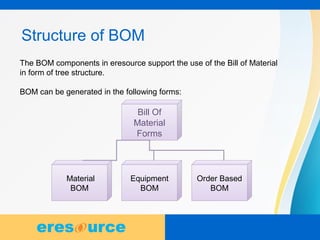

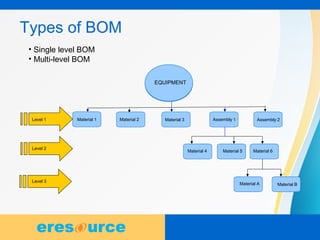

The document discusses Bills of Materials (BOMs) in an ERP system called eresource. A BOM specifies the components required to manufacture a product. eresource supports single-level and multi-level BOMs in a tree structure. It allows creating BOMs for materials, equipment, orders, and revisions through engineering change requests. The system also manages standard and customer-specific BOMs.