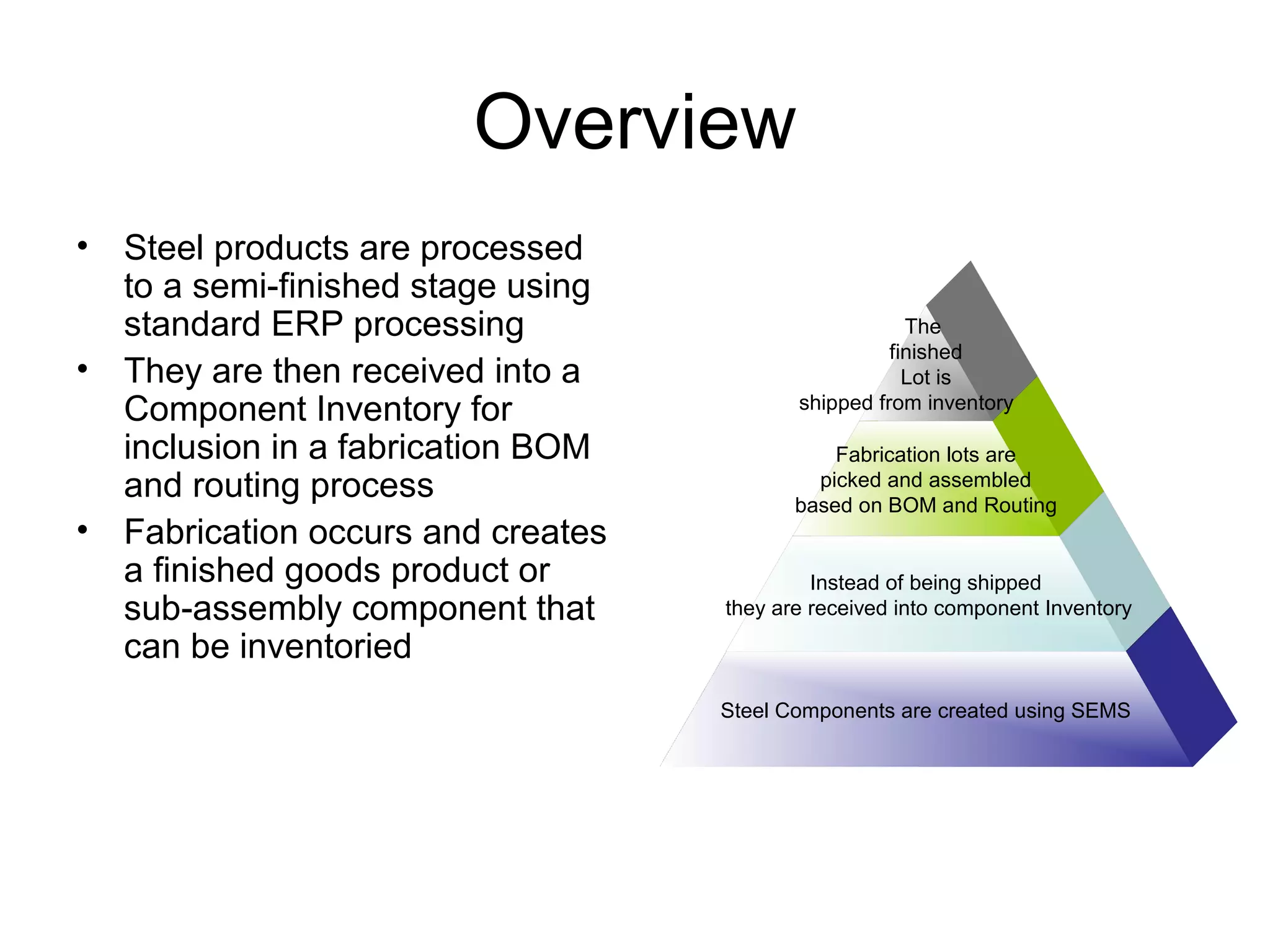

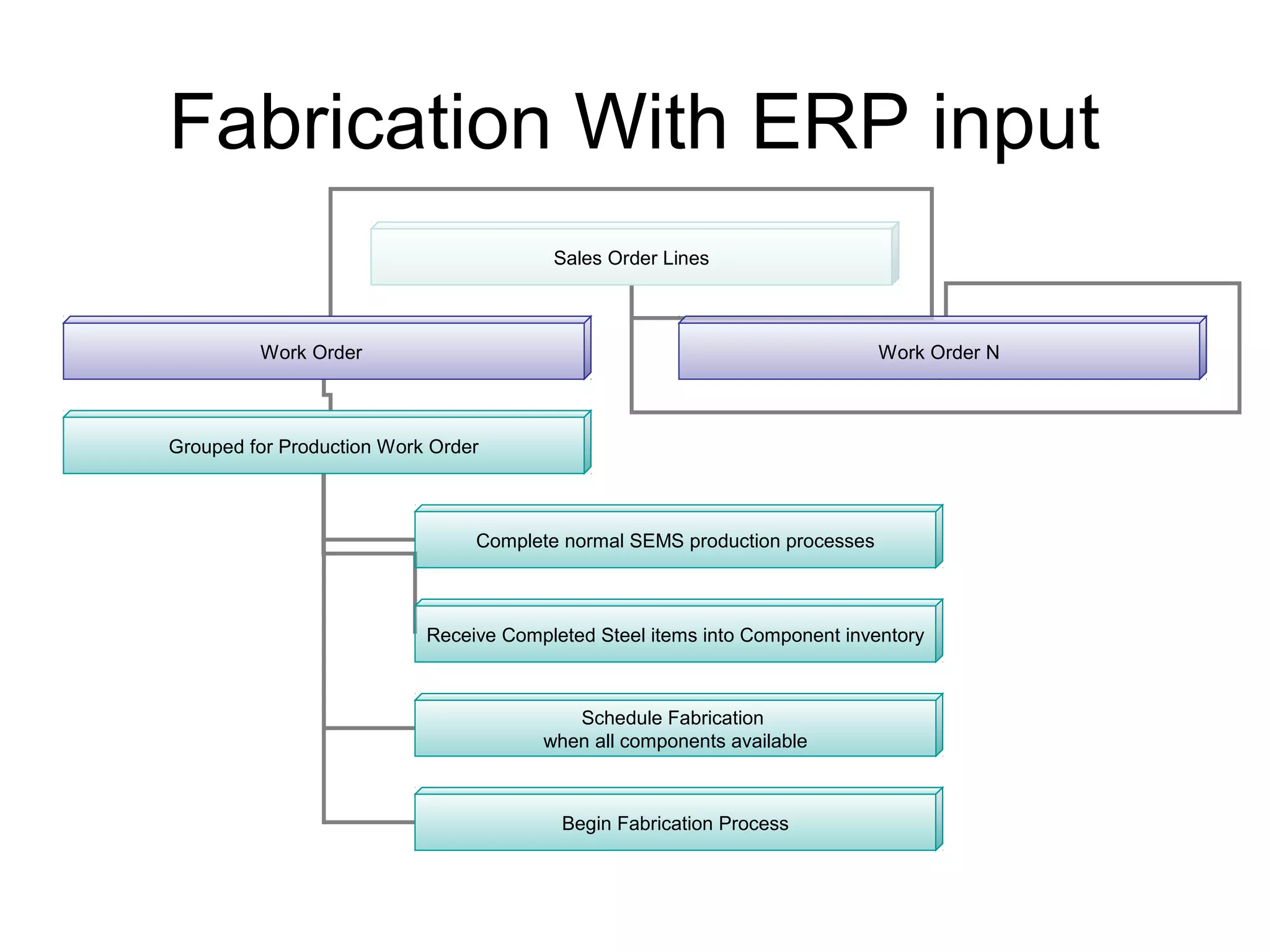

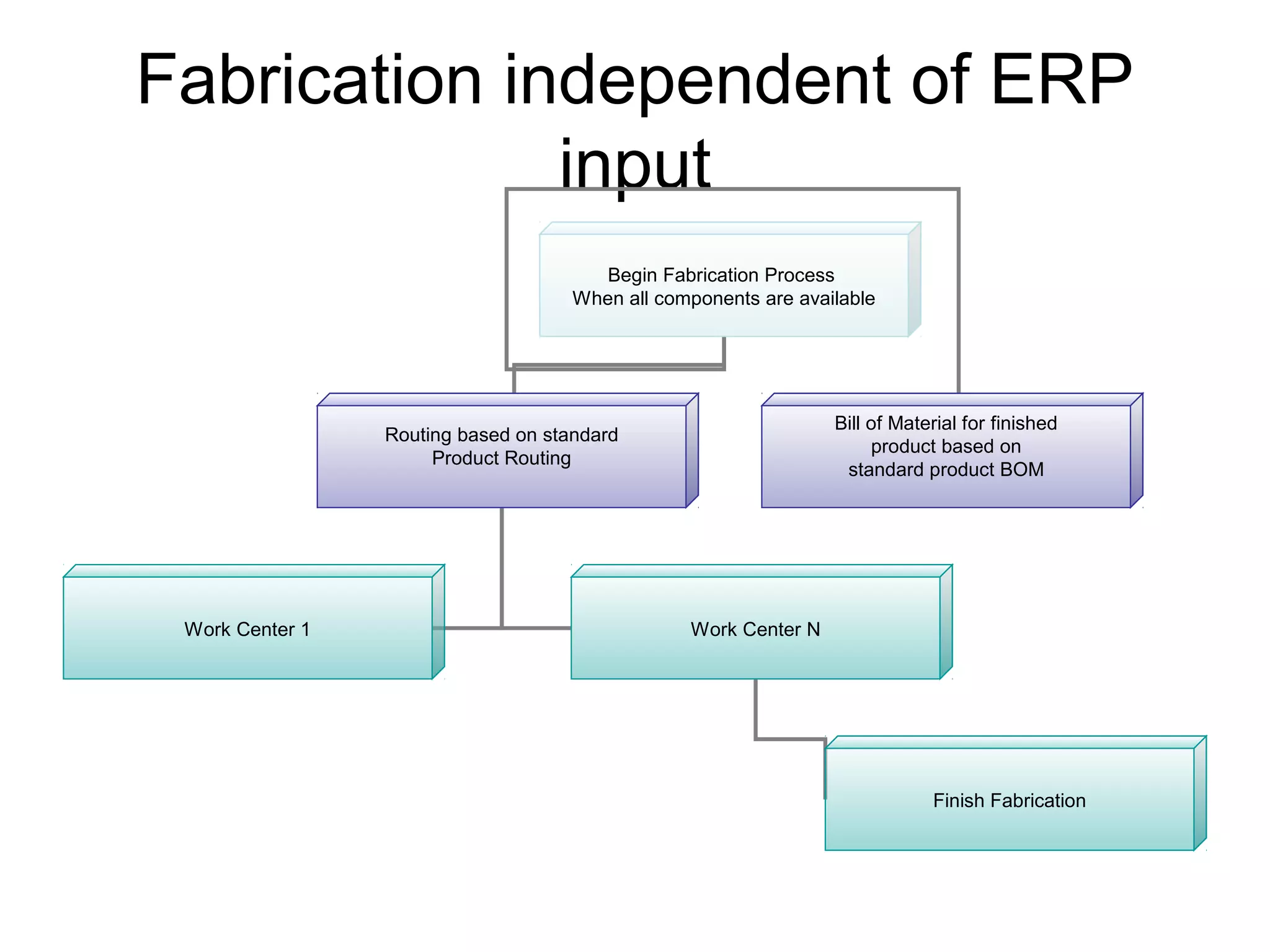

