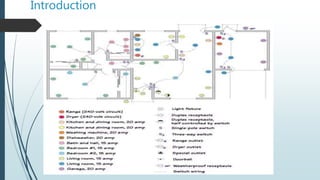

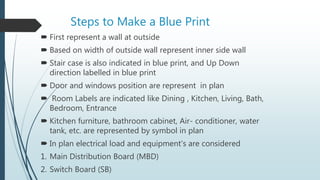

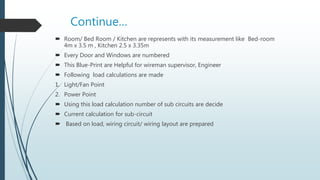

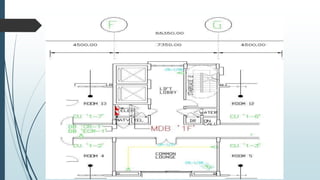

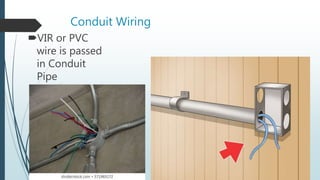

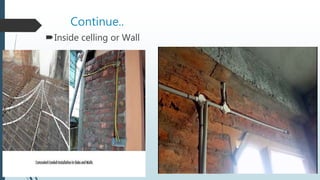

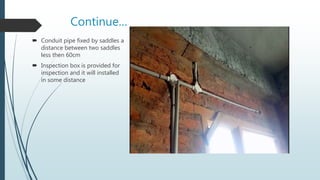

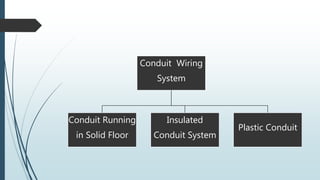

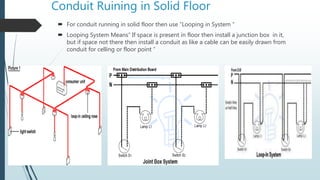

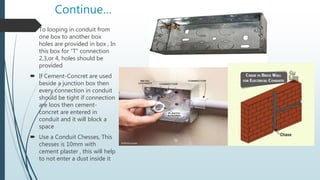

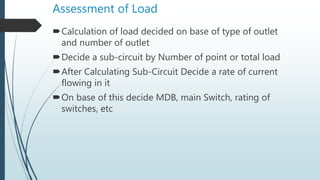

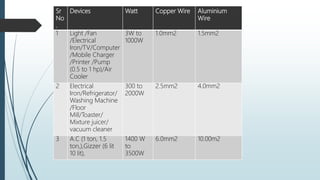

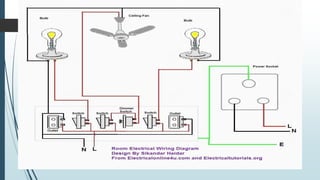

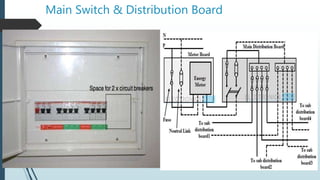

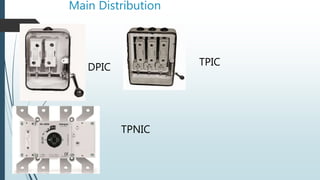

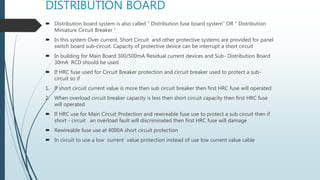

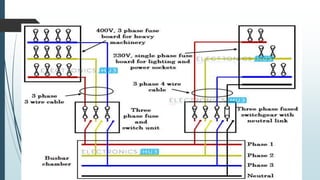

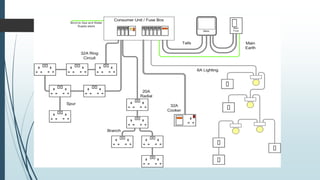

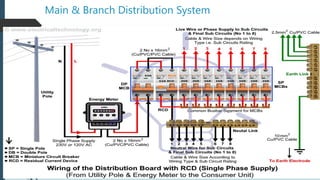

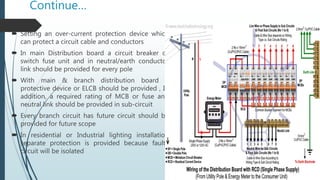

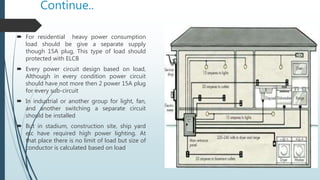

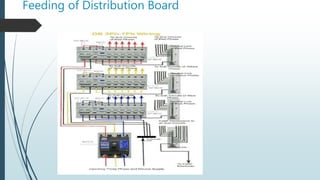

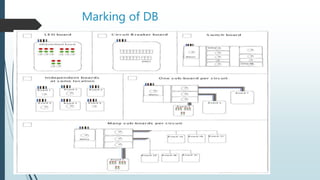

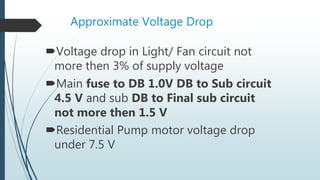

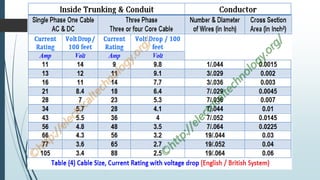

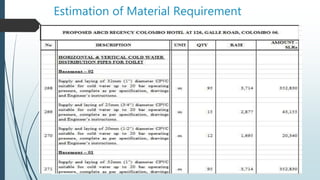

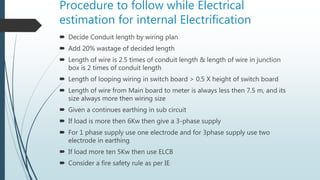

This document provides information about electrical installation planning and wiring layout for multistorey buildings. It discusses how to create a wiring blueprint based on the building plan, including indicating loads, distribution boards, outlets and wiring routes. It also covers calculating the electrical load and number of circuits, sizing cables and conductors, and preparing an estimation of materials. Proper wiring layout allows electricians to easily install wiring according to the diagram. Distribution boards are also summarized, including types, installation procedures and protection devices.