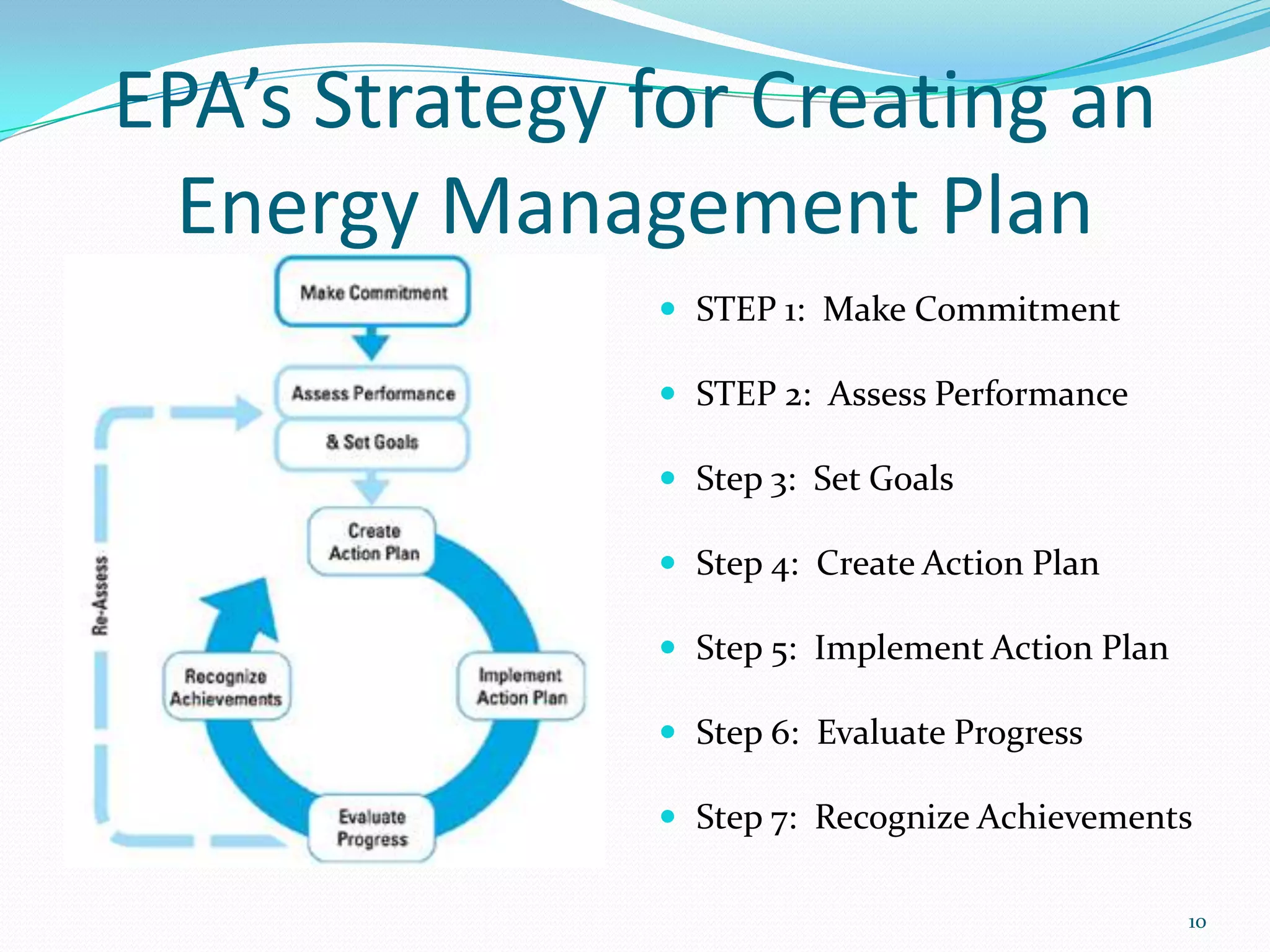

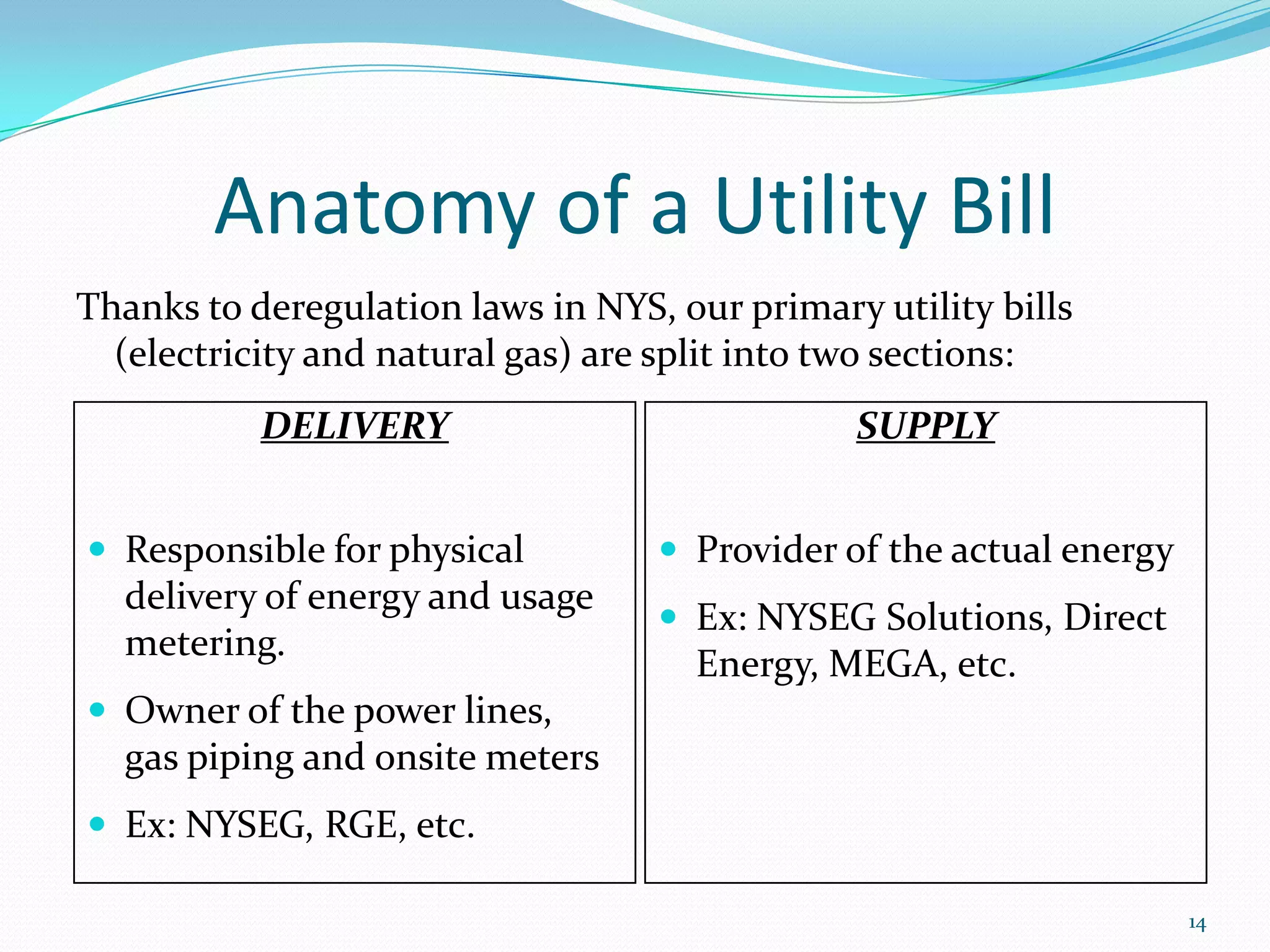

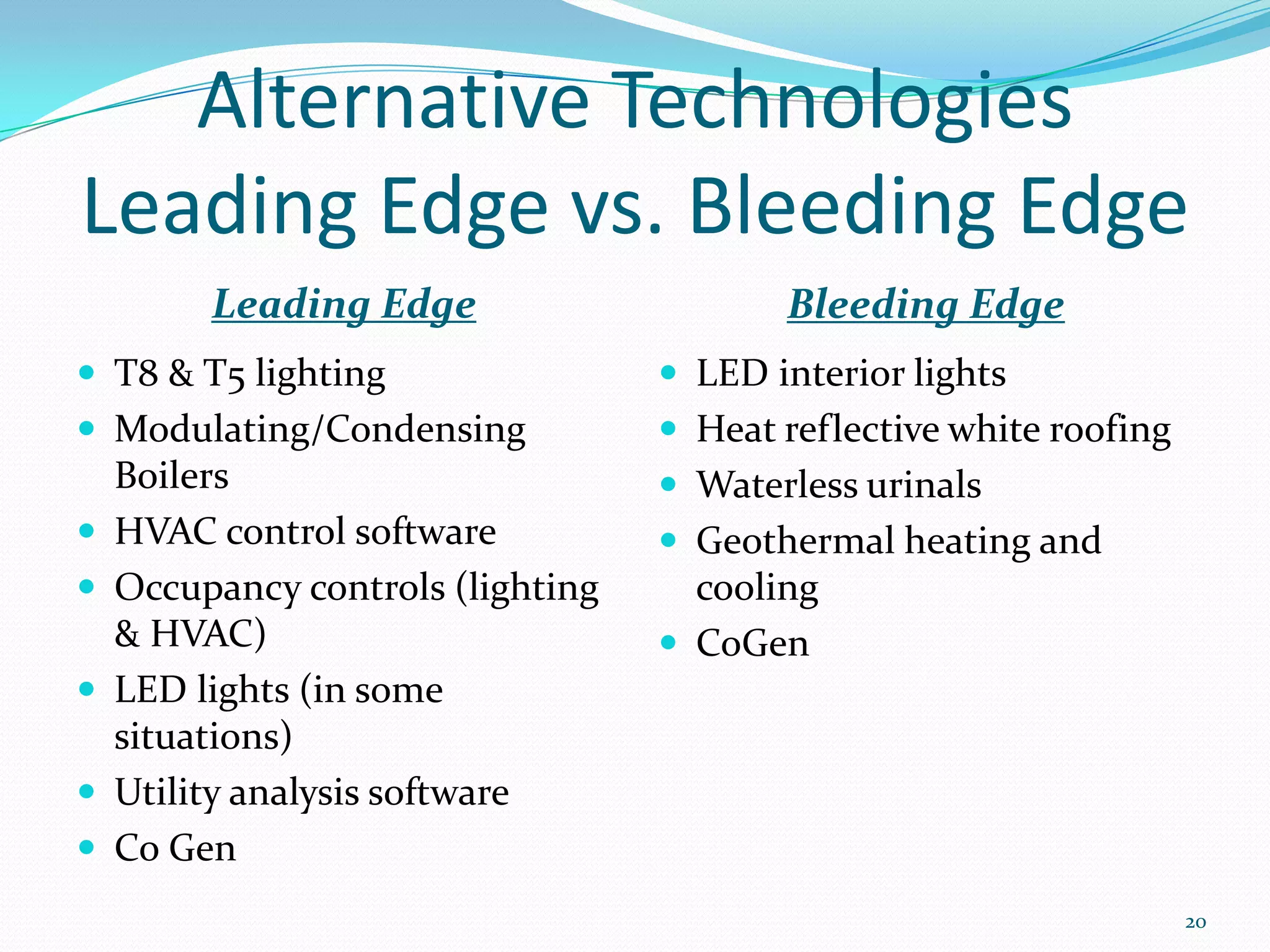

