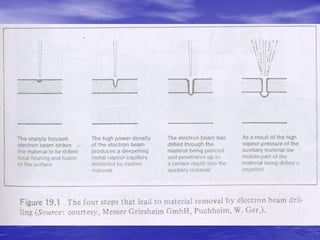

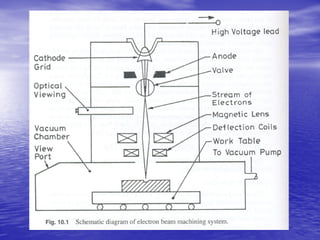

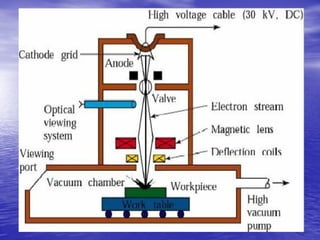

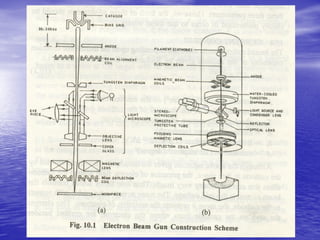

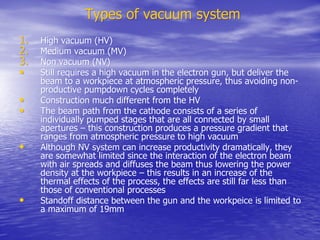

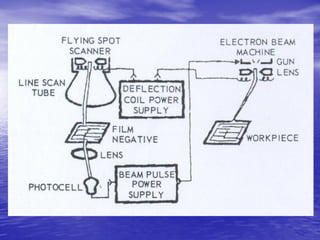

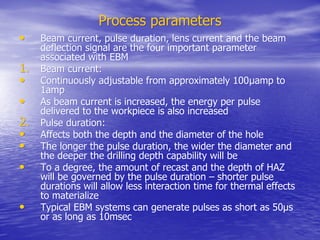

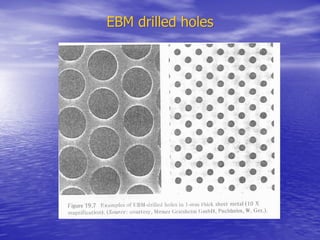

Electron Beam Machining (EBM) is a thermal material removal process that uses a focused beam of high-velocity electrons to perform high-speed drilling and cutting. It was invented in Germany in 1952. EBM utilizes an electron beam gun to generate, shape, and deflect an electron beam to drill or machine a workpiece. Key process parameters include beam current, pulse duration, lens current, and beam deflection signal, which control the energy delivered to the workpiece and characteristics of the drilled holes such as diameter and depth. EBM provides advantages such as high drilling speeds, ability to drill small holes, and no required mechanical contact force.