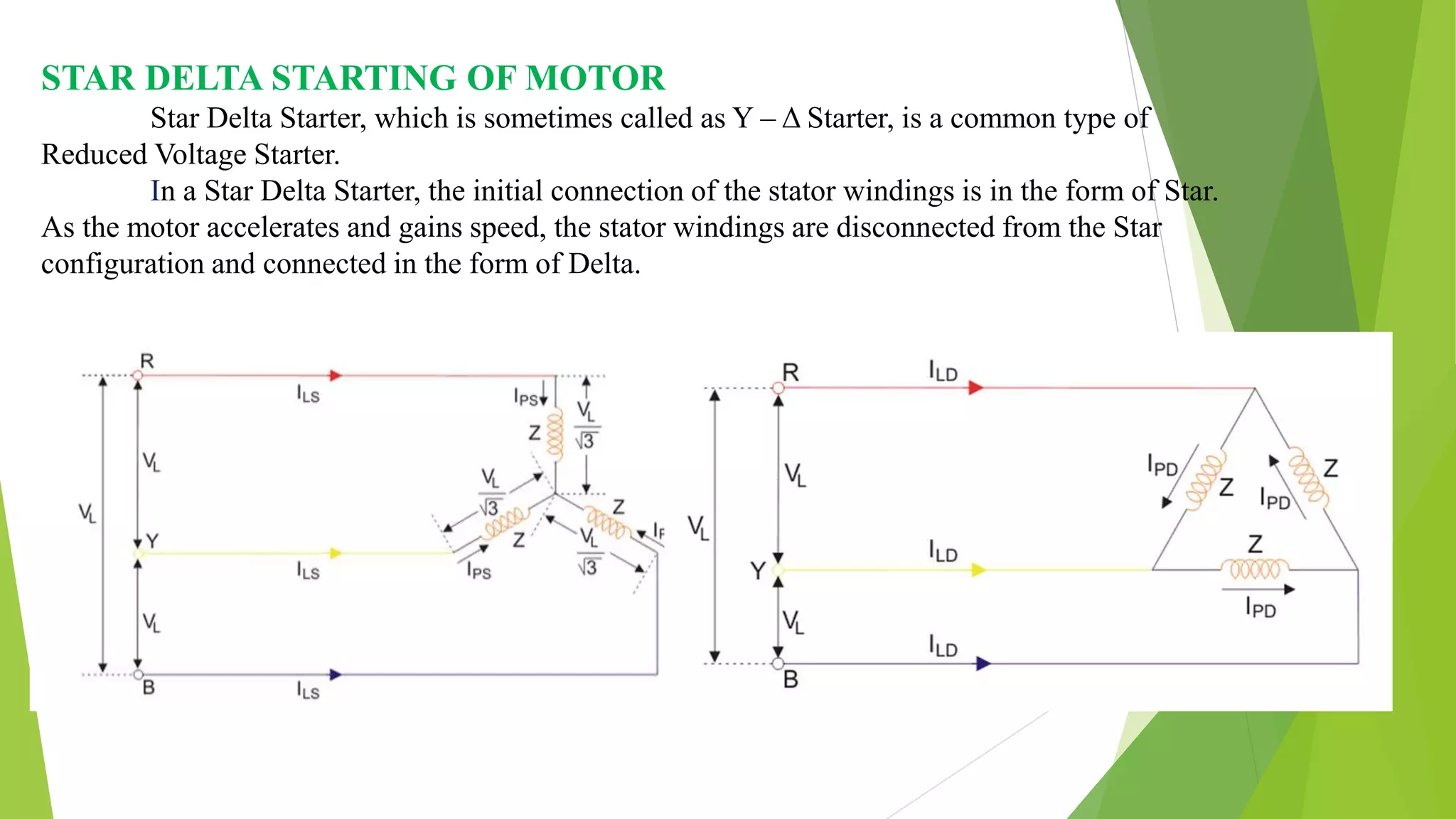

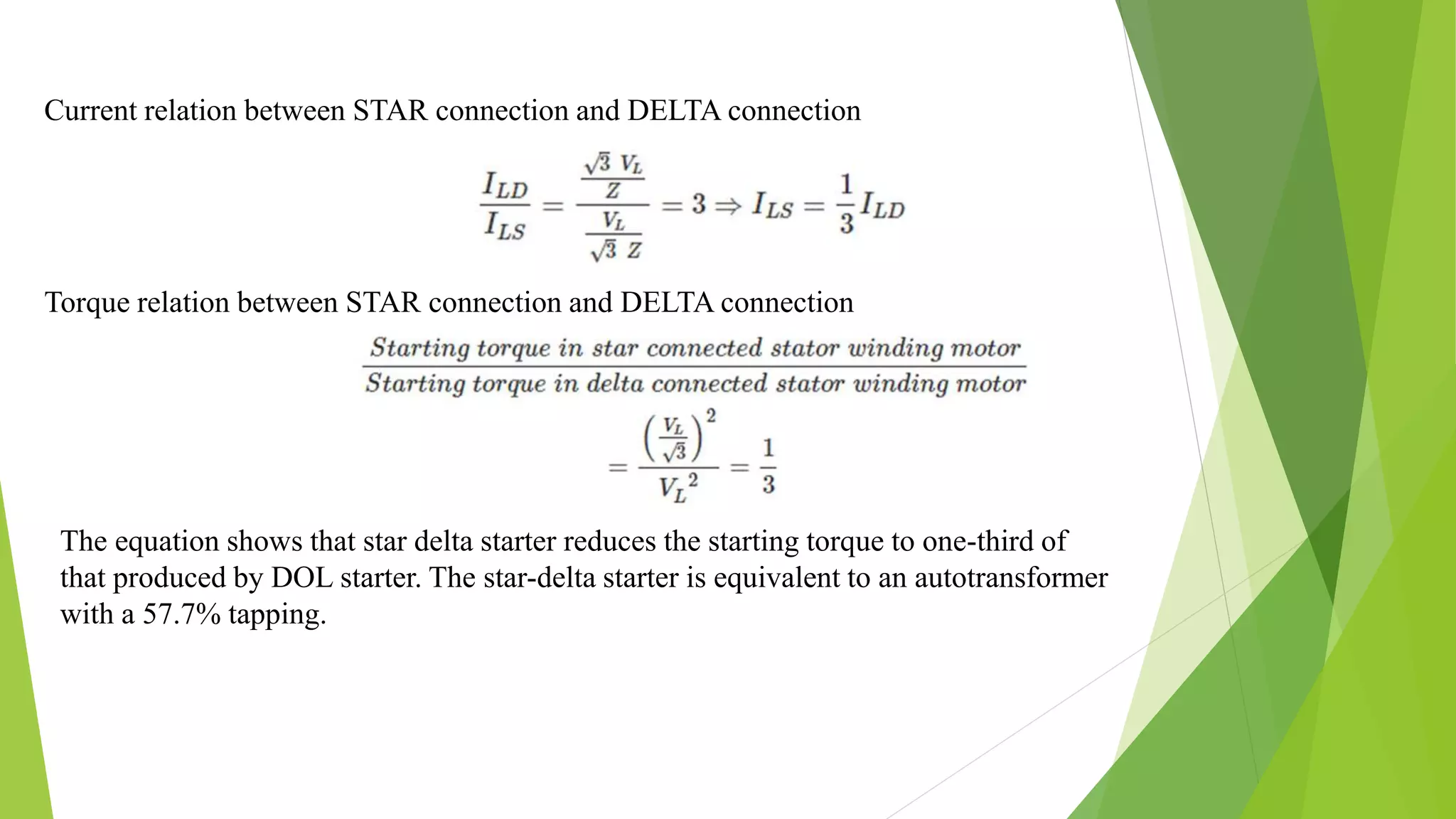

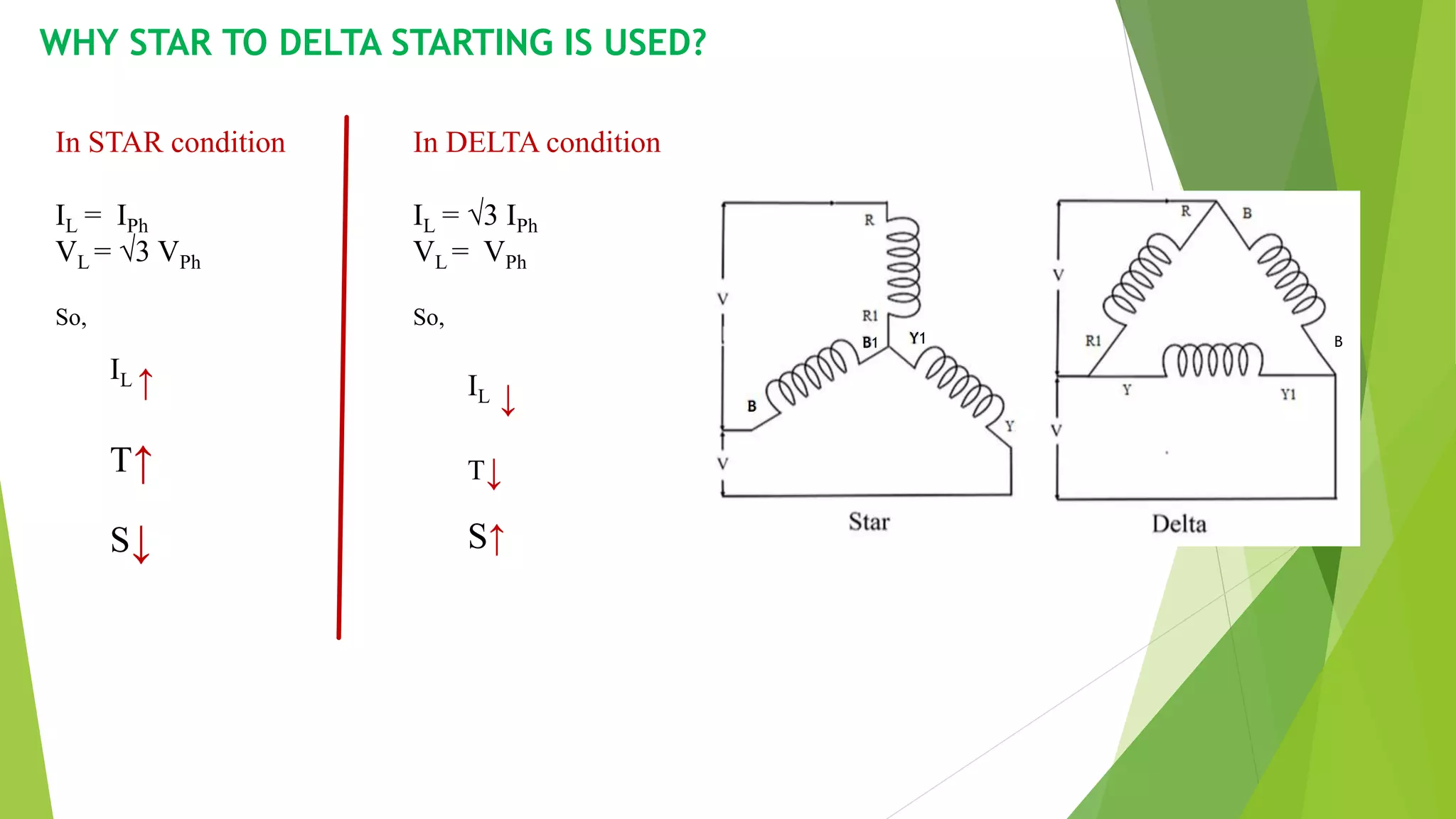

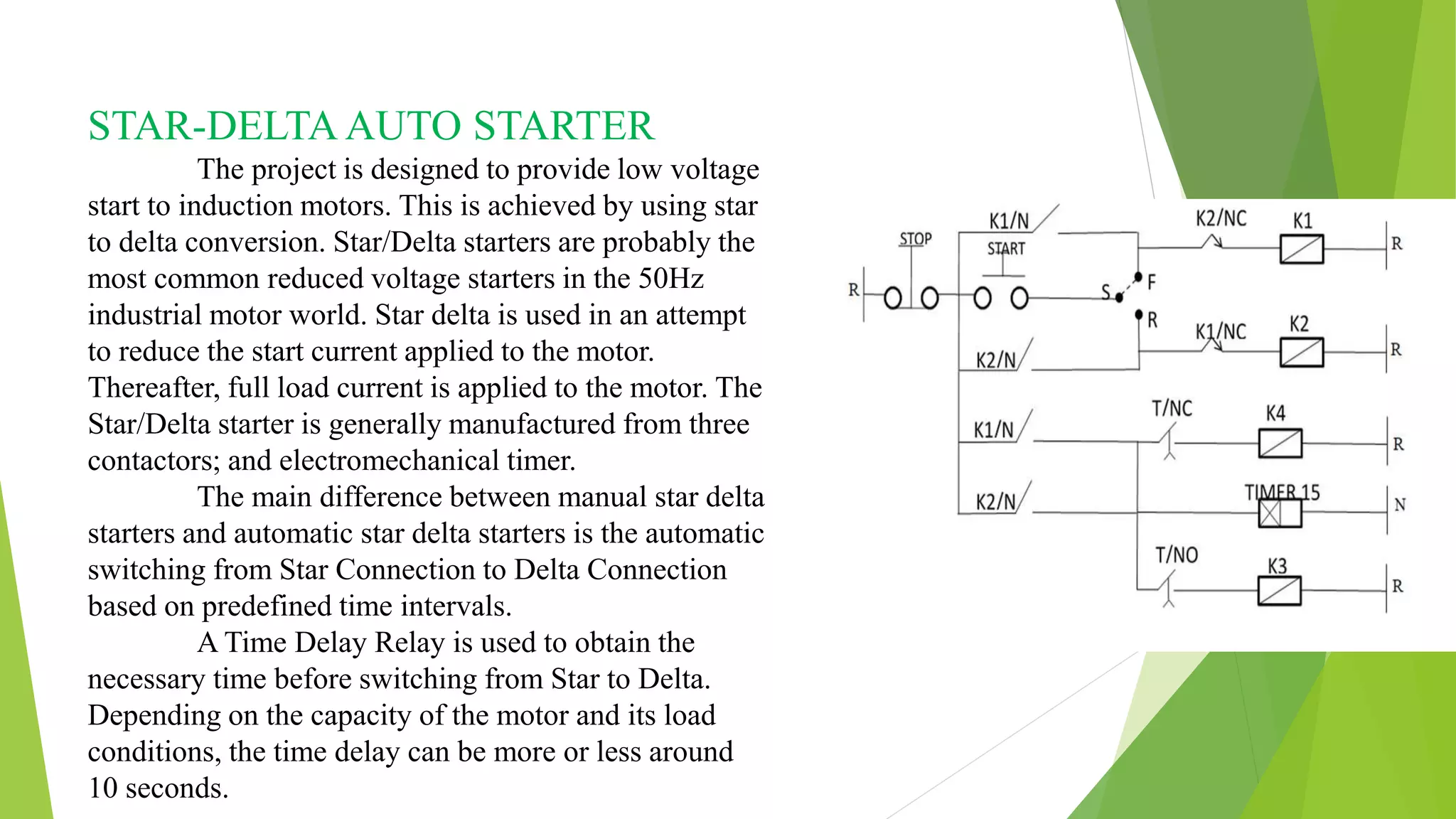

