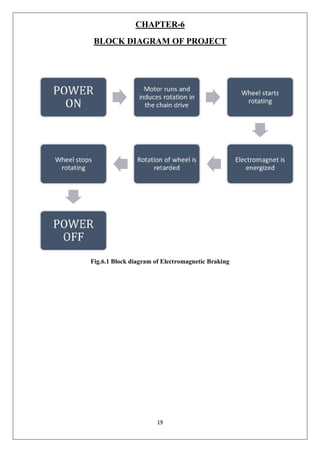

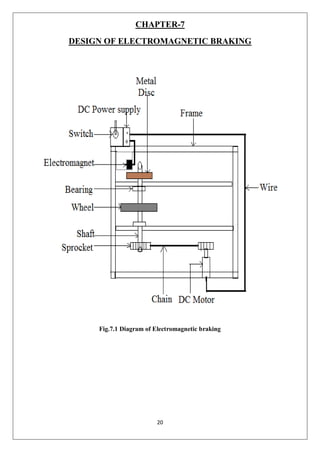

This document provides information about an electromagnetic braking system project report. It includes a title page, certificate of completion signed by faculty, an acknowledgments section thanking those who provided guidance, and an abstract summarizing the project. The project aims to create an electromagnetic braking system model capable of applying brakes without friction loss by using magnetic force and inducing eddy currents to slow rotation. It also includes sections on introduction, literature review, problem definition, block diagram, design, construction, parts, advantages/disadvantages, conclusion, and references.

![29

CHAPTER-12

REFRENCES

[1] www.google.com

[2] www. wikipedia/elctromagnetic brake.com

[3] Putman, P.T, (1986) „Capture Dynamics of Coaxial Magnetic Brakes‟ Vol.6

[4] G. Guna* , S. Dinesh ,()2016),Electro Magnetic Braking System, Journal of Chemical and

Pharmaceutical Sciences,Issue No -5,pp.427-428.

[5] Sagar Wagh, 2Aditya Mahakode, 3Abhishek Mehta and 4Vaneela Pyla (2017),”Electromagnetic Braking

System in Automobile” International Journal of Trend in Research and Development, Volume 4(3),228](https://image.slidesharecdn.com/electromagneticbraking5thsemreport-220608142559-e01f511b/85/electromagnetic-braking-system-by-Indrakumar-R-Padwani-pdf-29-320.jpg)