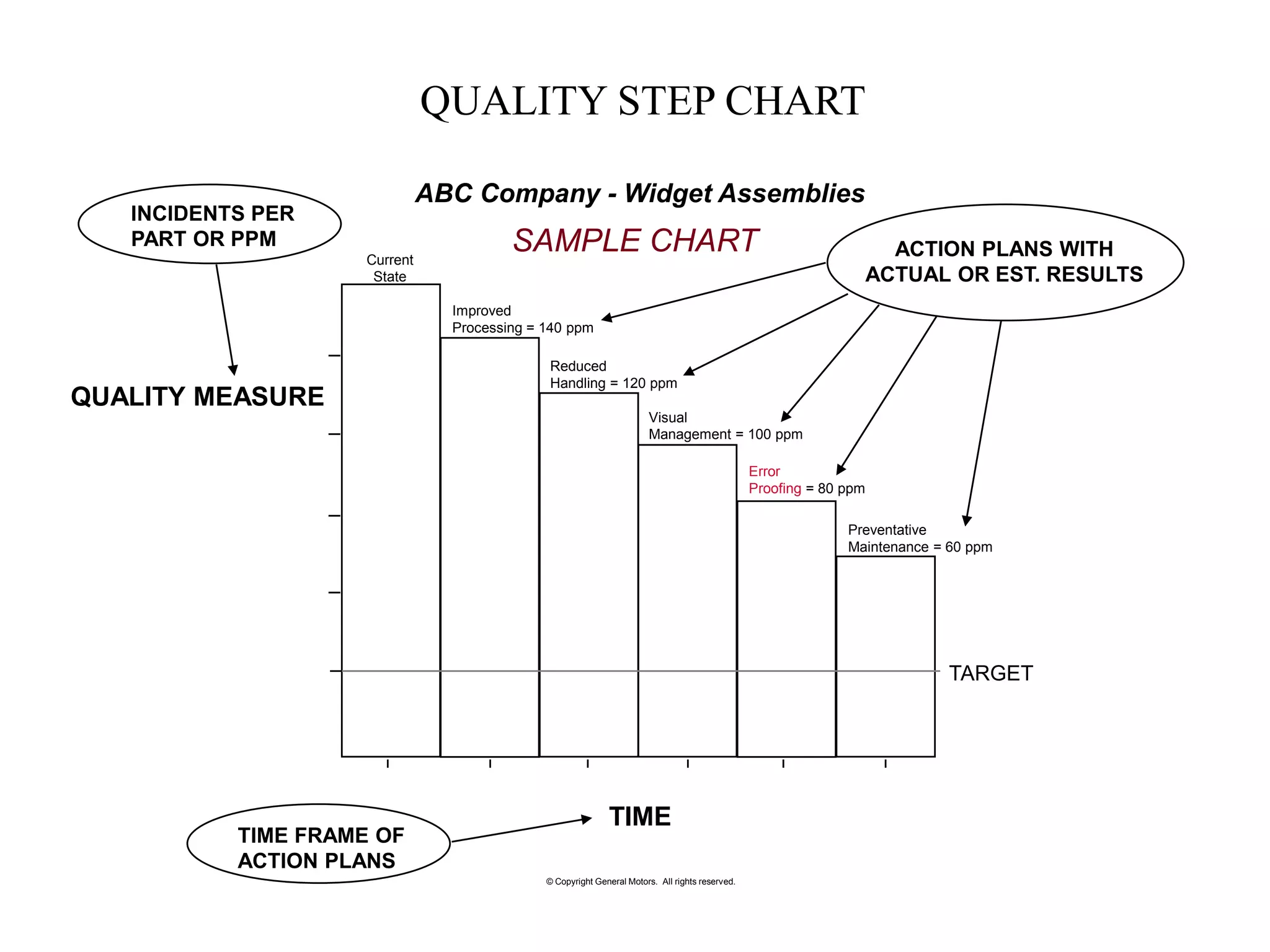

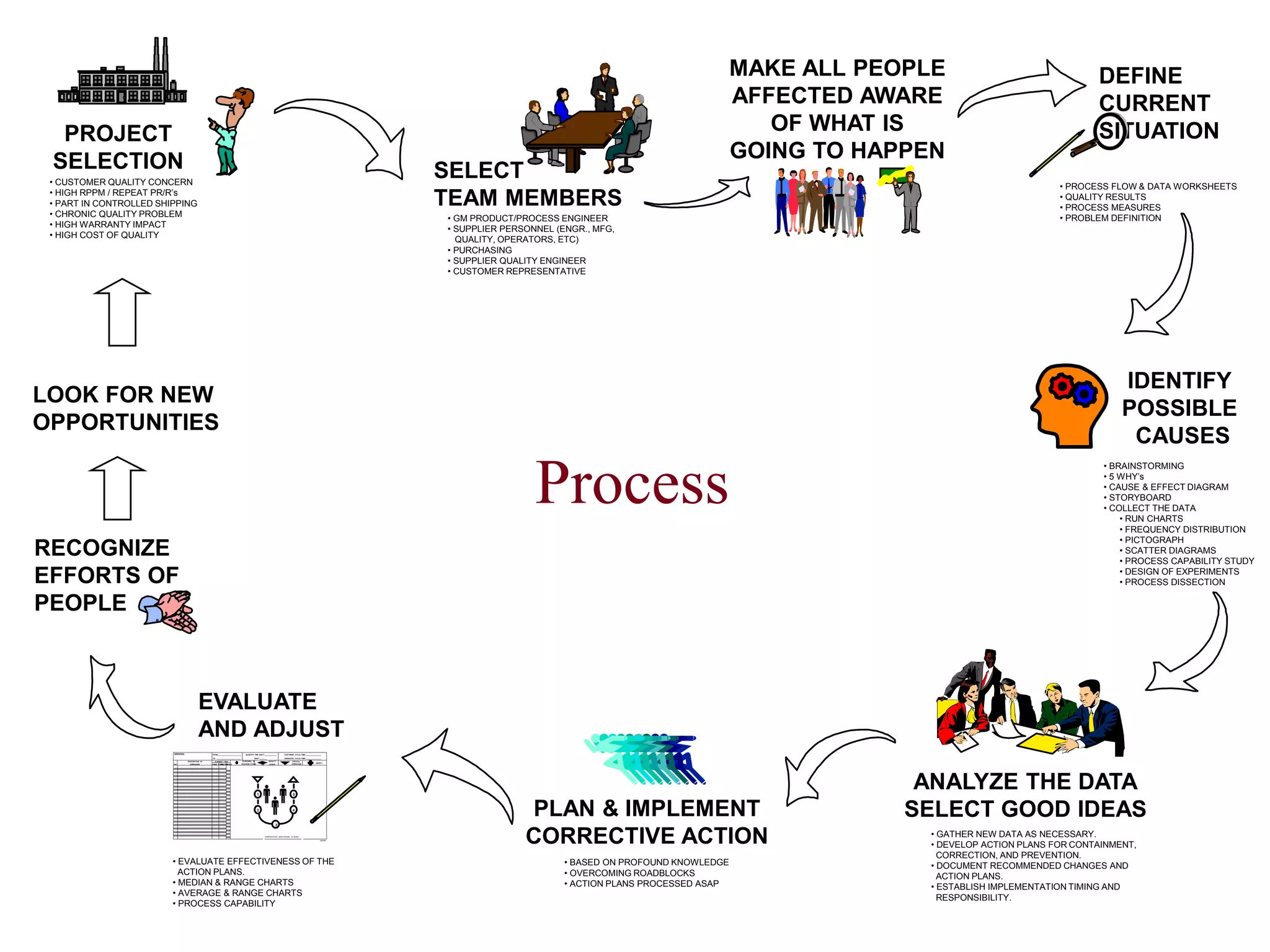

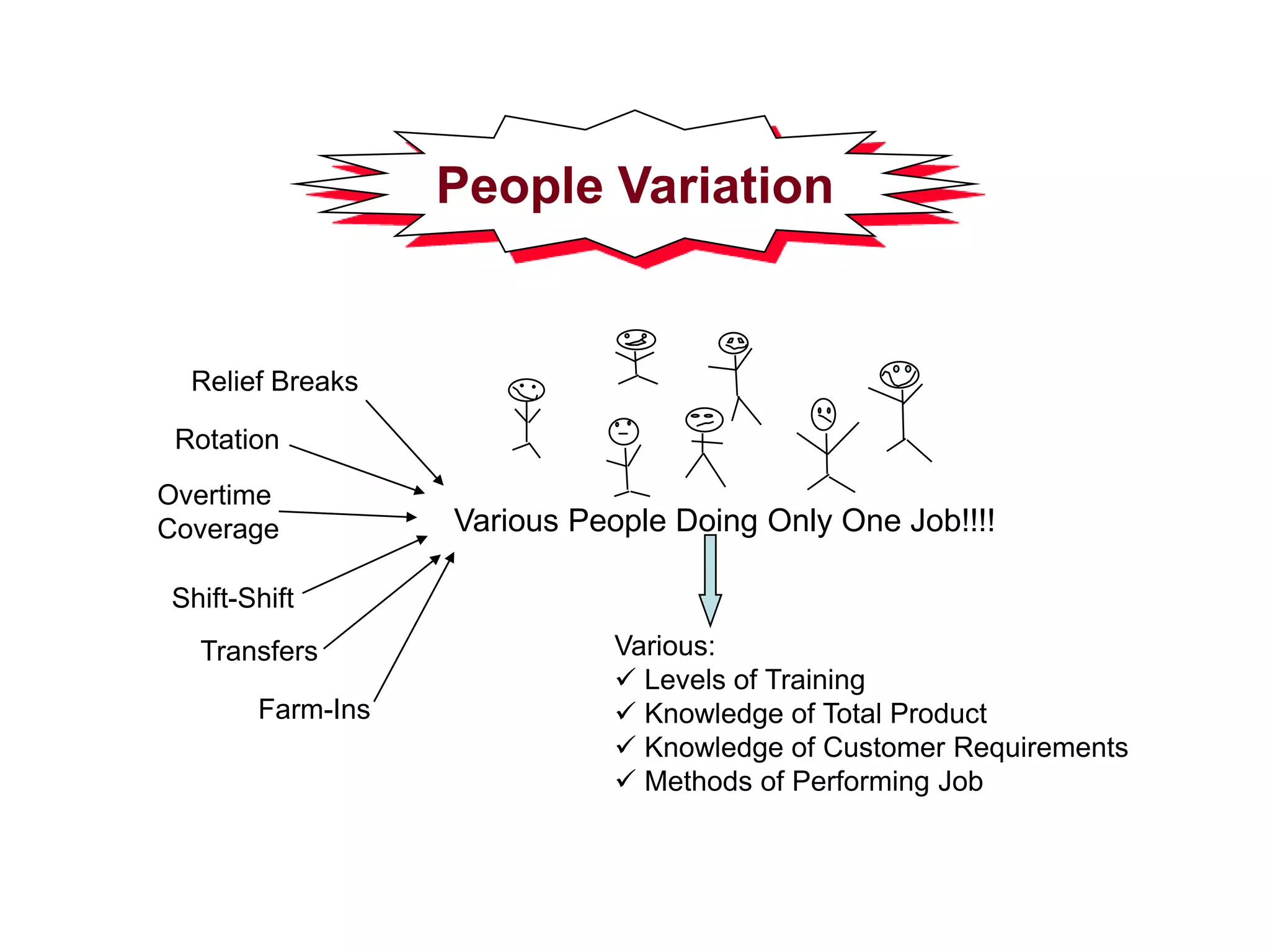

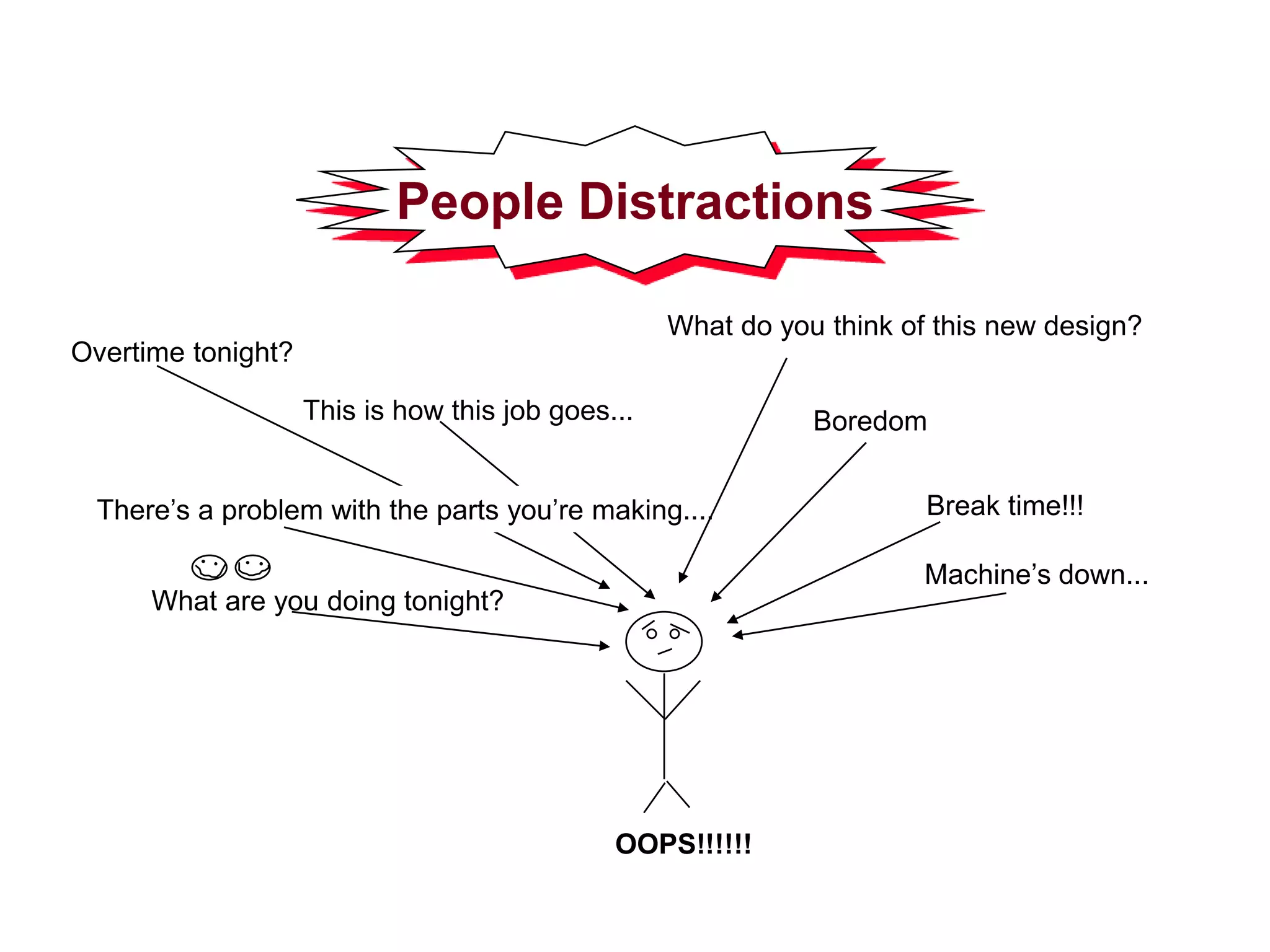

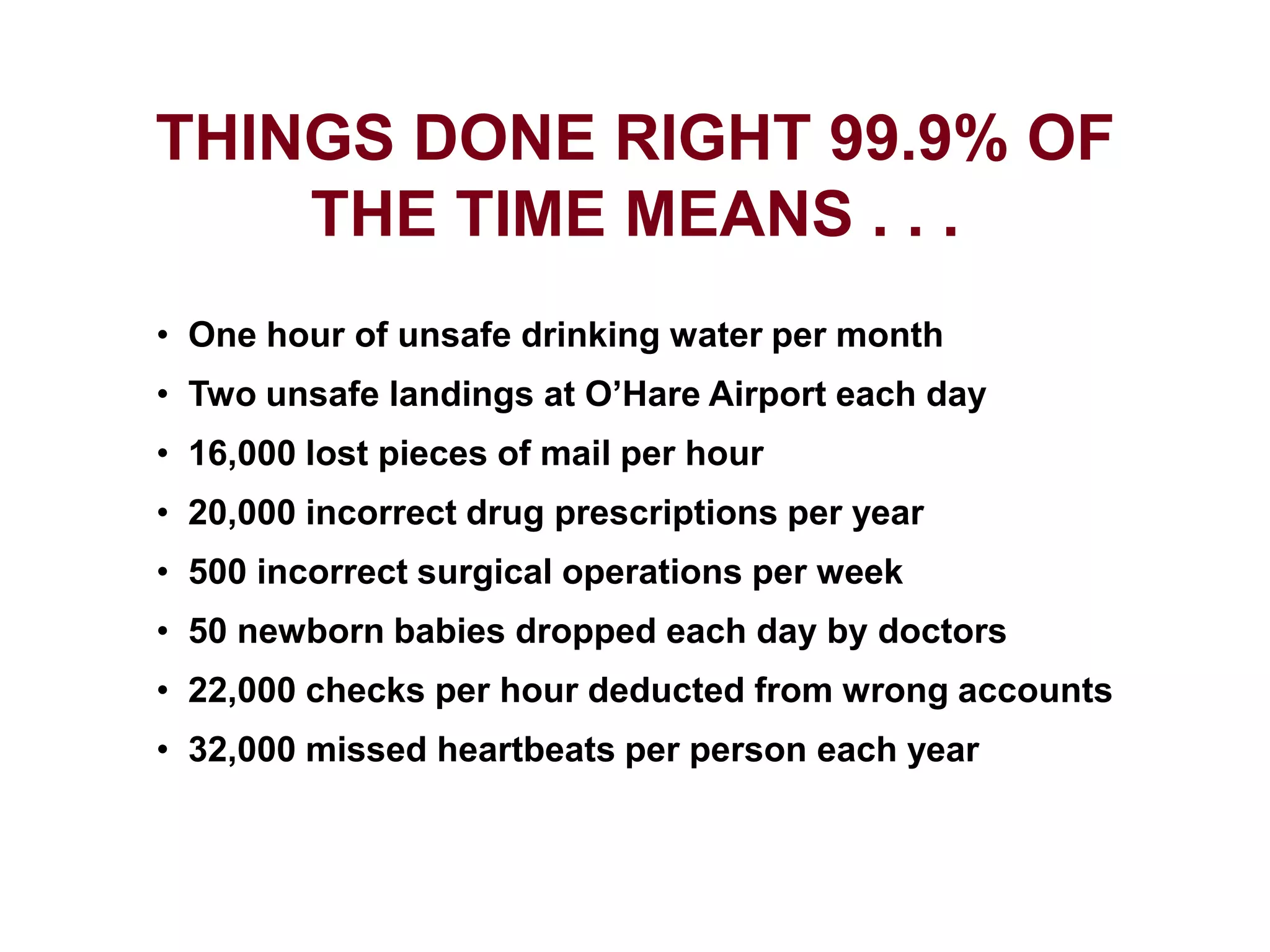

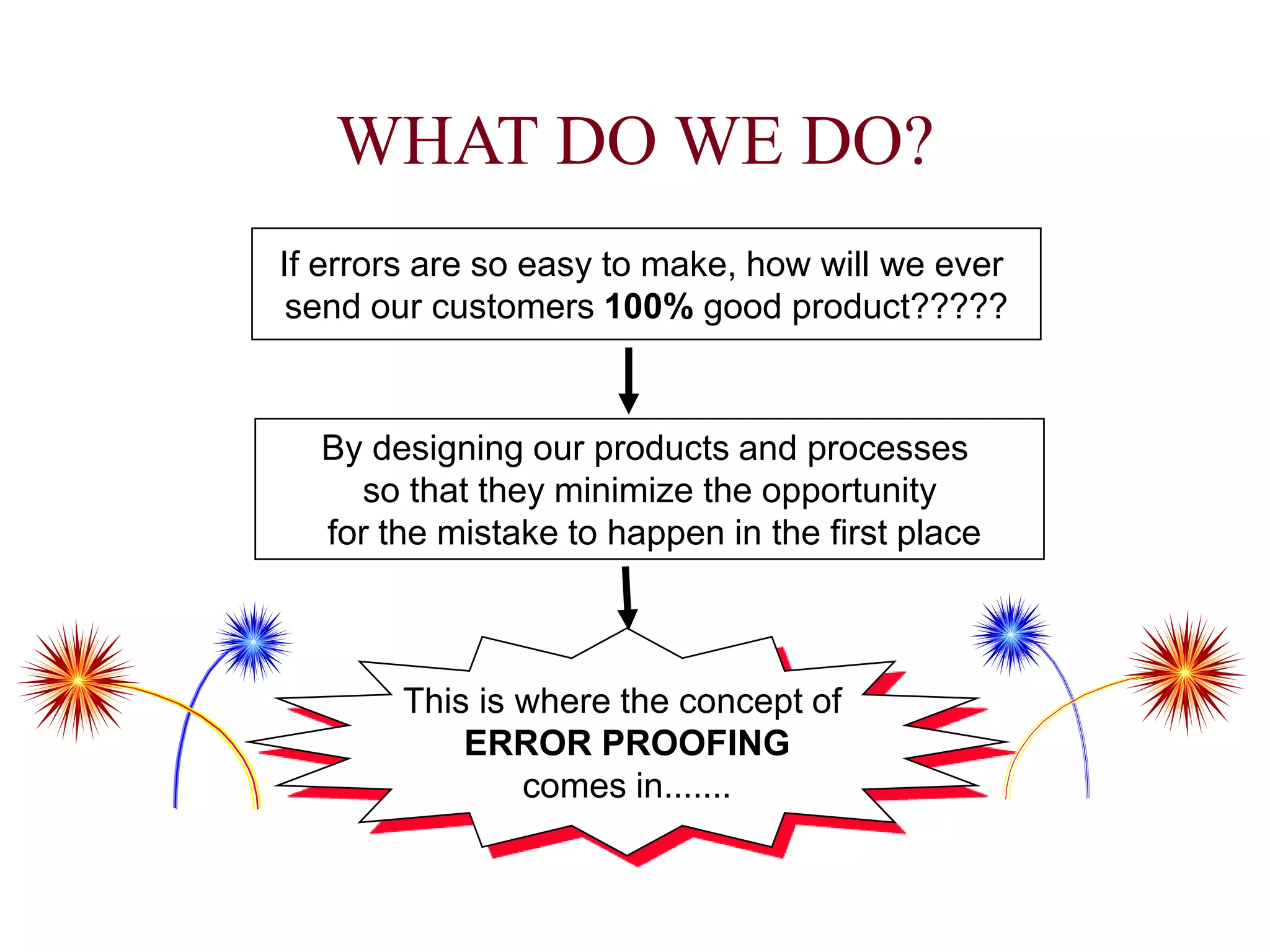

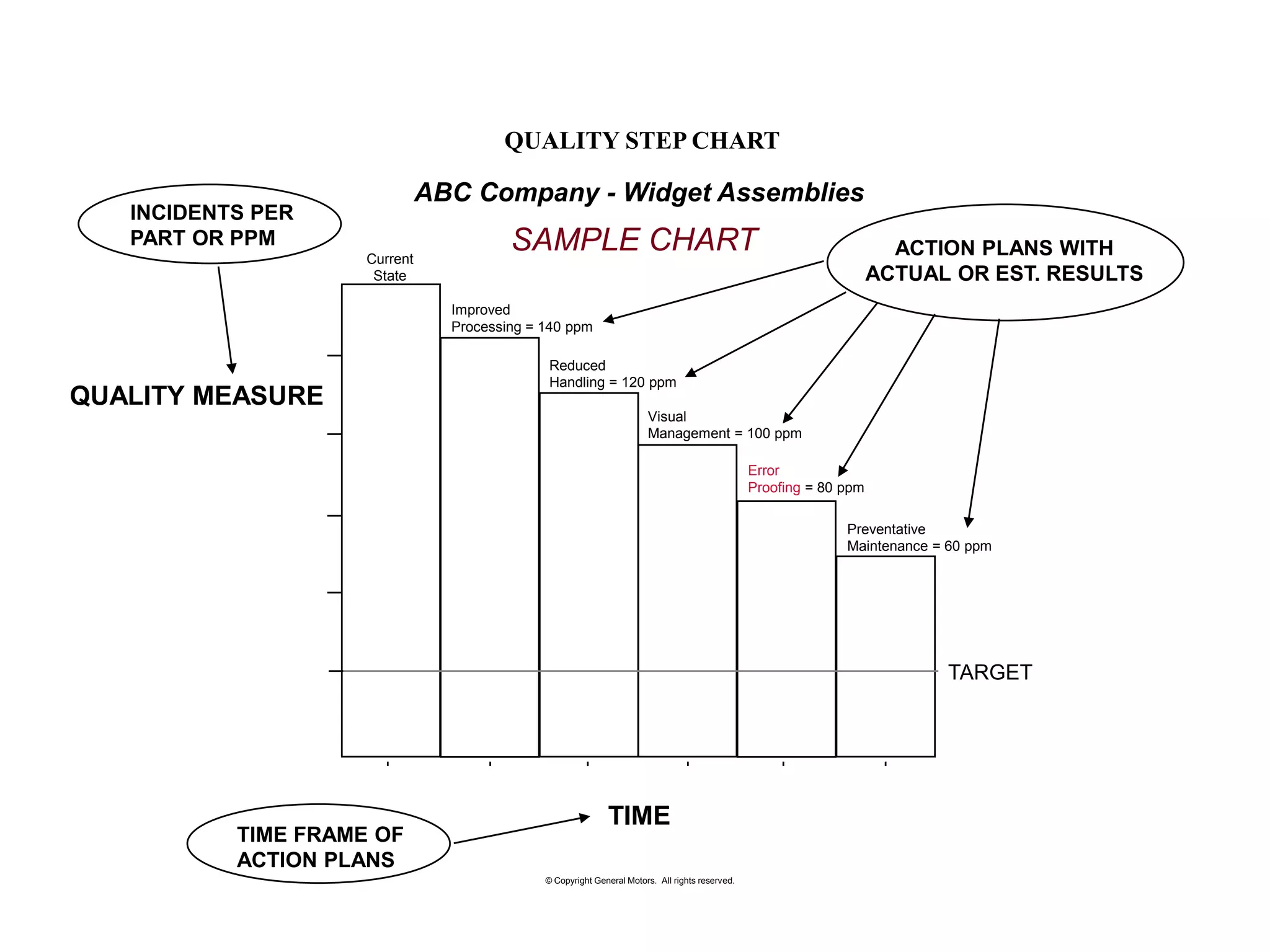

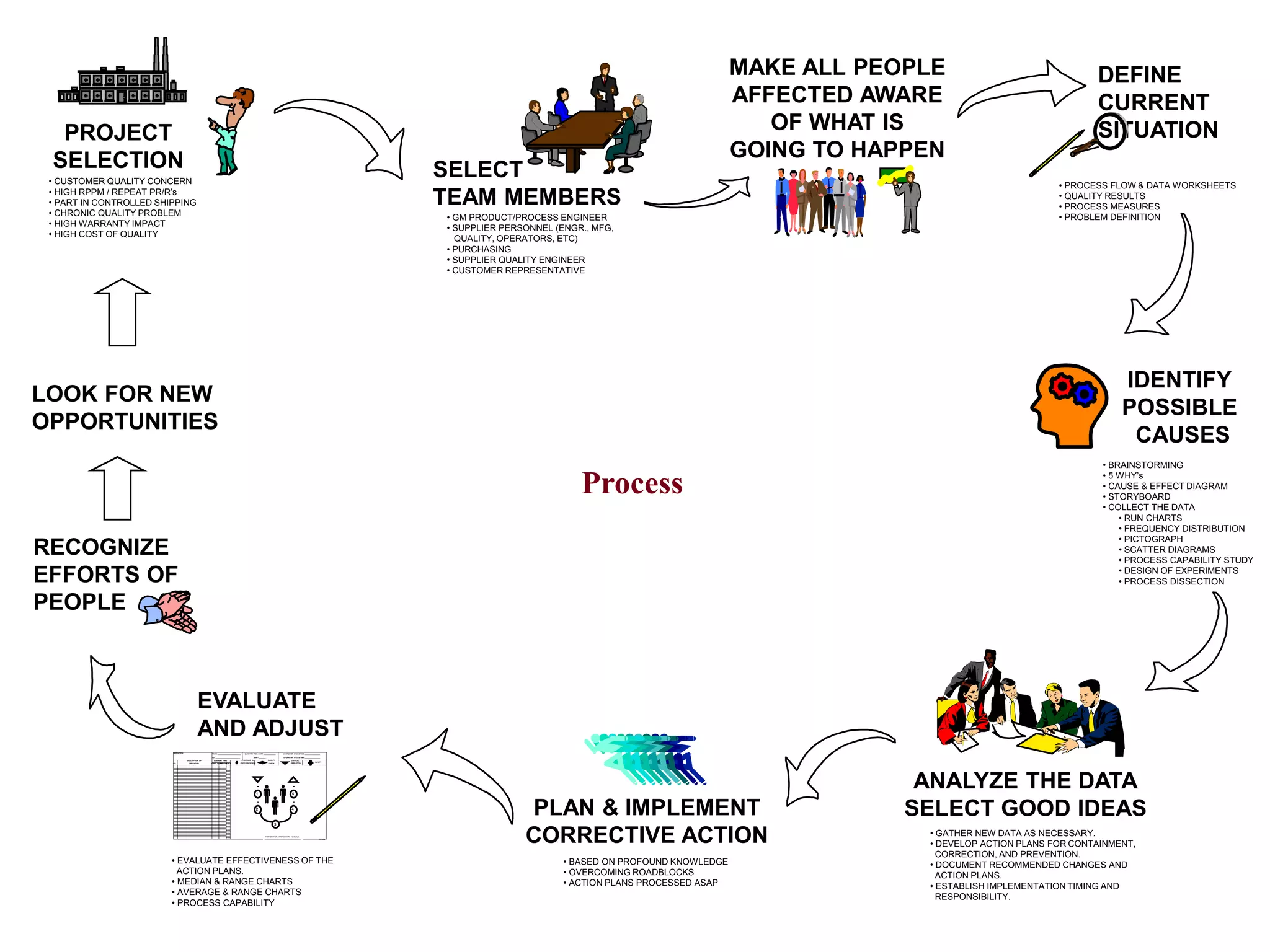

