1) Construction equipment productivity refers to the time equipment is productively working, and higher productivity means tasks can be completed more efficiently. Poor productivity increases unexpected costs and budget overruns.

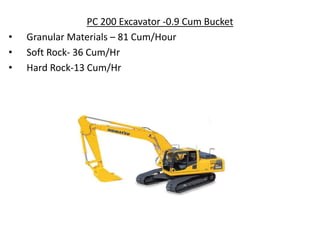

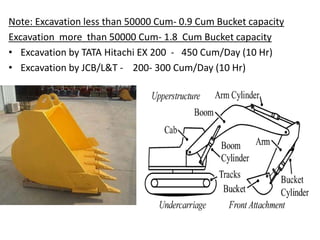

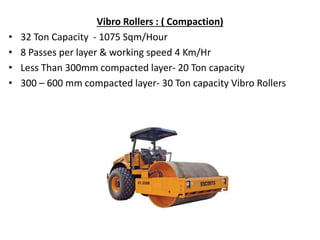

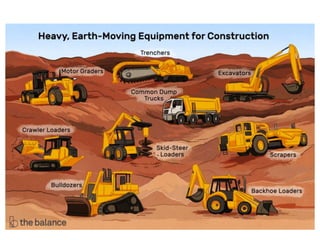

2) The document provides productivity rates for various pieces of heavy construction equipment processing different materials, such as a 32-ton bulldozer moving 83 cubic meters of earth per hour.

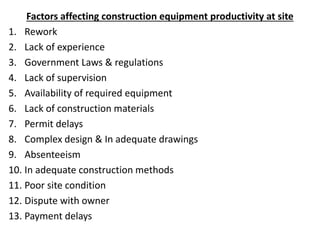

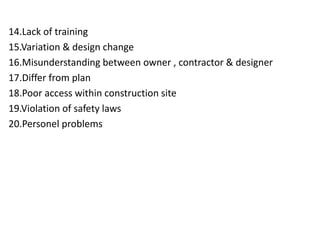

3) It also lists factors that affect productivity like rework, lack of experience, and regulatory delays, and provides tips to maximize productivity like regular maintenance, trained operators, and following safety guidelines.