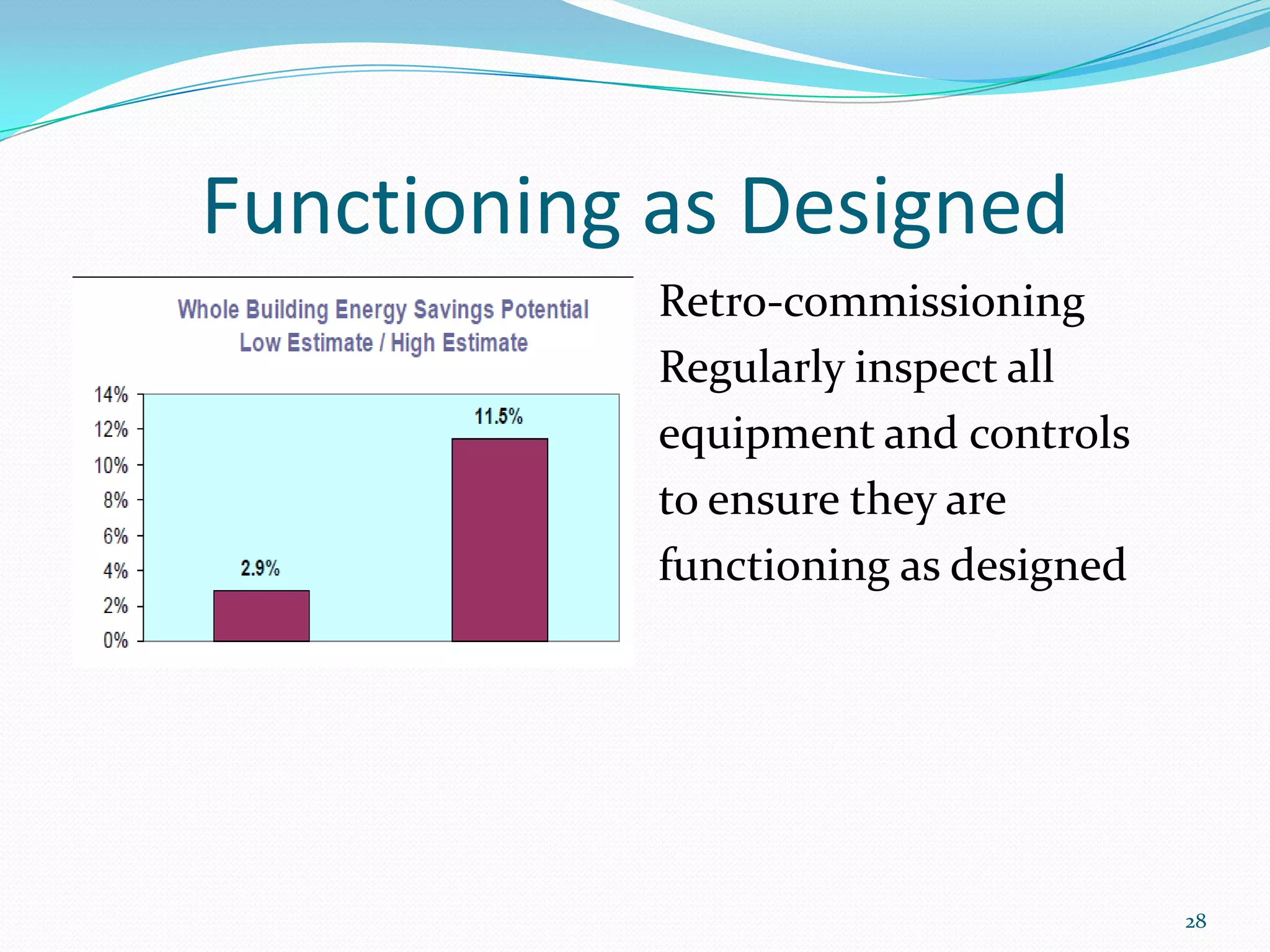

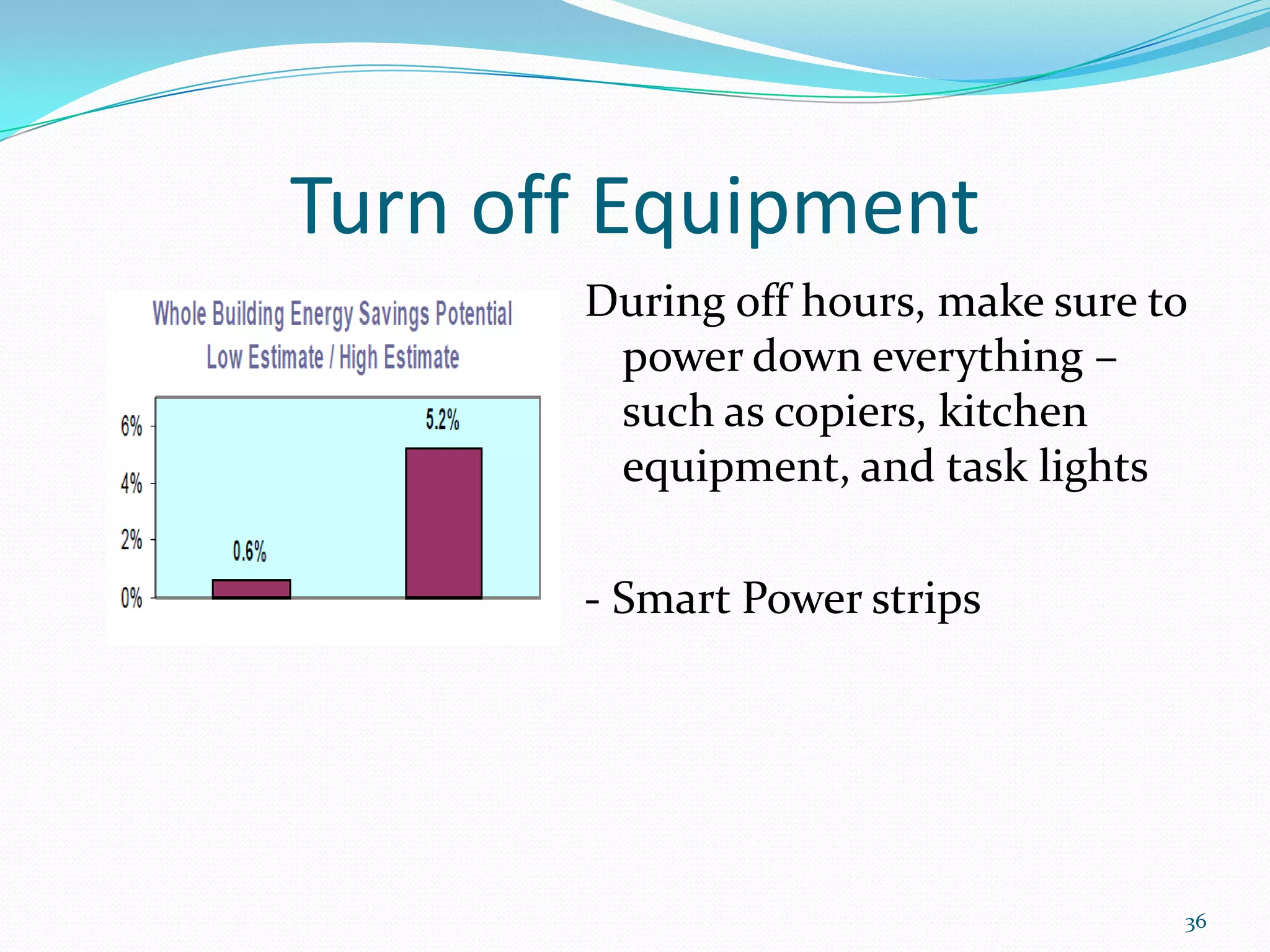

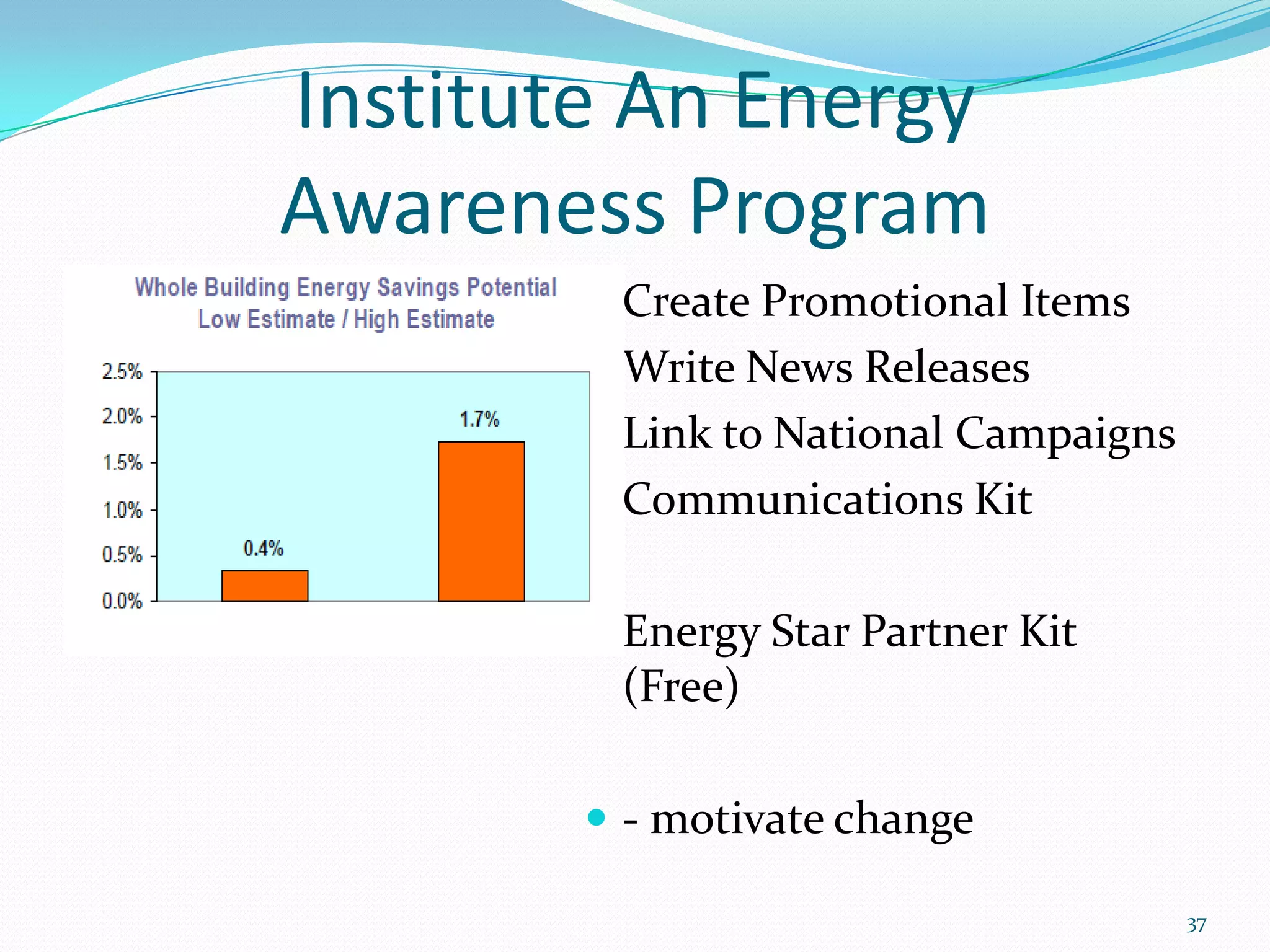

