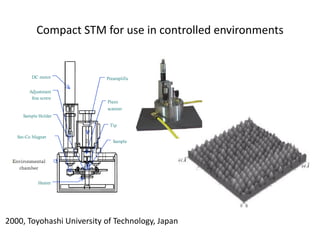

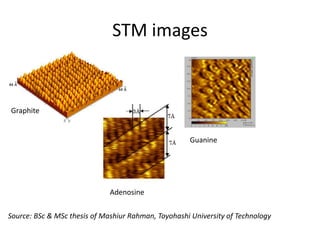

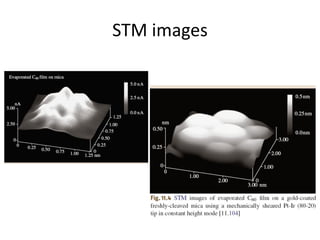

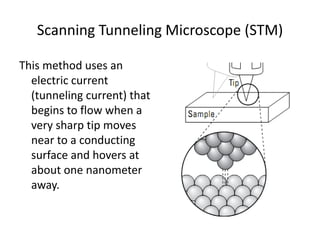

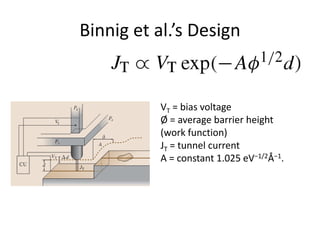

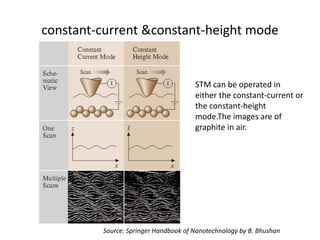

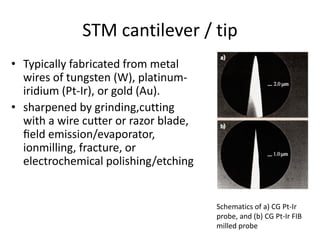

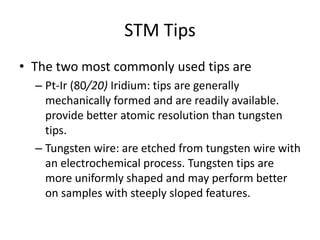

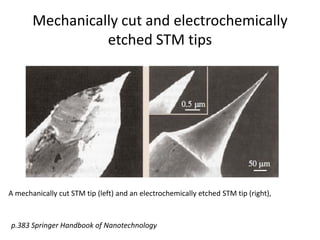

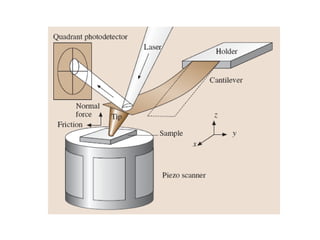

This document provides an overview of scanning tunneling microscopy (STM), scanning electron microscopy (SEM), and transmission electron microscopy (TEM). It describes the basic principles and operation of STM, including how it uses a sharp tip to detect tunneling current at the surface of a sample. It also discusses sample and tip preparation, as well as constant current and height modes. SEM and TEM are briefly introduced, with SEM using secondary electrons to image surface topography and composition, while TEM projects electrons through a sample to image atomic structure.