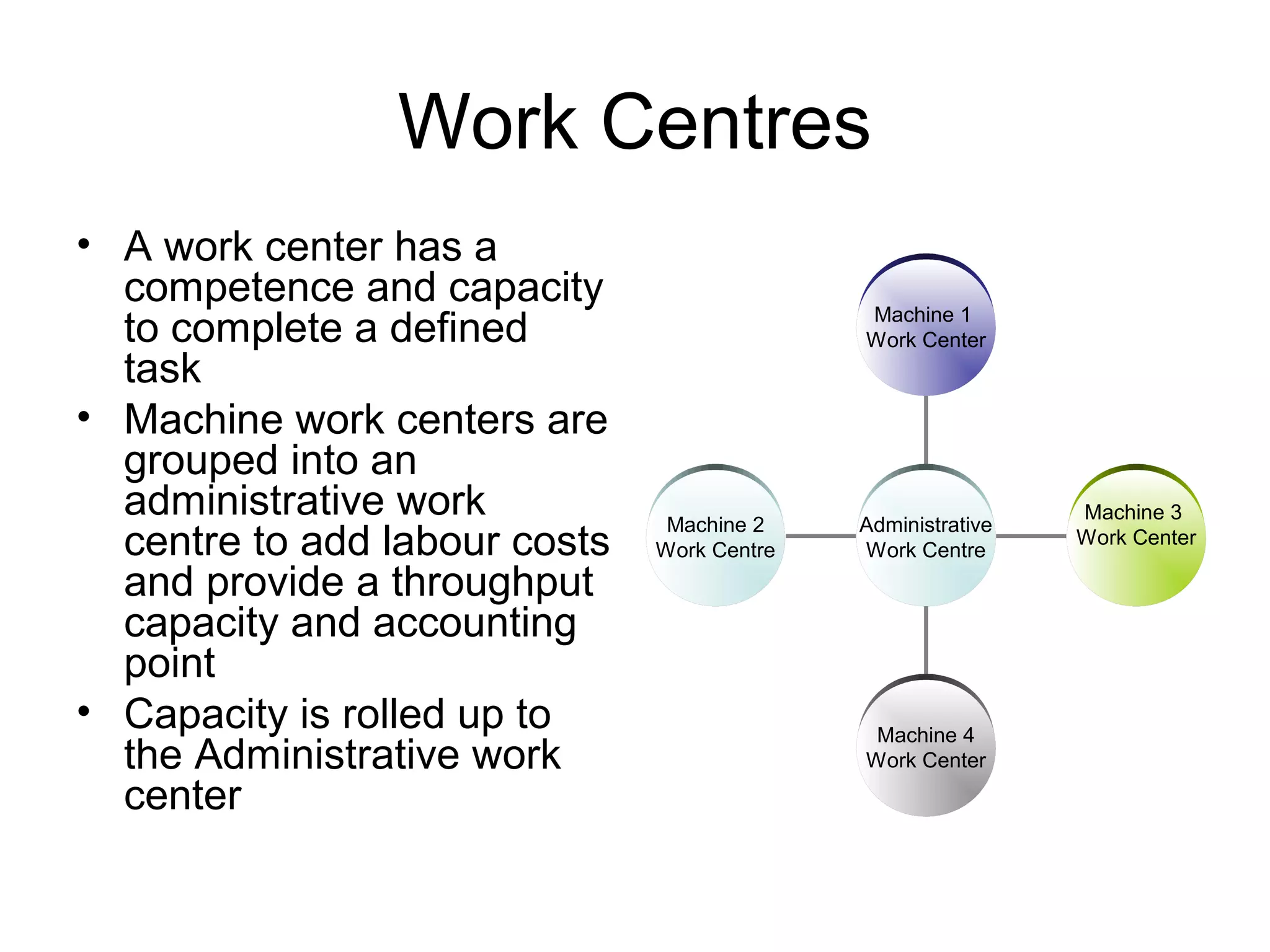

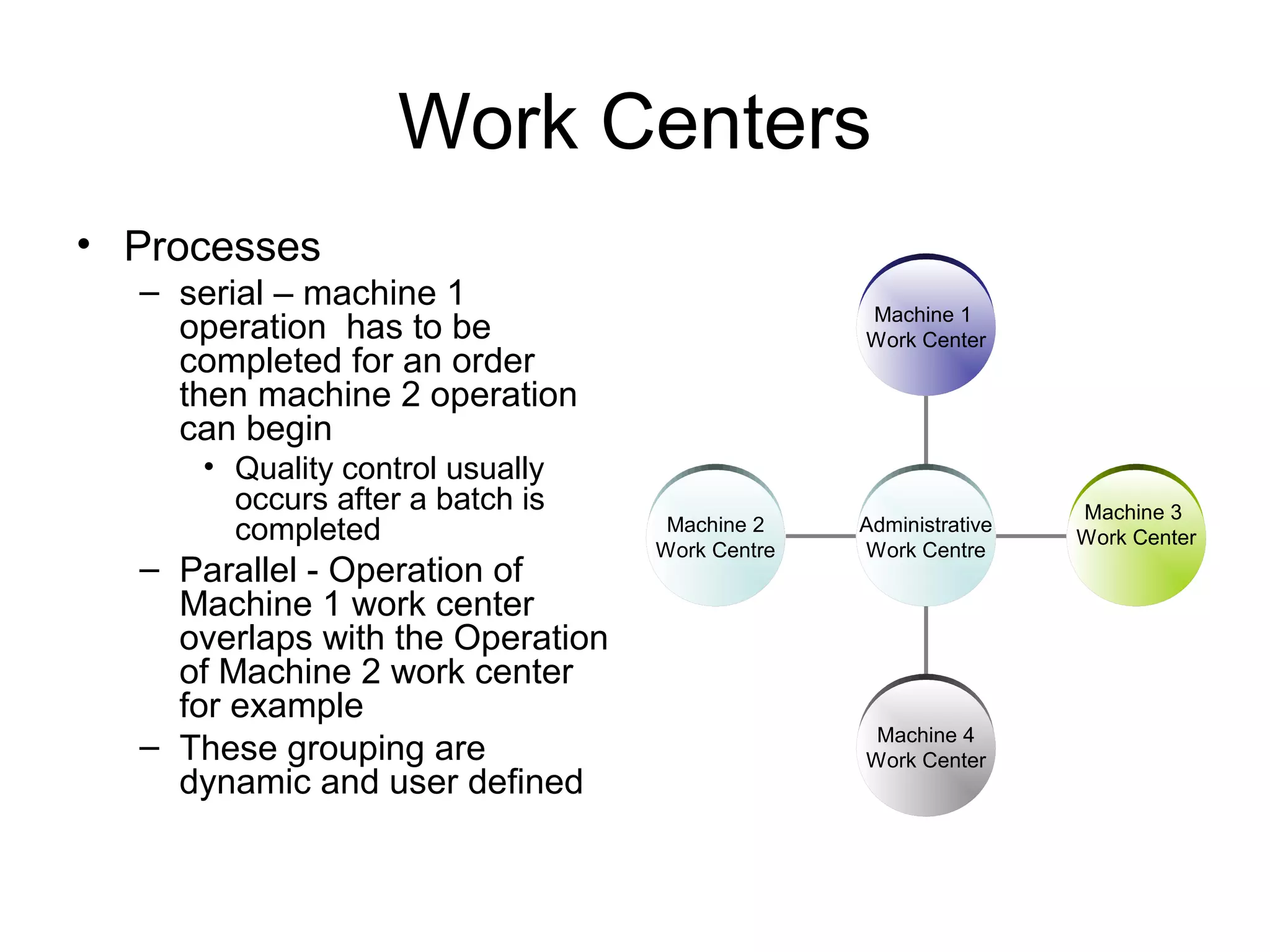

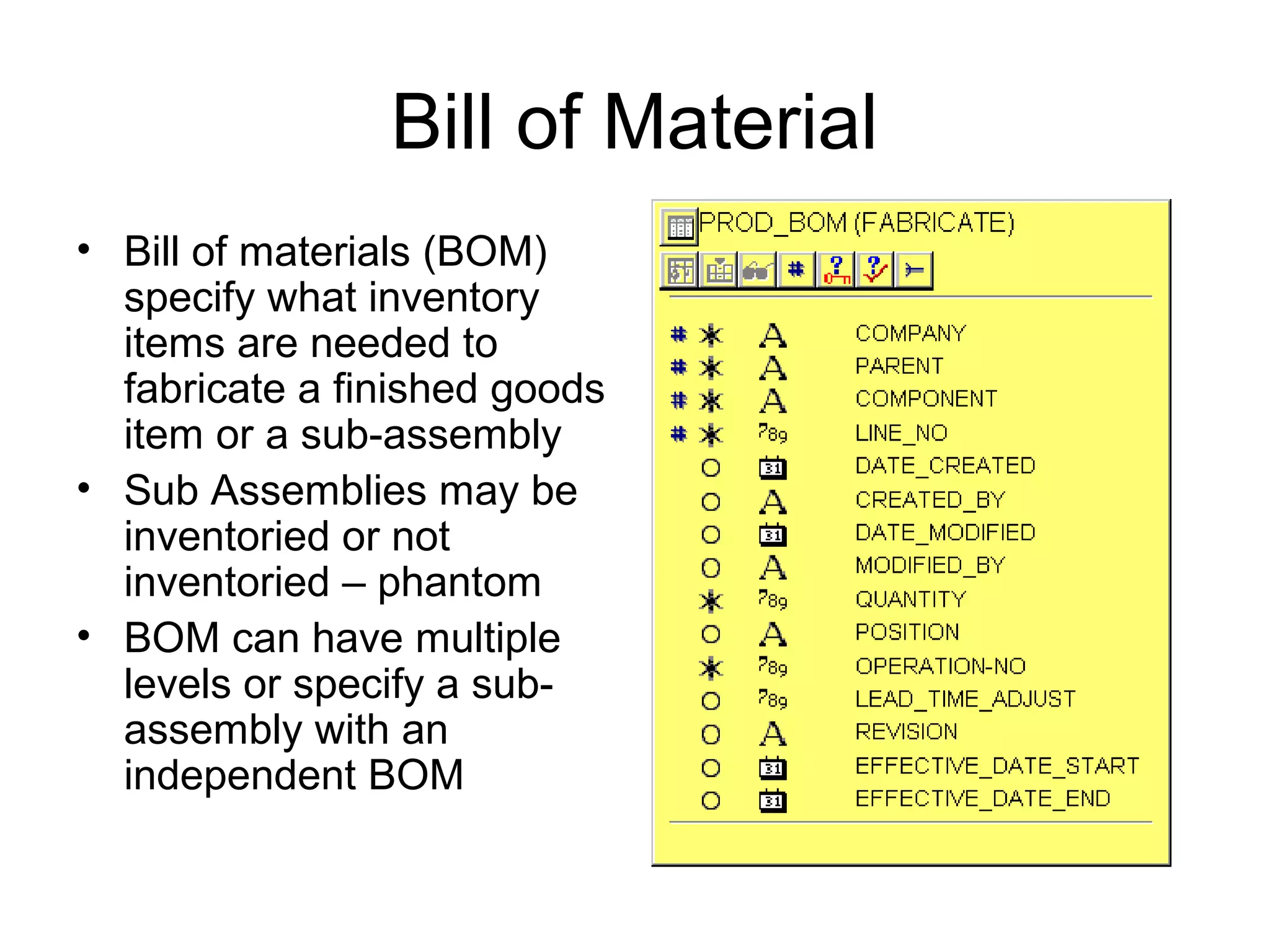

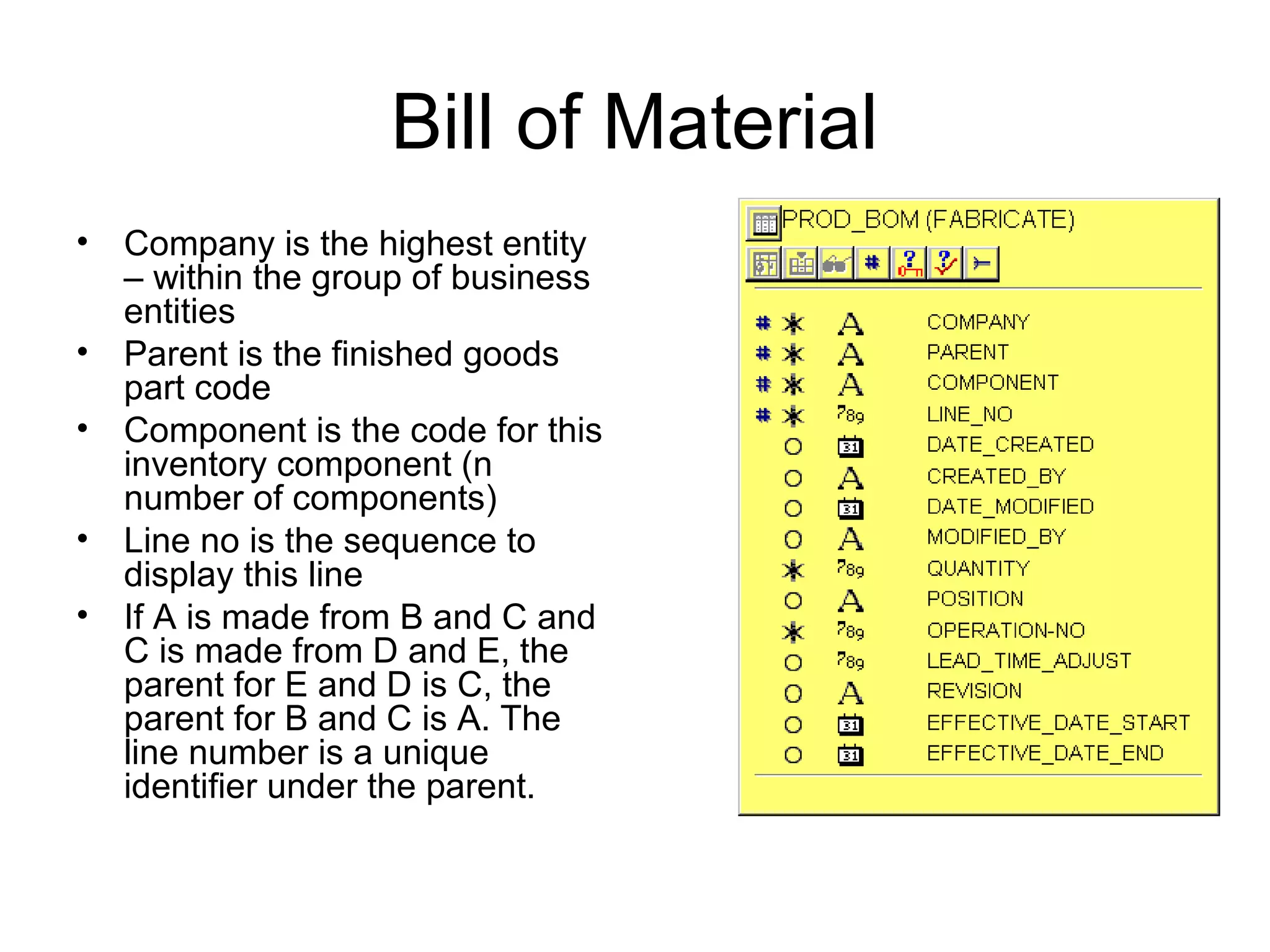