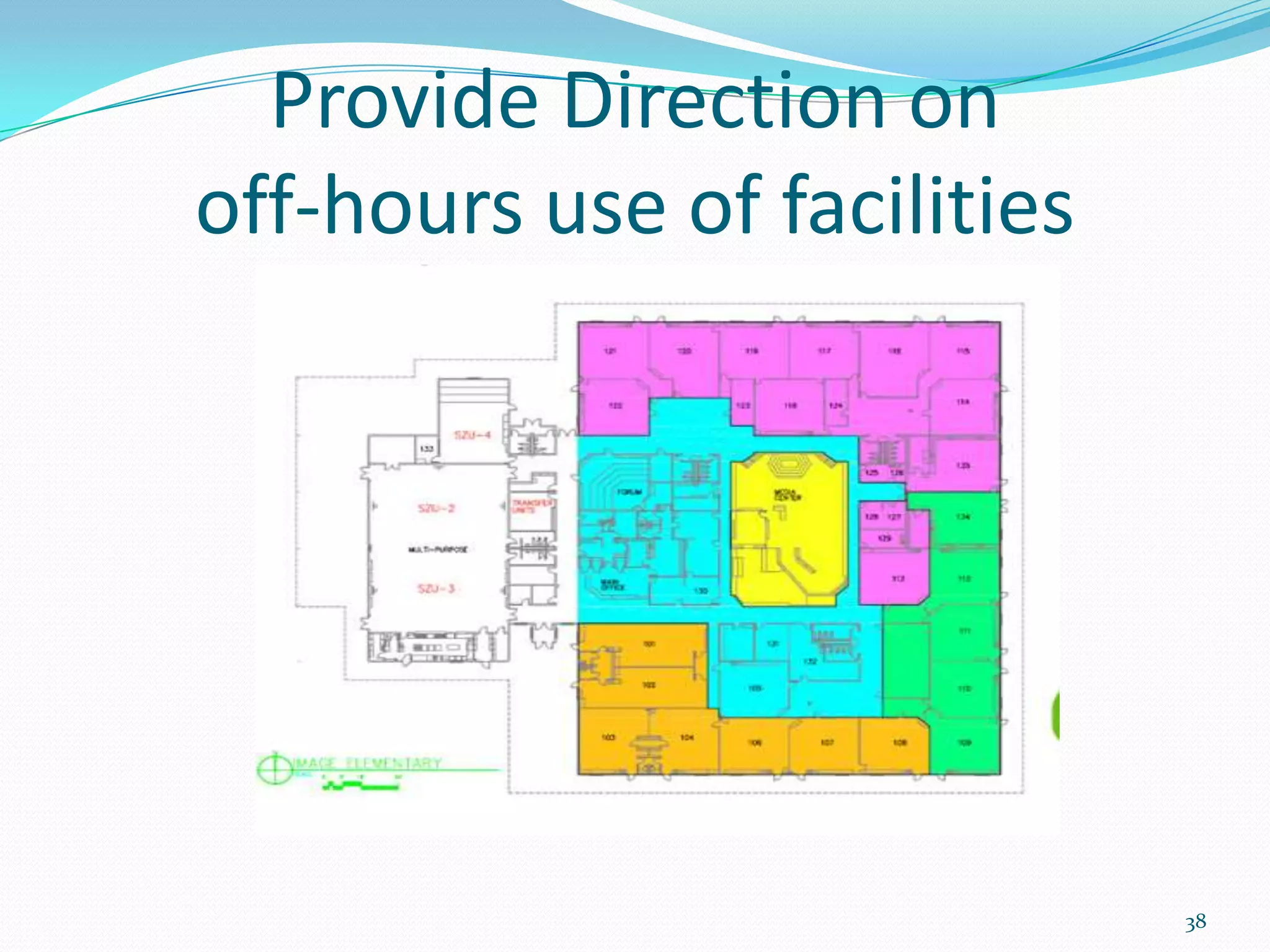

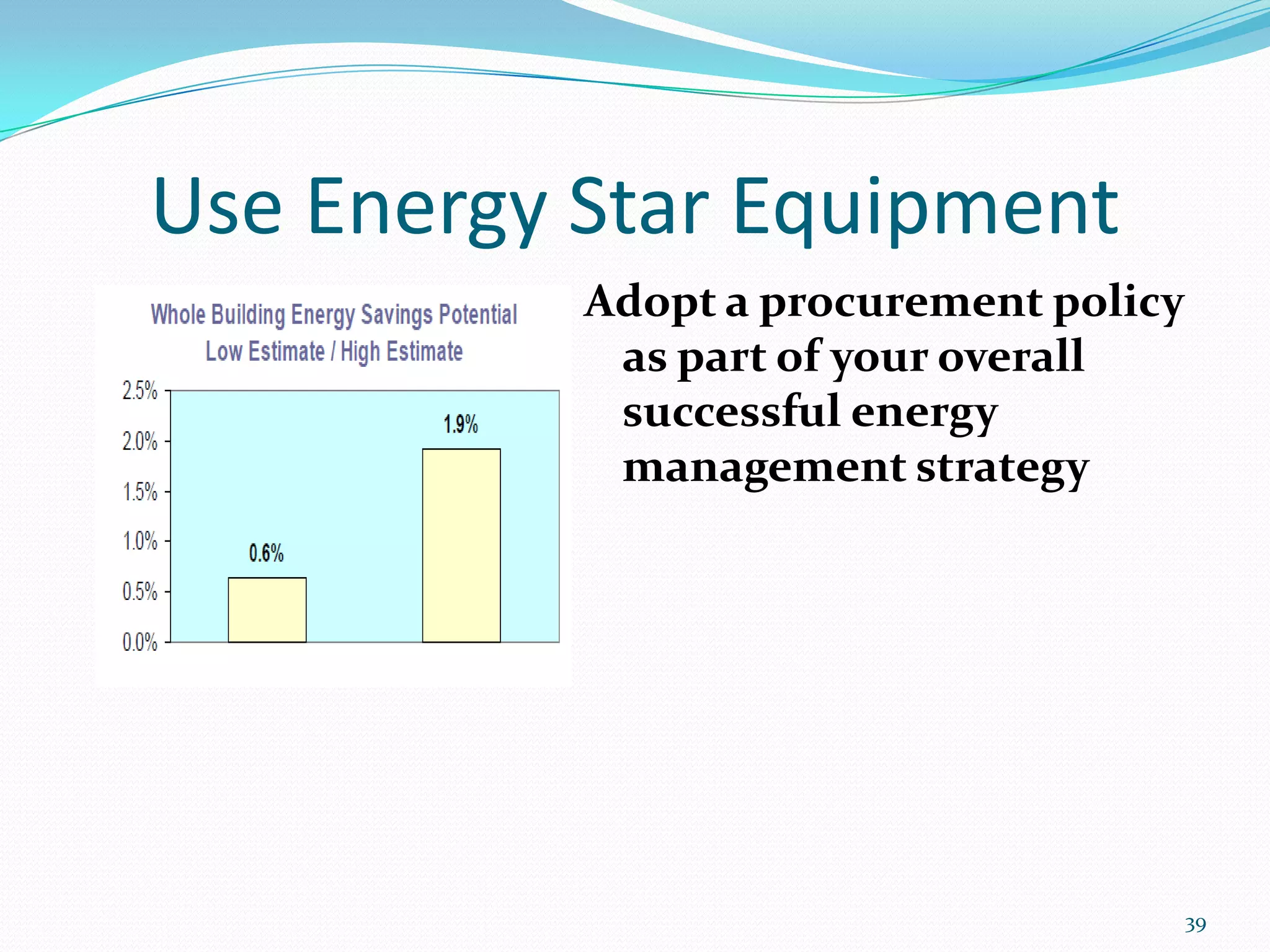

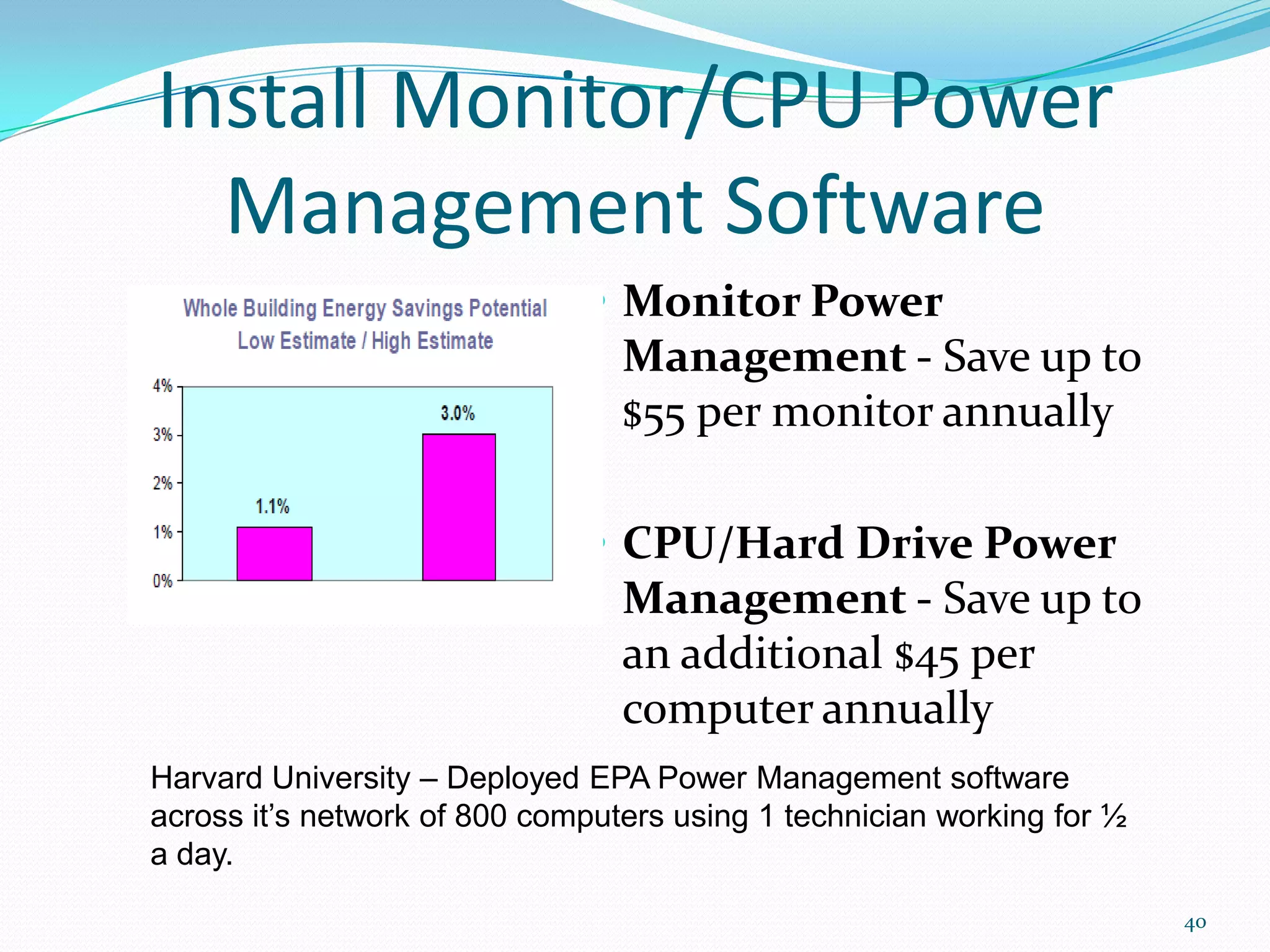

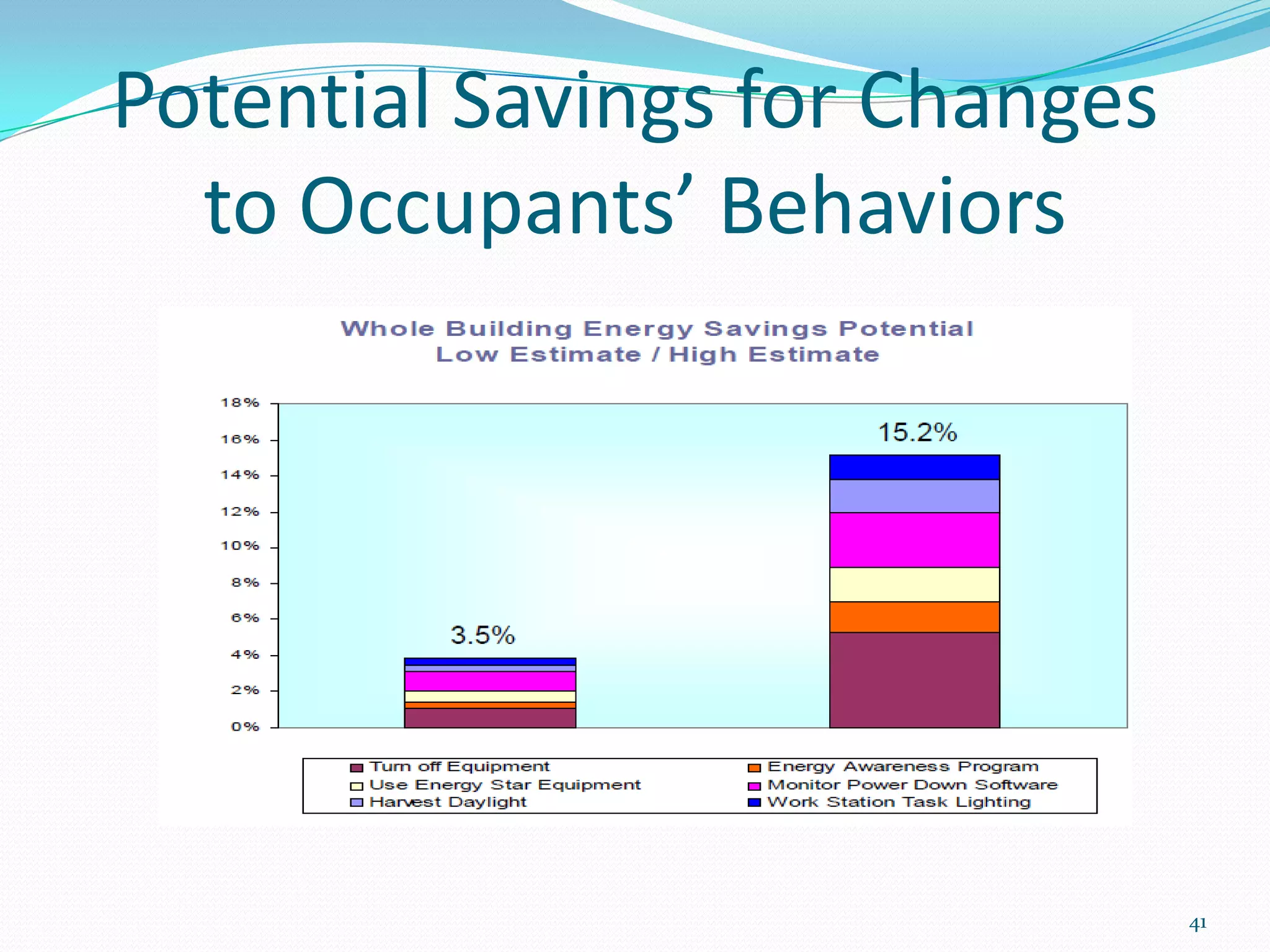

