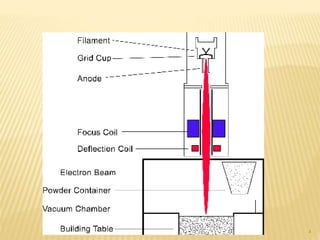

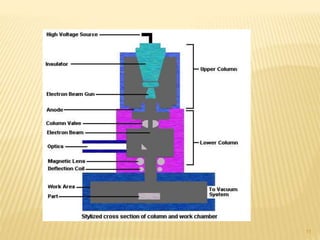

This document discusses electron beam machining (EBM). EBM uses a focused beam of high-velocity electrons to melt and vaporize material from a workpiece. It operates within a vacuum chamber at pressures of 10^-5 mm Hg. The electron gun generates the beam using a tungsten filament, grid cup, and anode. The beam is focused by electromagnetic lenses and its path is controlled by deflector coils. EBM can machine any material, achieves close tolerances with no tool wear, and concentrates heat at a small spot. However, it requires high vacuum and power while providing a low material removal rate. Applications include microdrilling and machining materials with low thermal conductivity.