The document describes the design of an electromagnetic braking system as an alternative to conventional braking systems. Key points:

- The objective is to design an electromagnetic braking system that is less costly and higher performing than traditional braking, and requires no maintenance.

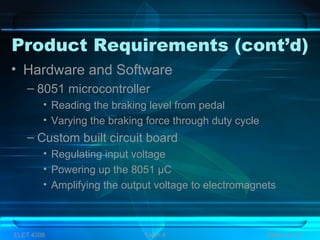

- The design will use an 8051 microcontroller to control three electromagnets based on input from a brake pedal. This will generate braking force electronically rather than through brake pads.

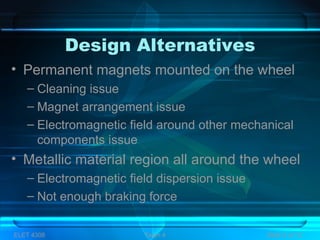

- Alternatives considered were permanent magnets or metallic material around the wheel, but these had issues with cleaning, arrangement, or not providing enough braking force.

- The final design specifications include an 8051 microcontroller, Toyota hub/sp

![Design Specifications (cont’d)

• General view

– Pedal

– 8015 Microcontroller

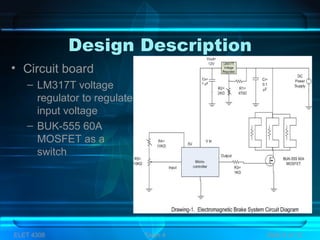

– Circuit board

– Electromagnets

– DC power supply

Pedal

8051 µC

EM

DC

power

supply

Circuit

board

5 [V]

output

Input

Square

Wave

12 [V]

power

42 [V]

power

Amplified

output

ELET 4308 Team 4 Slide 7 of 13](https://image.slidesharecdn.com/electromagneticbrakingsystem-151220144403/85/Electromagnetic-braking-system-8-320.jpg)