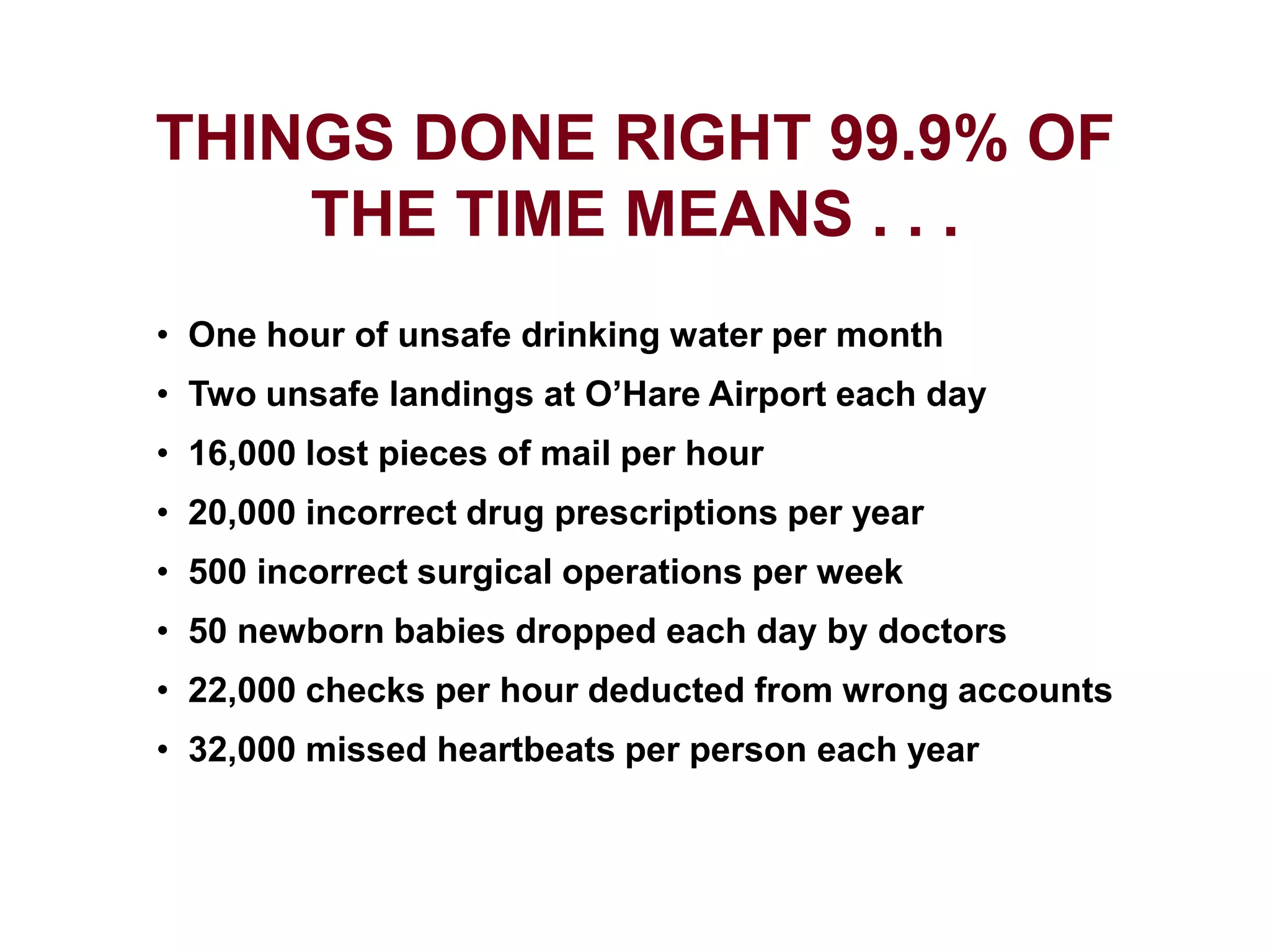

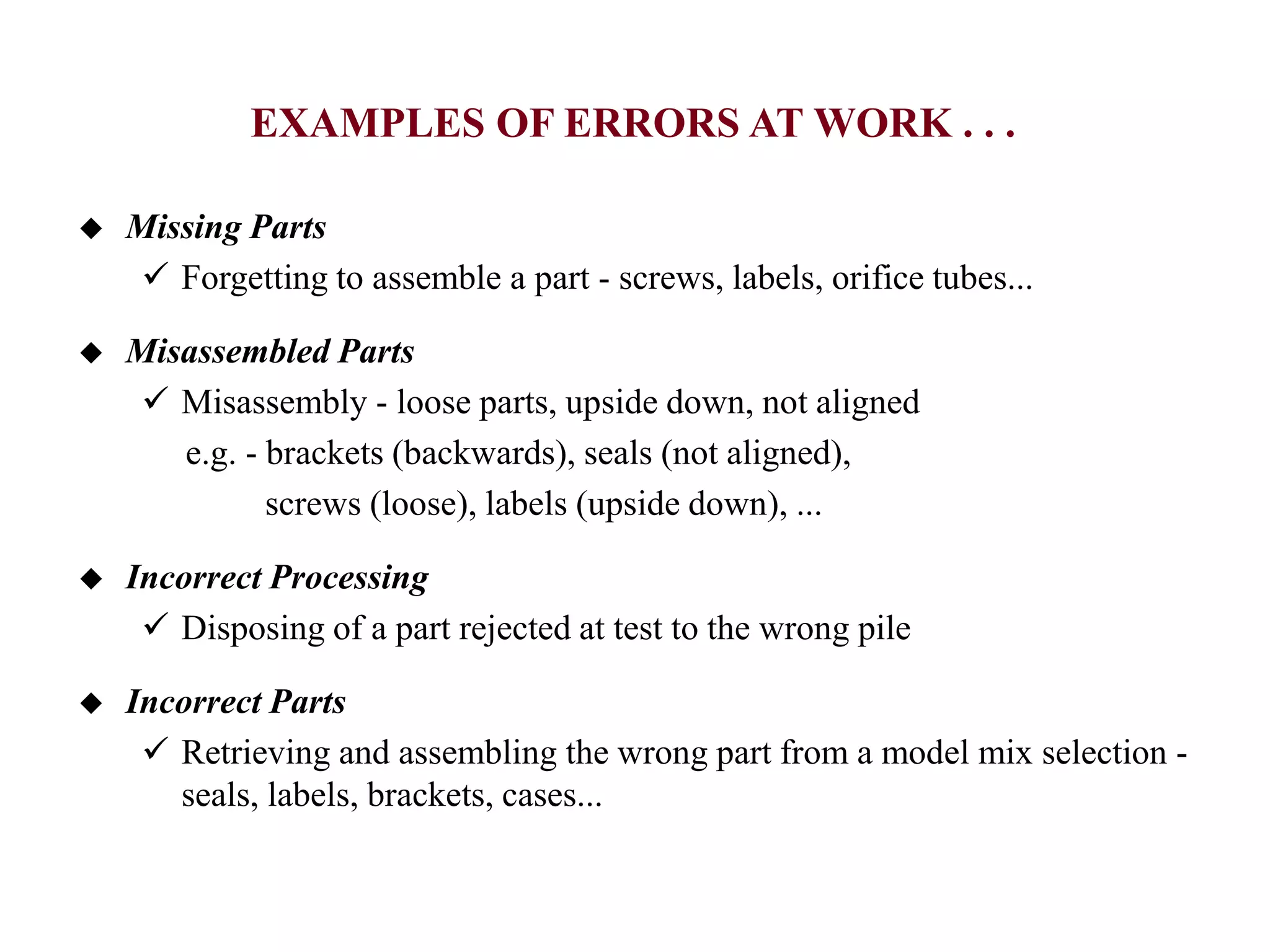

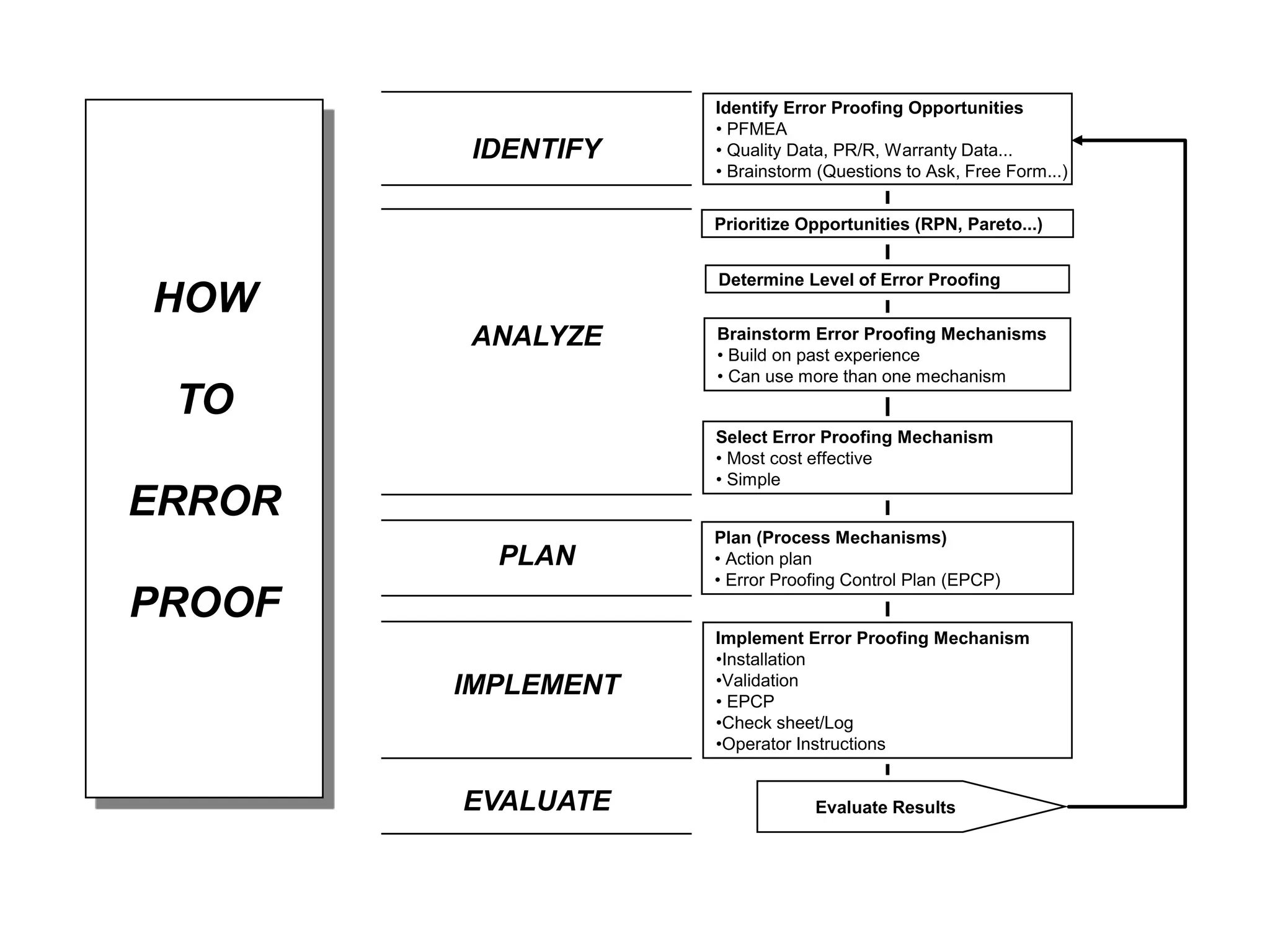

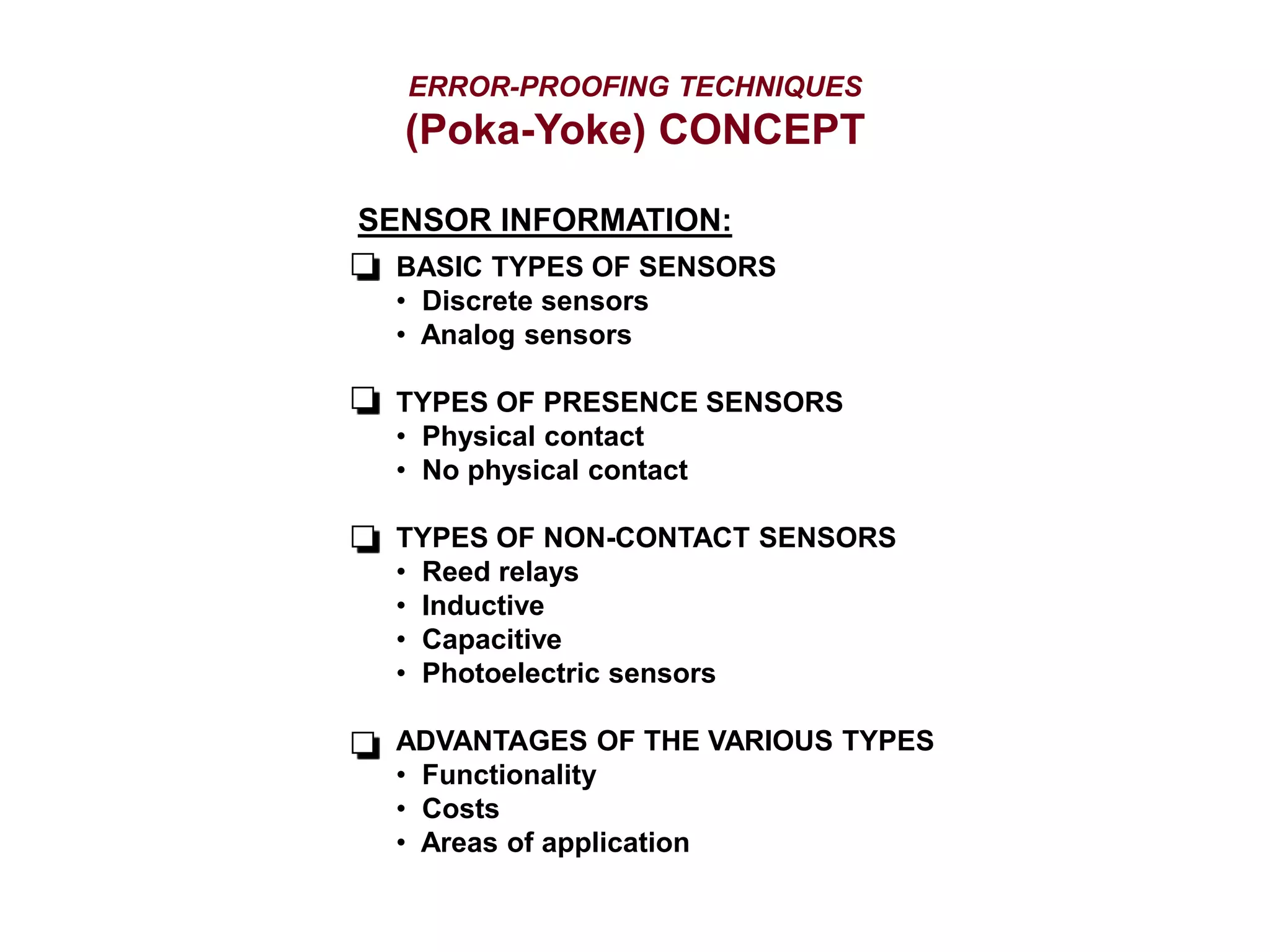

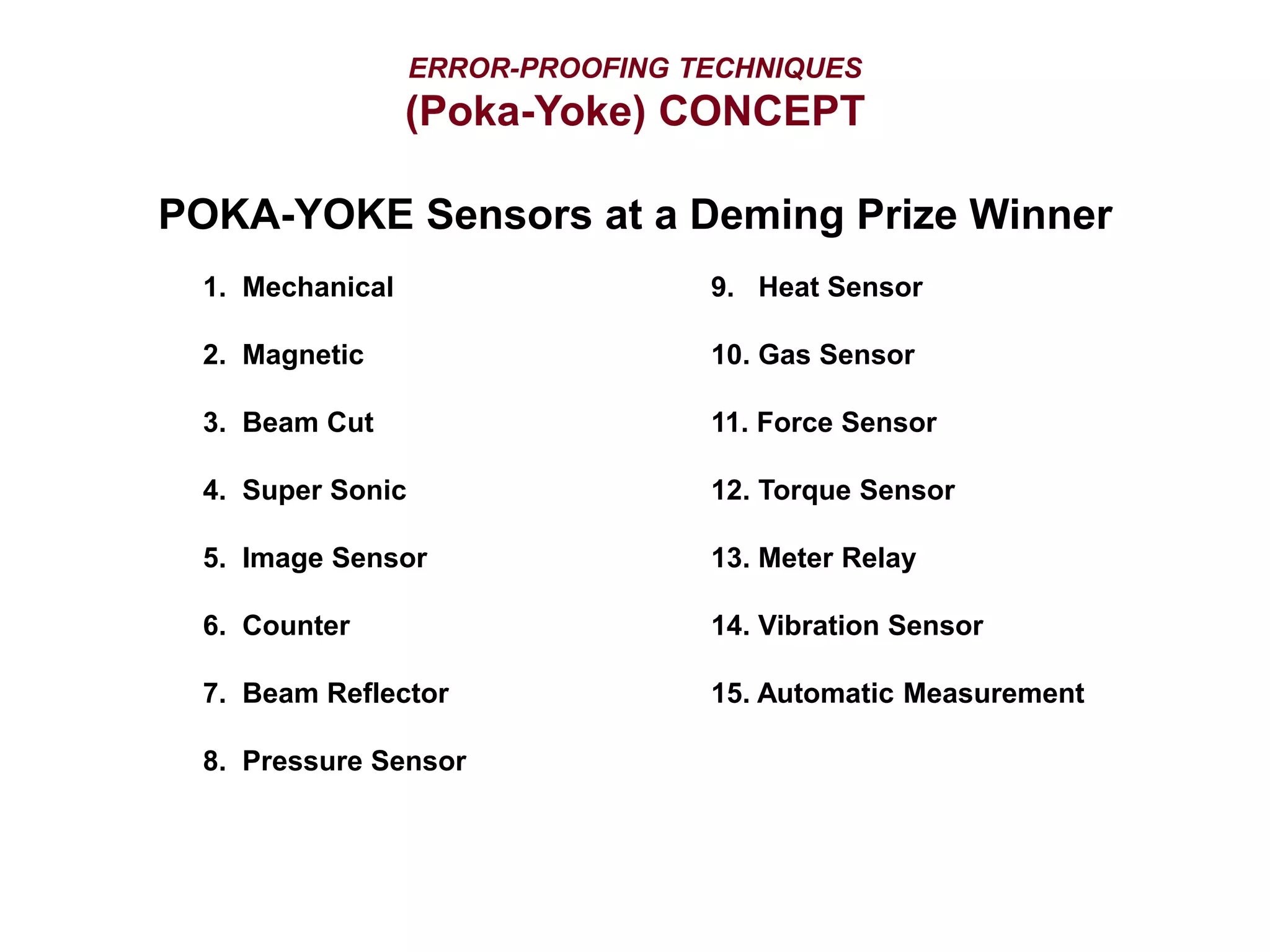

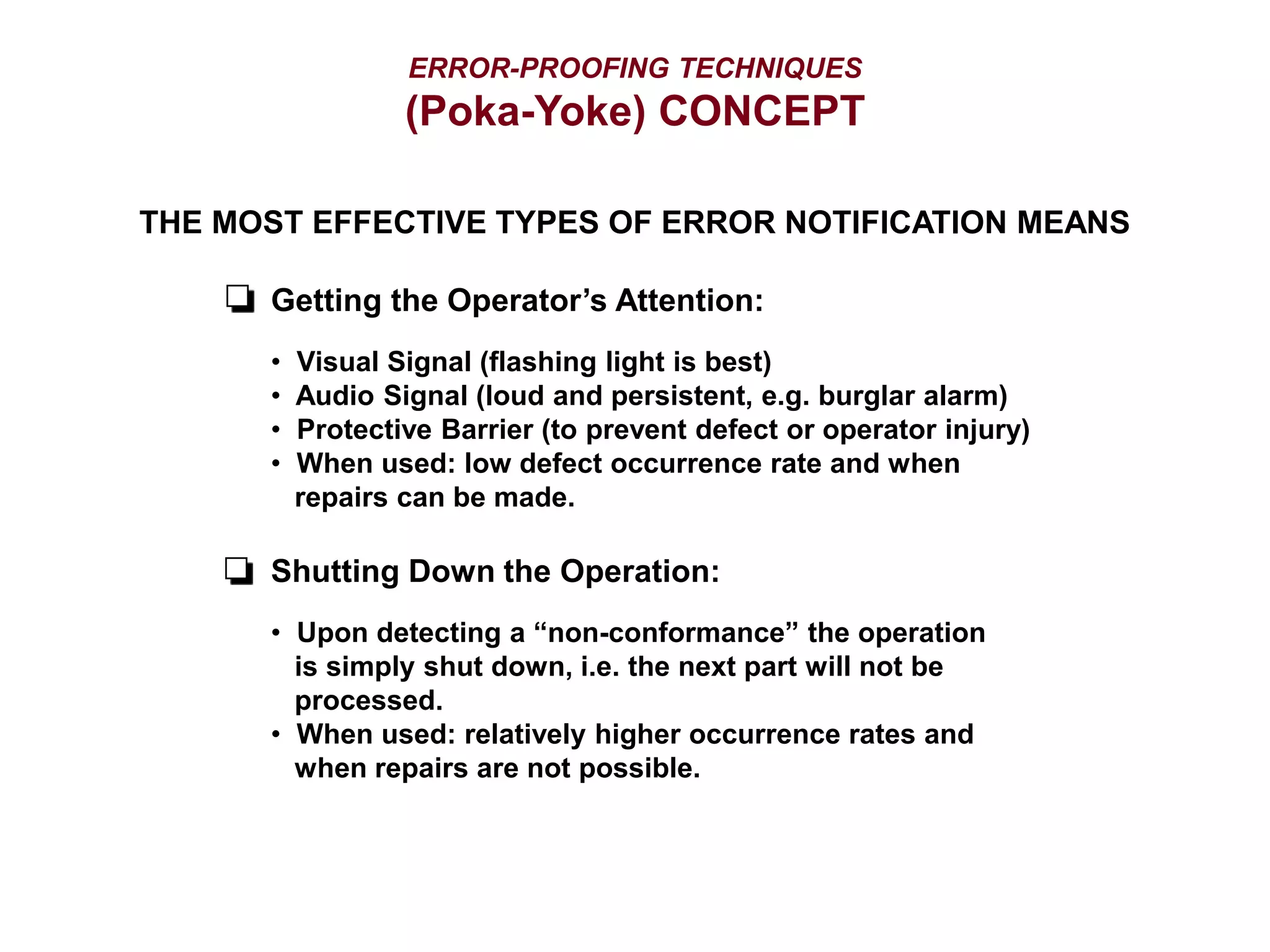

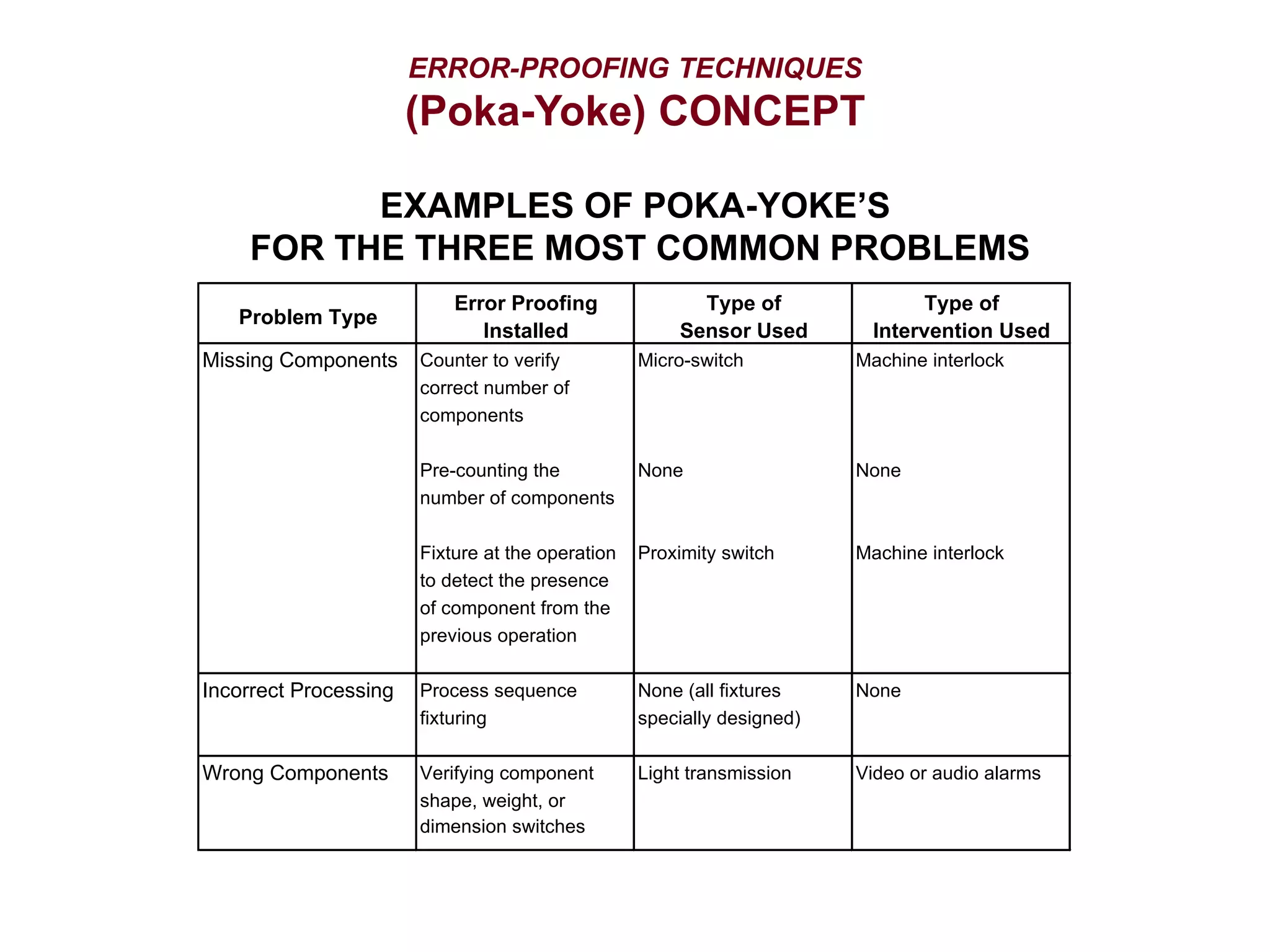

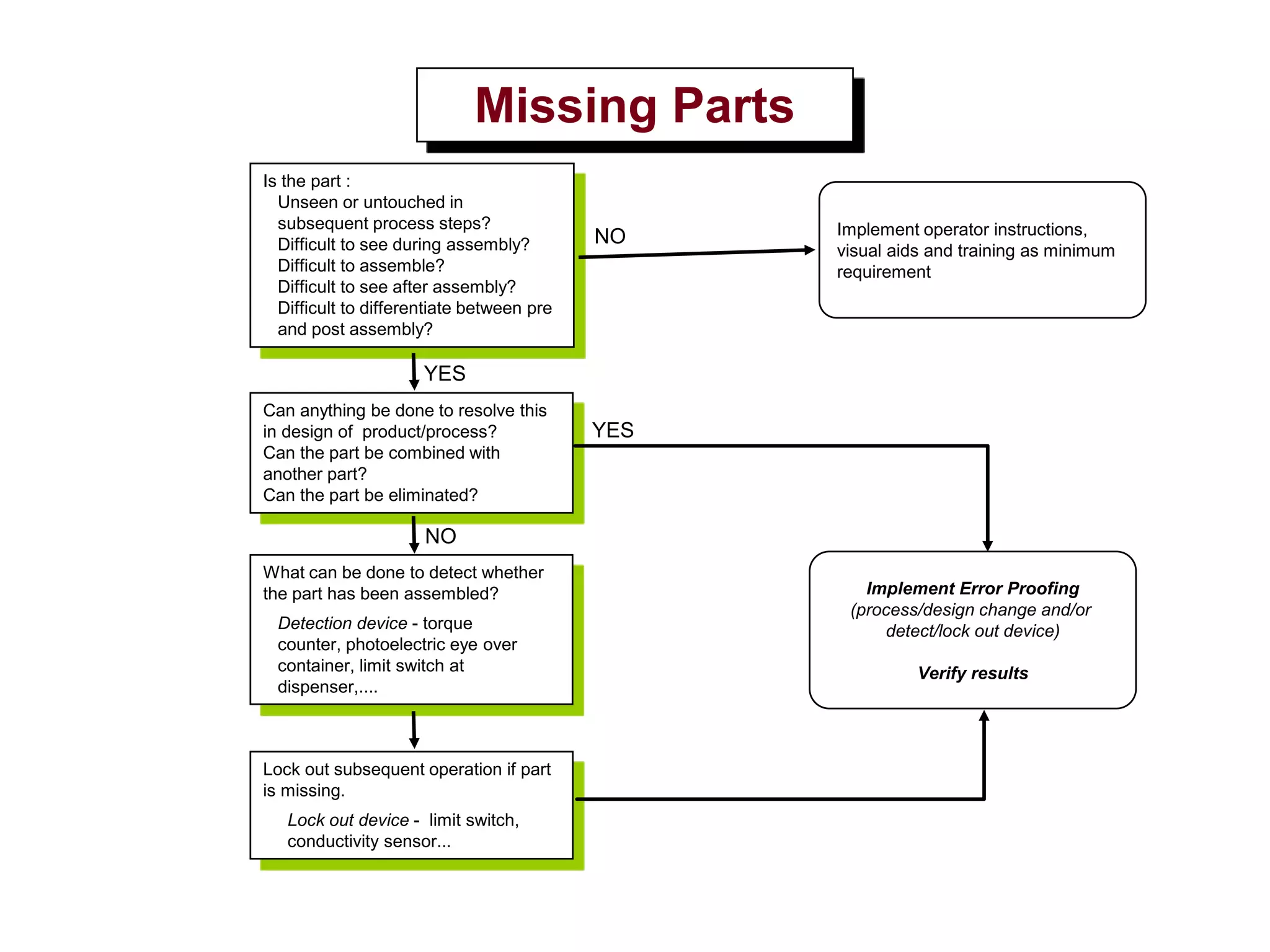

