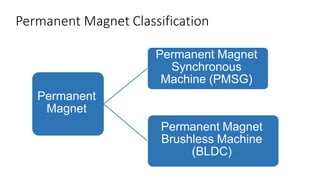

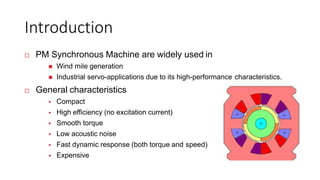

The permanent magnet synchronous generator uses permanent magnets on the rotor instead of an external excitation source. It has a simpler design without slip rings or brushes. These generators are commonly used with wind turbines, gas turbines, and hydro turbines. They have higher efficiency than generators with electromagnetic excitation due to not having excitation losses. However, large high power permanent magnet synchronous generators can be more expensive than other types.