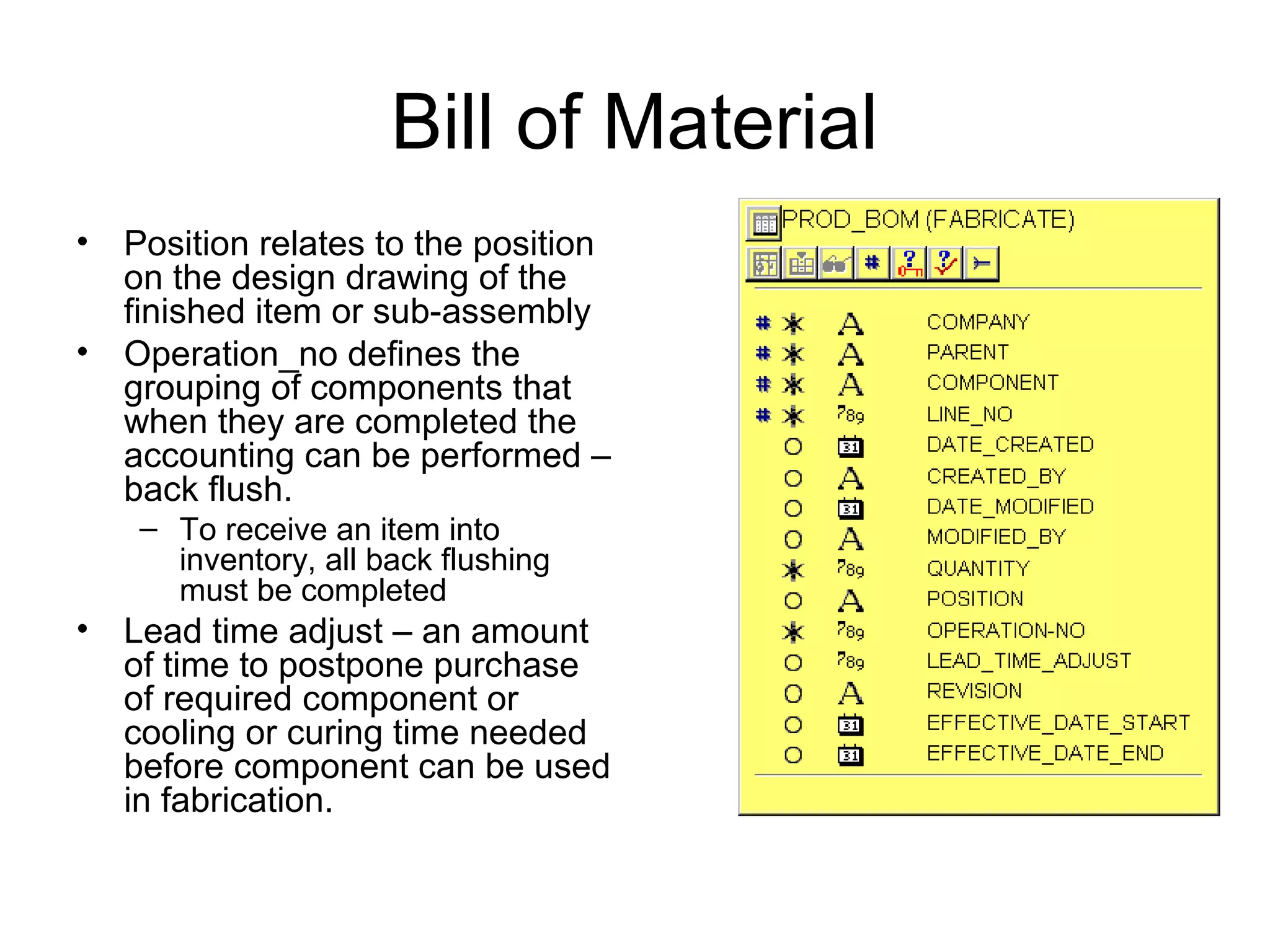

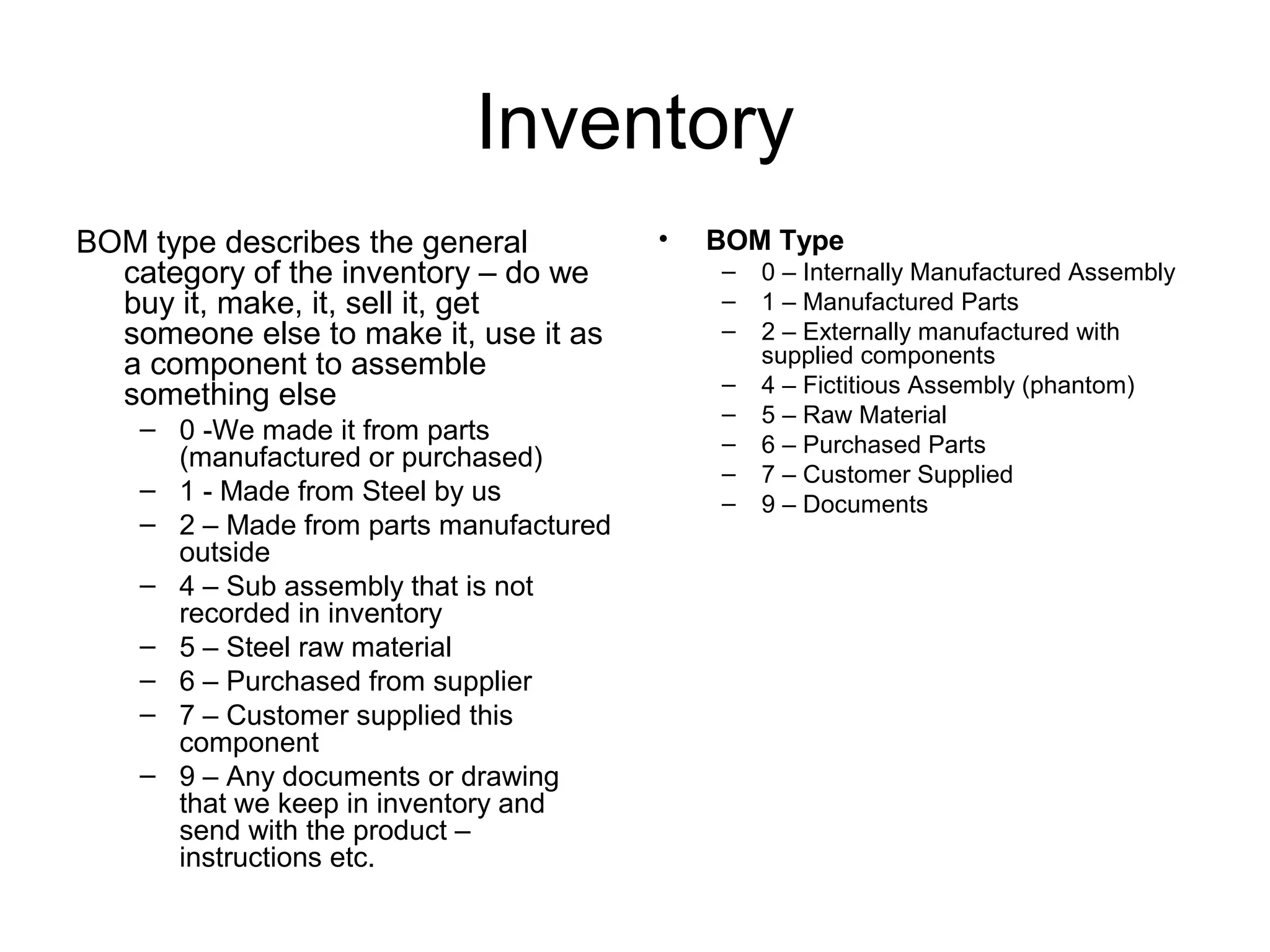

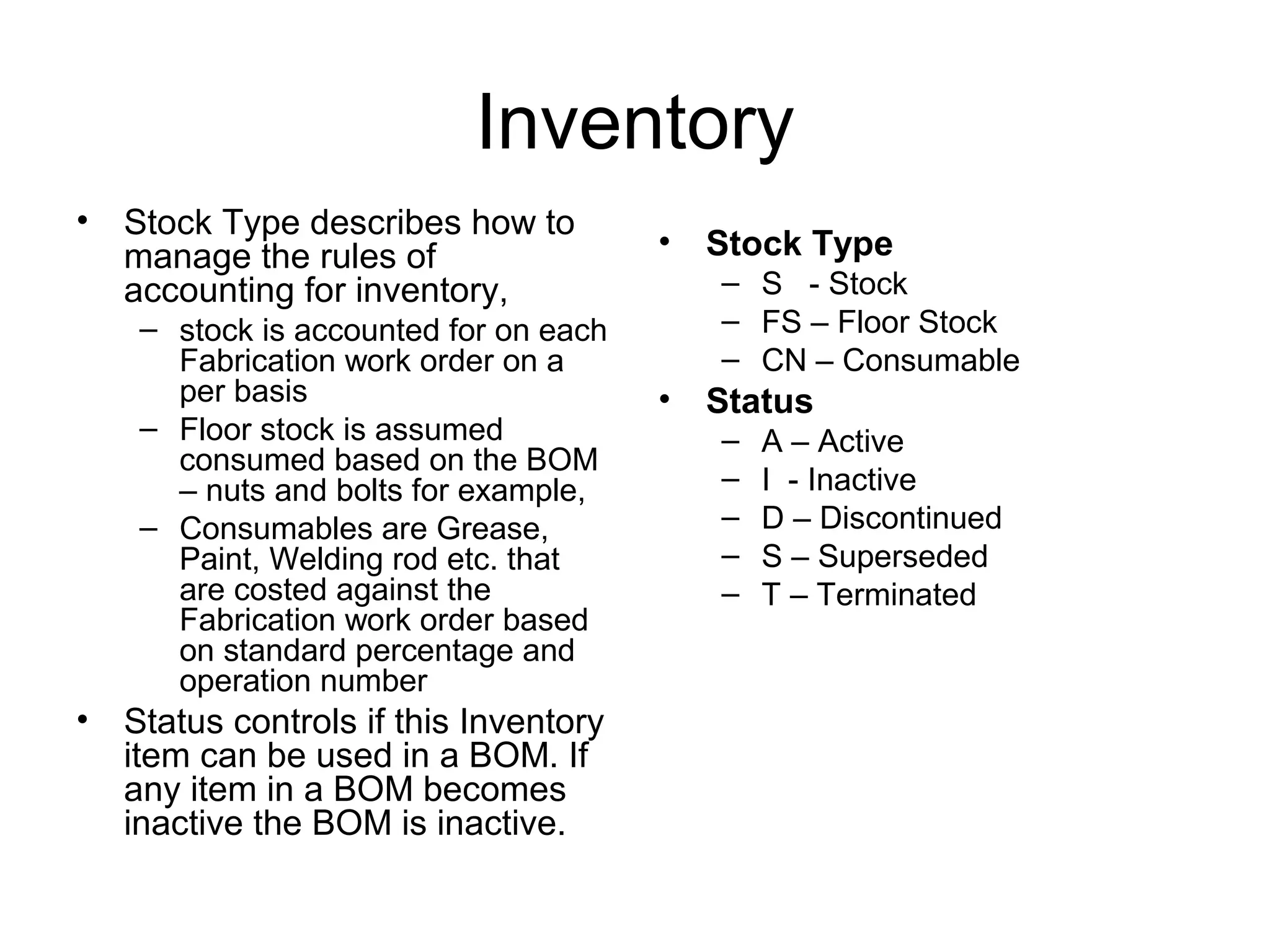