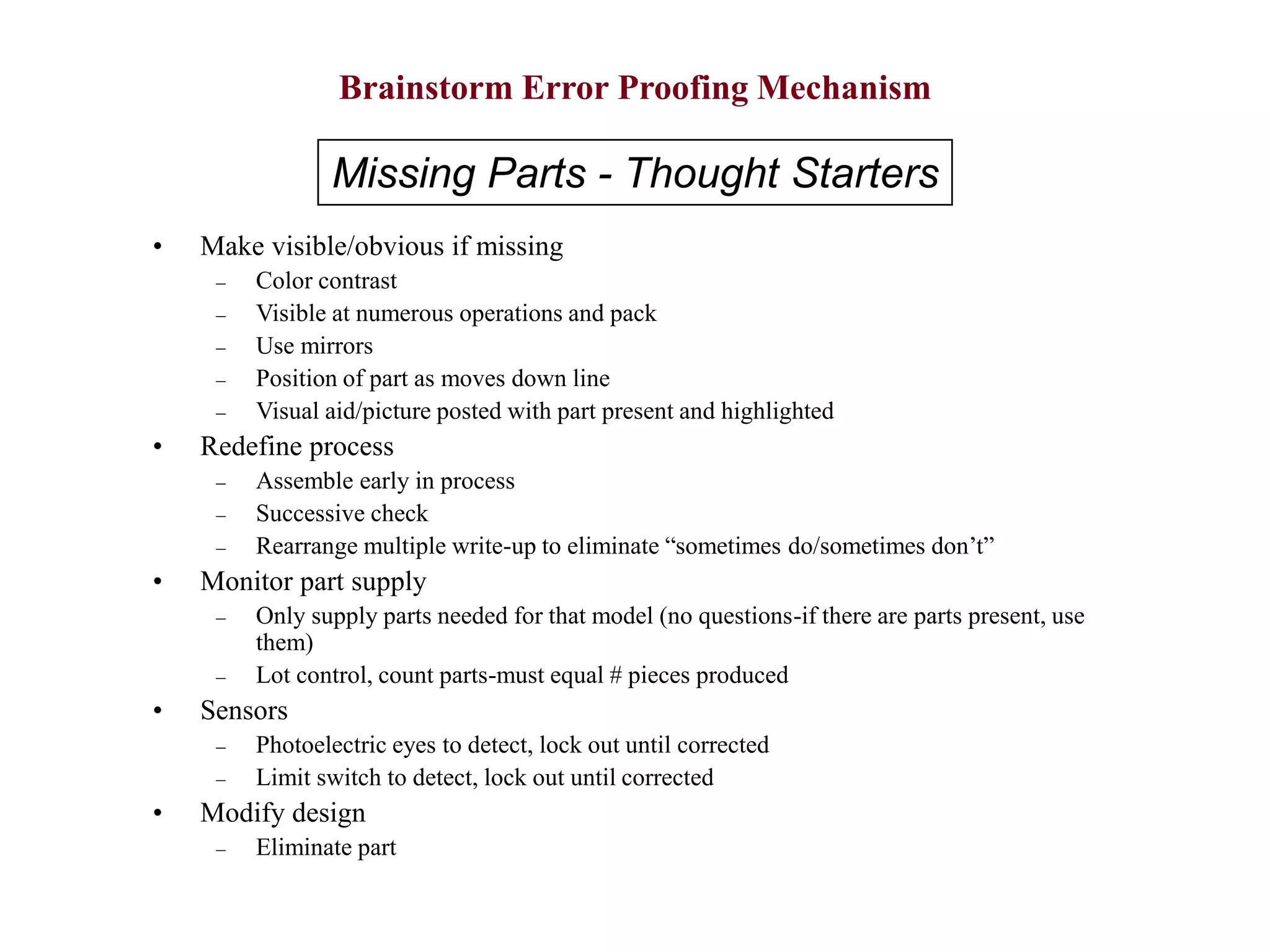

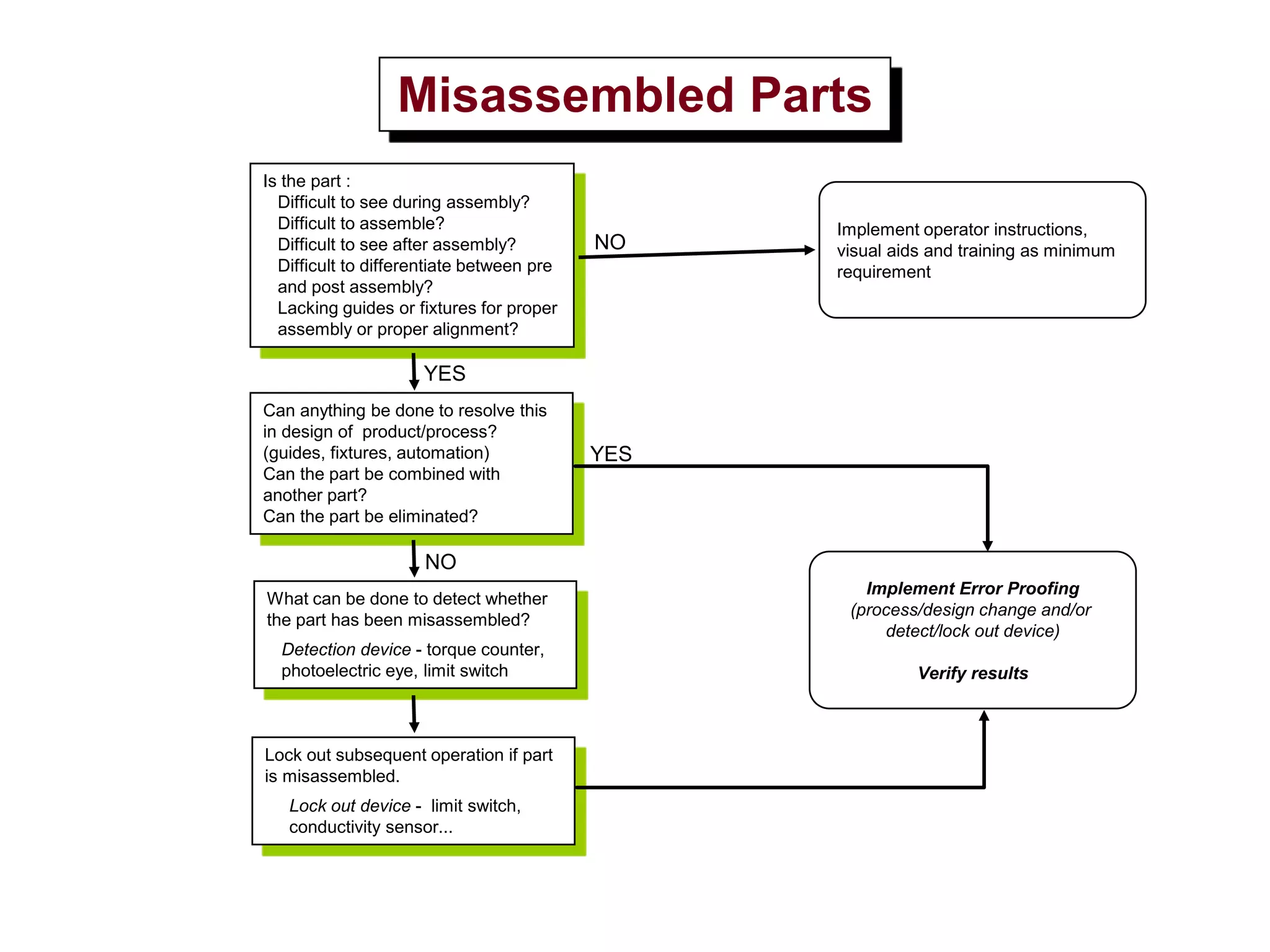

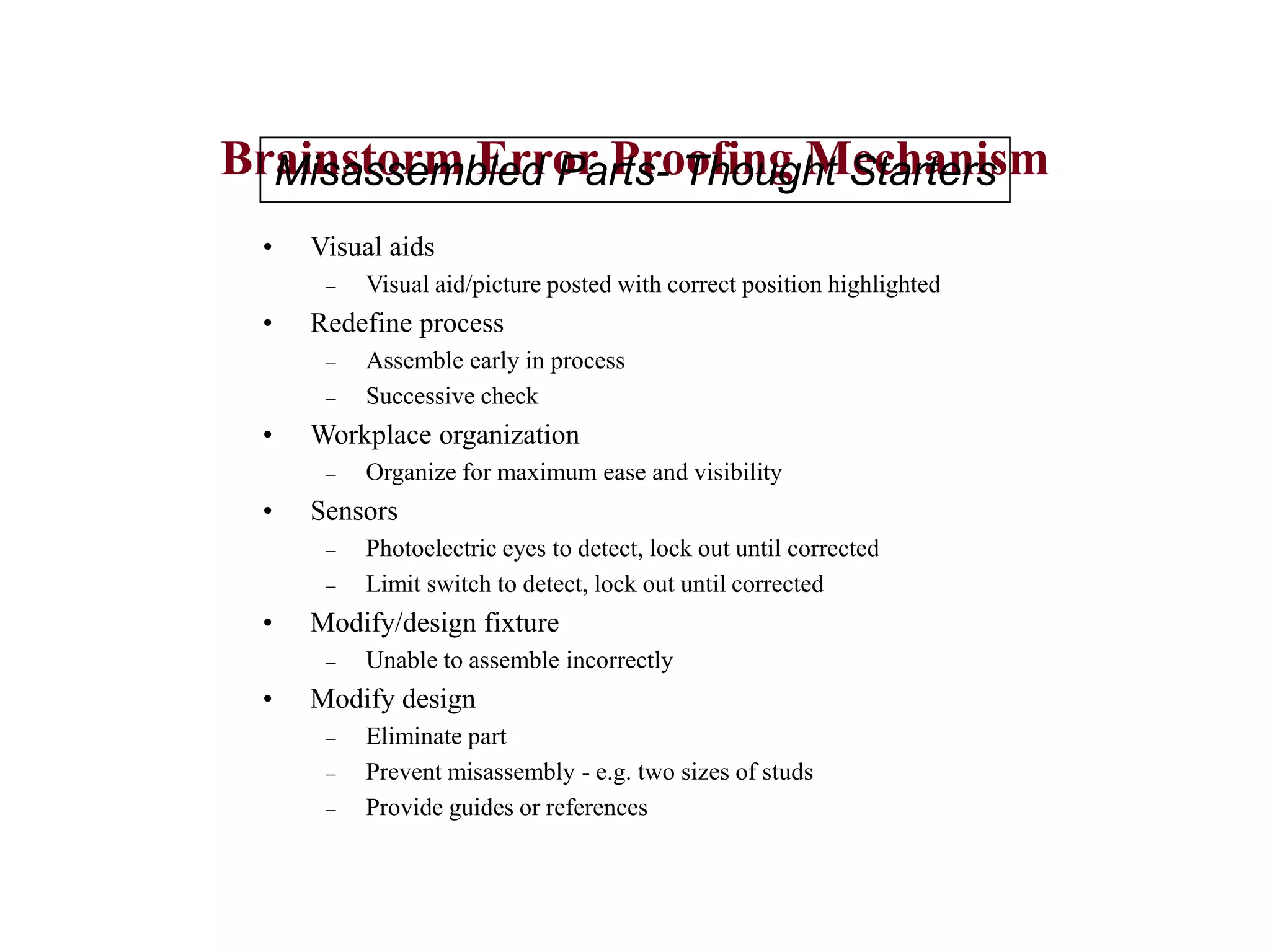

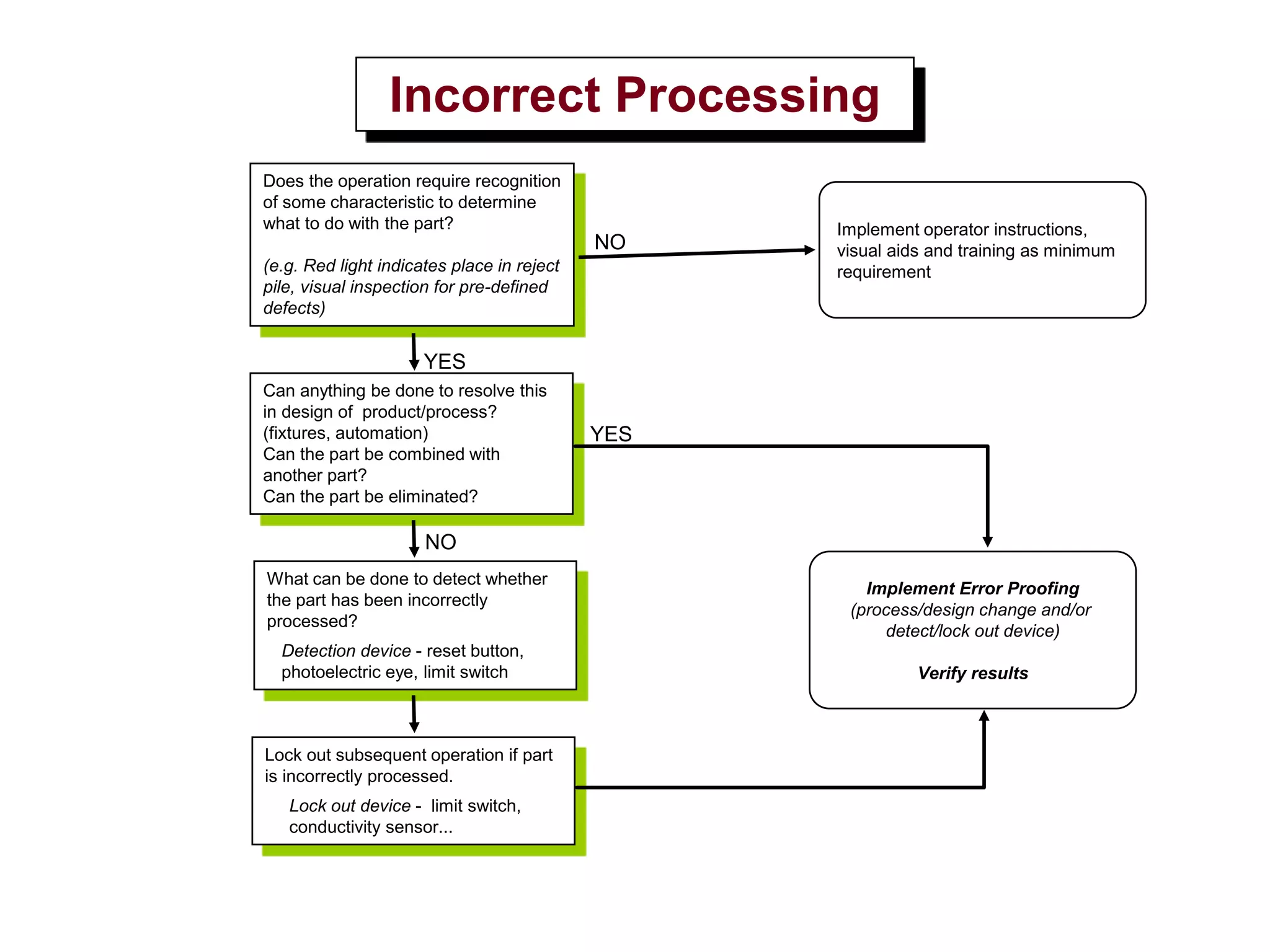

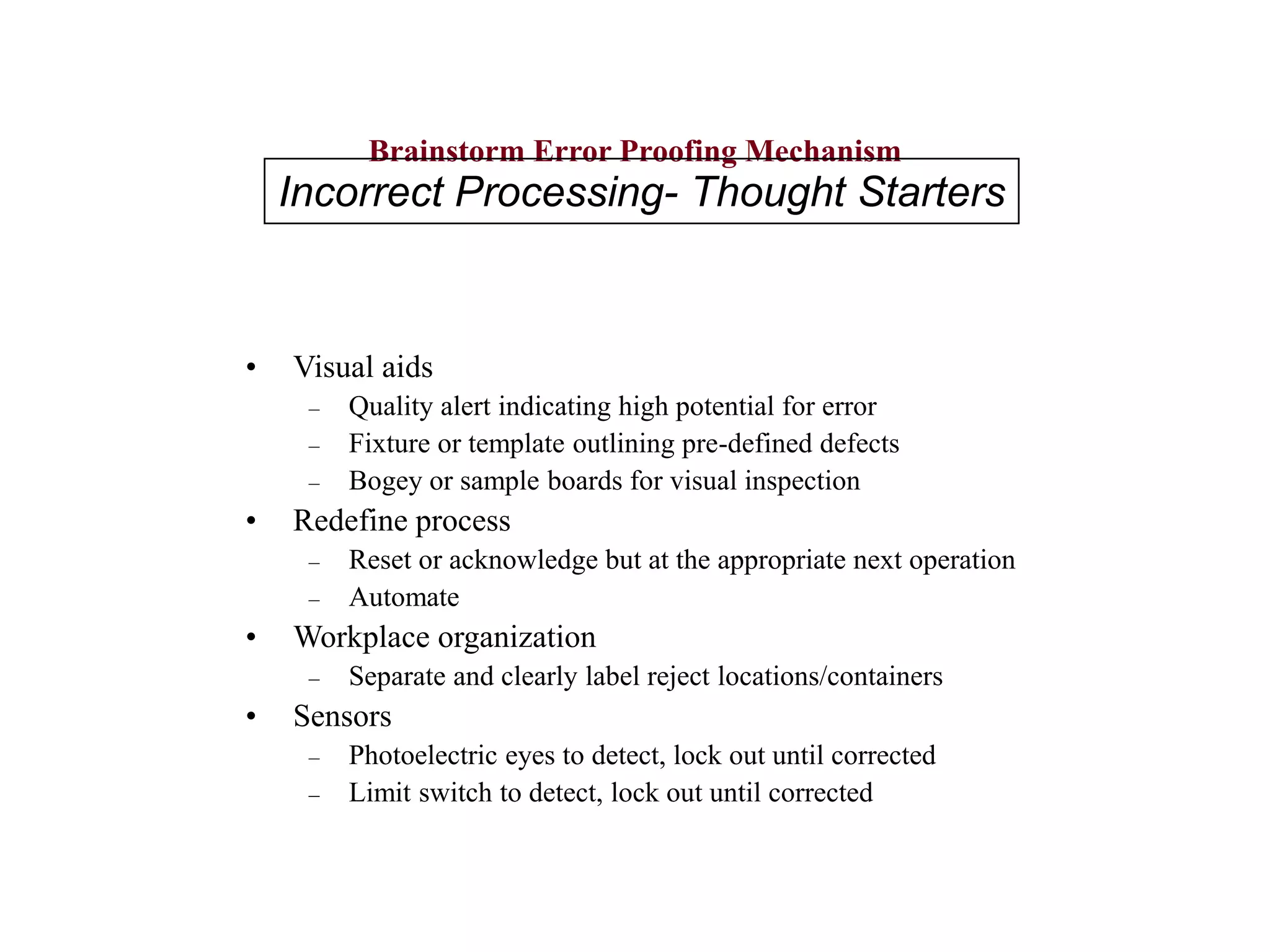

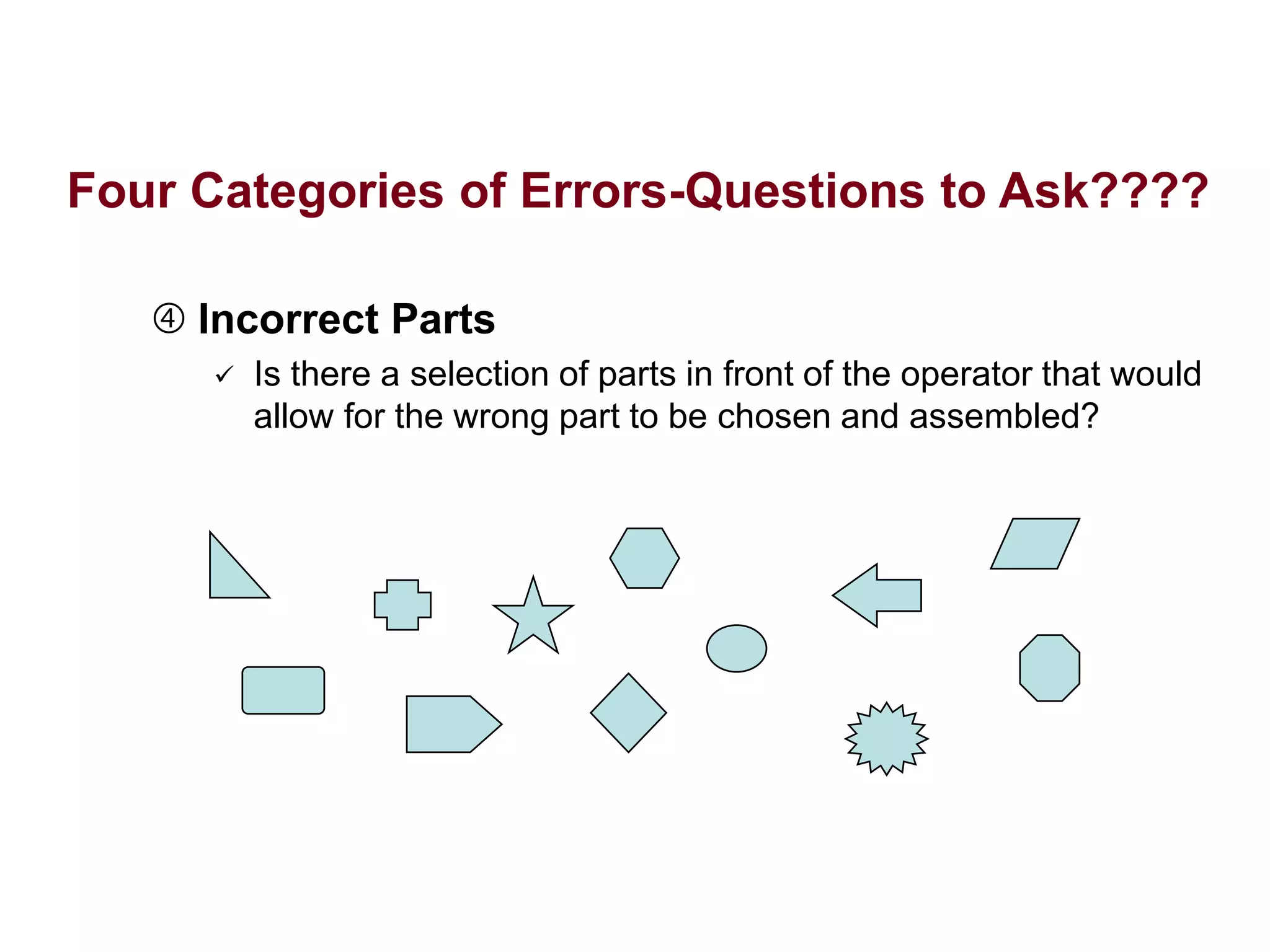

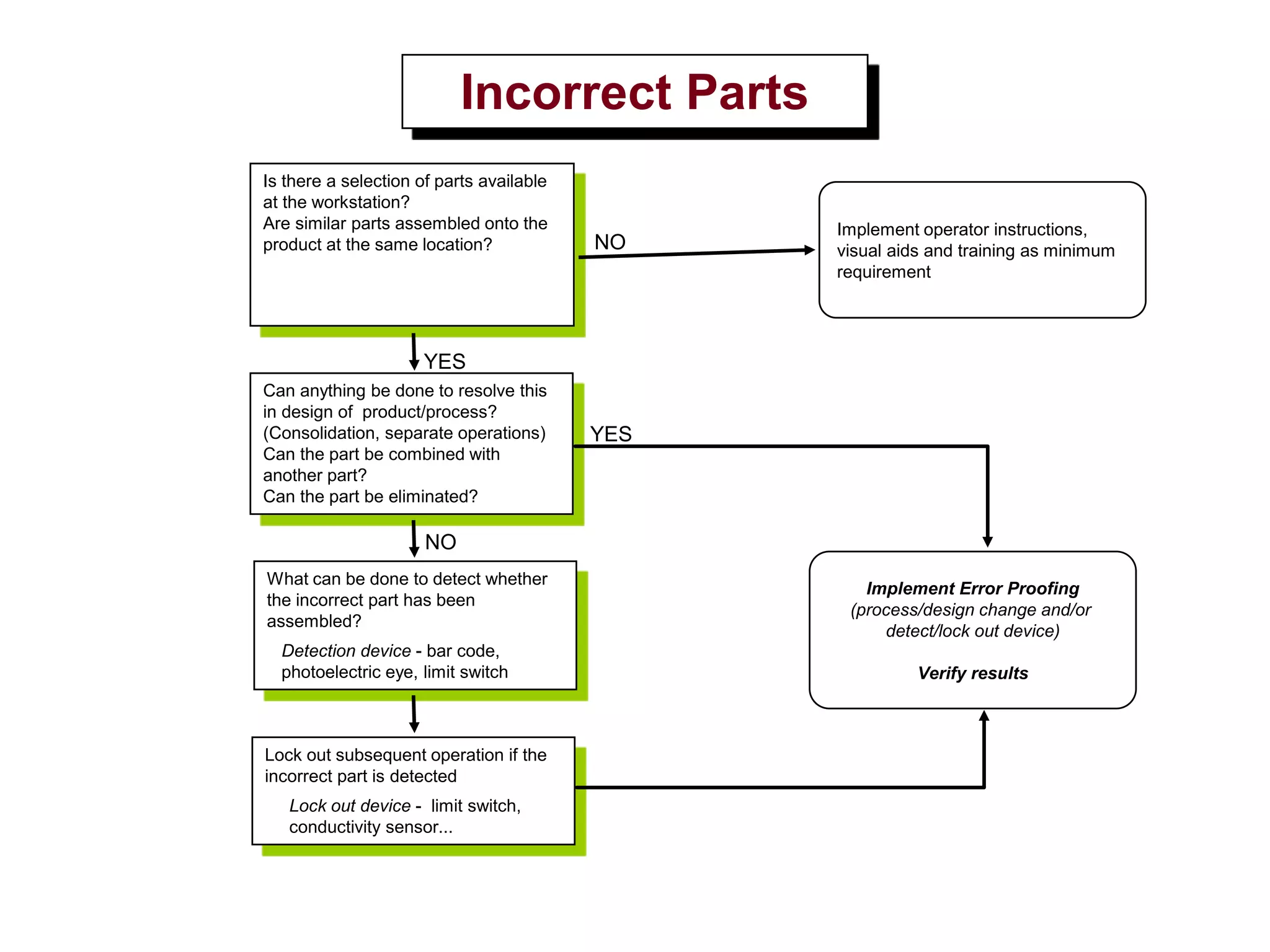