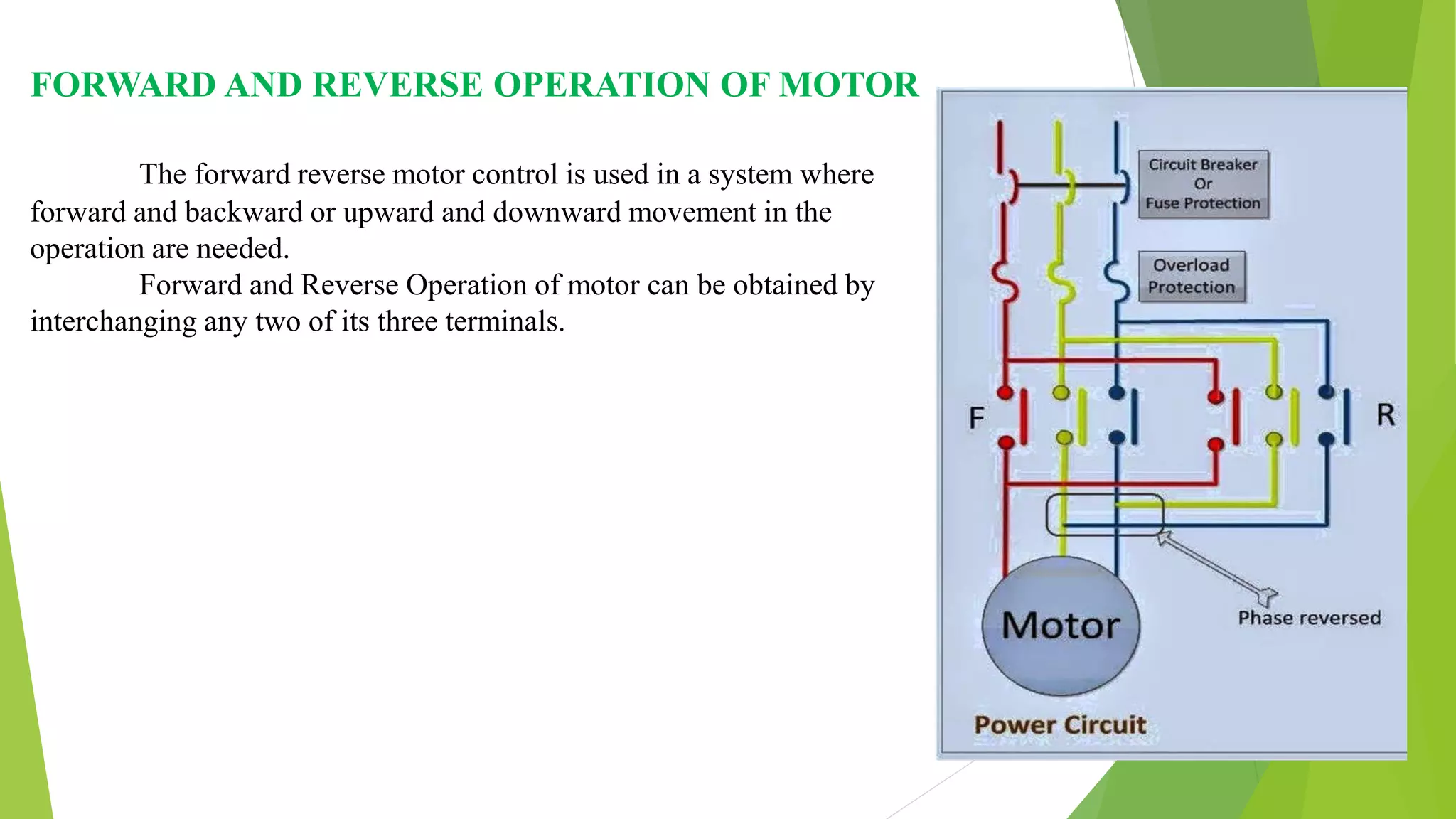

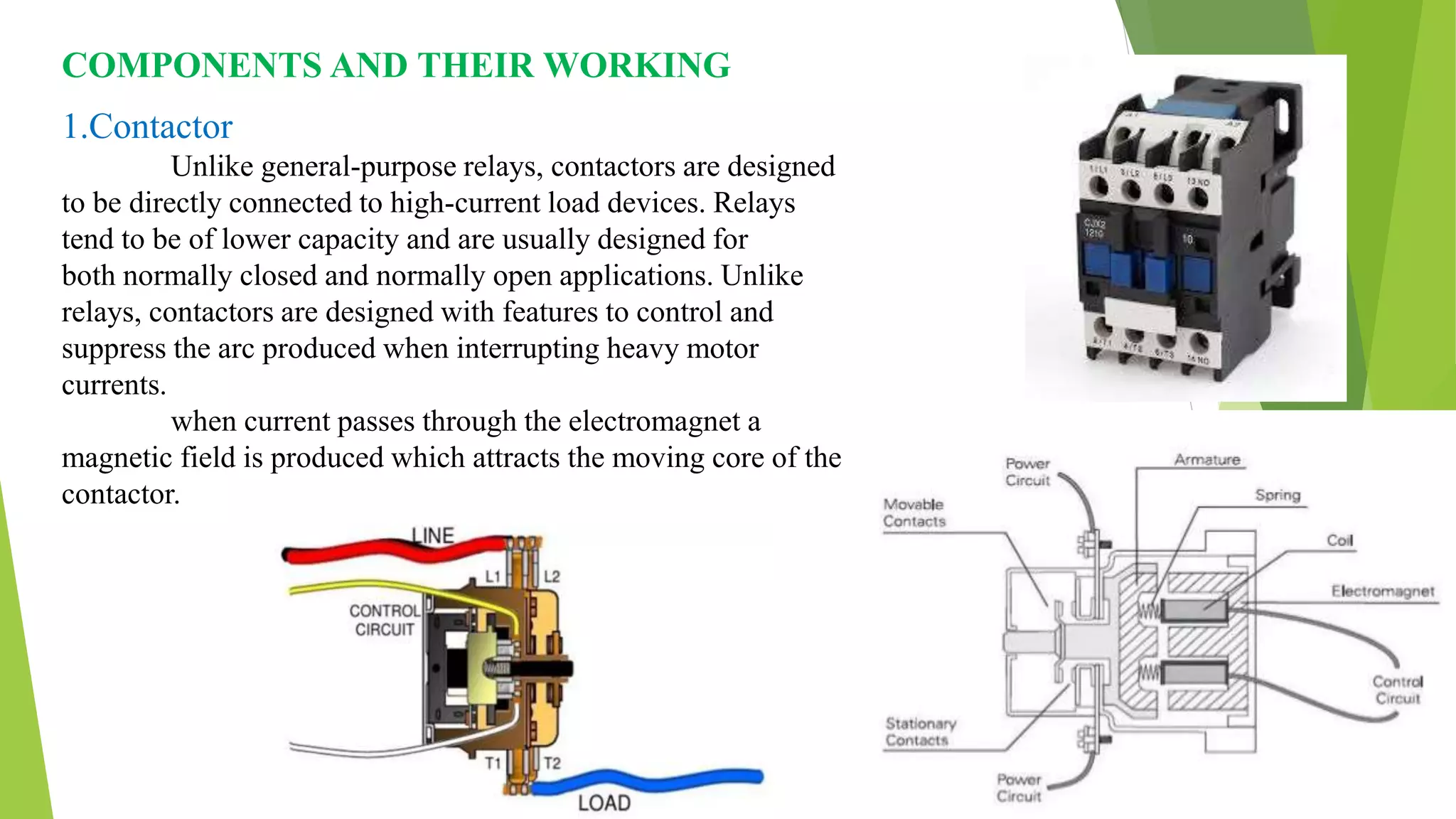

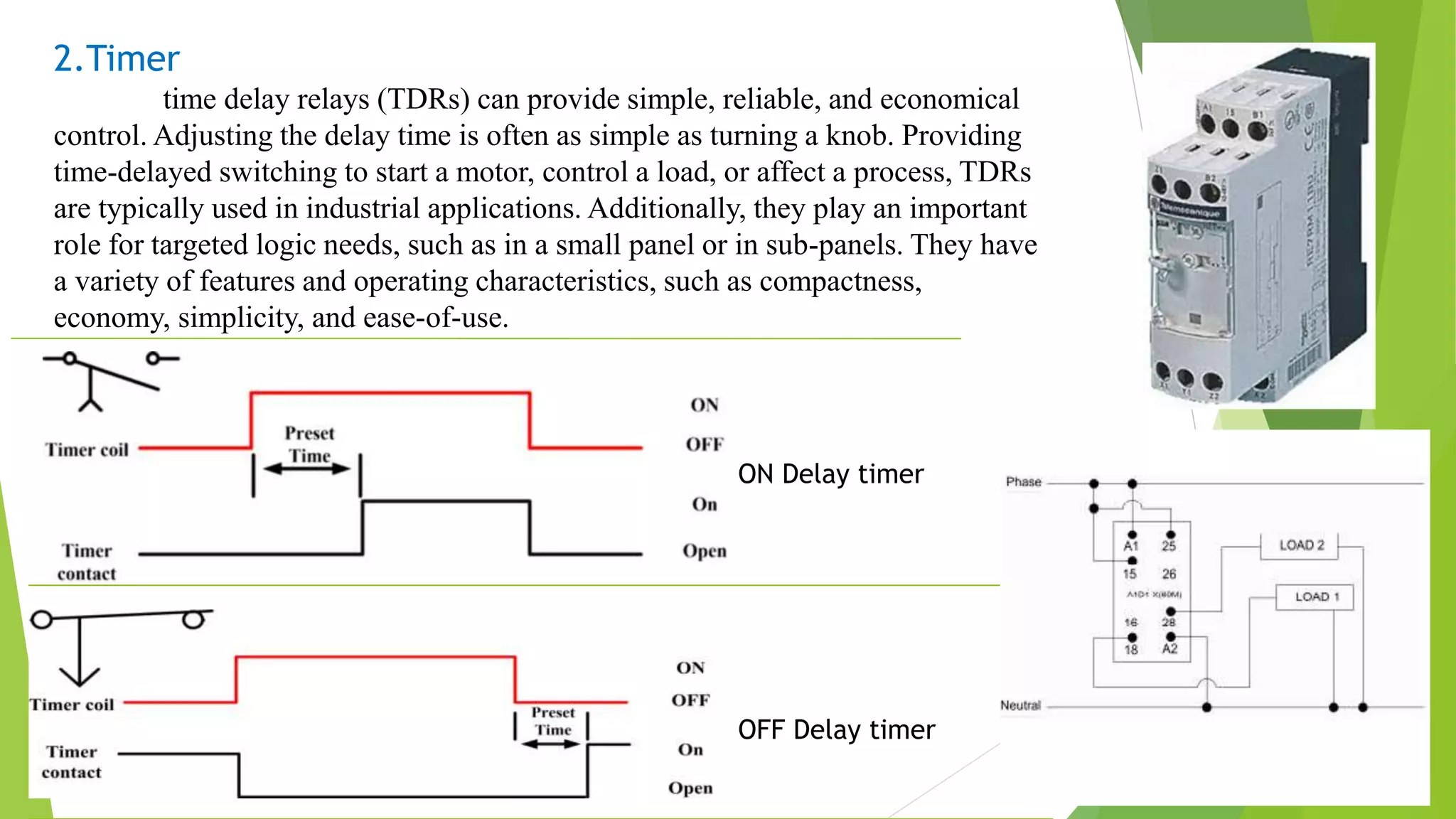

