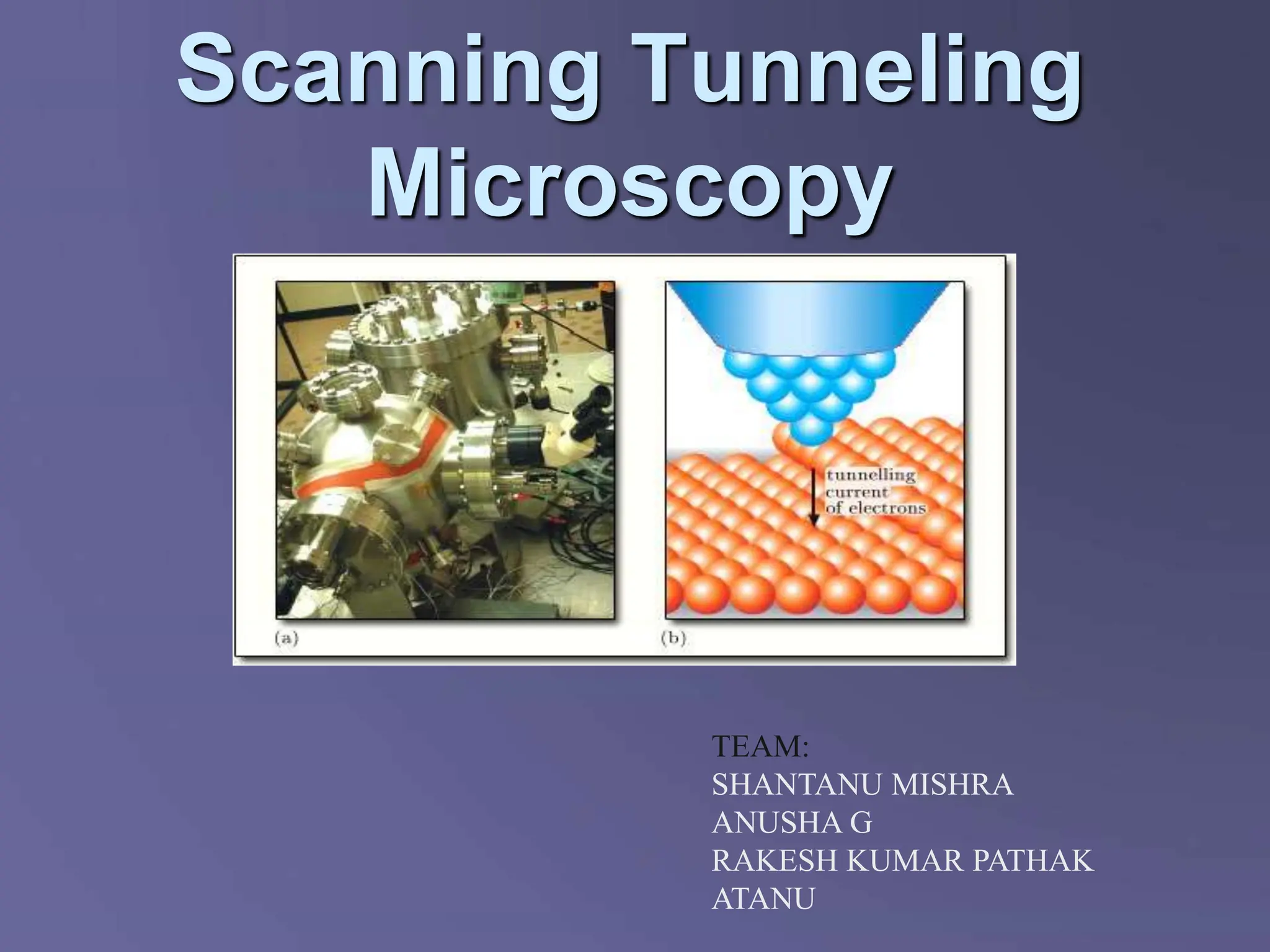

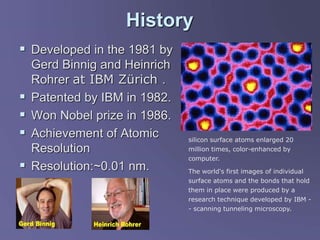

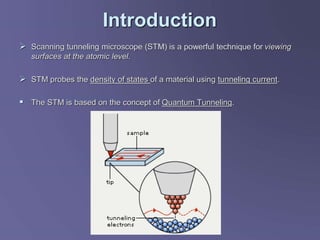

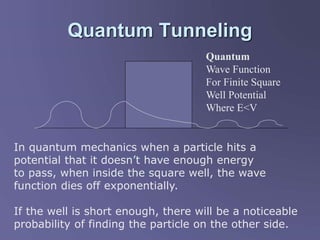

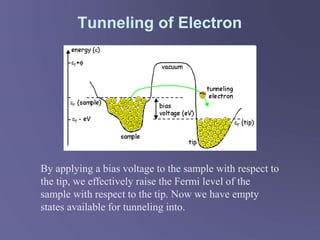

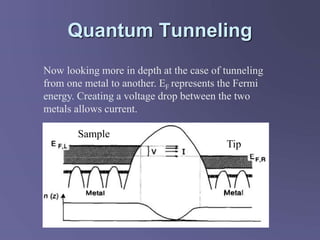

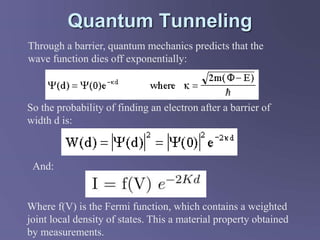

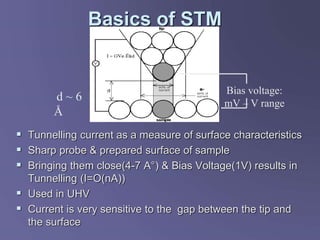

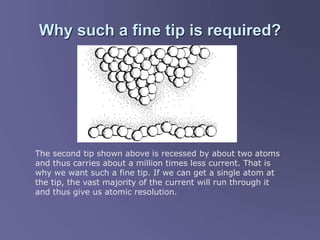

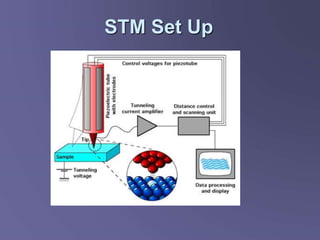

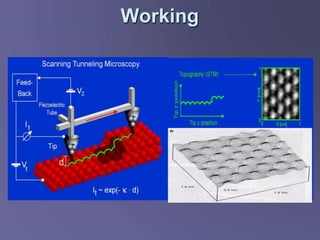

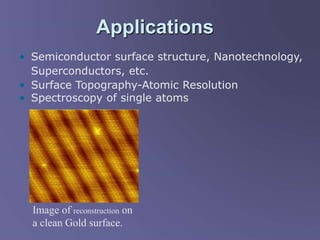

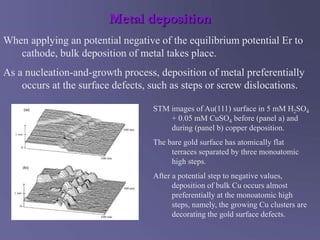

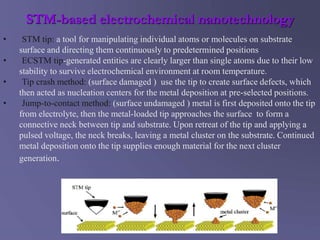

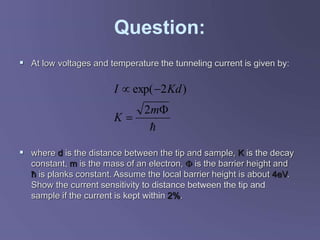

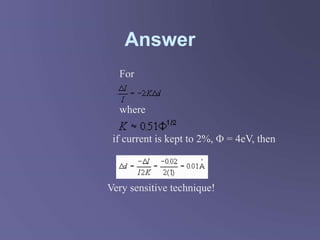

Scanning tunneling microscopy (STM) is a technique developed in the 1980s by IBM researchers that allows imaging surfaces at the atomic level through quantum tunneling of electrons. The STM operates by scanning a fine conducting tip close to a sample surface, measuring tunneling current to create high-resolution images. Key applications include studies in semiconductor surfaces, nanotechnology, and electrochemical processes.