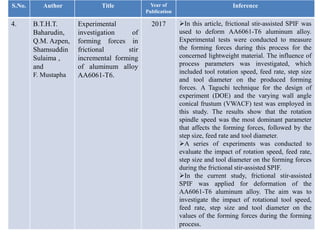

- The document discusses formability effects of process parameters on forming forces in single point incremental forming (SPIF). It outlines the objectives to study the nature of cutting forces expected during SPIF and the effect of different process parameters on these forming forces.

- The study aims to optimize forming parameters like forming step depth, tool feed, and spindle speed using SPIF on aluminum alloys. Surface roughness, wall thickness, and formability will be analyzed. Experiments will be validated through numerical simulation to study material behavior and any twisting developed during forming.