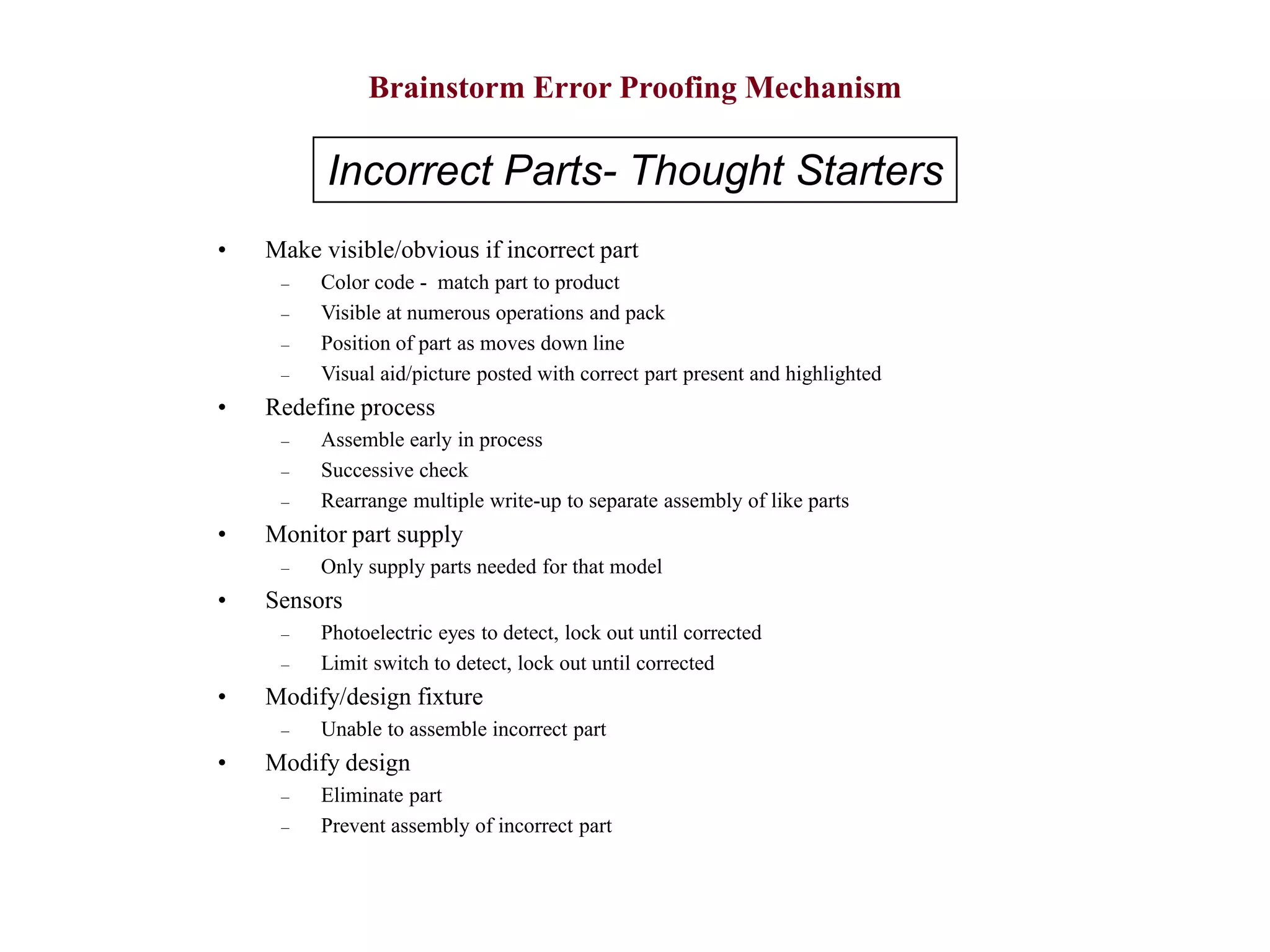

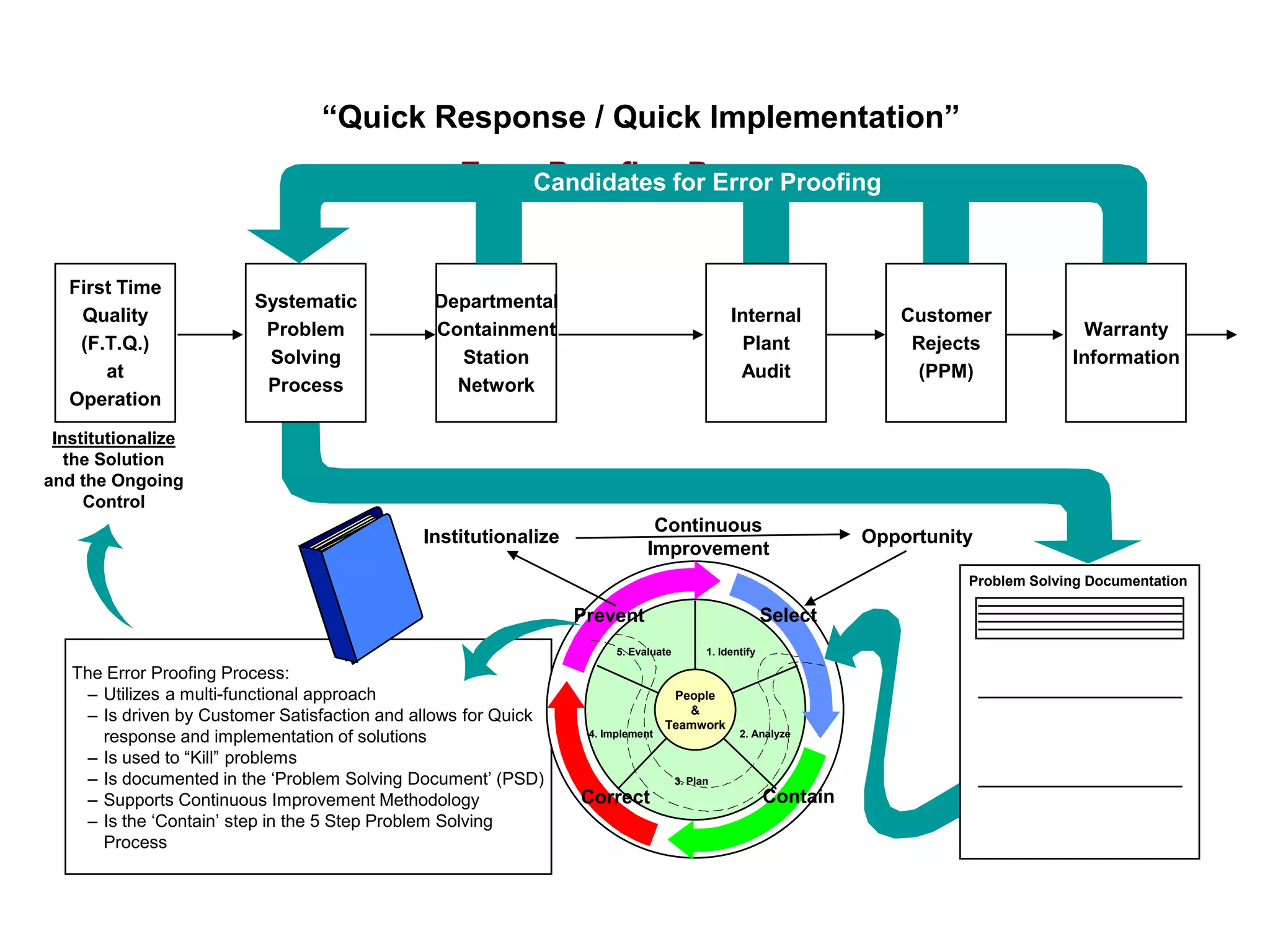

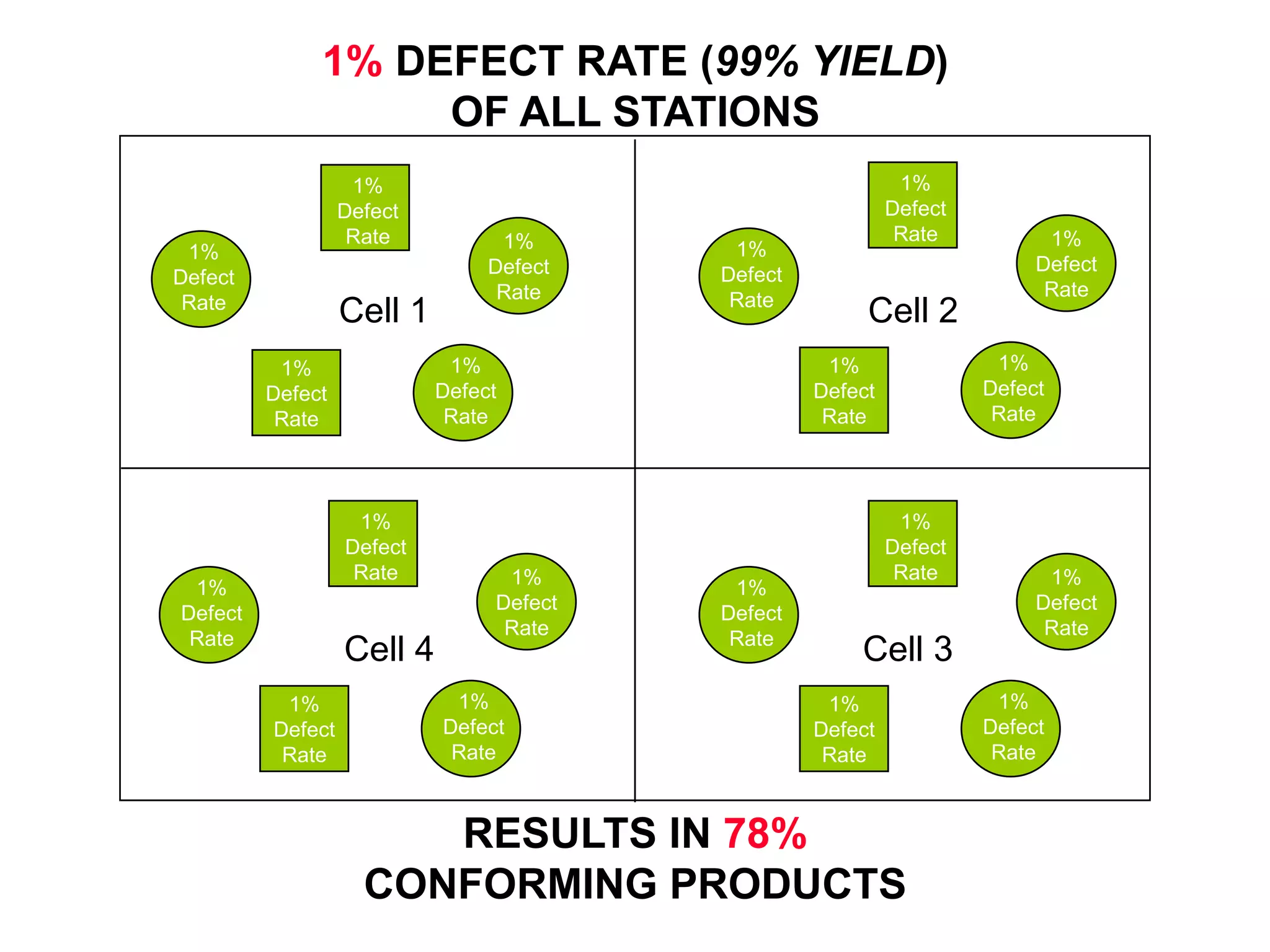

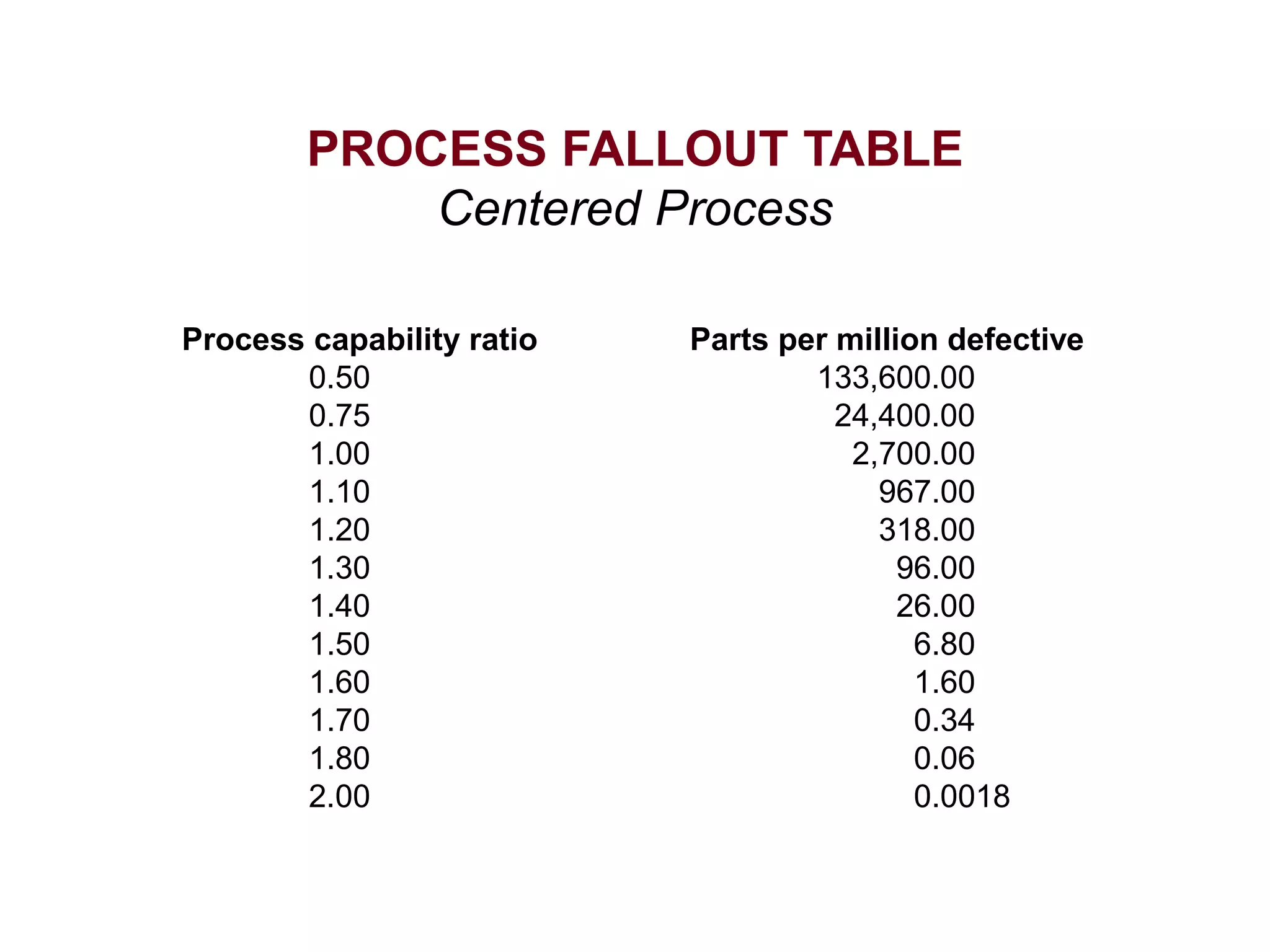

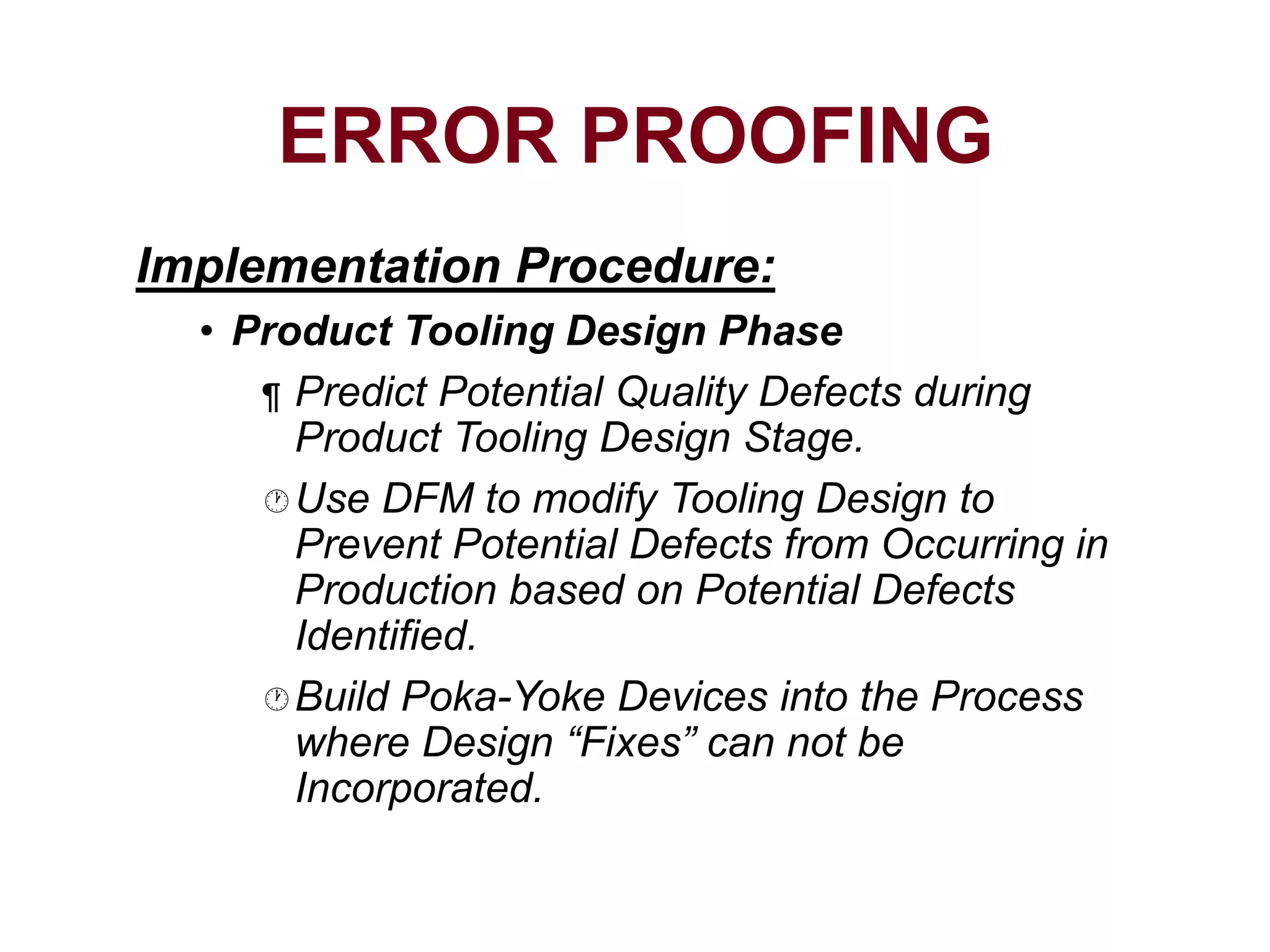

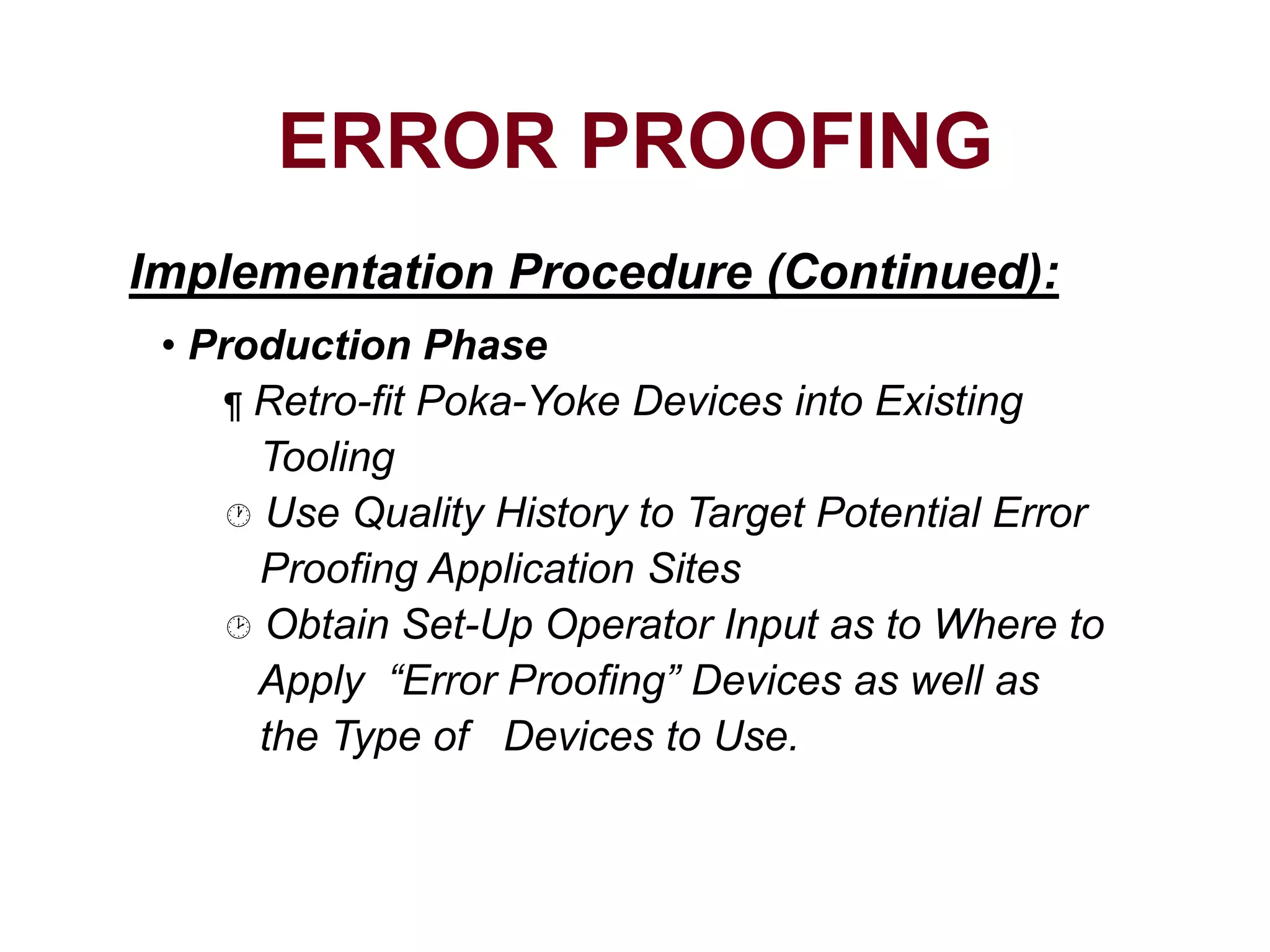

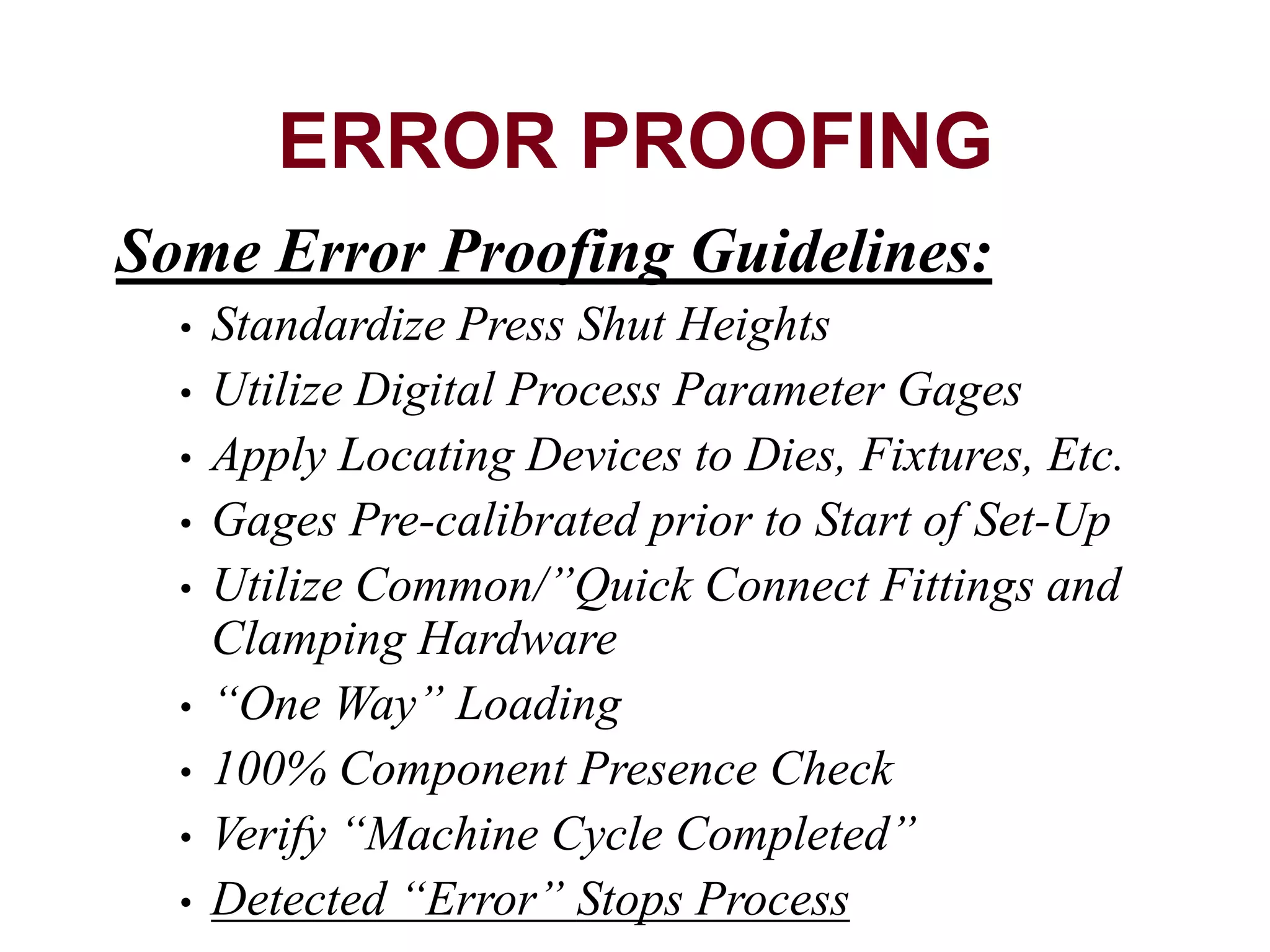

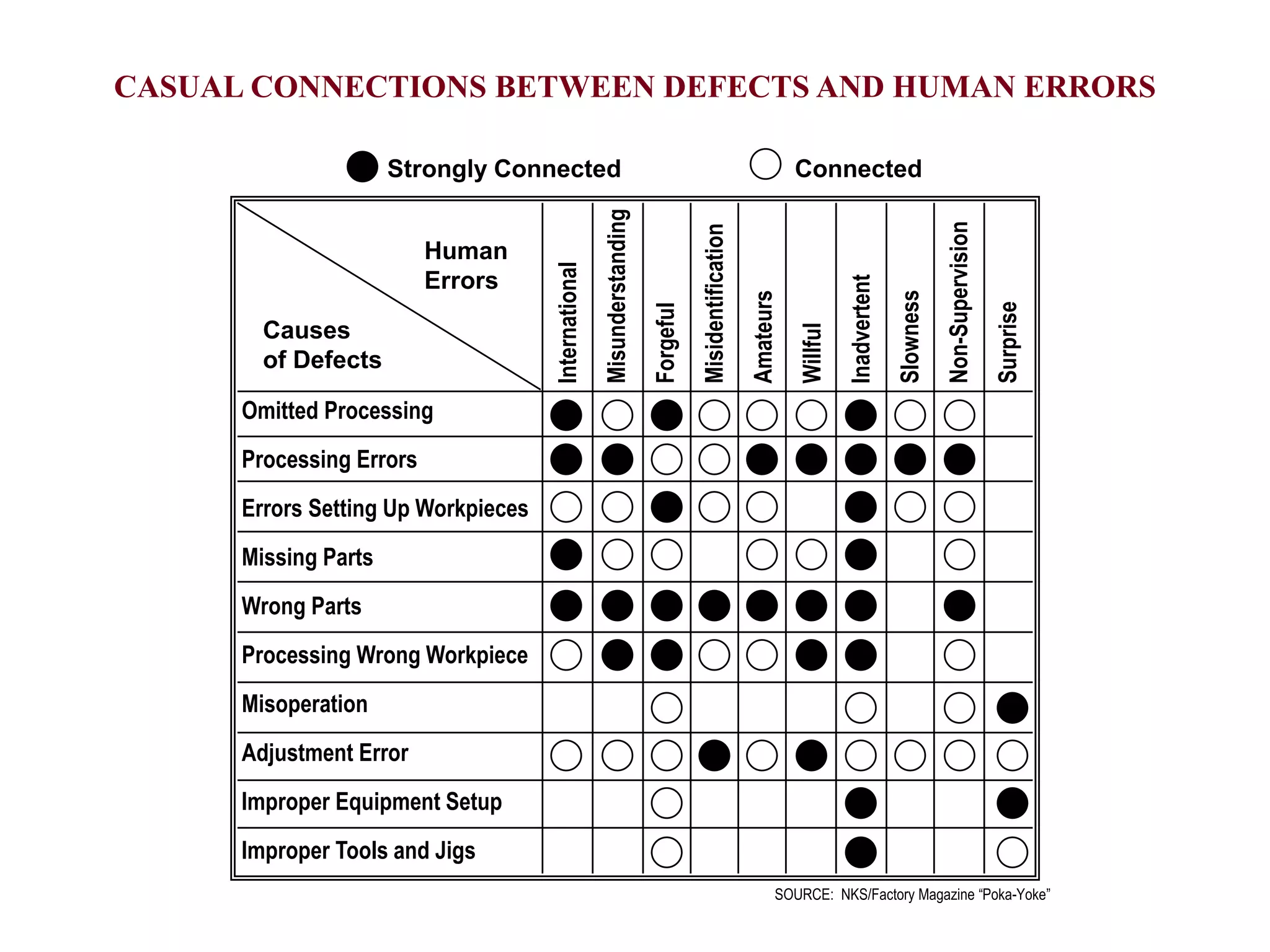

