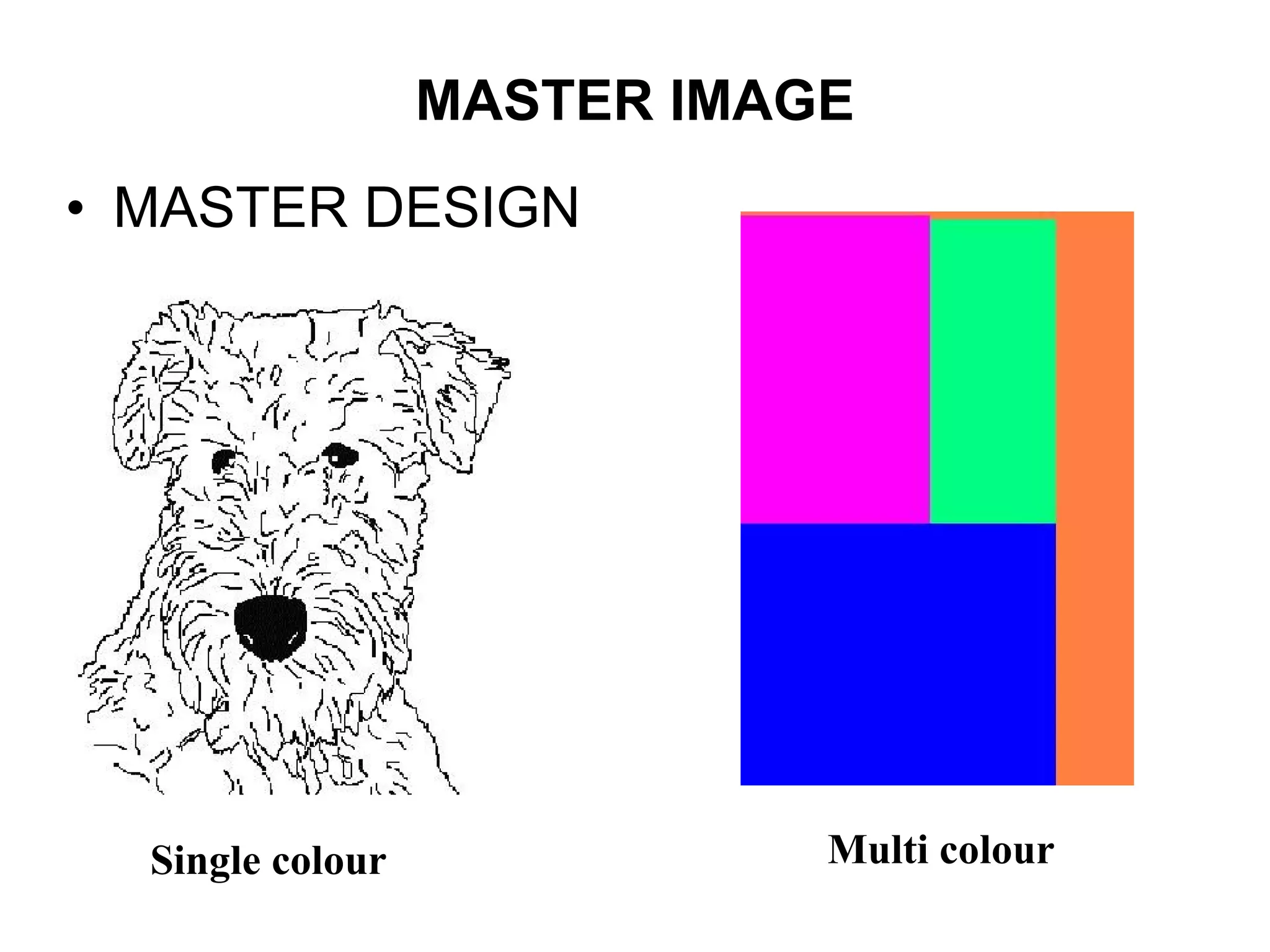

