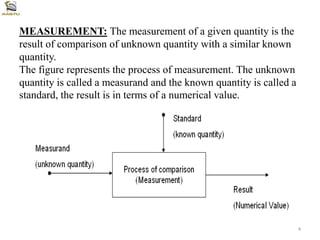

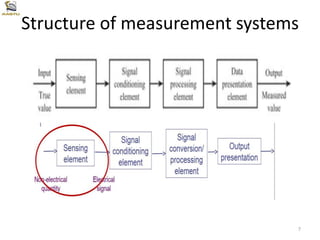

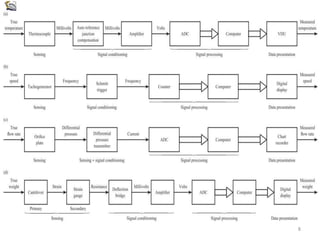

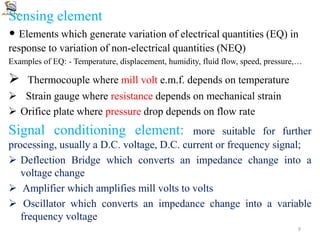

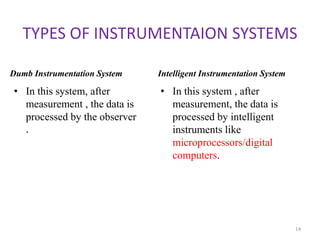

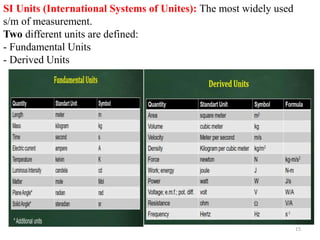

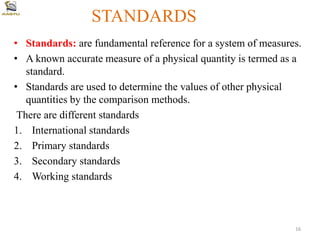

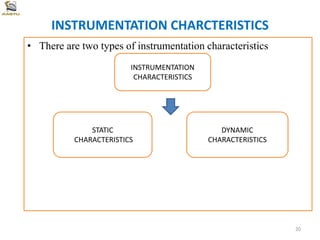

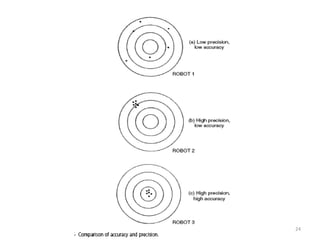

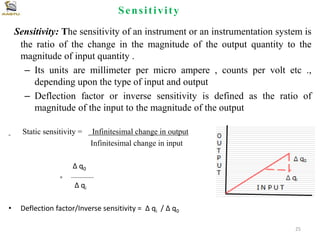

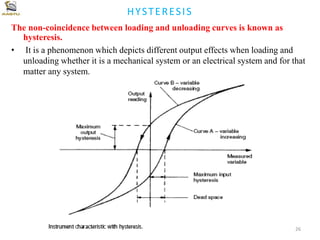

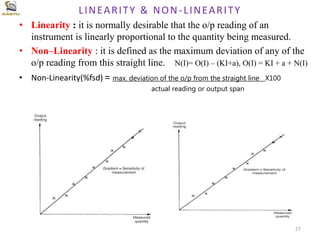

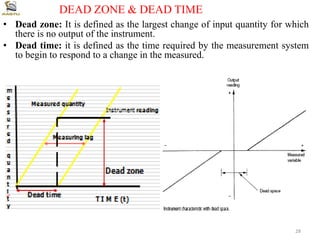

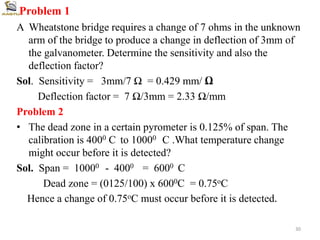

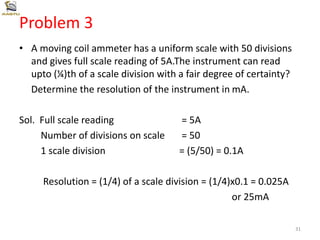

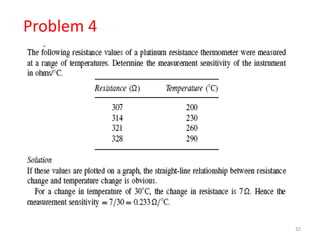

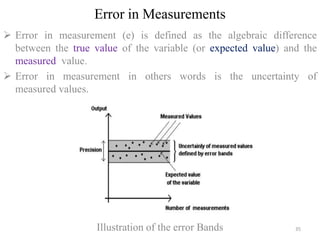

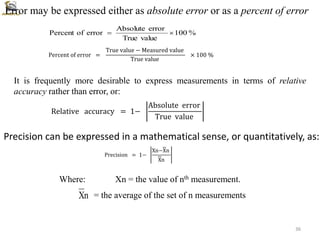

The document discusses program education objectives (PEOs) for graduates and measurement concepts. The PEOs are for graduates to become professional engineers, start their own companies, be employed in high-ranking positions, and conduct research. The document then summarizes key concepts of measurement including comparing an unknown quantity to a standard, instrumentation transforming physical variables into measurable signals, and requirements for measuring instruments. It provides examples of measurement systems and discusses static and dynamic instrument characteristics.