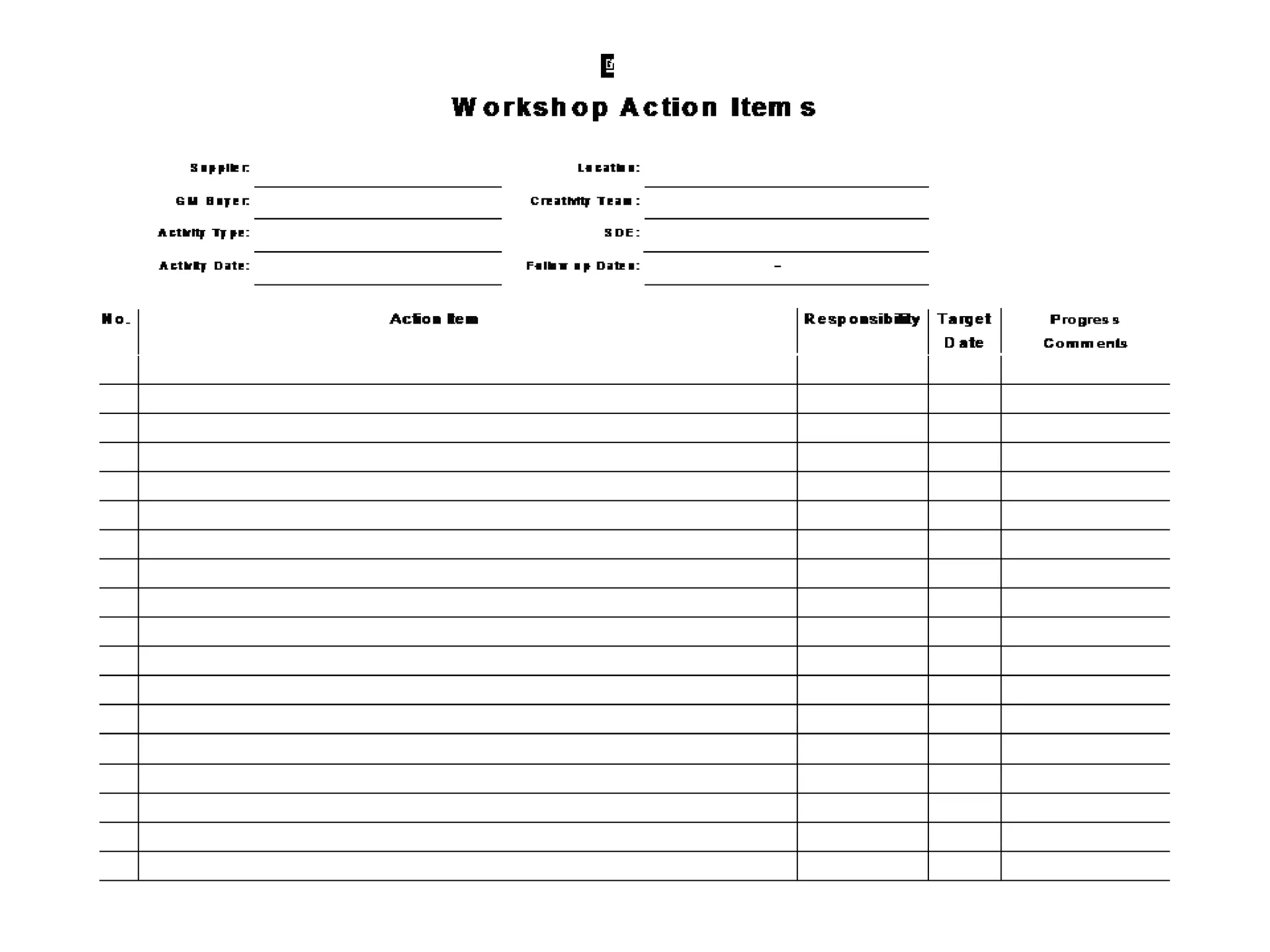

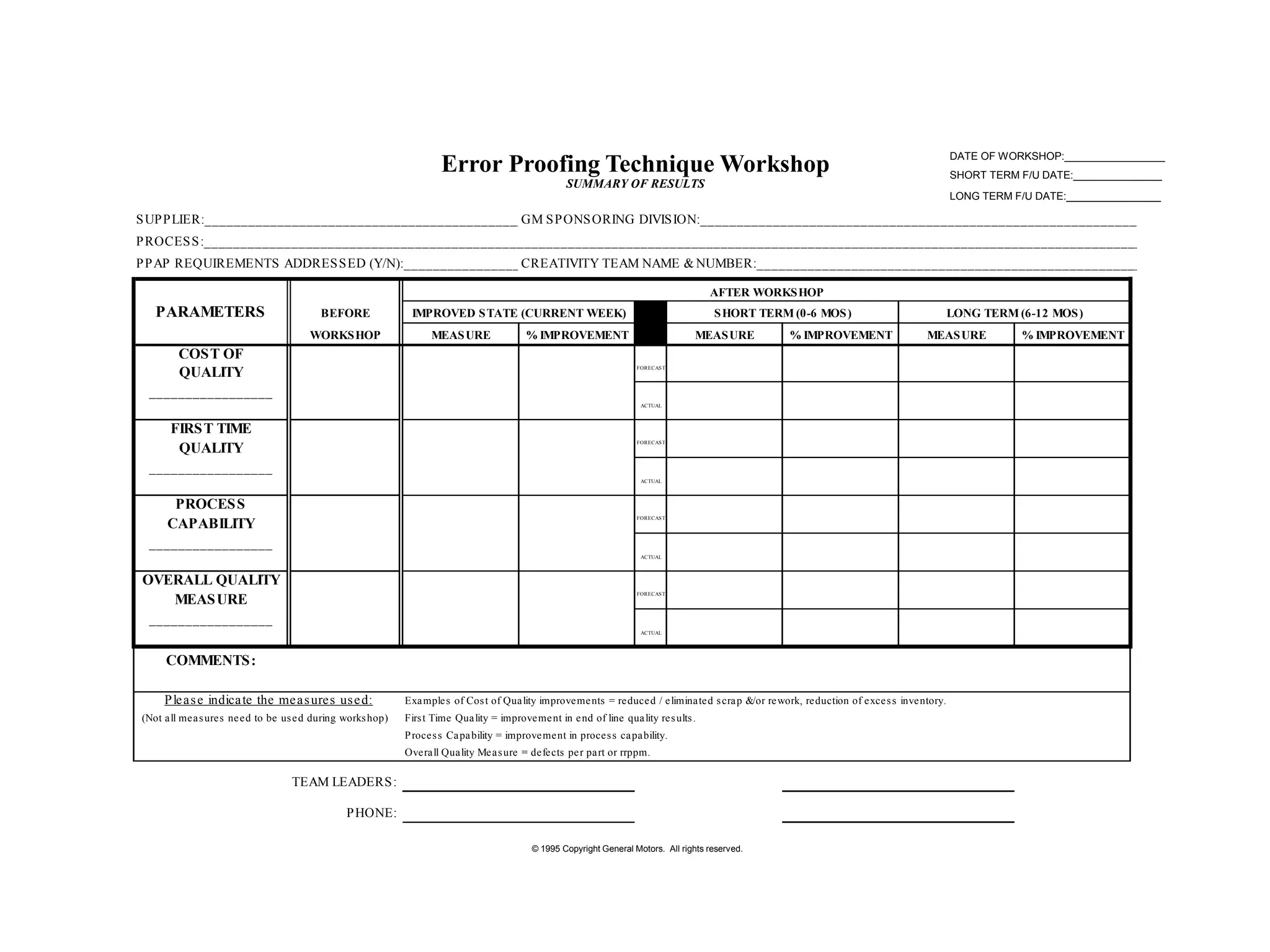

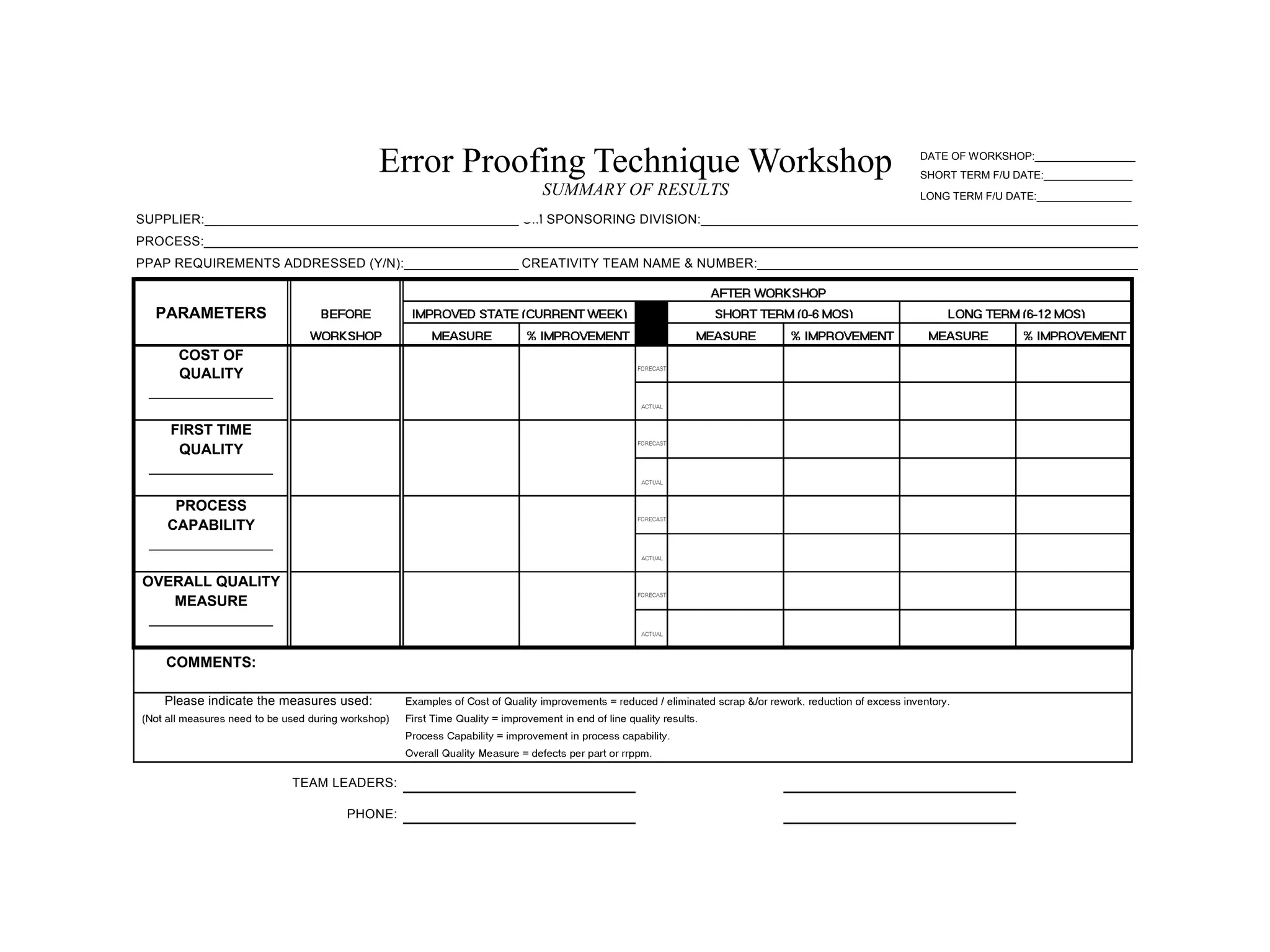

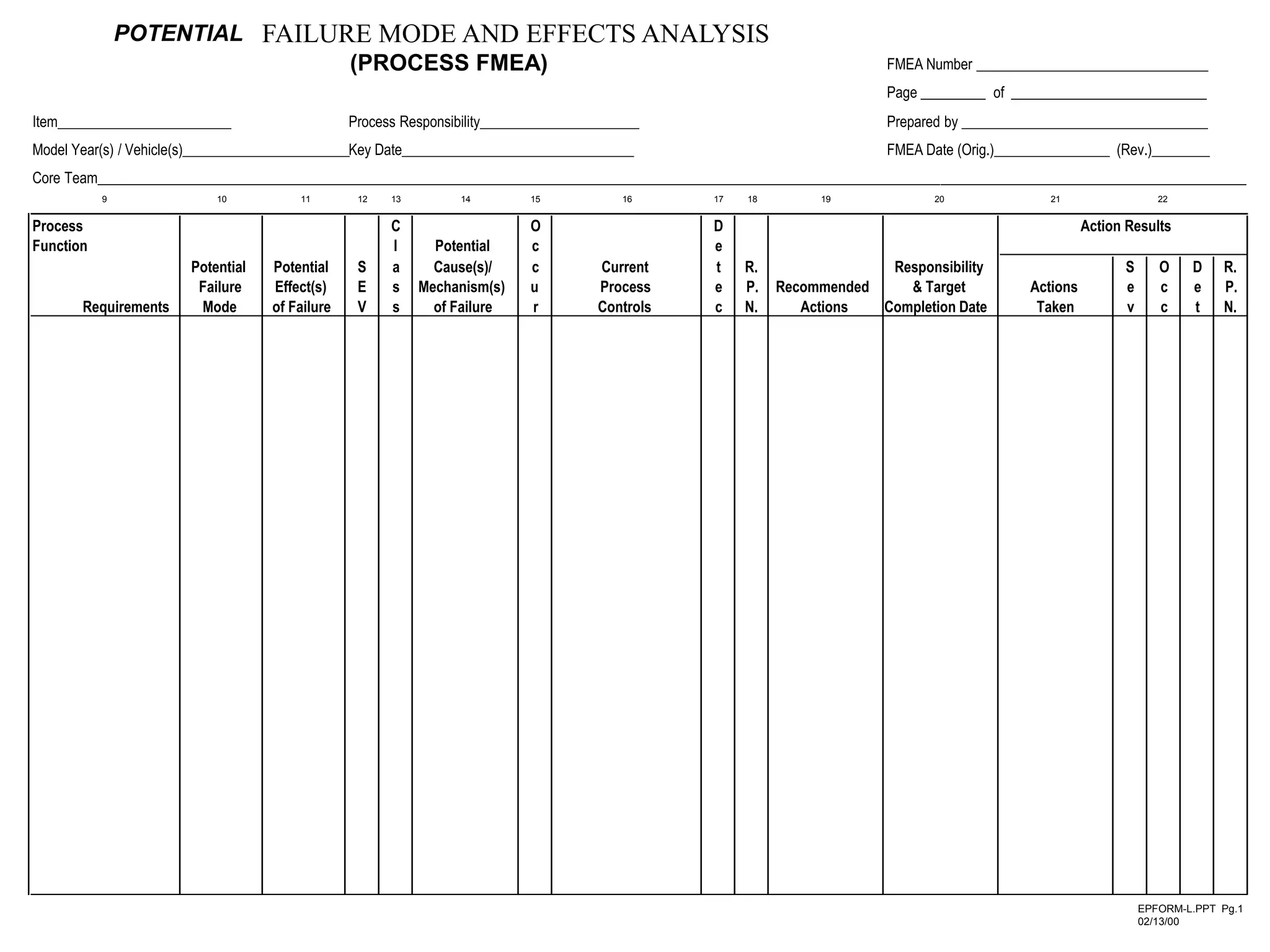

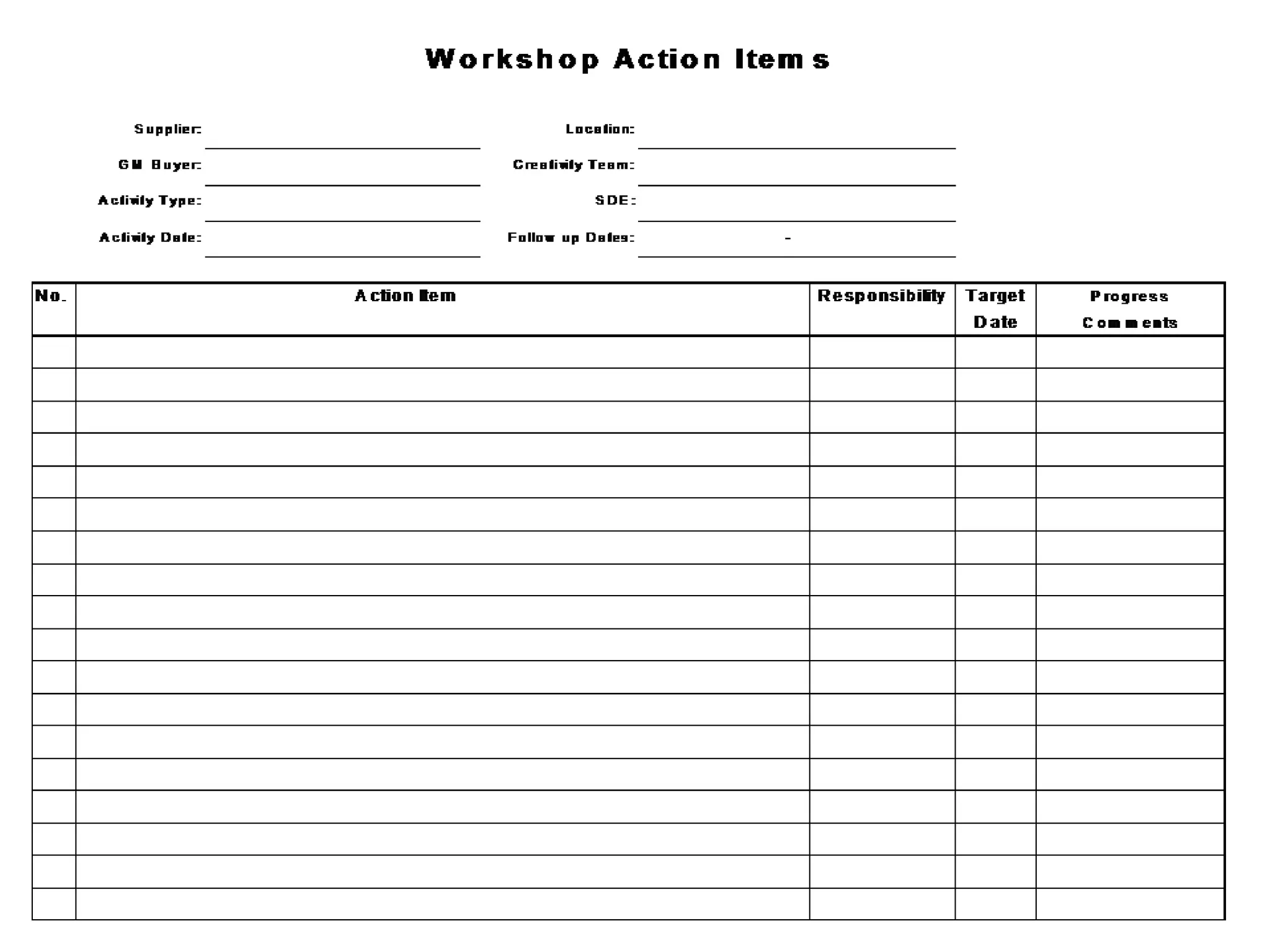

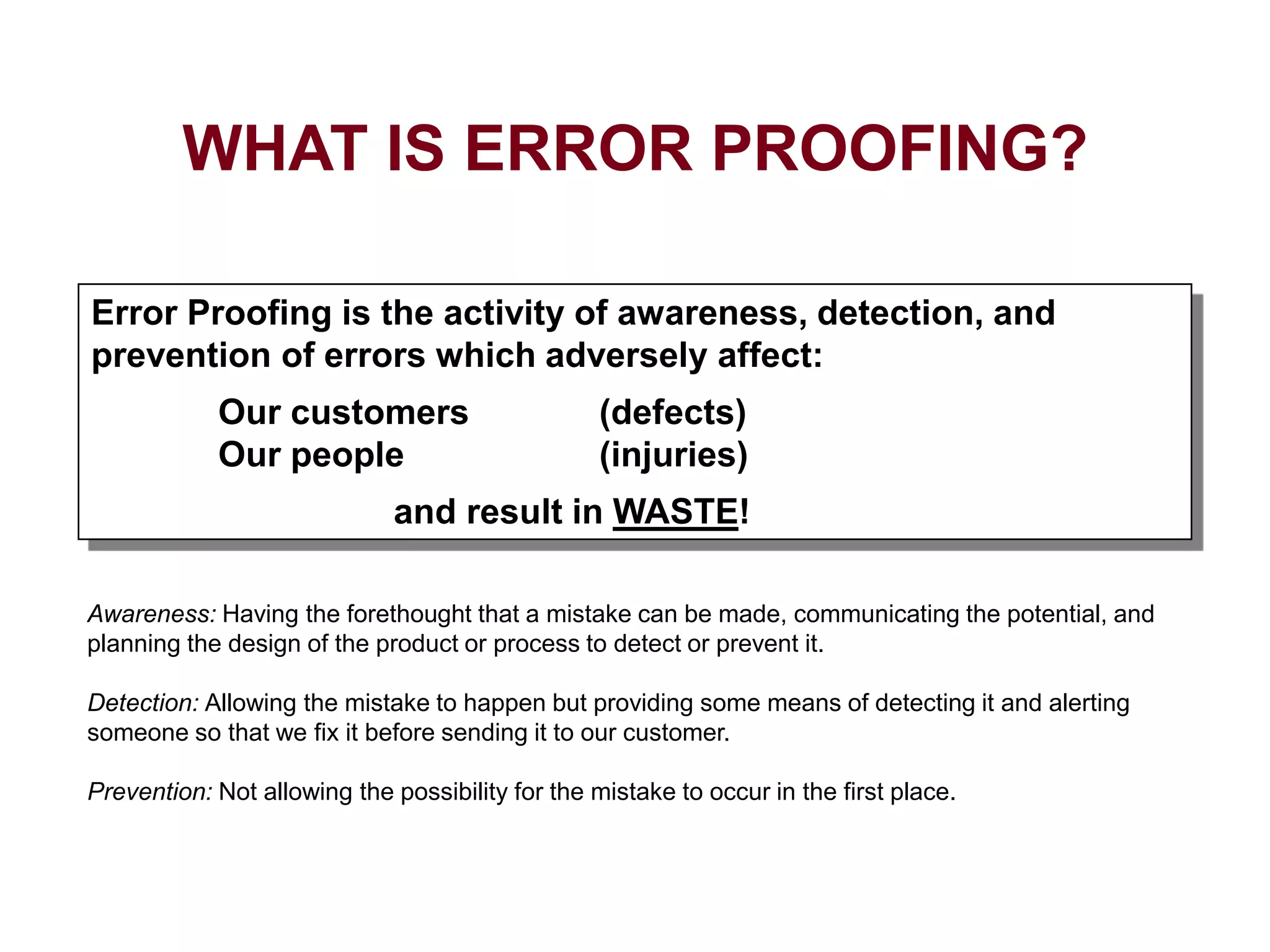

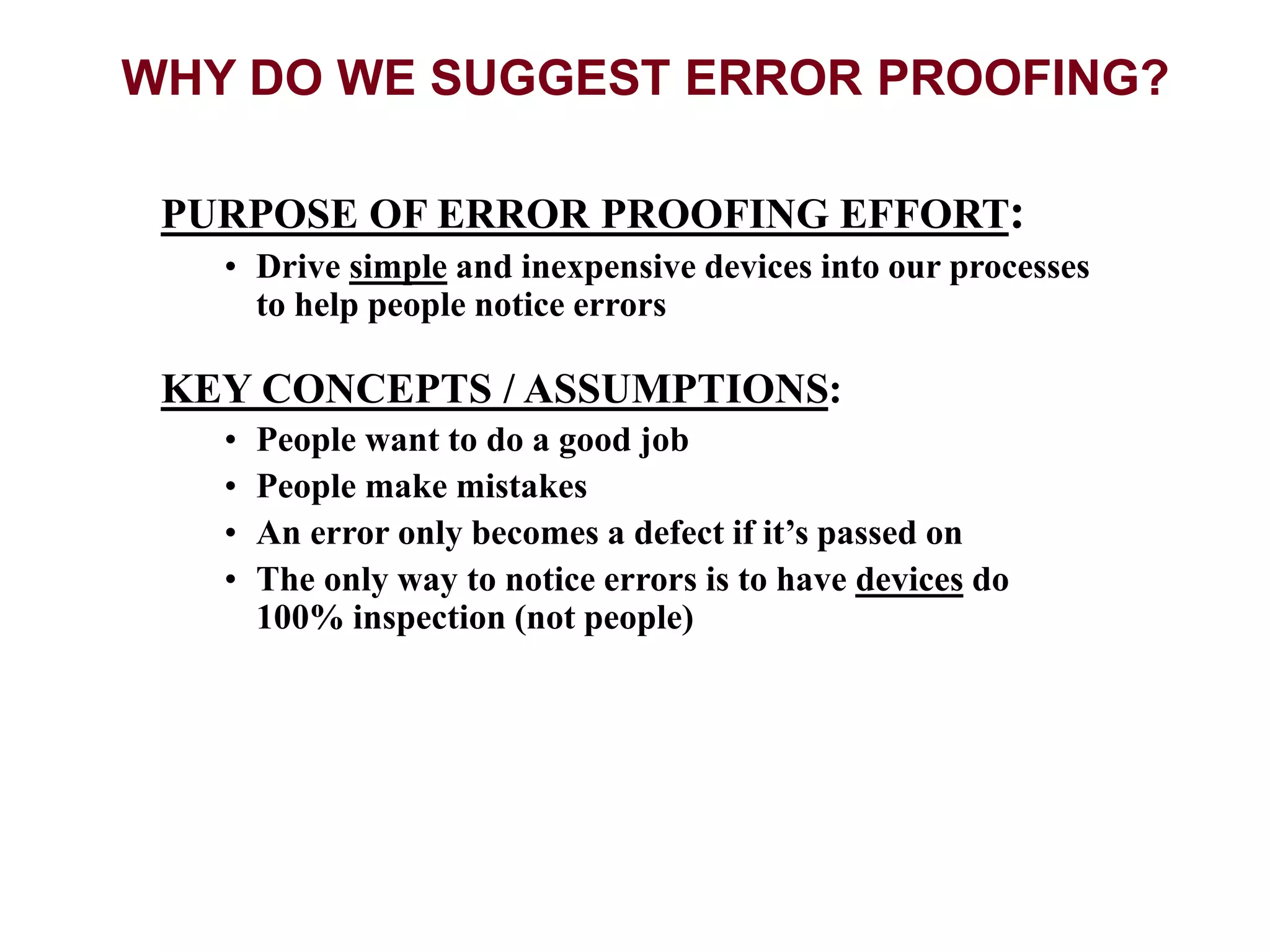

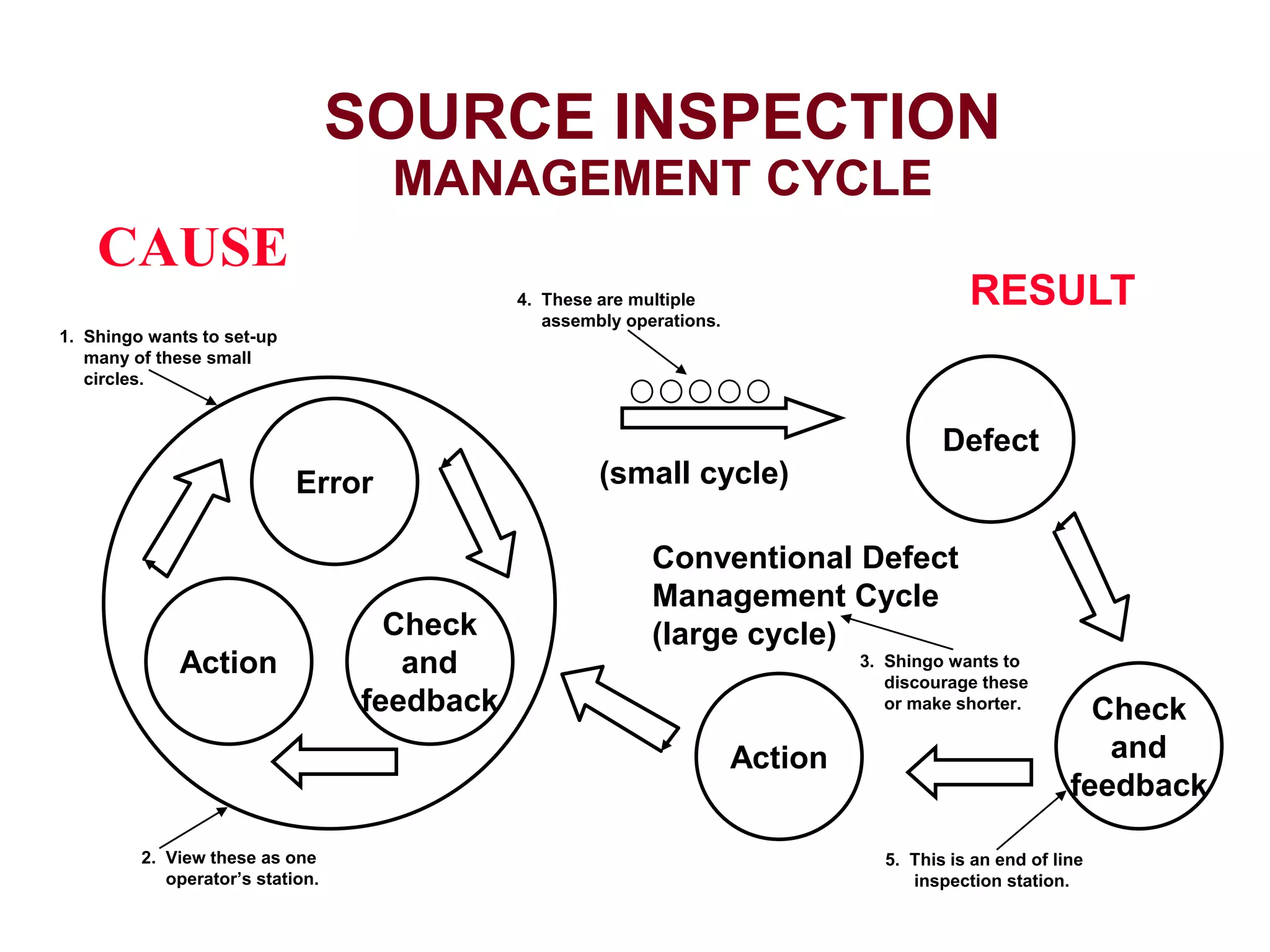

