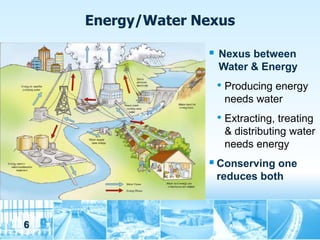

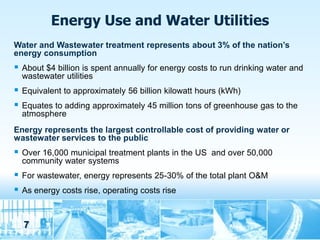

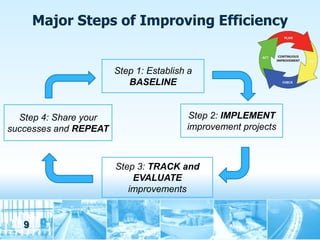

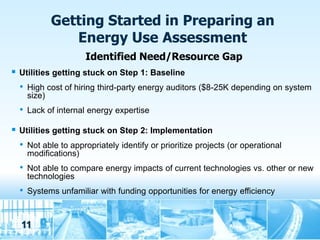

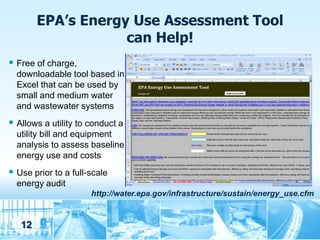

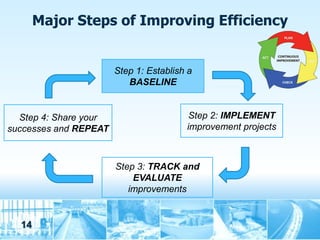

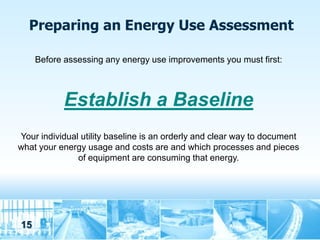

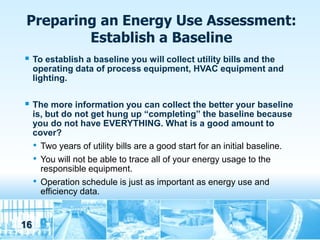

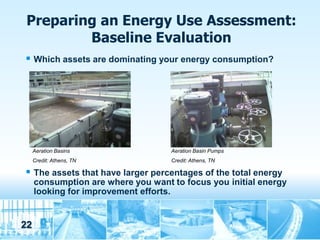

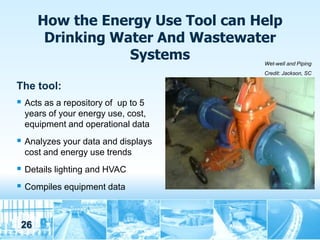

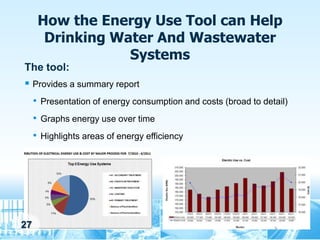

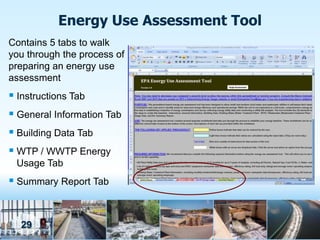

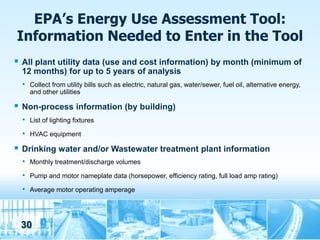

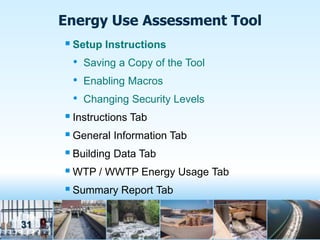

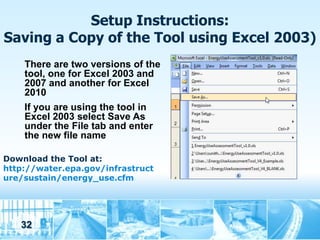

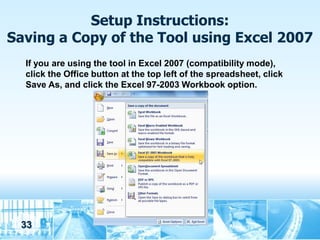

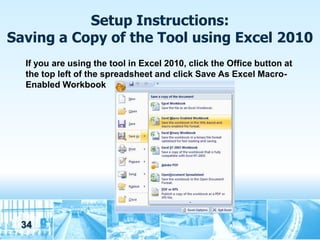

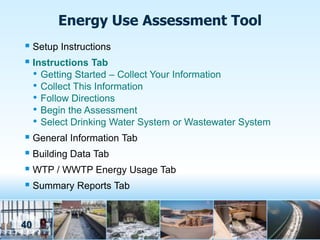

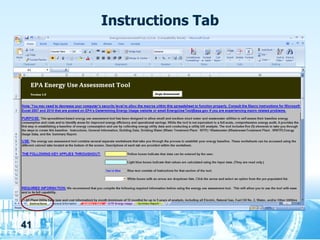

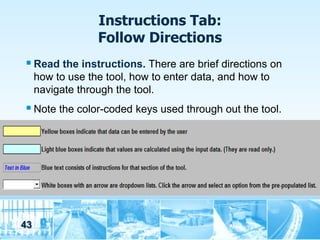

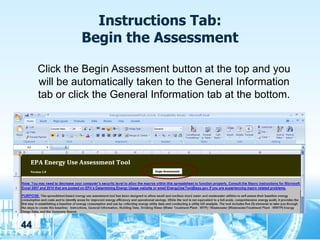

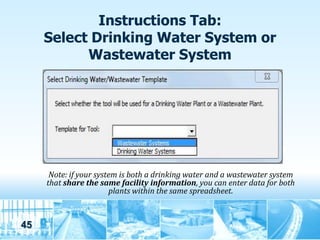

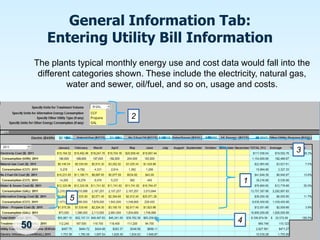

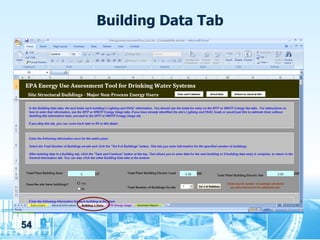

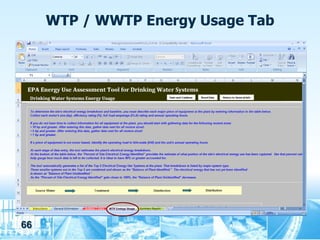

The document provides an overview of the EPA's energy use assessment tool aimed at enhancing energy efficiency in water and wastewater systems. It discusses the relationship between energy and water, highlights the importance of establishing an energy baseline, and outlines steps for conducting an energy use assessment. Additionally, it emphasizes the tool's role in helping utilities manage energy consumption and costs effectively.