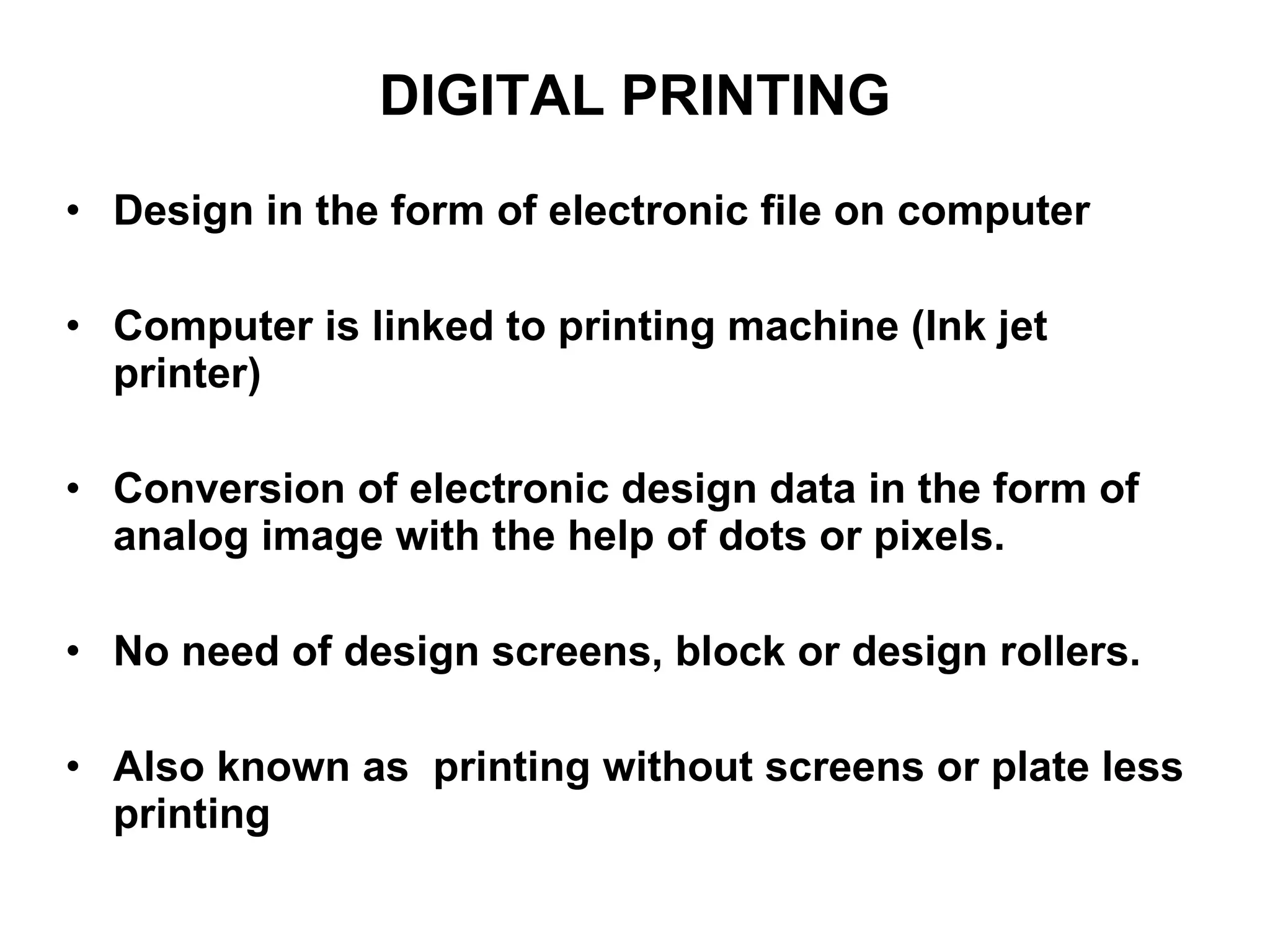

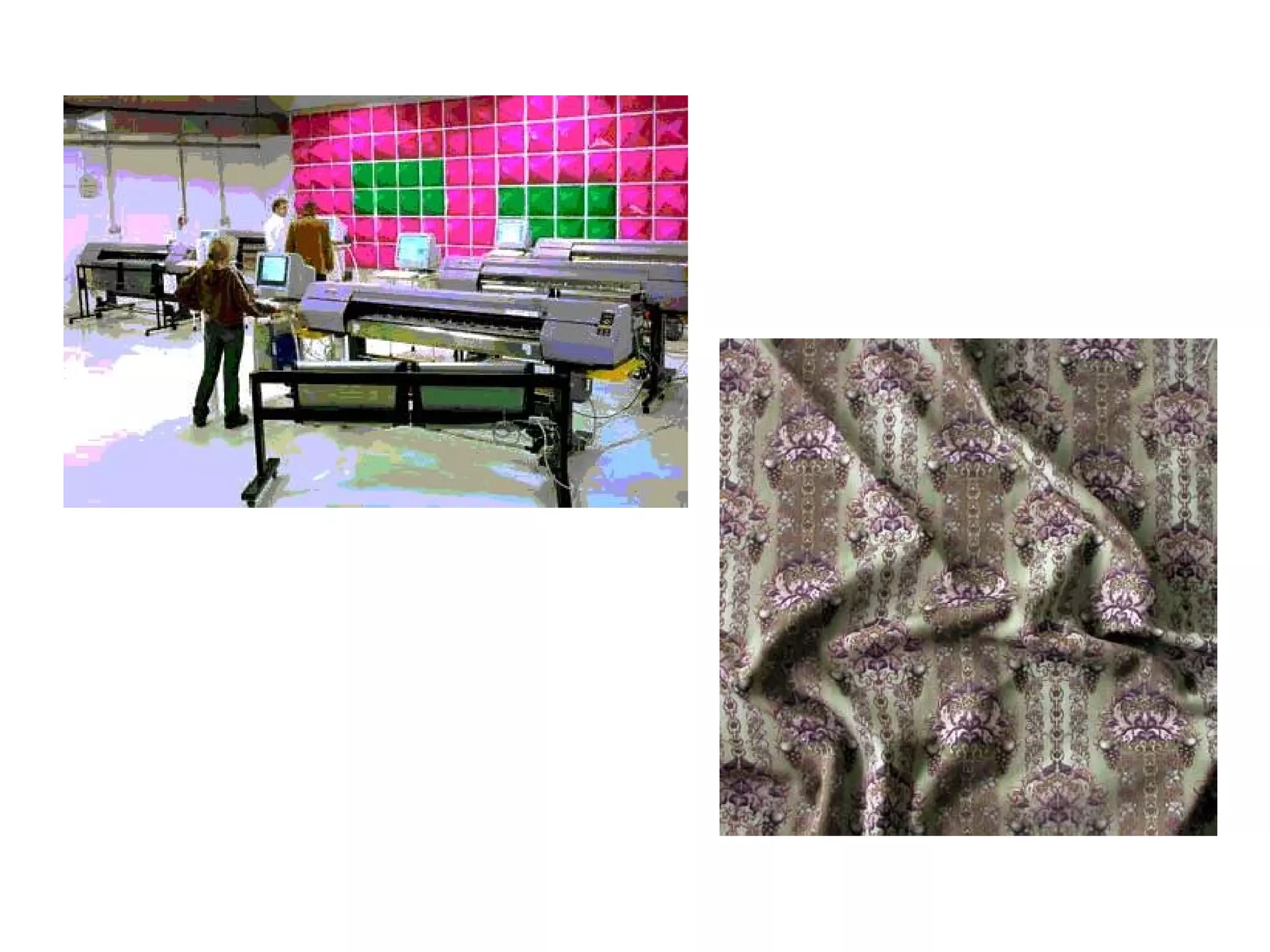