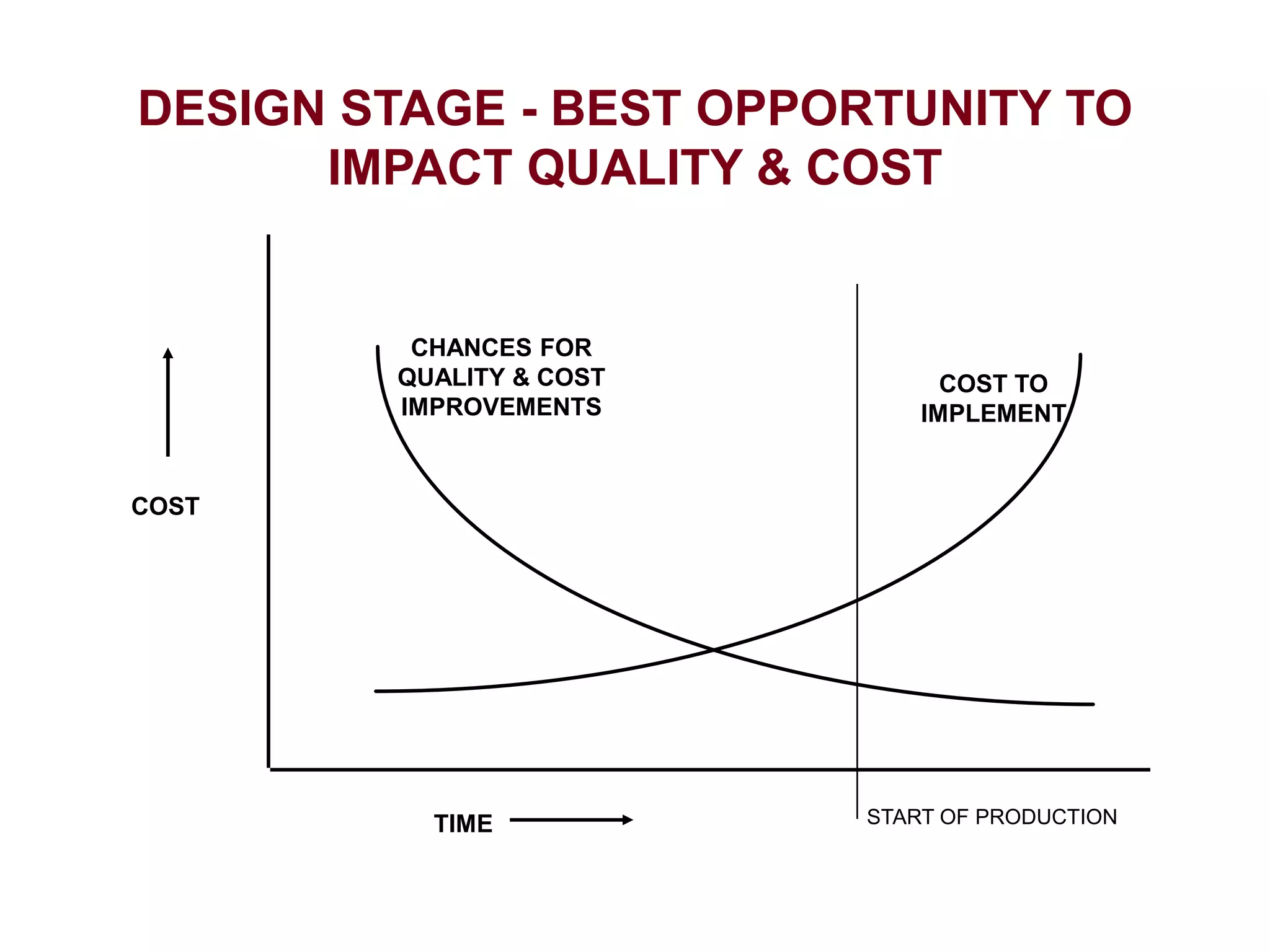

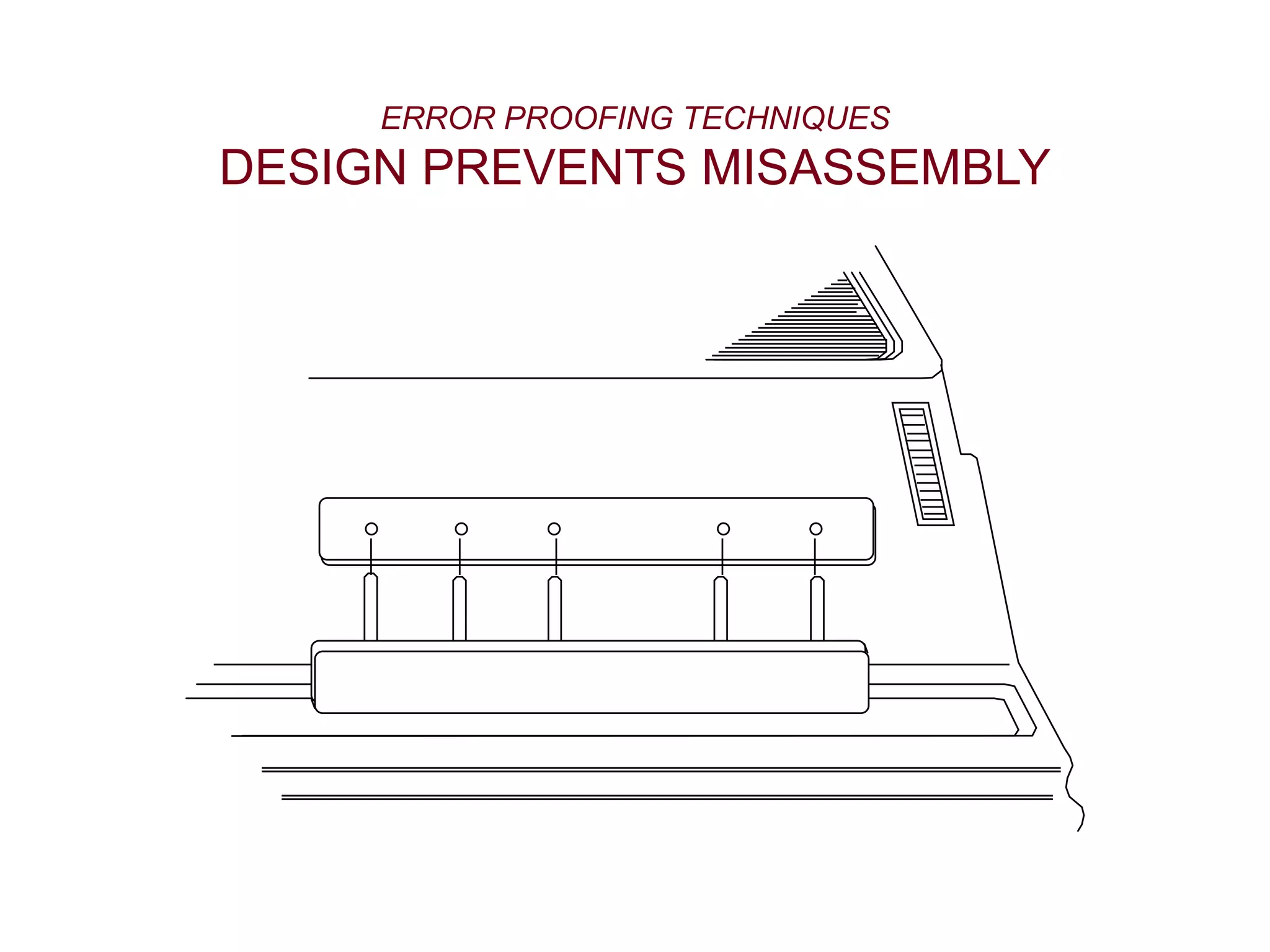

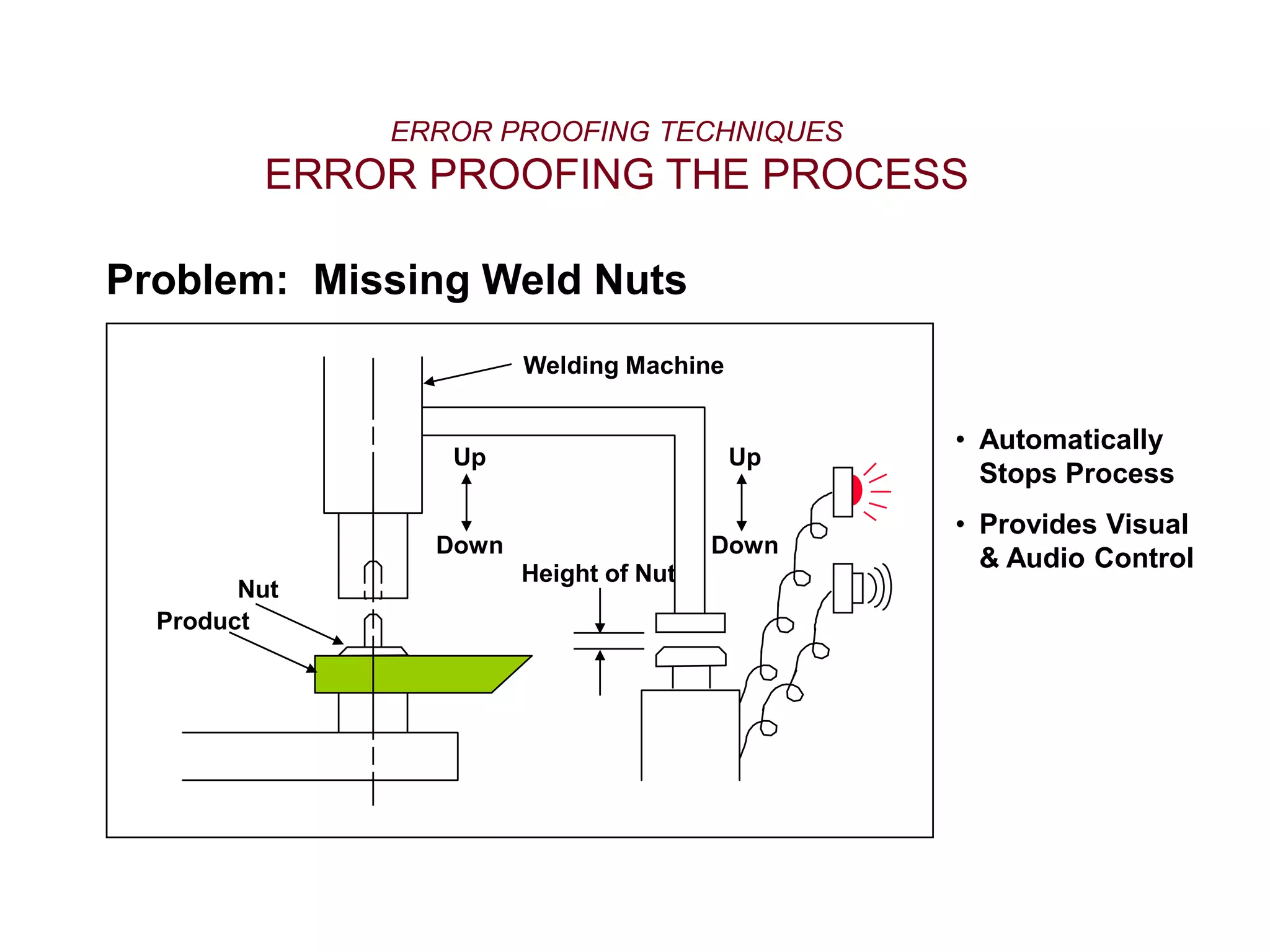

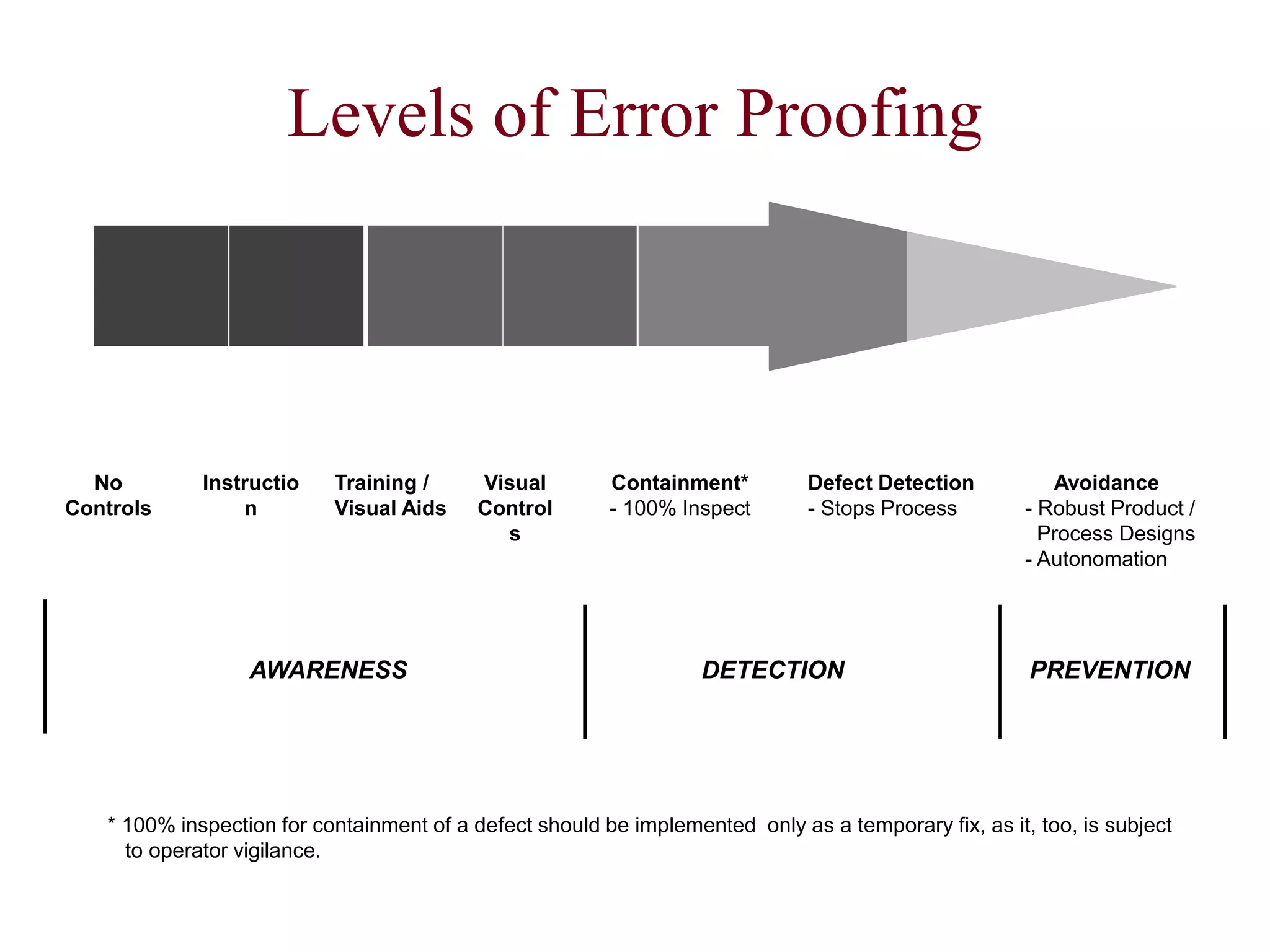

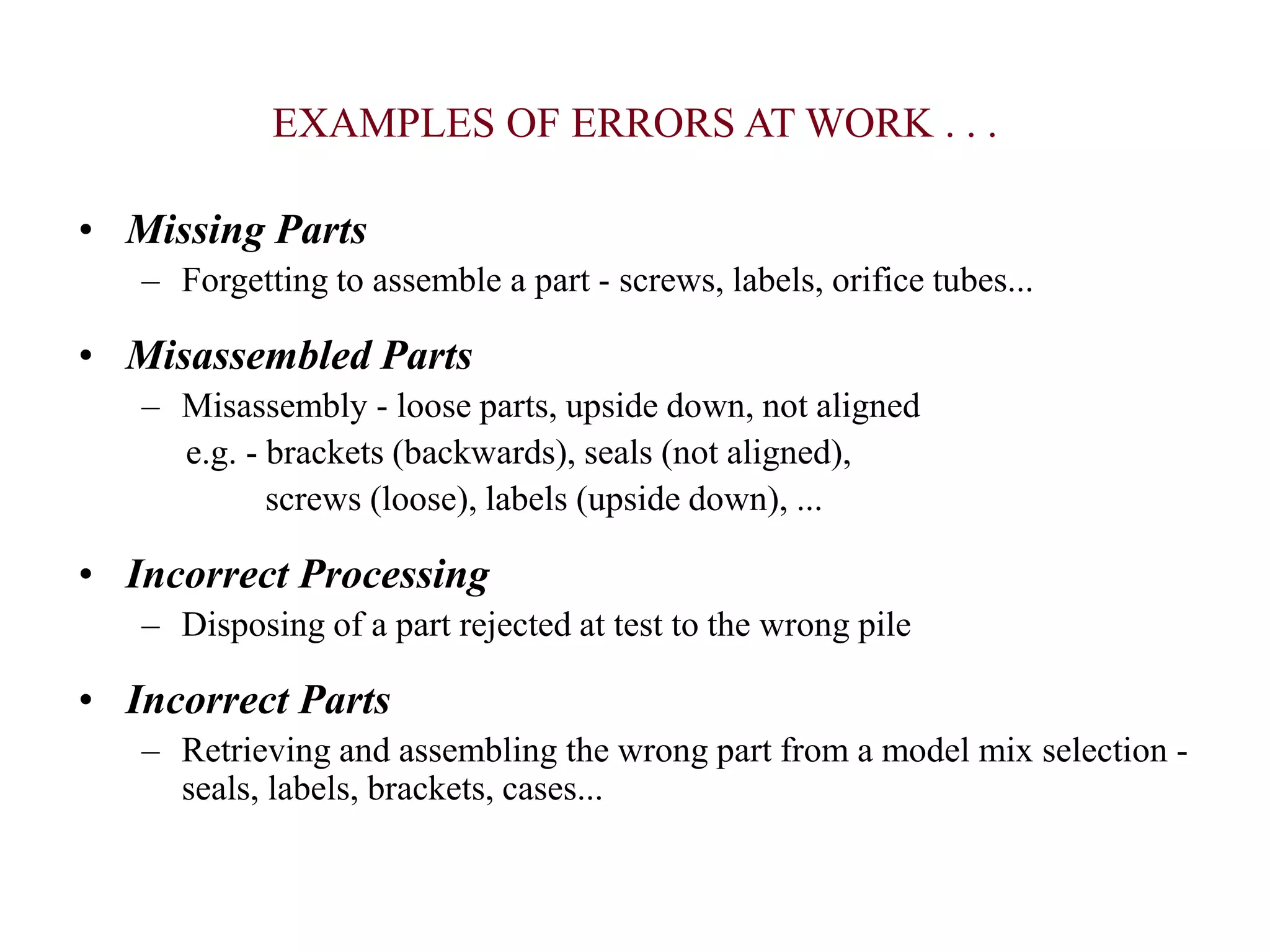

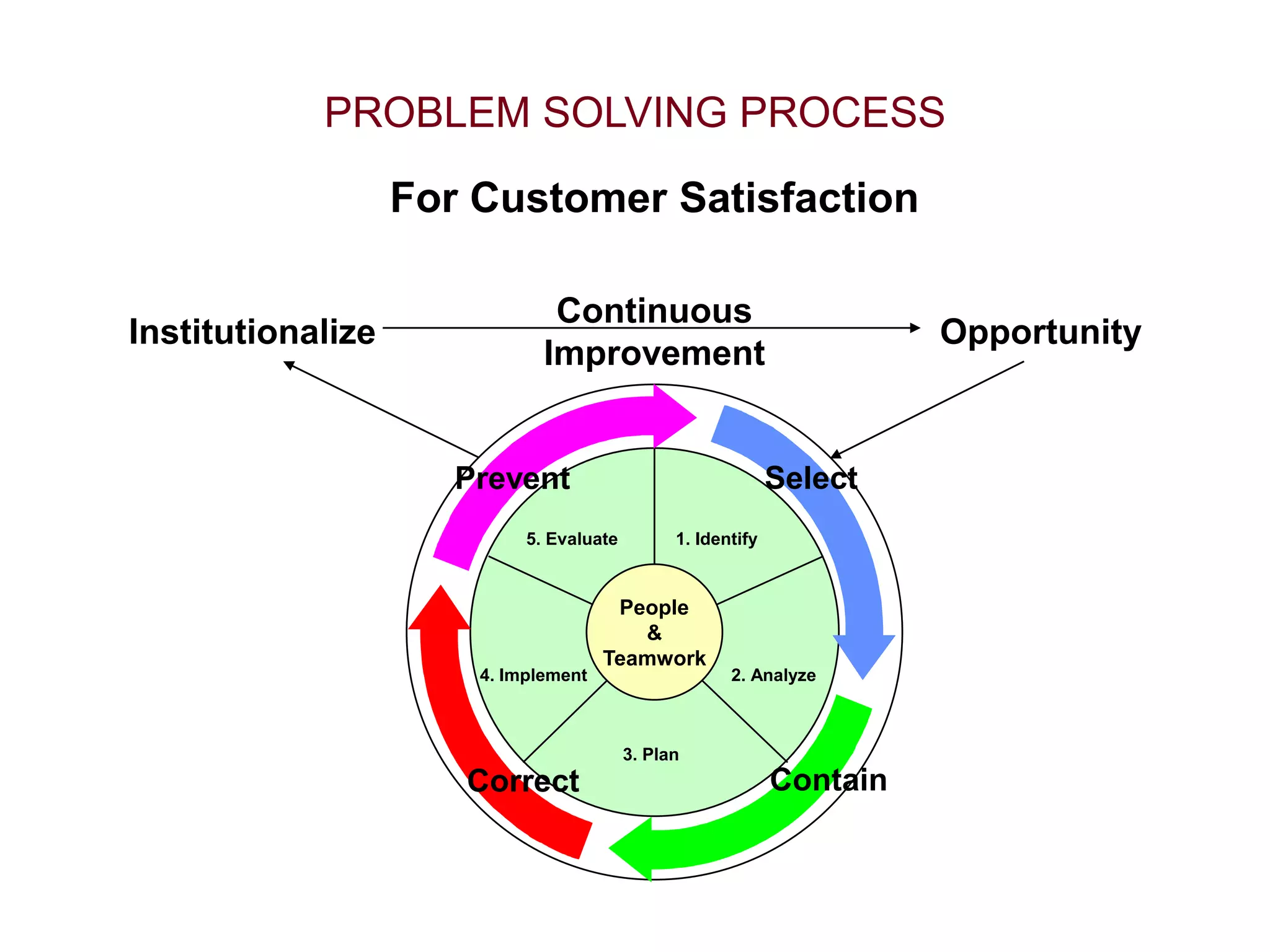

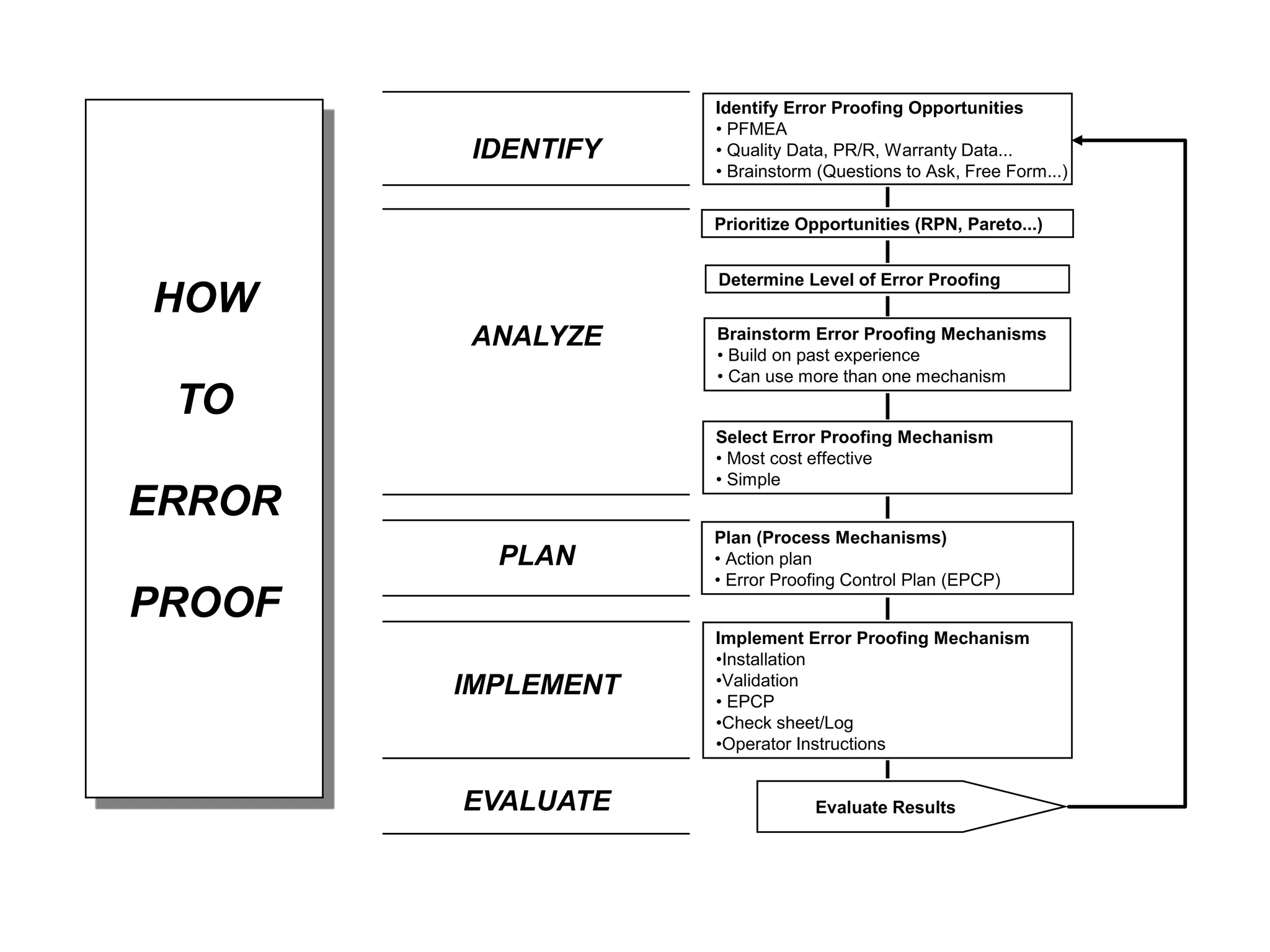

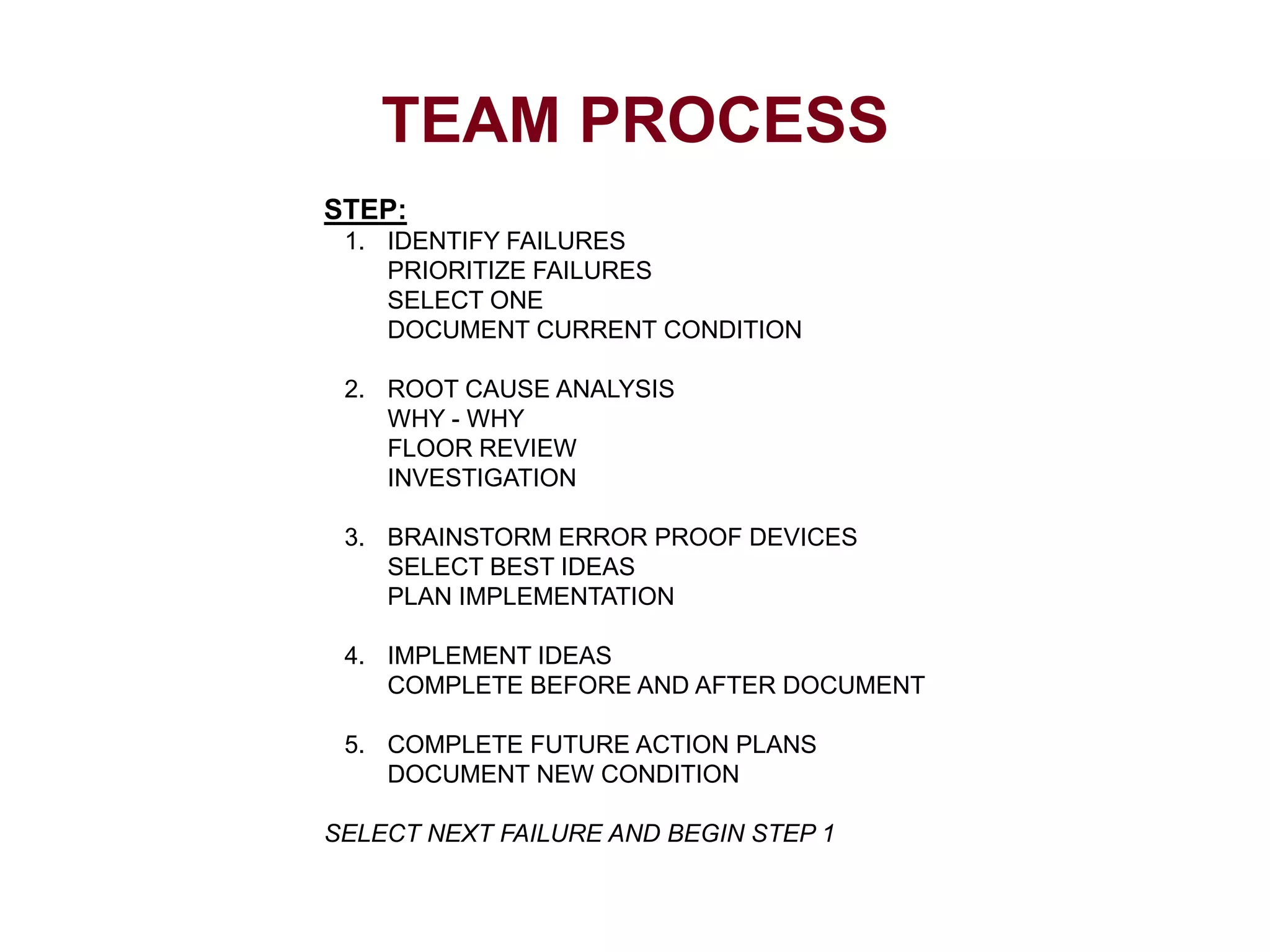