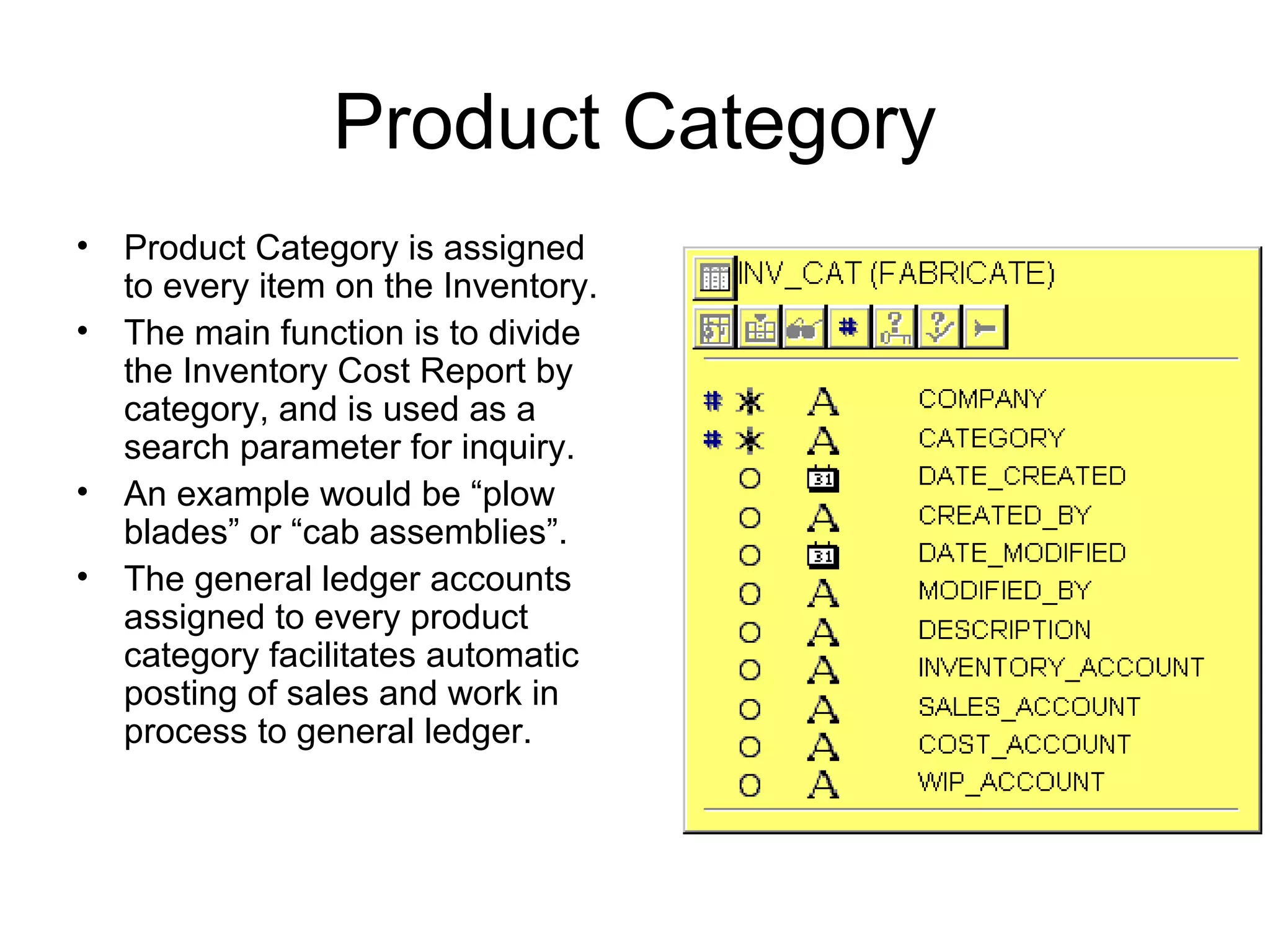

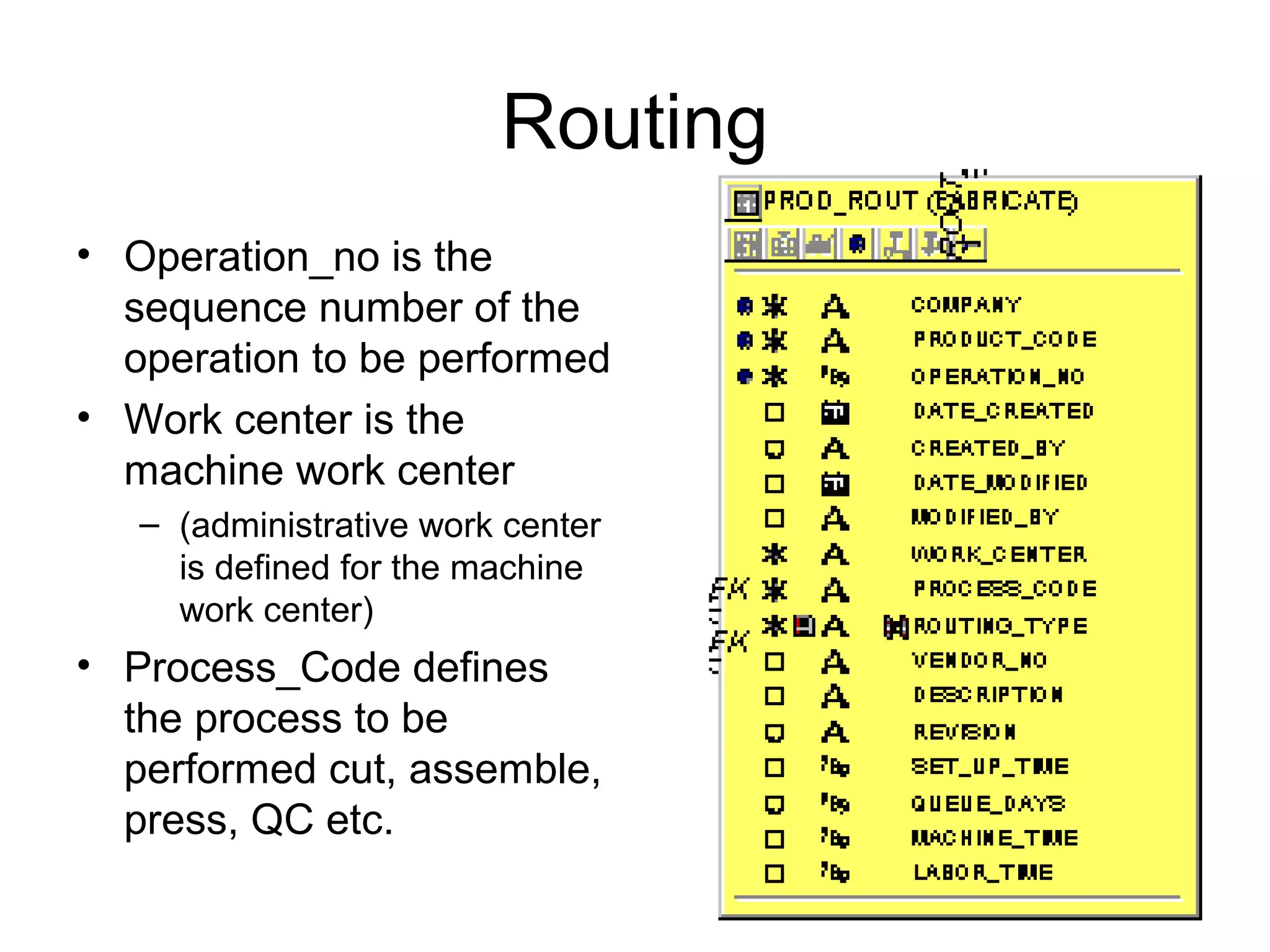

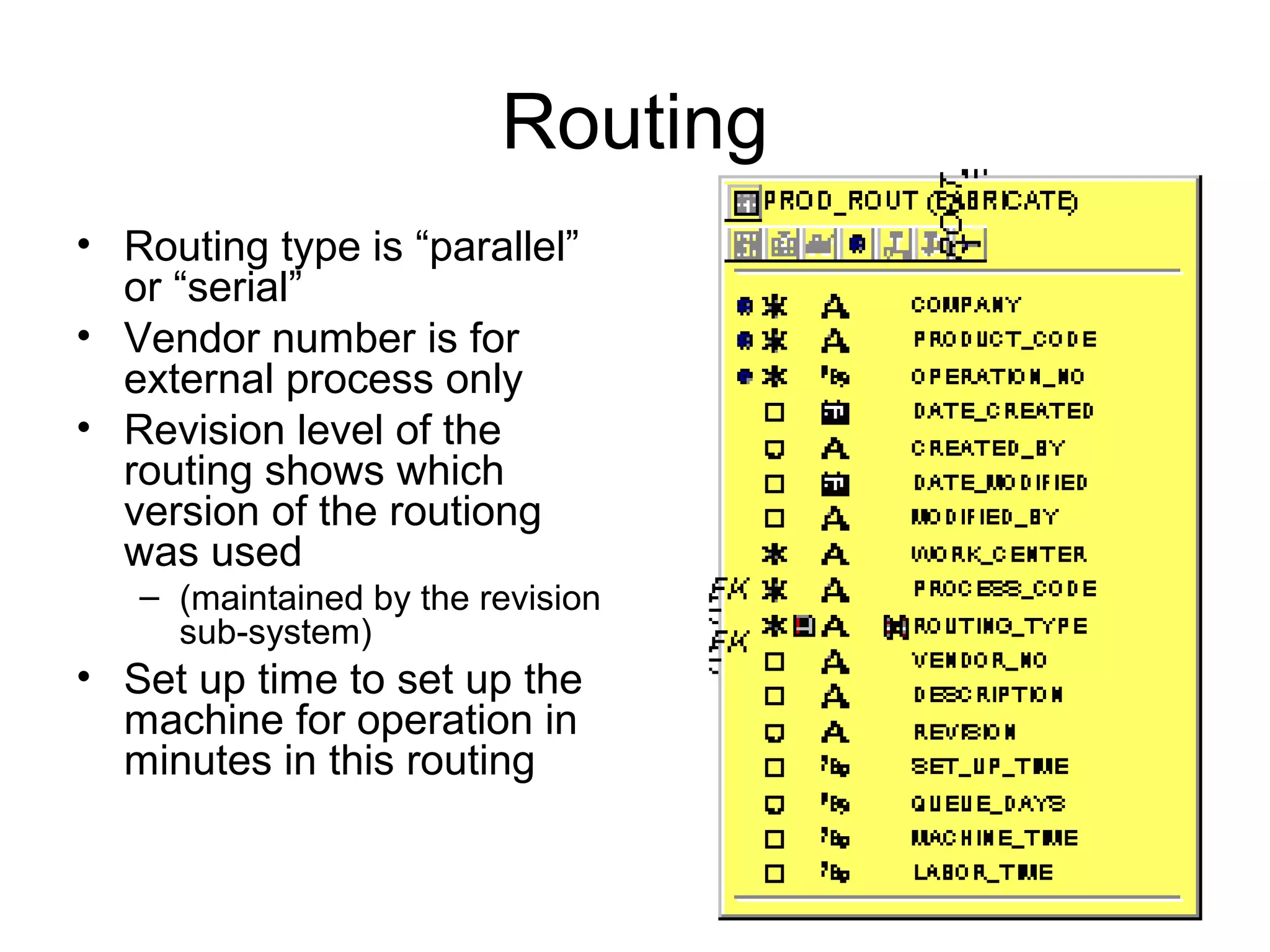

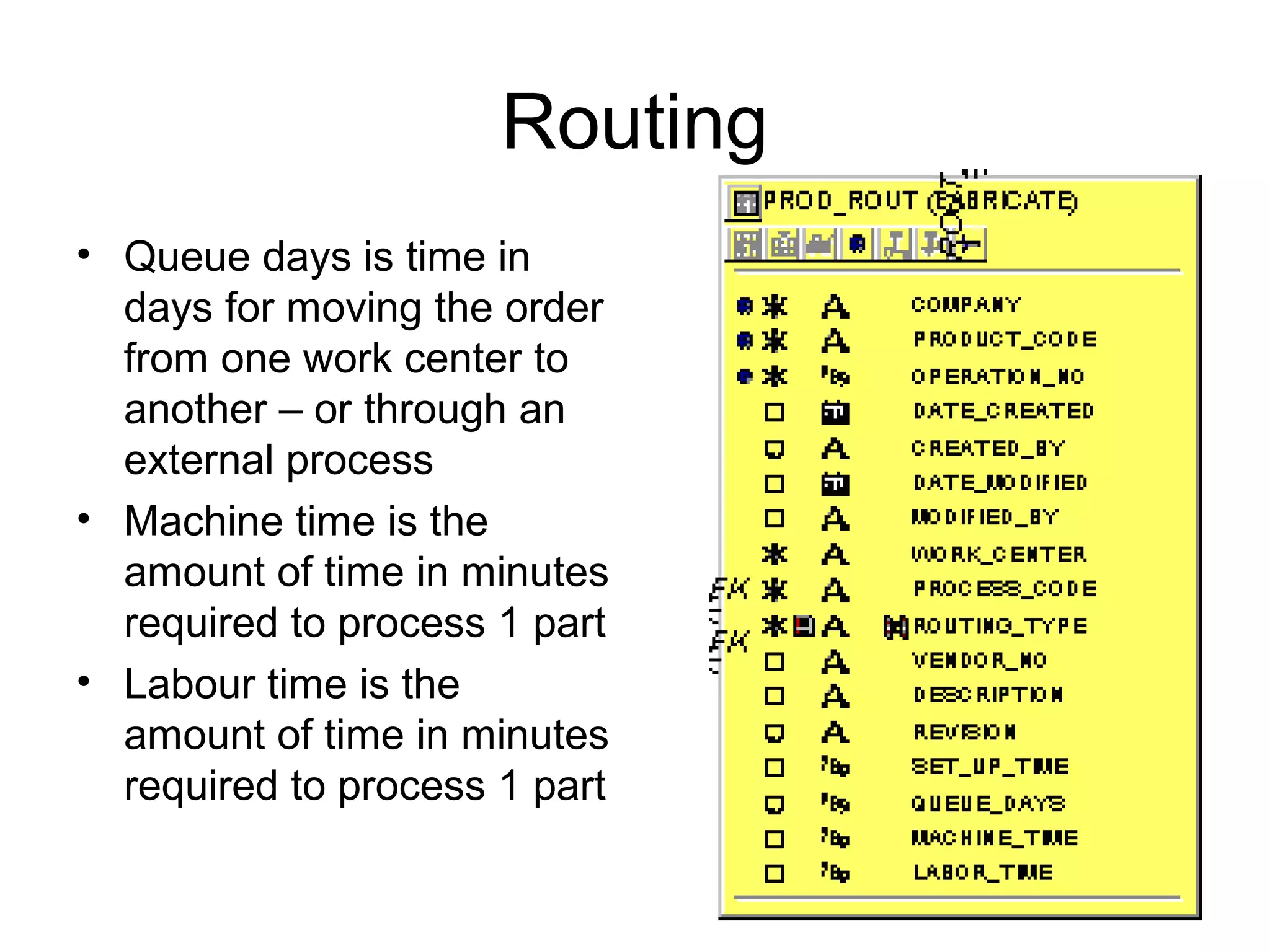

This document describes a fabrication module design that extends standard ERP production processes. Fabrication involves combining manufactured components with purchased parts to create finished inventory items in batches. Key concepts covered include fabrication work orders, component inventory, bills of materials specifying fabrication requirements, routing plans detailing work center processes, and accounting for actual costs while using standard costs where needed. The goal is to track costs from raw materials to finished goods for fabricated products.