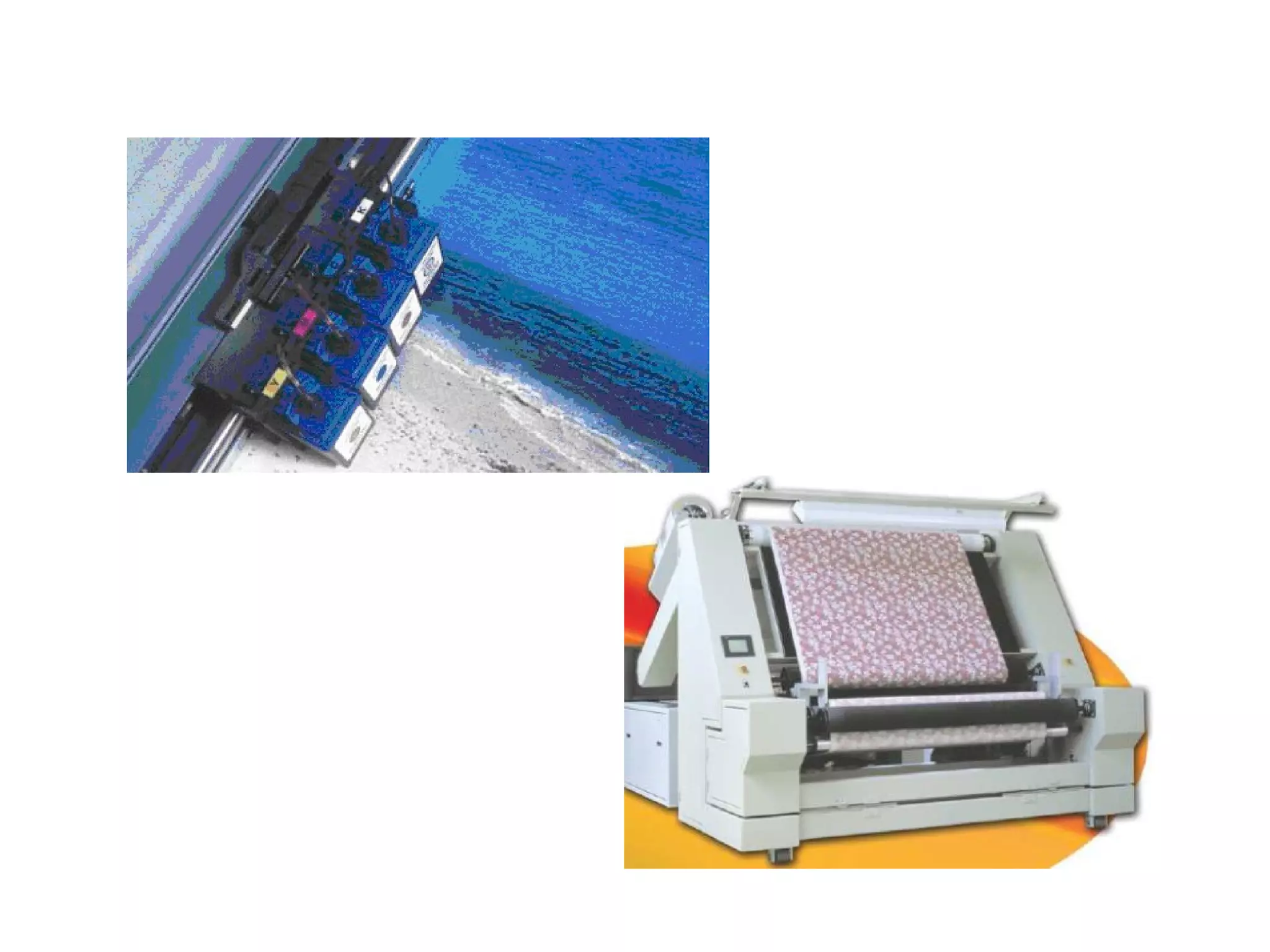