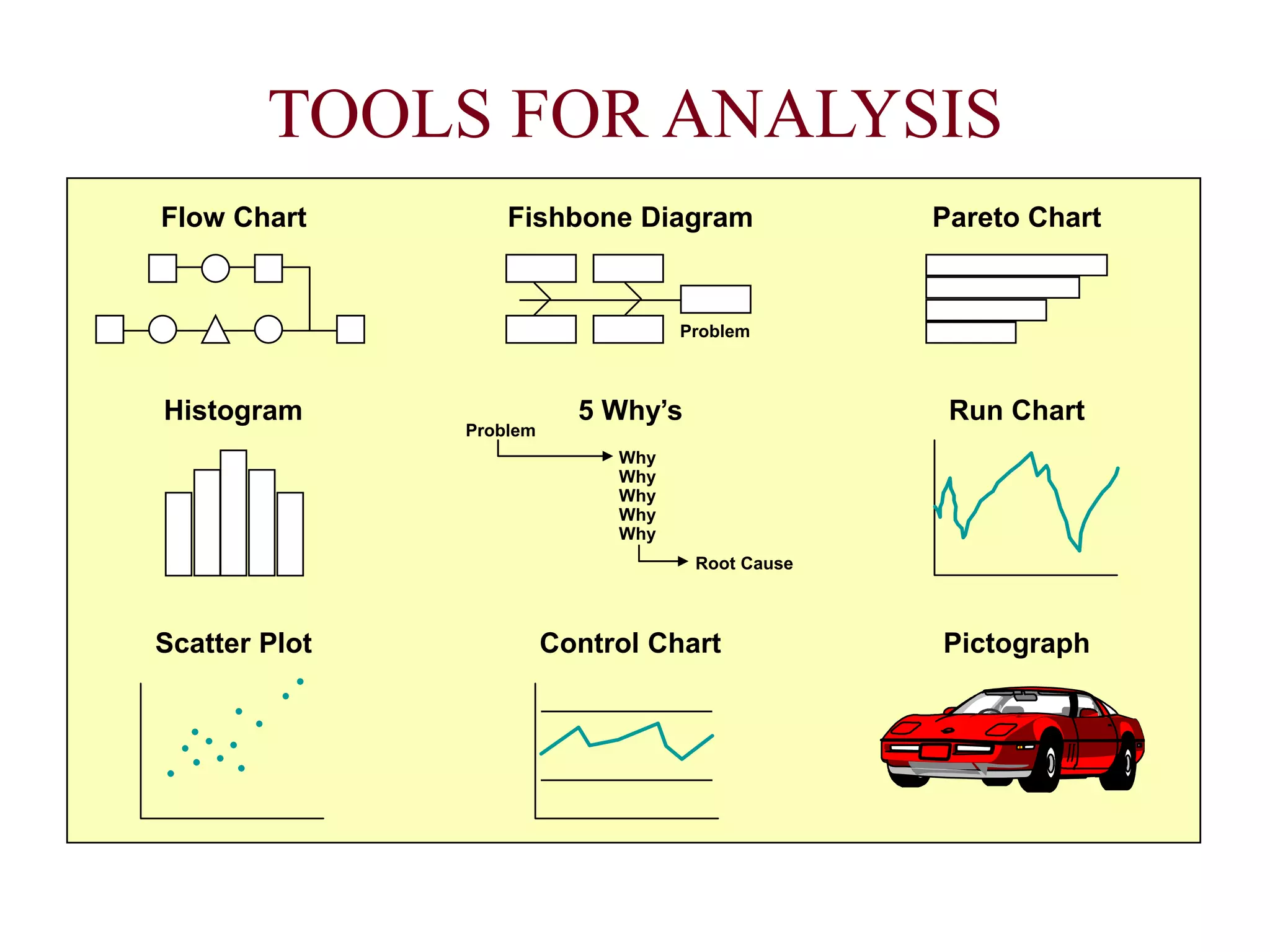

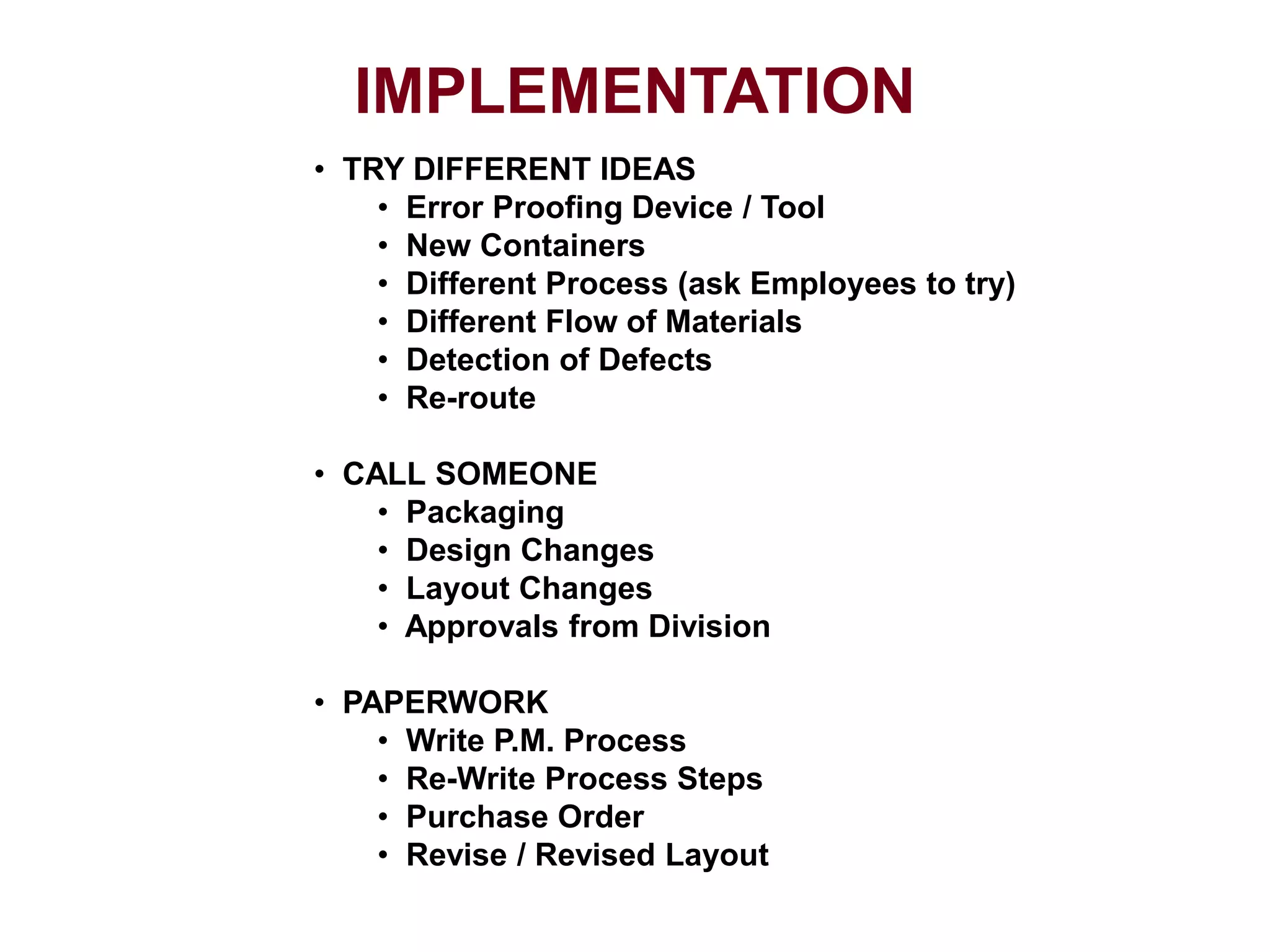

The document outlines an agenda for an error proofing techniques workshop. It discusses defining the current problem state and quality issues using metrics like parts per million defects. It emphasizes that people will inadvertently make mistakes and that the goal of error proofing is to develop systems for detecting and preventing defects before they reach customers. Example error proofing techniques presented include design for manufacturability and "Poka-Yoke" setup devices to help operators assemble products correctly from the first piece.