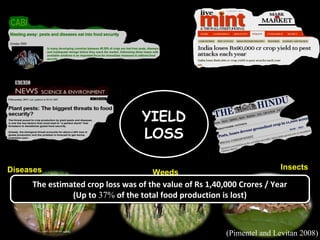

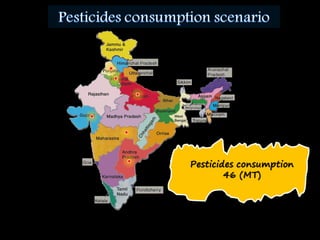

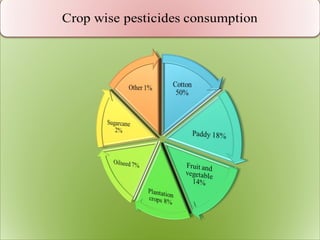

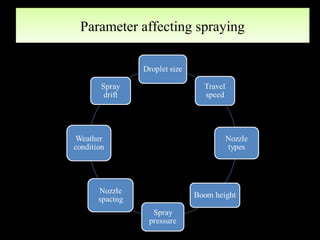

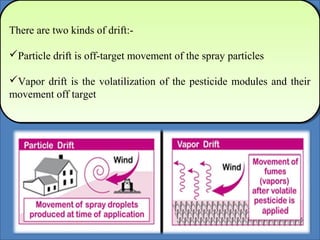

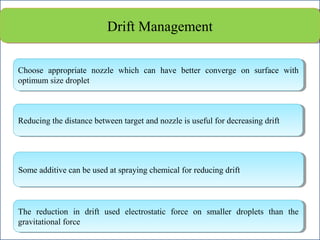

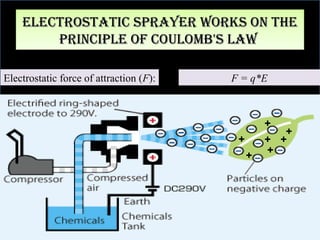

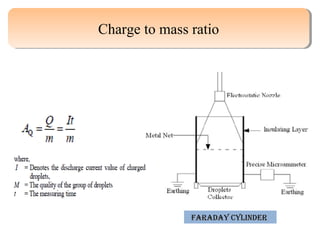

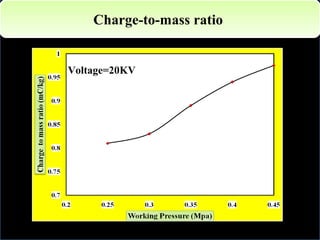

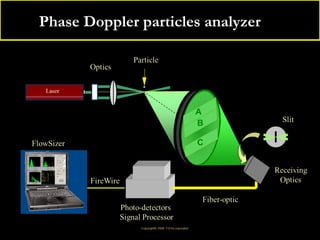

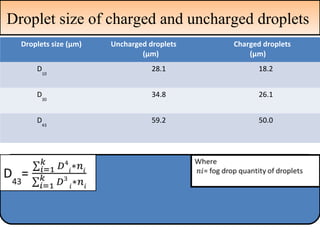

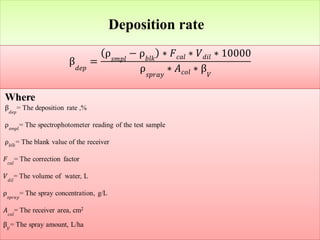

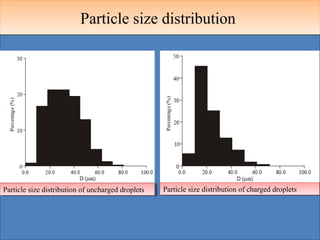

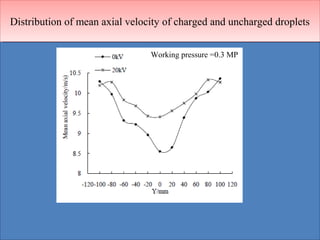

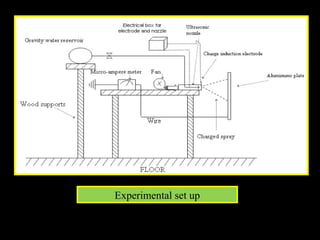

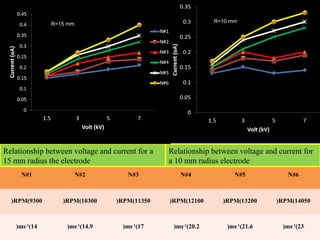

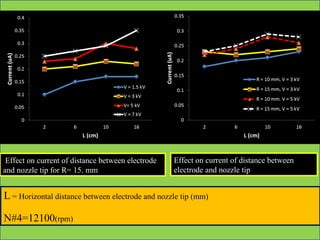

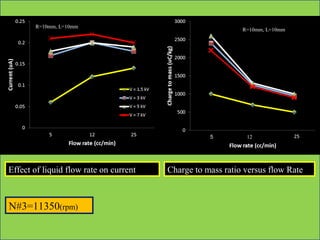

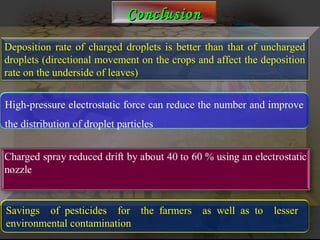

The document discusses the significant crop losses in India amounting to Rs 1,40,000 crores annually due to pests and weeds, encapsulating the advantages and disadvantages of pesticide use. It emphasizes the need for efficient pesticide spraying technologies, particularly electrostatic sprayers, which enhance droplet charge and improve deposition rates on crops while reducing environmental contamination. Various case studies are cited to illustrate the effectiveness of different electrostatic parameters and their impact on maximizing agricultural productivity.