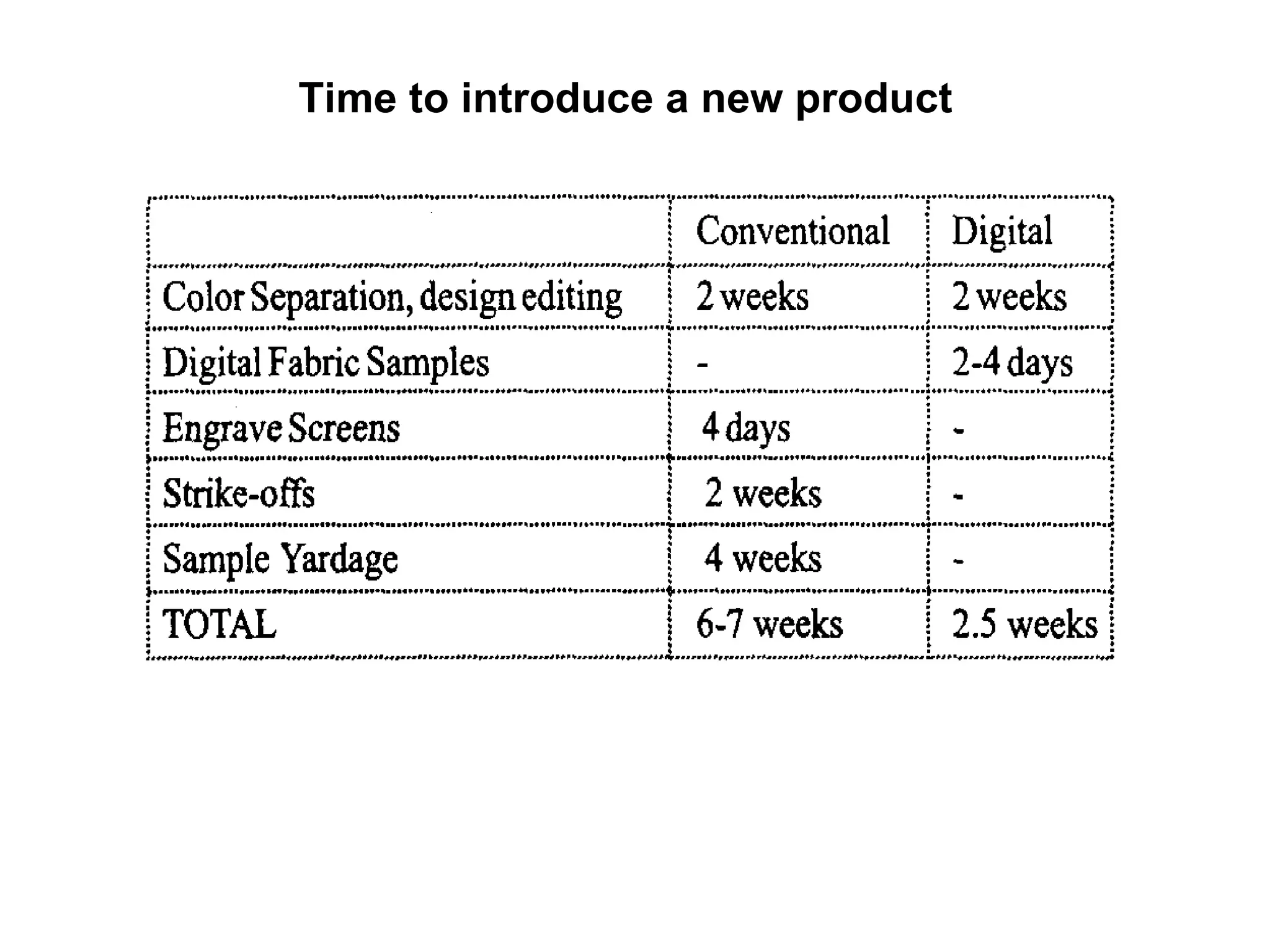