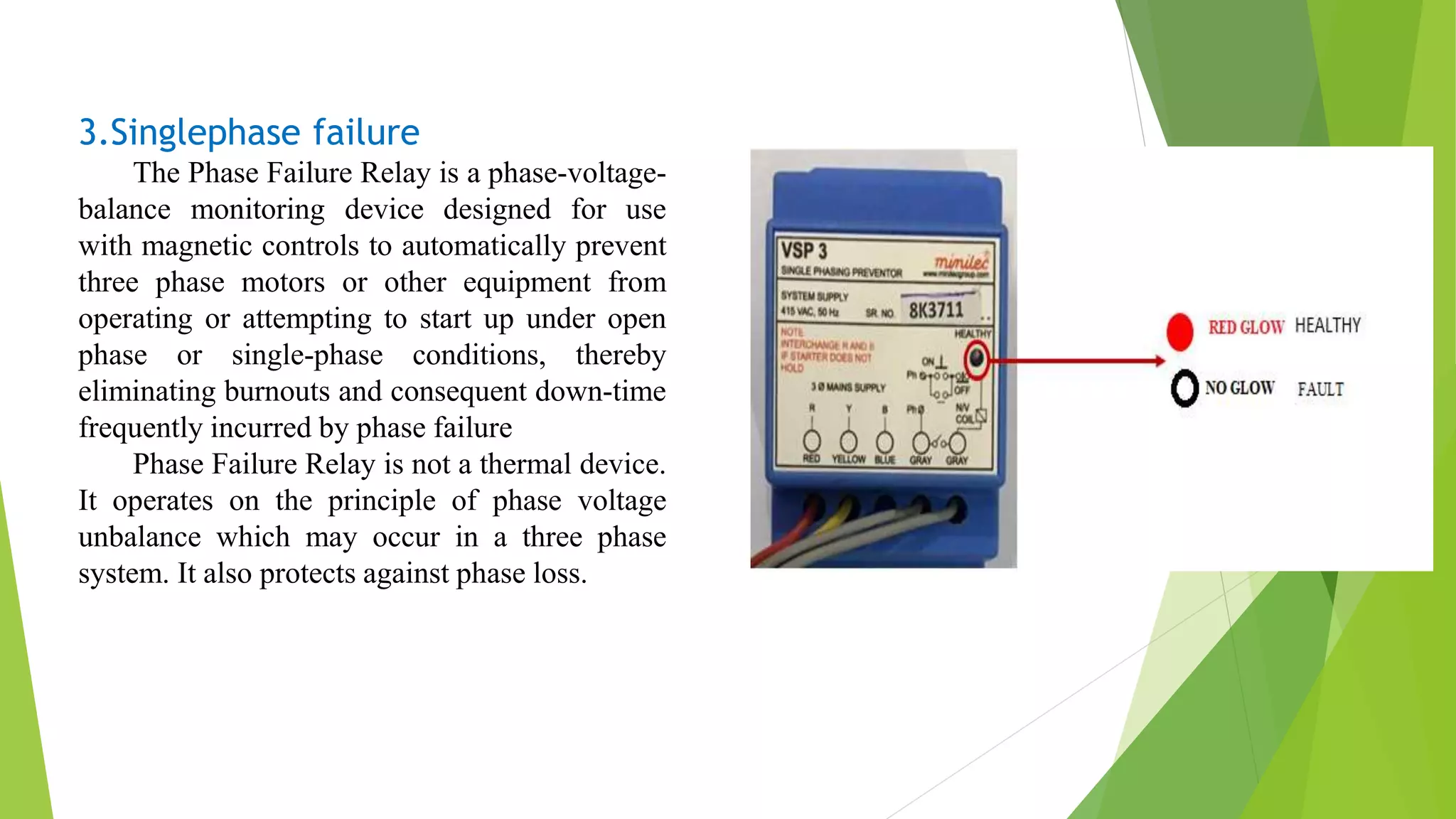

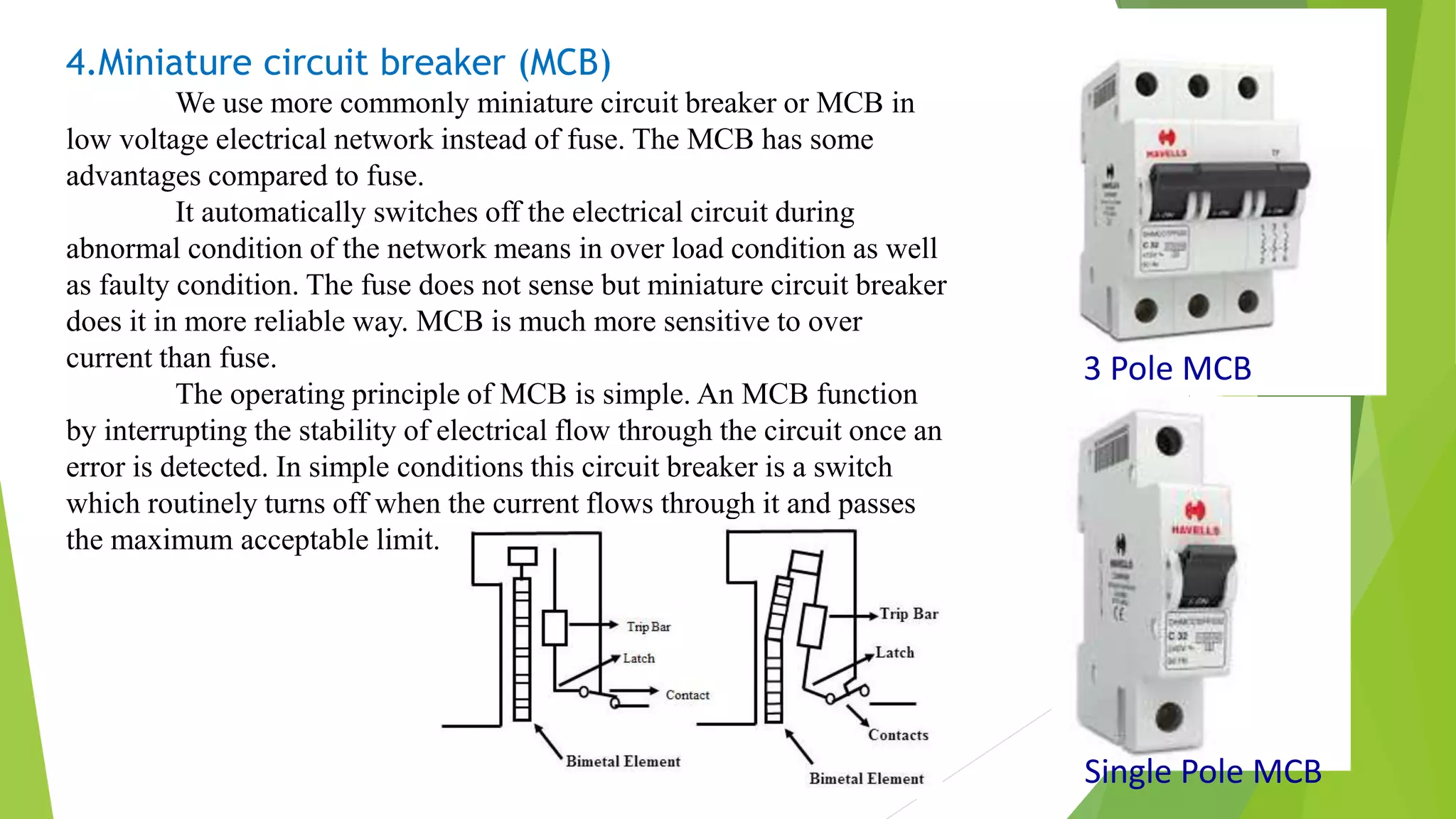

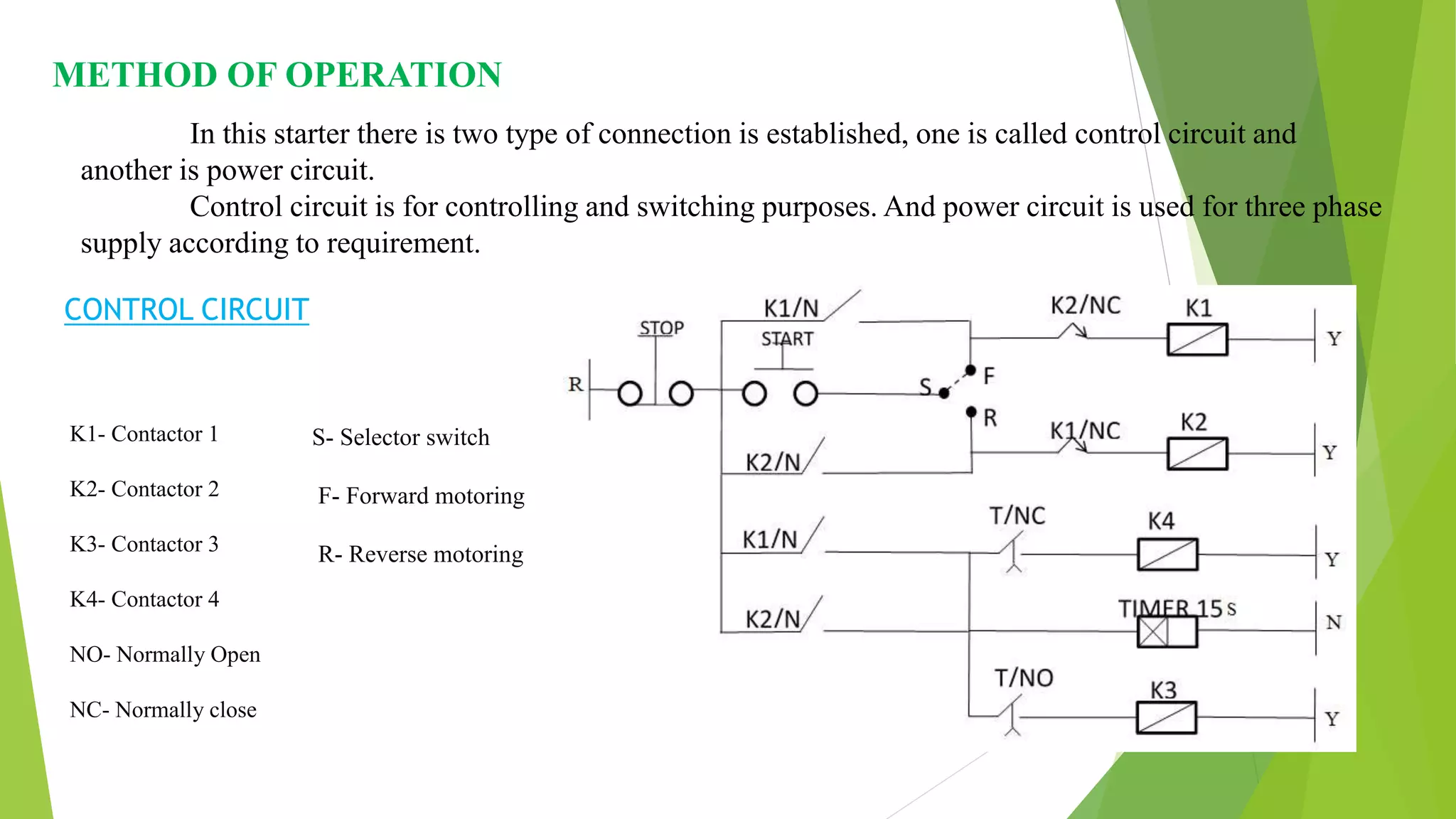

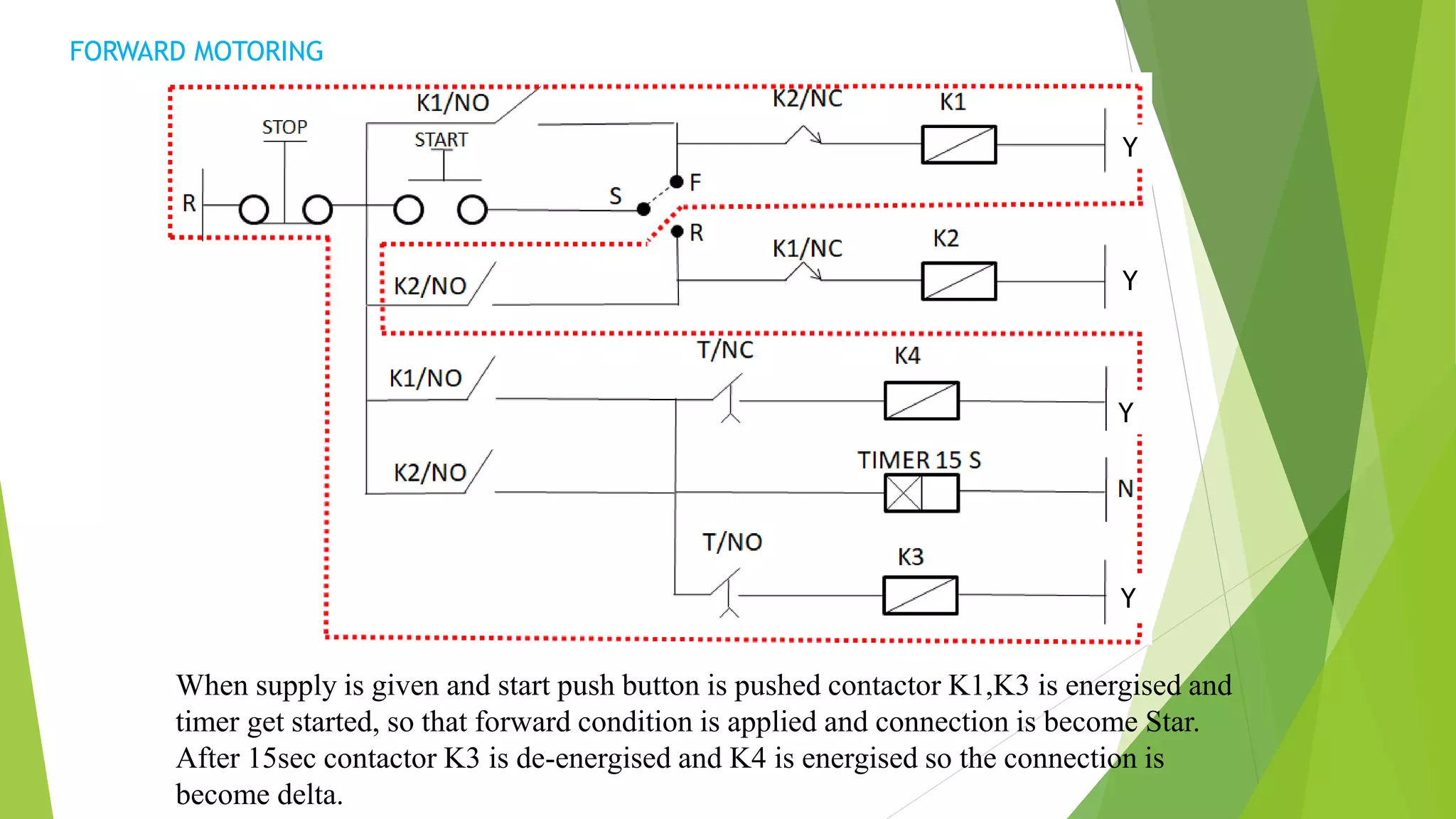

