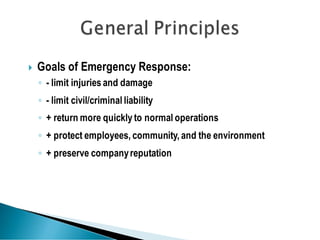

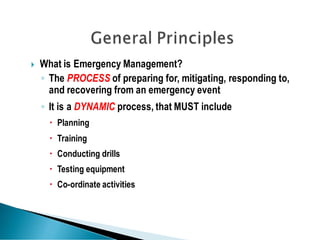

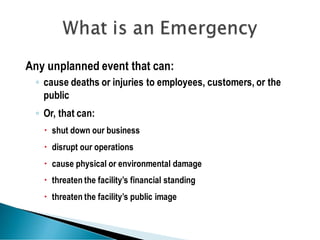

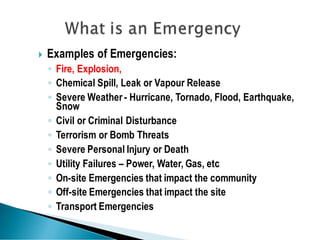

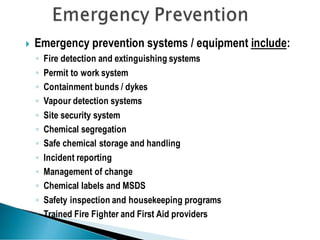

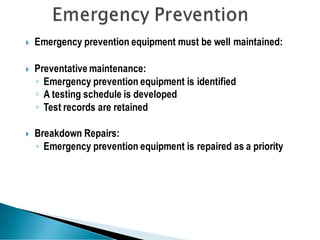

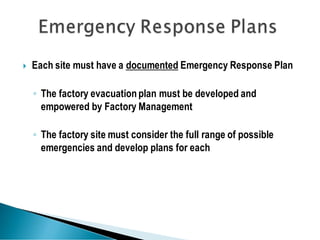

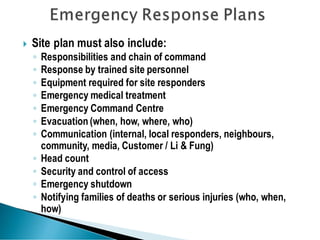

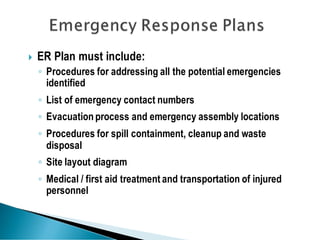

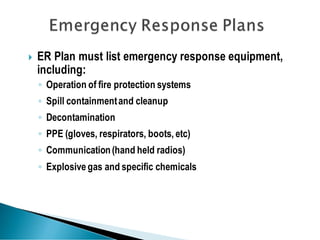

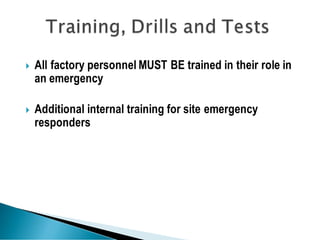

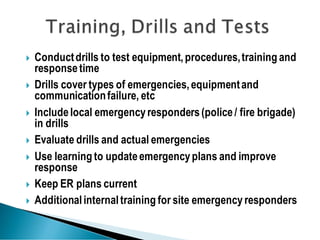

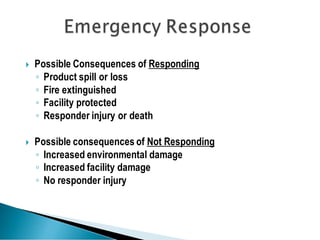

This document outlines essential aspects of emergency management, emphasizing the importance of preparation, prevention, and response planning in mitigating the effects of emergencies. It details the types of emergencies, the necessary prevention equipment, and the key elements that should be included in an emergency response plan, such as responsibilities, communication, and training. Regular drills and updates to the emergency plans are critical for effective response and minimizing potential damages.