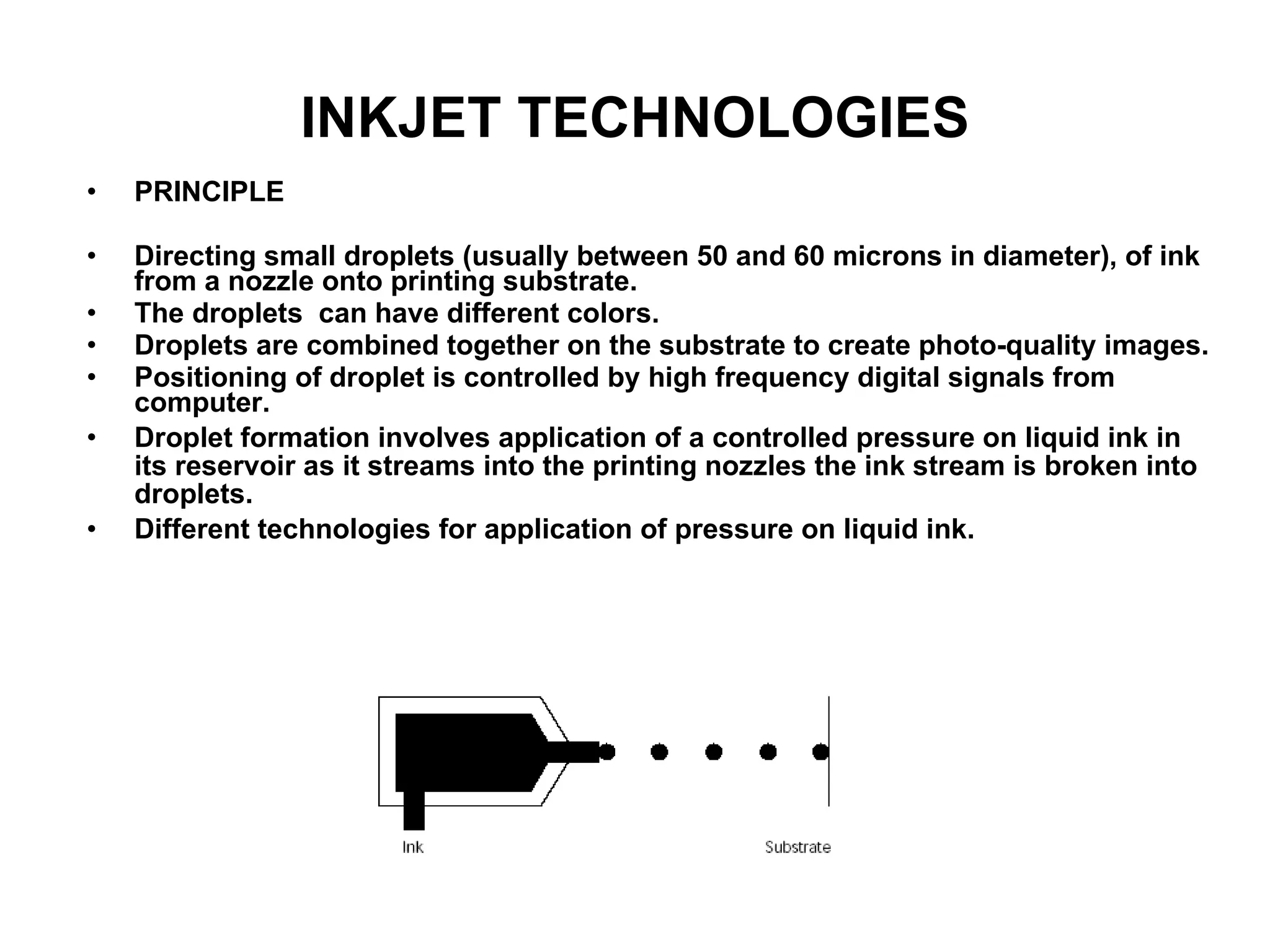