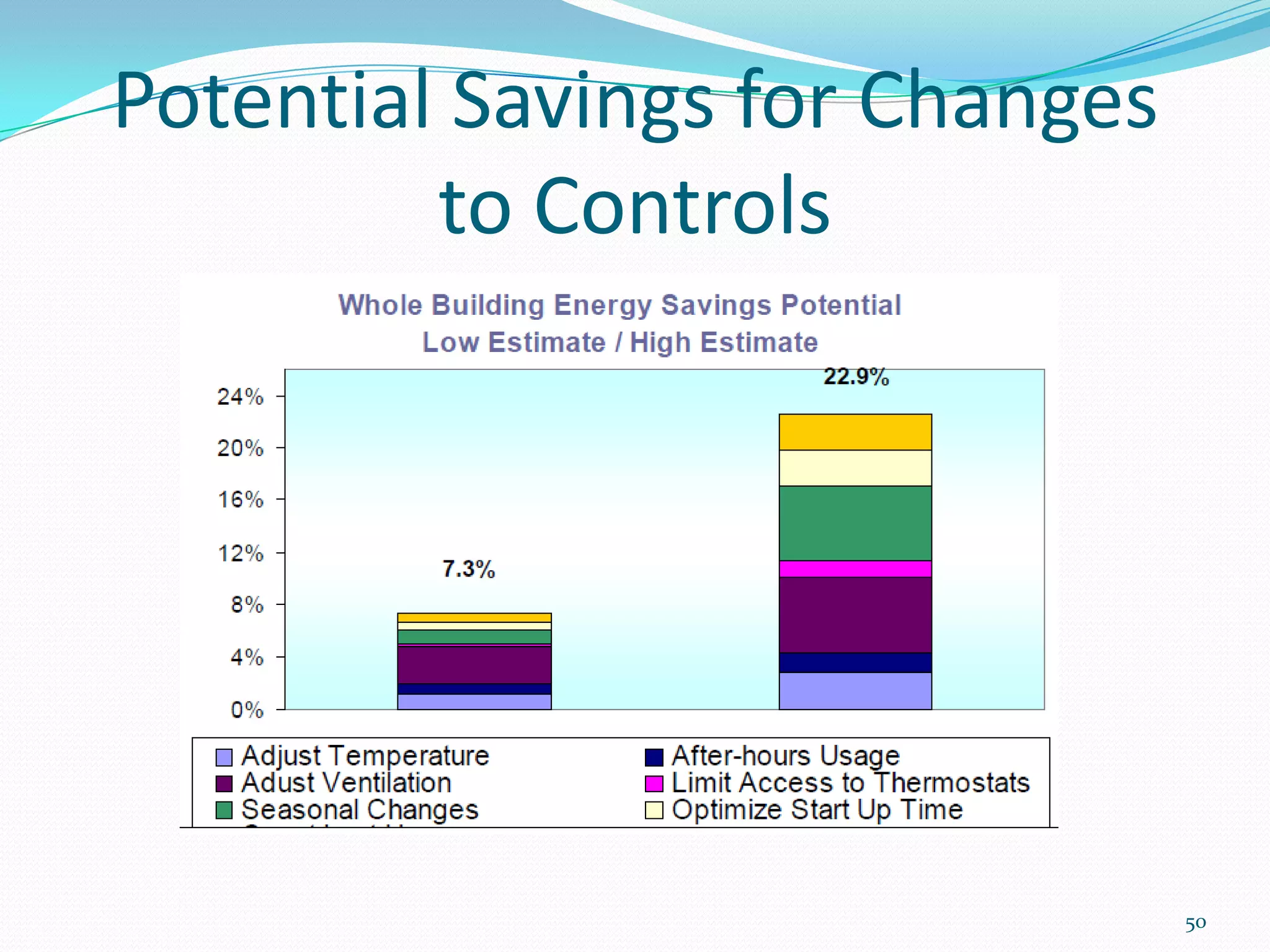

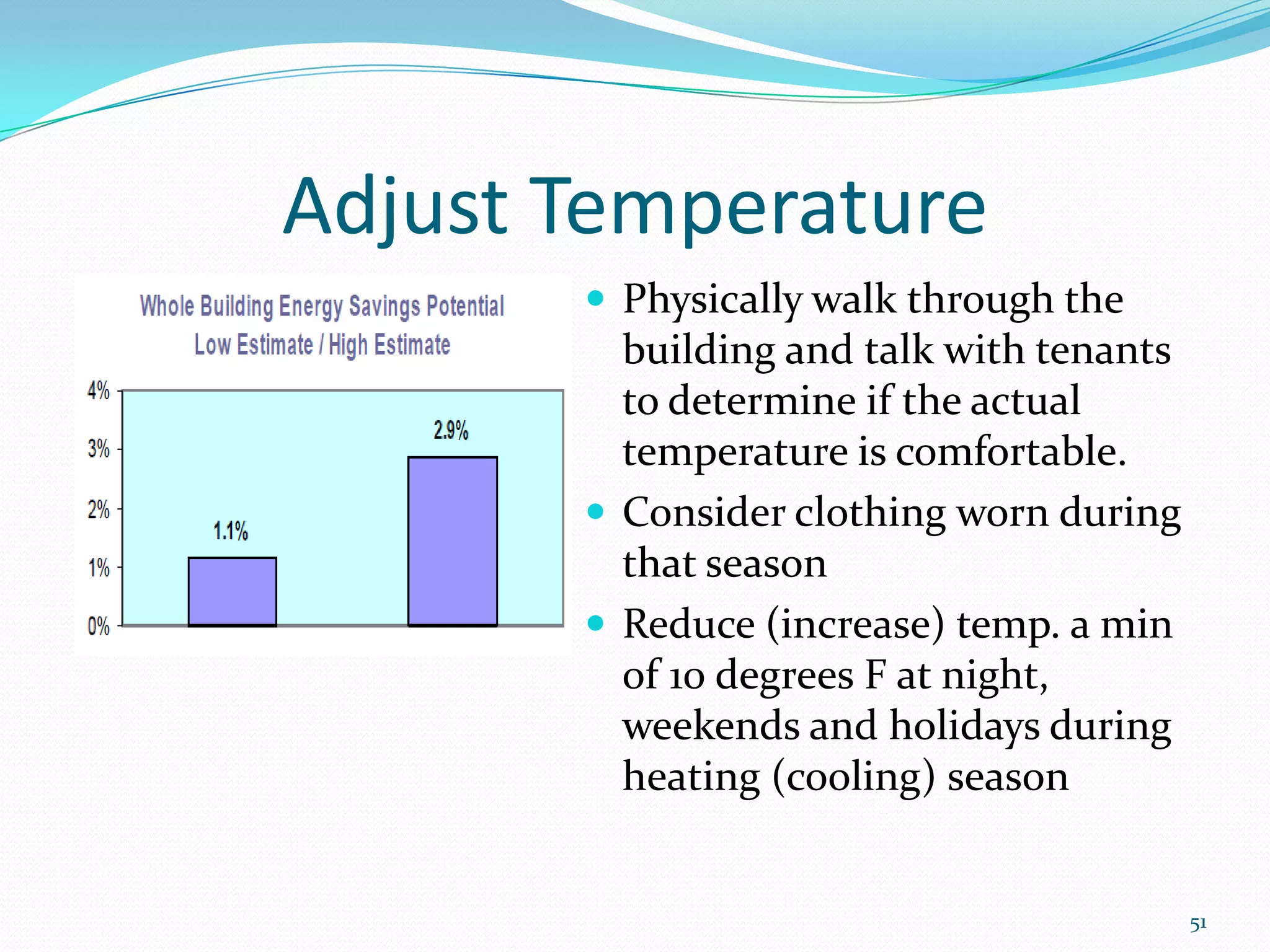

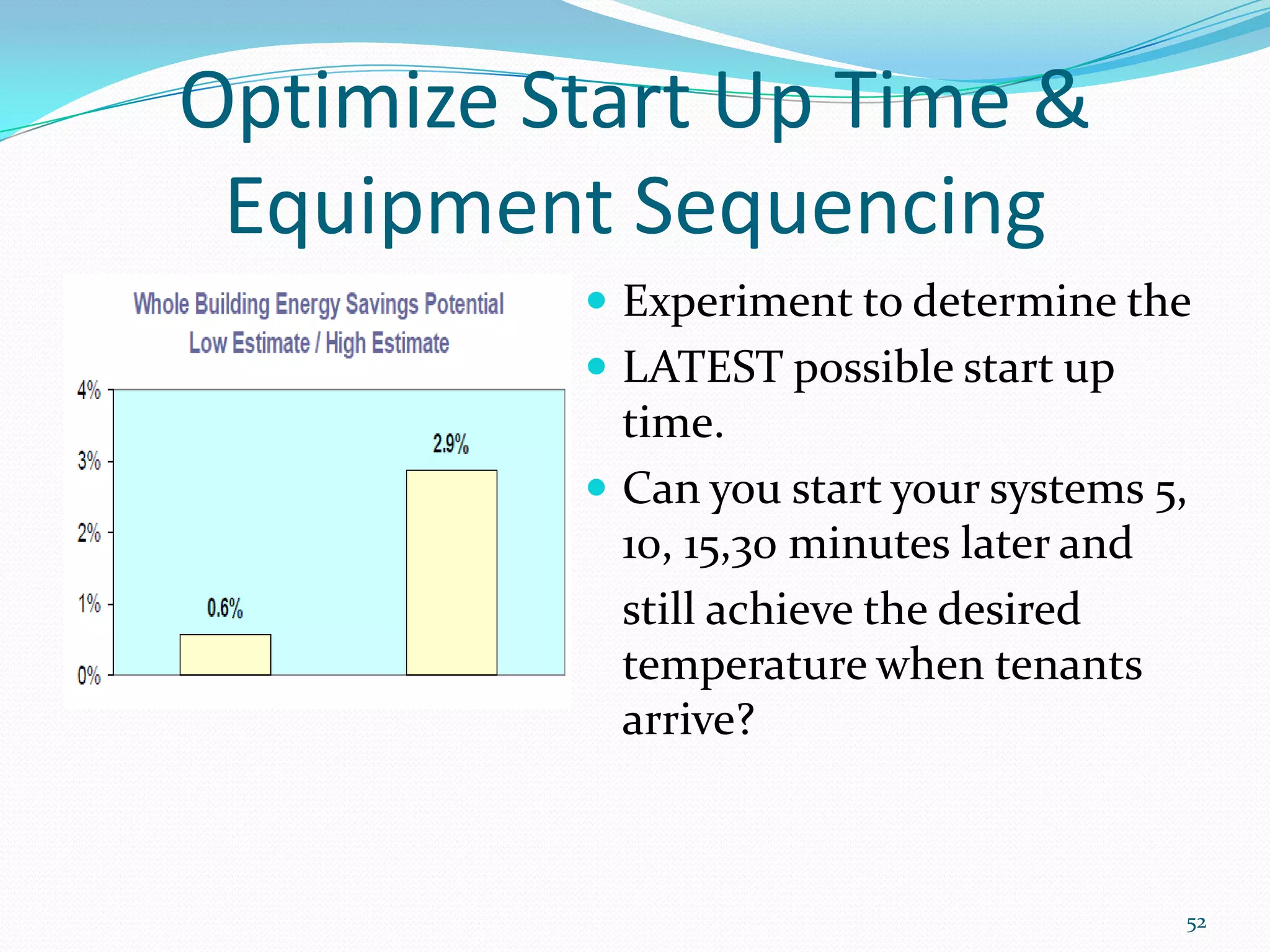

The document provides an overview of energy management for school districts. It discusses making the case for energy efficiency by outlining signs of energy waste in schools and potential savings from effective management. It also covers understanding energy bills, renewable technologies, funding opportunities, and developing an energy management plan. The key points are identifying low-cost opportunities to reduce costs, benchmarking to compare performance, and leveraging various funding sources like NYSERDA and utility programs.