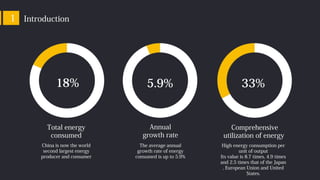

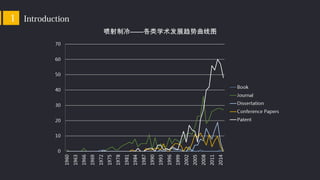

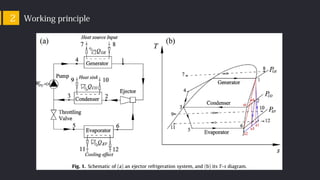

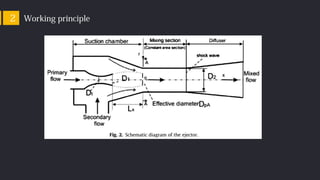

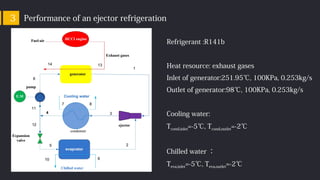

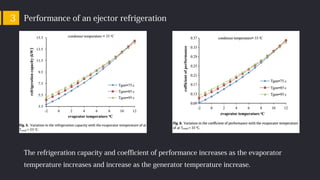

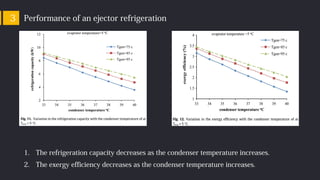

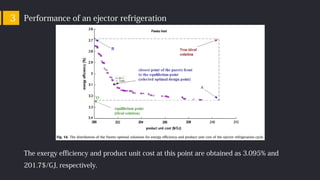

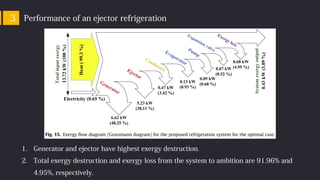

The document discusses an ejector refrigeration cycle driven by an internal combustion engine, detailing its working principle, performance metrics, and energy consumption statistics in China. It highlights the efficiency challenges, particularly regarding exergy destruction and the associated costs, emphasizing the need for optimized operating conditions. The study concludes with performance data and references to related research.

![References4

1. 房煦峰 . 潜 回收型 射式制冷性能分析及 射器数 模热 喷 喷 值 拟 [D]. 大 海事大连

学 , 2014.

2. 董景明 . 高效 射式制冷系 性能的理 与 研究喷 统 论 实验 [D]. 大 海事大学连 ,

2012.

3. Chen J, Havtun H, Palm B. Conventional and advanced exergy analysis of

an ejector refrigeration system[J]. Applied Energy, 2015,144:139-151.

4. Sadeghi M, Mahmoudi S M S, Khoshbakhti Saray R. Exergoeconomic

analysis and multi-objective optimization of an ejector refrigeration cycle

powered by an internal combustion (HCCI) engine[J]. Energy Conversion

and Management, 2015,96:403-417.](https://image.slidesharecdn.com/ejector-150526040408-lva1-app6891/85/An-ejector-refrigeration-cycle-19-320.jpg)