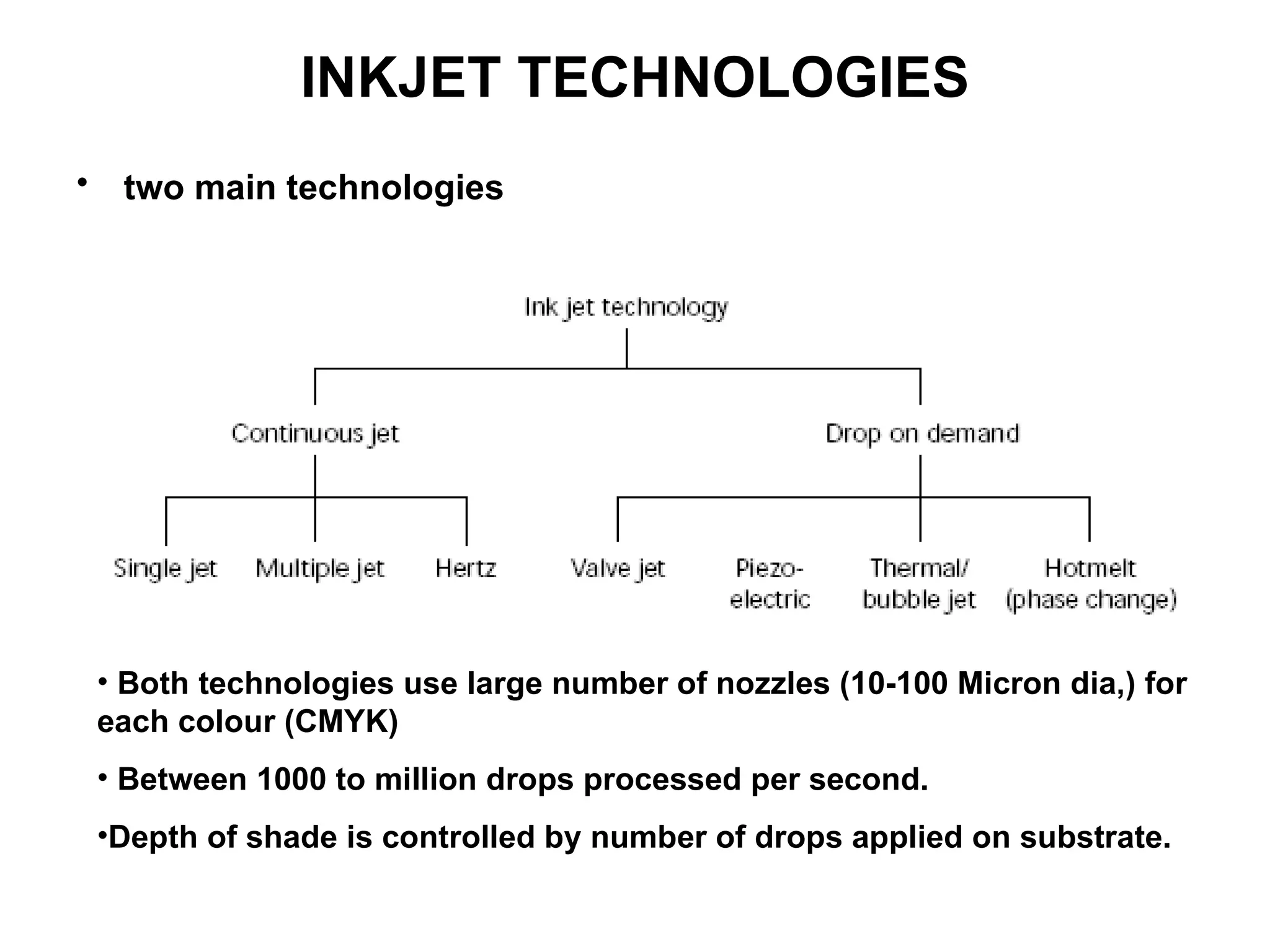

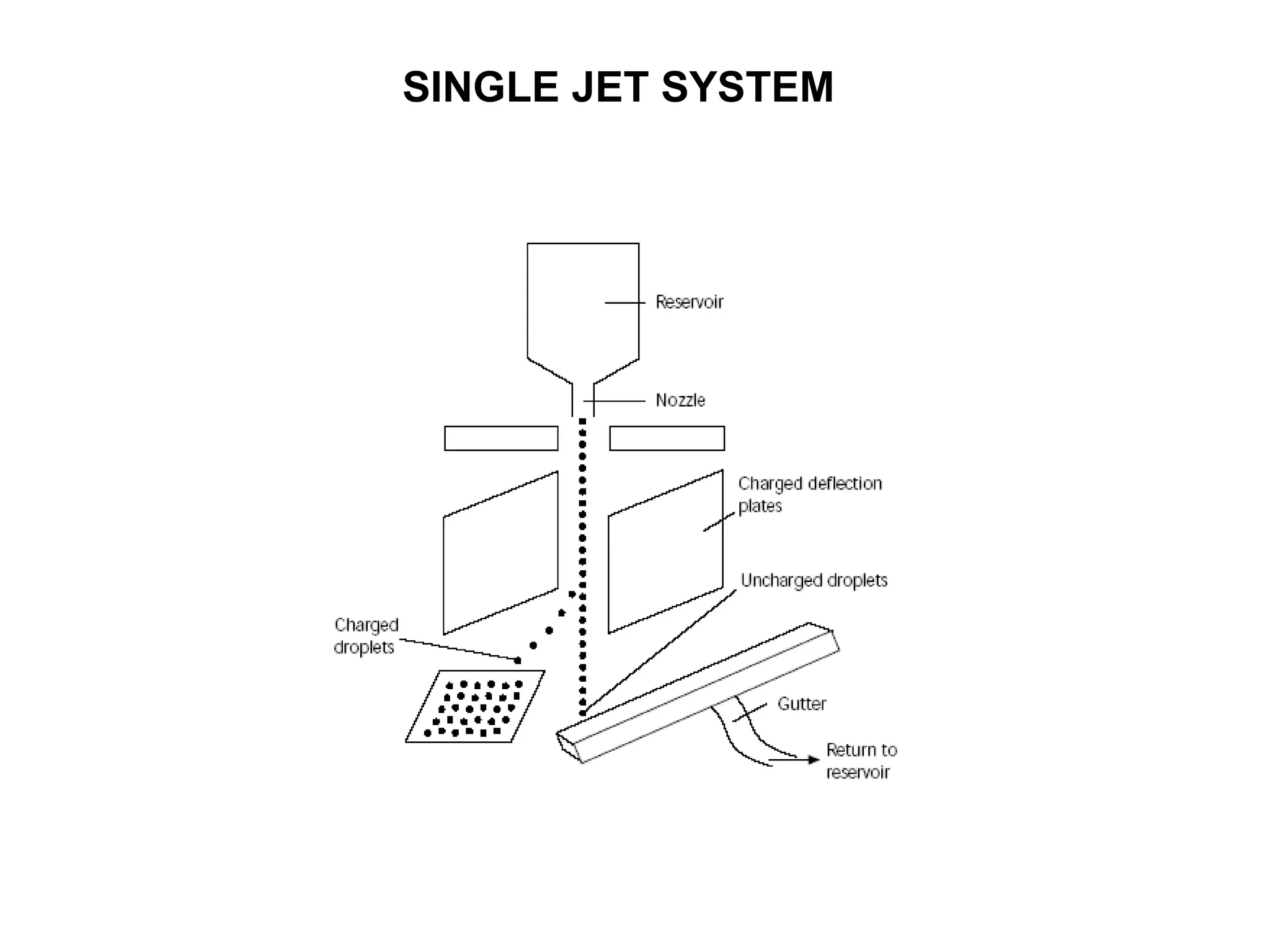