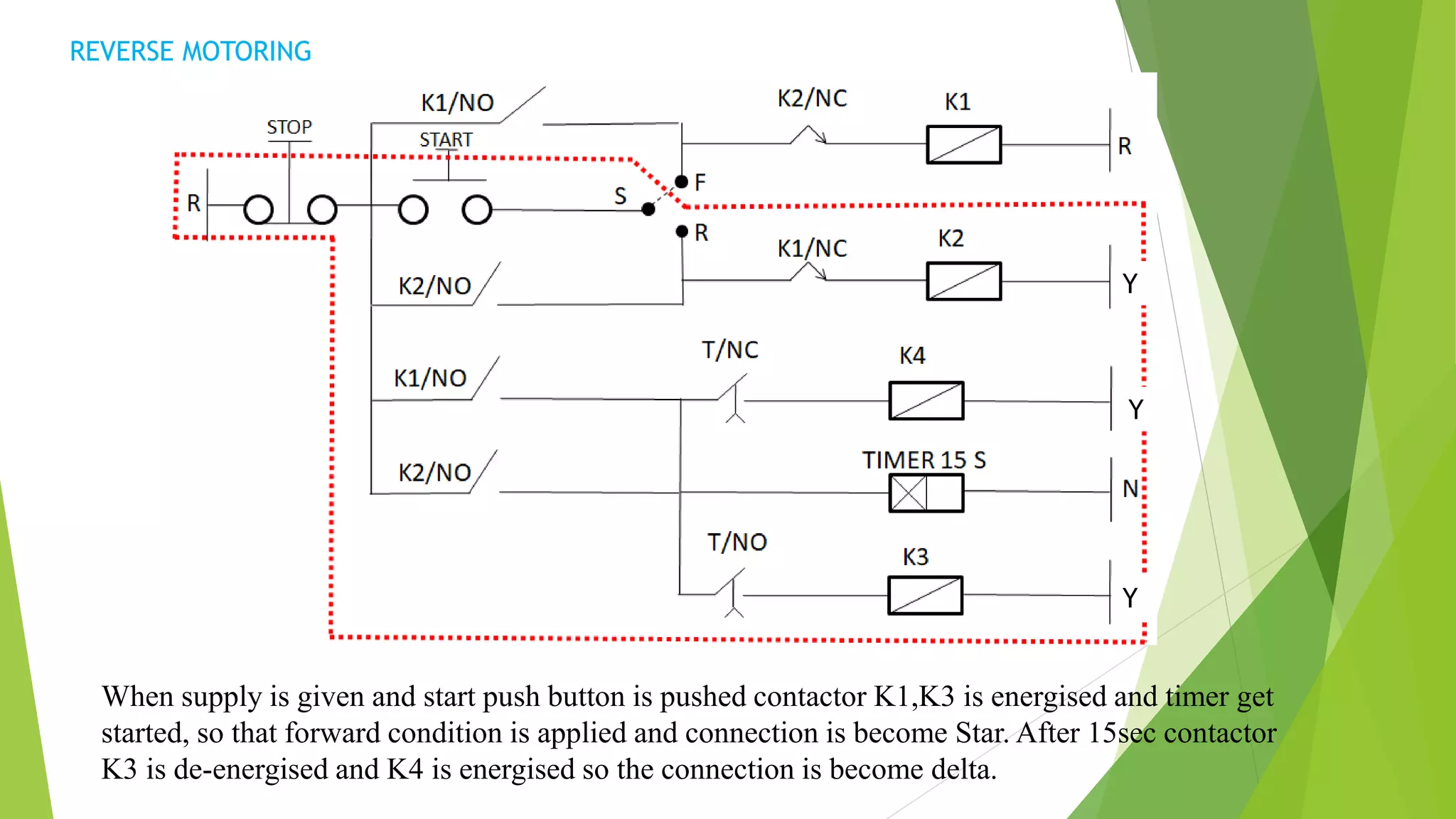

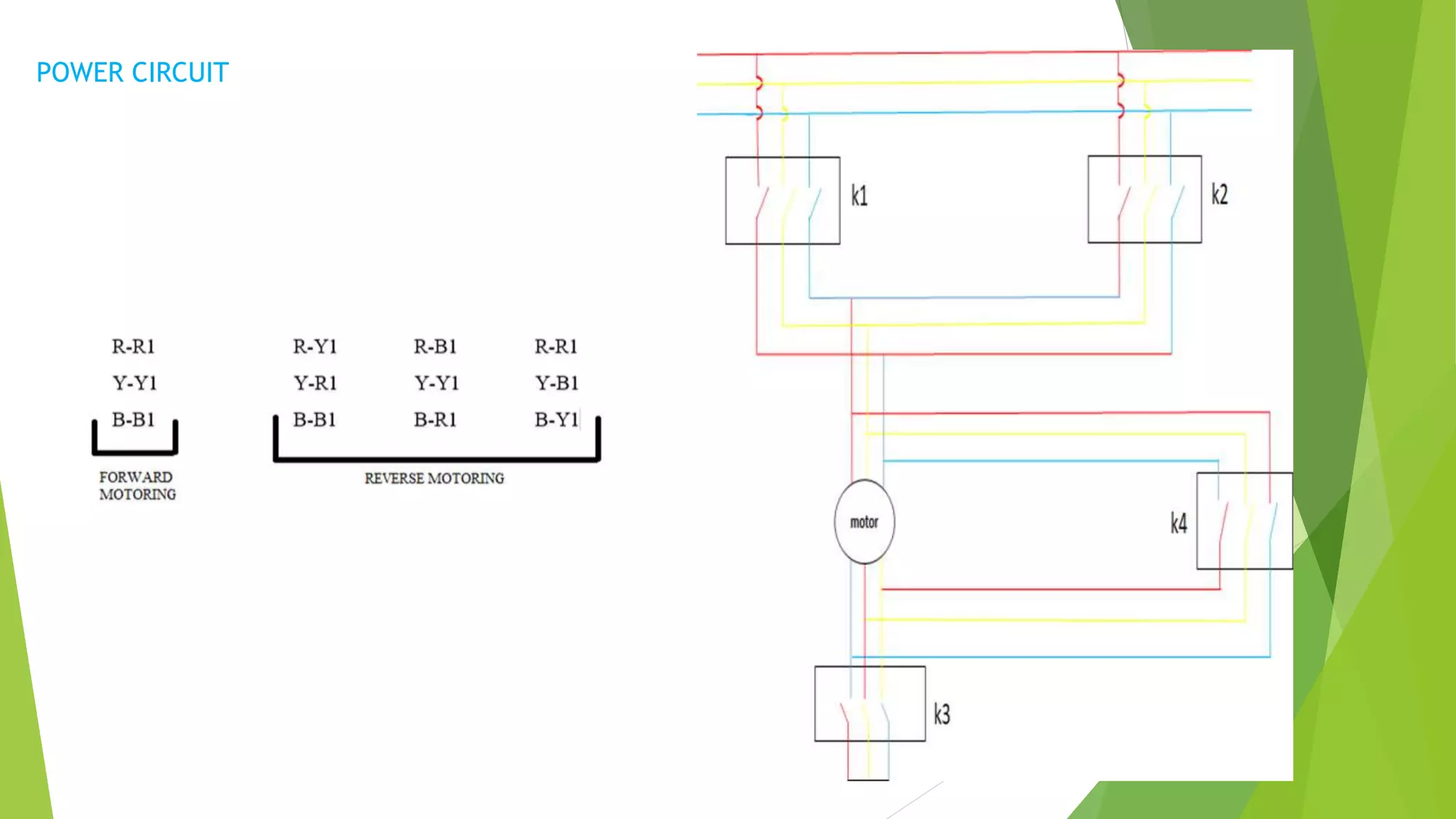

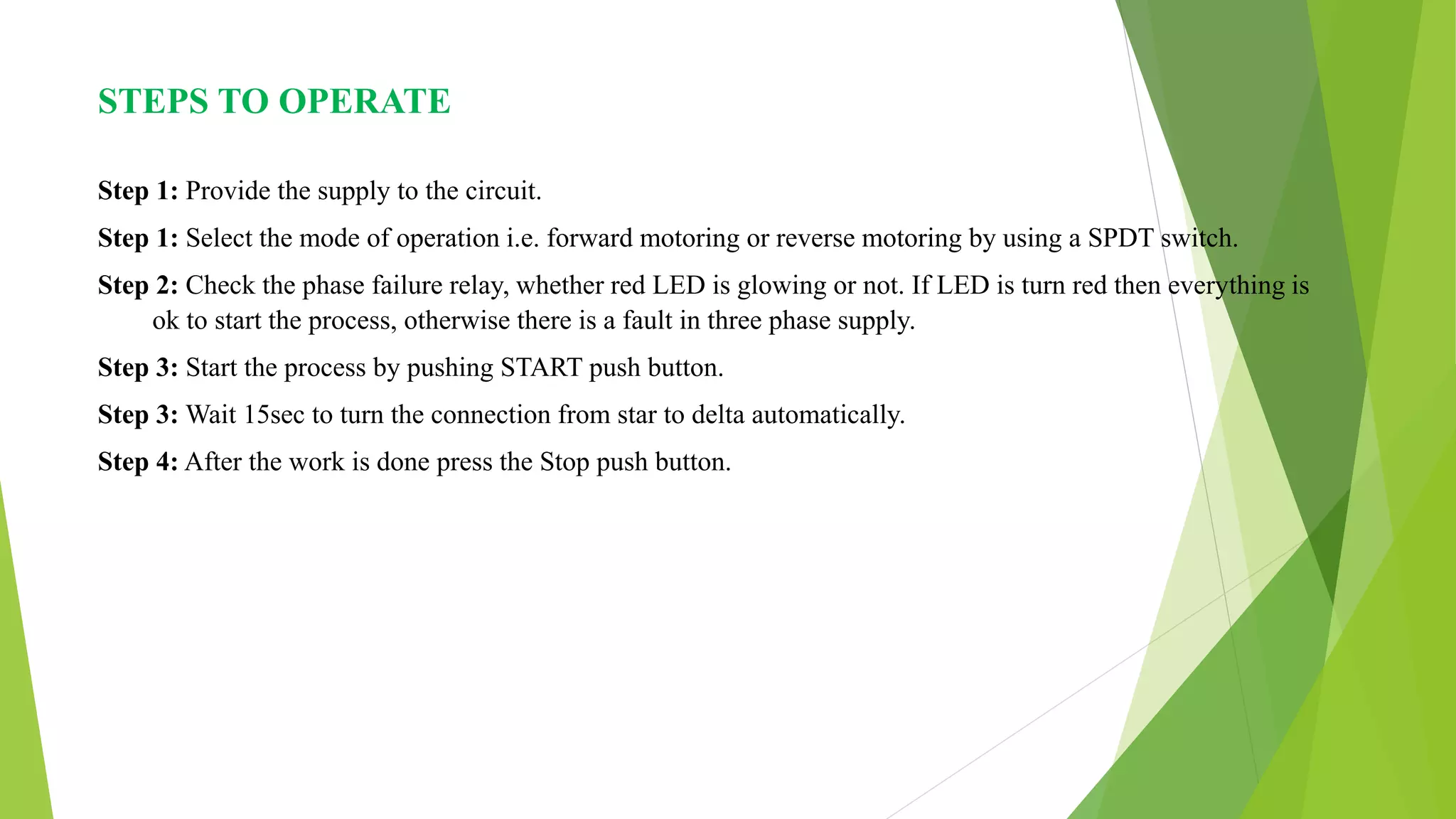

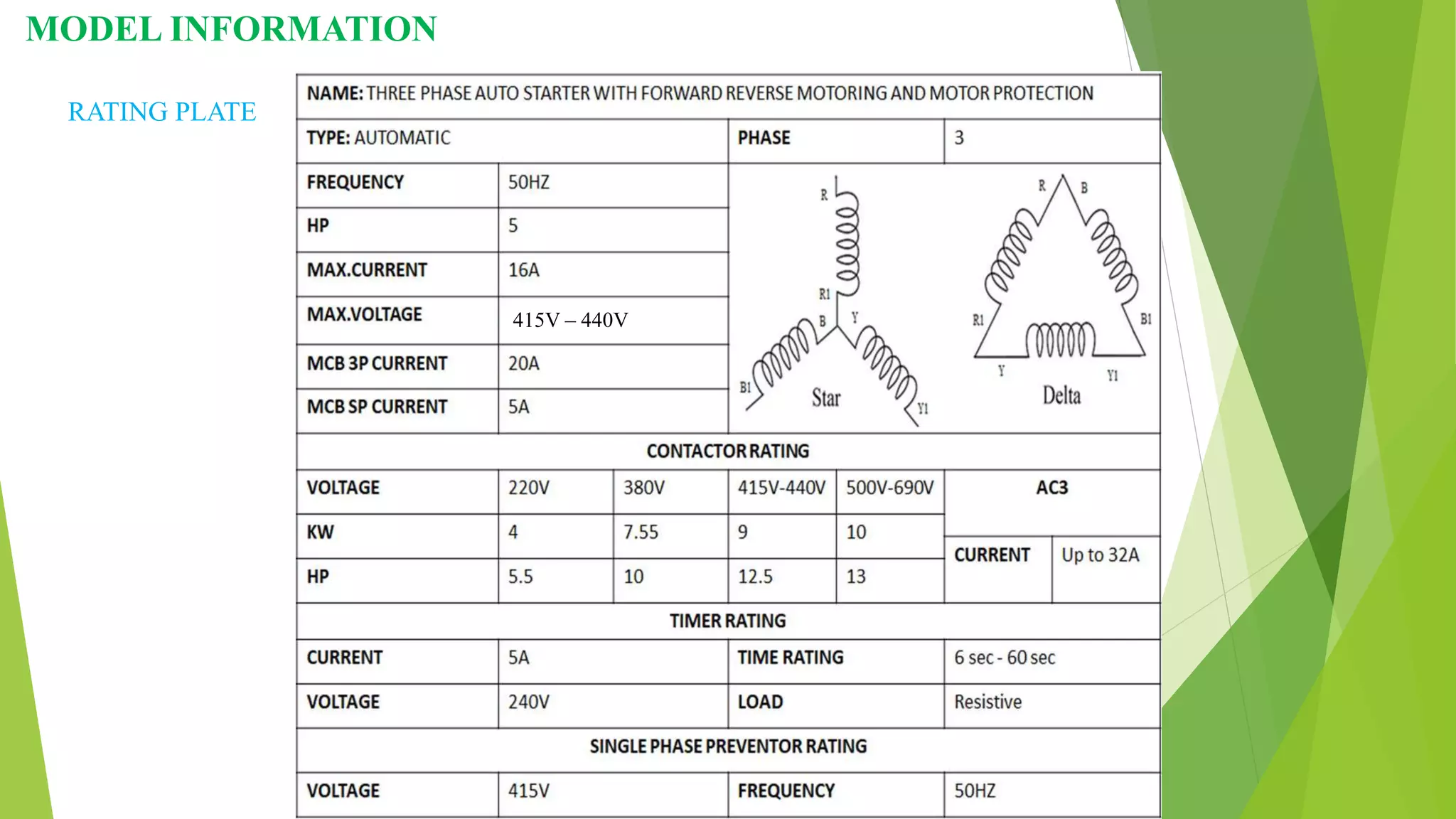

