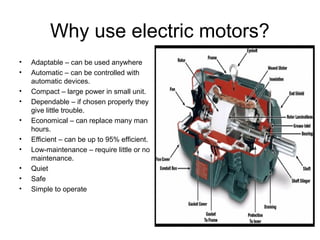

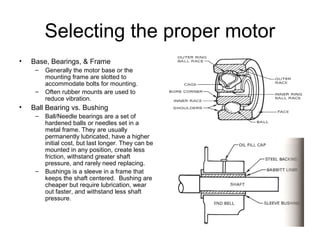

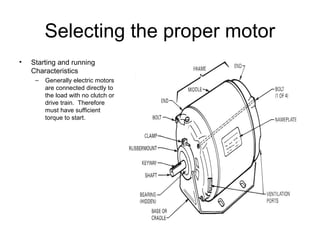

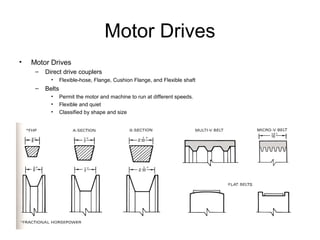

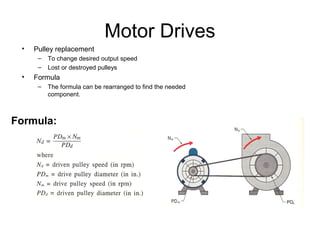

The document discusses the basics of electric motors including their advantages, factors to consider when selecting a motor such as power requirements and nameplate information, different types of motor drives including pulleys and belts, examples of calculations for determining pulley speeds and diameters, determining belt length, step pulleys, and types of motor switches. The document provides information on electric motors to help with proper selection and understanding of their operation.