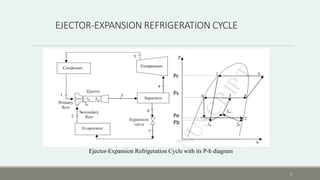

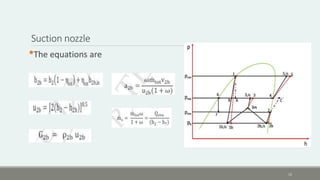

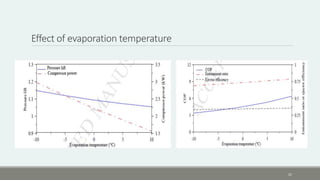

This document describes an ejector-expansion refrigeration system (EERS). It discusses the components and working of the EERS cycle including the compressor, condenser, ejector, separator, expansion valve and evaporator. It also describes the constant area ejector and working of the ejector. The document analyzes the system performance based on conservation equations and discusses the effects of evaporation and condensation temperatures on performance parameters like COP, compressor power and pressure ratio. It concludes that COP increases with evaporation temperature but decreases with condensation temperature.