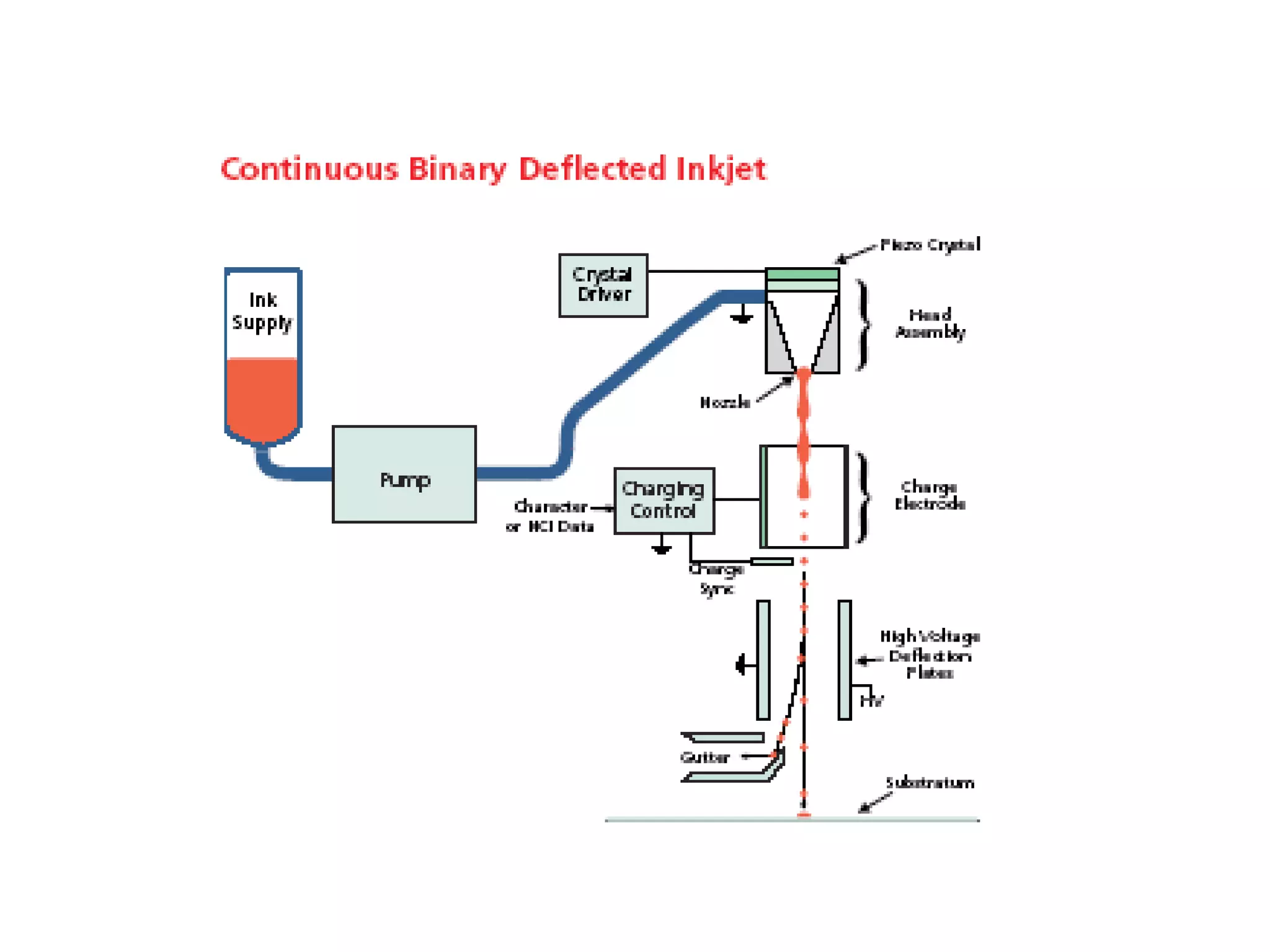

