b5c-160108062003/75/Evaporation-effects-on-jetting-performance-25-2048.jpg)

![Print Physics Notes: Evaporation Effects on Inkjet Performance and Image Quality

December 2008

27

Conclusions

Idle time brings to mind idyllic Summer scenes of sipping lemonade

on the porch swing. However, like most things inkjet, idle time is

anything but an easy, mindless exercise. This document has shown

that to quantify inkjet idle time one needs to make use of multiple

areas of science; ink formulations, heat and mass diffusion on both

sides of the liquid-air interface, thermodynamic interactions

between moist air and water, the thermo-hydrodynamics of jetting

and some aspects of image science. Even with all these fields

covered there are gaps in the unknown – for instance the

quantitative electro-kinetics of pigment retreat. There are always

gaps in knowledge, but that does not mean what is known is

irrelevant. This article has shown consistent veracity between

experimental results and simulations. Also, the analysis has shown

the self-limiting characteristic of idle time evaporation from a

quantitative viewpoint. Furthermore, it has shown direct cause and

effect between idle time evaporation and the resultant print quality

defects due to L* variations and drop placement error. As mixed

viscosity is important – indeed the ejector flow features are designed

and tuned to this value. However, this analysis clearly shows that

viscosity in the evaporated state is the dominant idle time lever.

Idle time has always been a topic of great concern and debate,

but it never got beyond the qualitative and empirical realms. For the

first time in nearly two decades of inkjet development at Lexmark,

we are now poised to start speaking of idle time issues and tradeoffs

quantitatively.

References

[1] Ross Allen, HP Scaleable Print Technology, 30th

Global Inkjet Printing

Conf., Prague, Czech Rep., (2007).

[2] Beverly, Clint & Fletcher, Evaporation rates of structured and non-

structured liquid mixtures, PCCP, 2, (2000).

[3] J.L. Threlkeld, Thermal Environmental Engineering, 2nd

ed., Prentice-

Hall, Inc., London, (1970).

[4] T. Kusuda, Humidity and Moisture, Vol. 1, (1965).

[5] J.P. Holman, Heat Transfer, McGraw-Hill, New York, (1972).

[6] L.J. Segerlind, Applied Finite Element Analysis, Wiley & Sons, New

York, (1976).

[7] Poling, Prausnitz & O’Connell, The Properties of Gases and Liquids,

McGraw-Hill, New York, (2000)

[8] Bird, Stewart & Lightfoot, Transport Phenomena, Wiley & Sons, New

York, (1976).

[9] V.P. Carey, Liquid-Vapor Phase Change Phenomena, Hemisphere

Publ., Washington, (1992).

[10] D.R. Lide (ed.), Handbook of Chemistry and Physics, 84th

Ed., CRC

Press, Boca Raton, (2003).

[11] Louchez, Zouzou, Liu’ & Sasseville, Modeling of Water Diffusion in

Ground Aircraft De/anti-icing Fluids for Numerical Prediction of

Laboratory Holdover Time, Transportation Development Centre, Montreal,

Quebec, (1997).

[12] D.L. Logan, A First Course in the Finite Element Method, PWS-Kent,

Boston, (1986).

[13] K.H. Huebner, The Finite Element Method for Engineers, Wiley &

Sons, New York, (1975).

[14] R.W. Cornell, Using Solid Mechanics to Evaluate the Capillary and

Viscous Behavior on Non-circular Tube Shapes, Proc. IS&T-NIP23,

(2007).

[15] J.A.C. Yule & W.J. Nielsen, The Penetration of Light into Paper and

its Effect on Halftone Reproduction, Proc TAGA, (1951).

[16] Epson product information sheet PIS T060320, Ver. 3.51 (08/2005).

[17] Geschke, Klank & Tellemann, Microsystem Engineering of Lab-on-a-

Chip Devices, Wiley-VCH, (2004).

[18] S.S. Saliterman, Fundamentals of BioMEMEMS and Medical

Microdevices, SPIE Press, (2006).

[19] W. Jost, Diffusion in Solids, Liquids and Gases, Academic Press, New

York, (1960).](https://image.slidesharecdn.com/2ef8fd00-29b8-44cb-9a8a-fc4d36d27b5c-160108062003/75/Evaporation-effects-on-jetting-performance-27-2048.jpg)