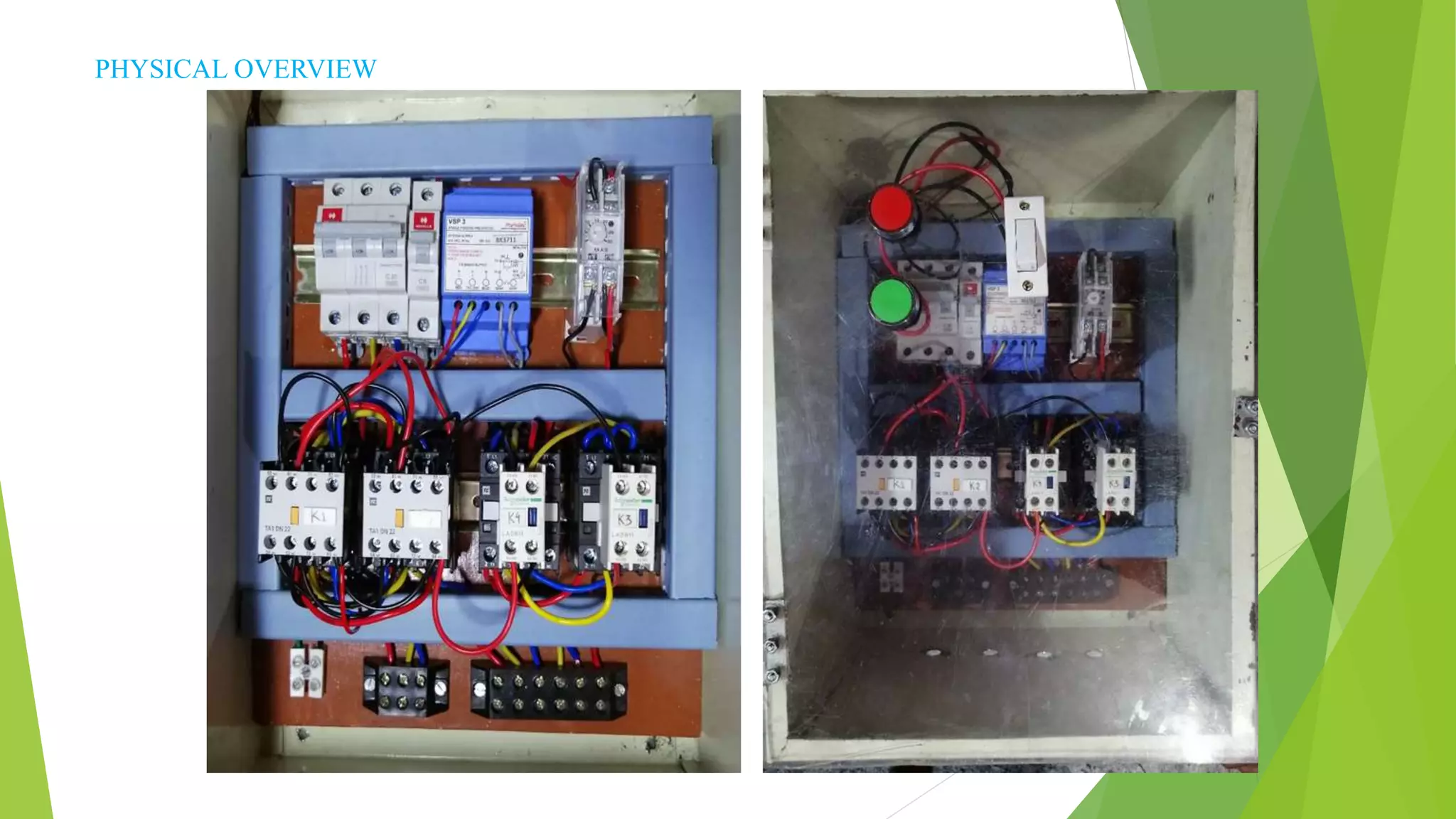

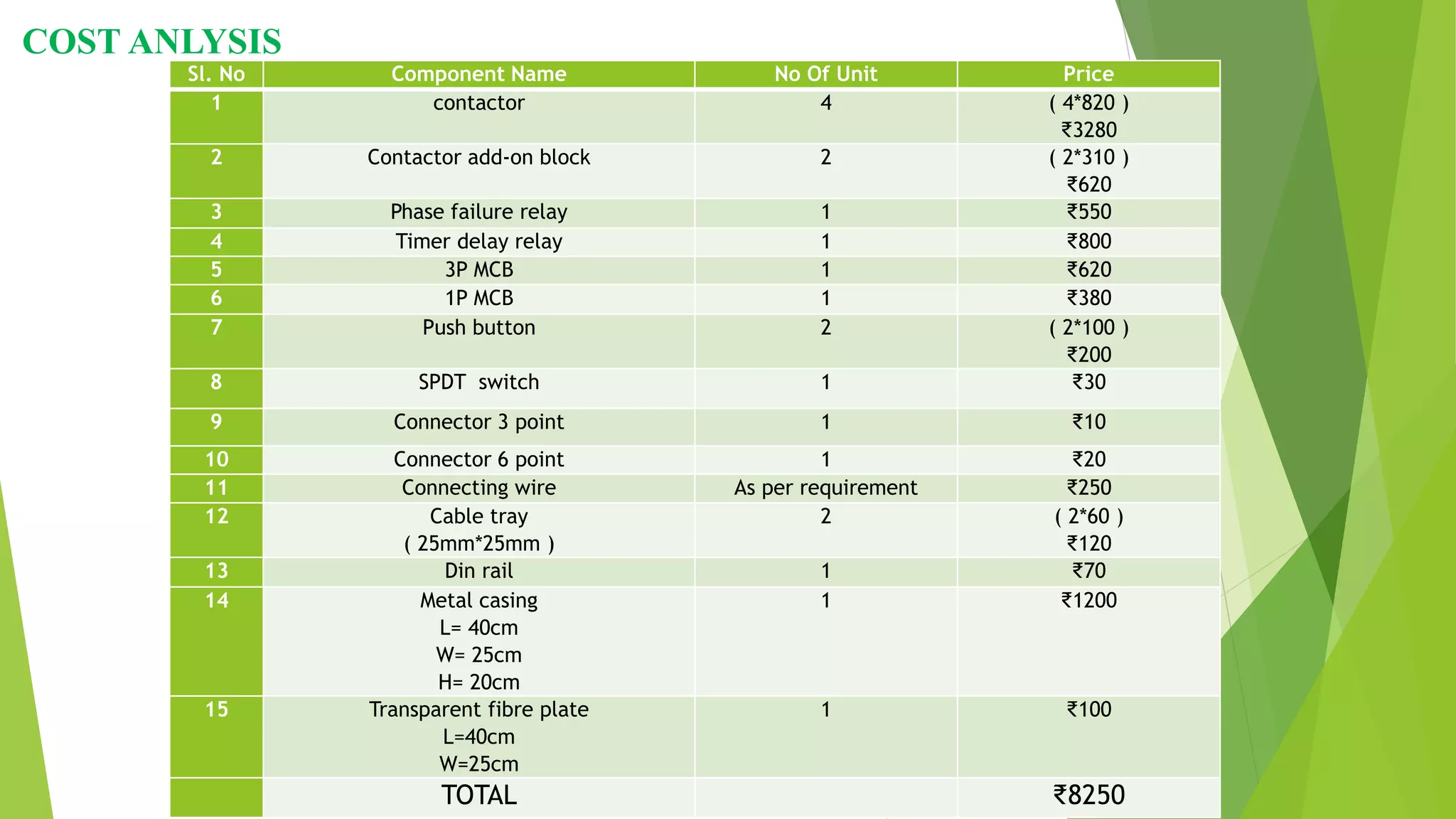

The document provides a comprehensive project guide on the star-delta starting method for induction motors, emphasizing the reduction of high starting currents and motor protection features. Key objectives include achieving automatic star to delta switching and enabling forward and reverse motor operations while ensuring safety through various protection mechanisms. The project details components, operation methods, cost analysis, and concludes with the benefits of using this approach over direct online starters.