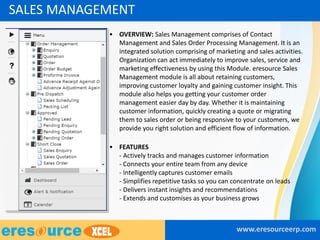

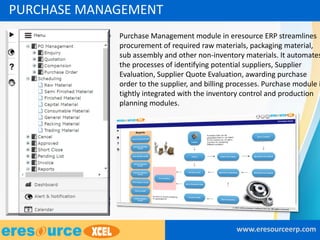

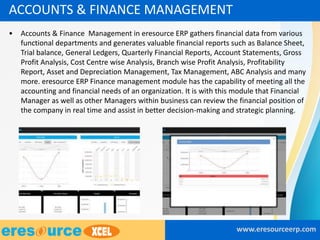

The document provides an overview of eresource Xcel ERP, a next-generation ERP system tailored for the manufacturing industry, emphasizing its real-time data access, collaborative features, and integration of various business functions. It outlines key modules including sales management, purchase management, production planning, quality control, and finance management, each designed to enhance operational efficiency and customer service. The ERP system aims to support manufacturing firms in maintaining competitiveness through cost reduction and quality improvement.