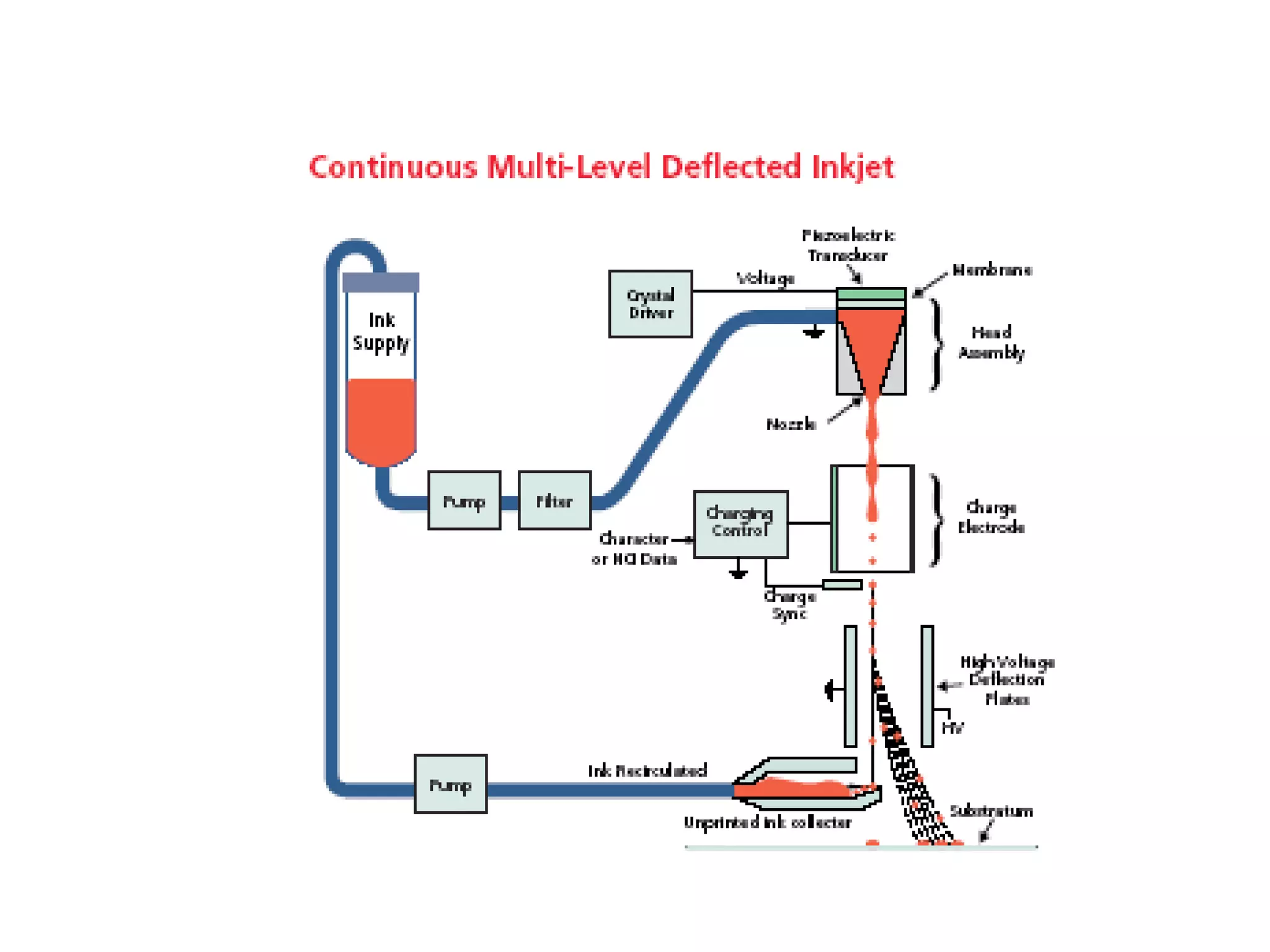

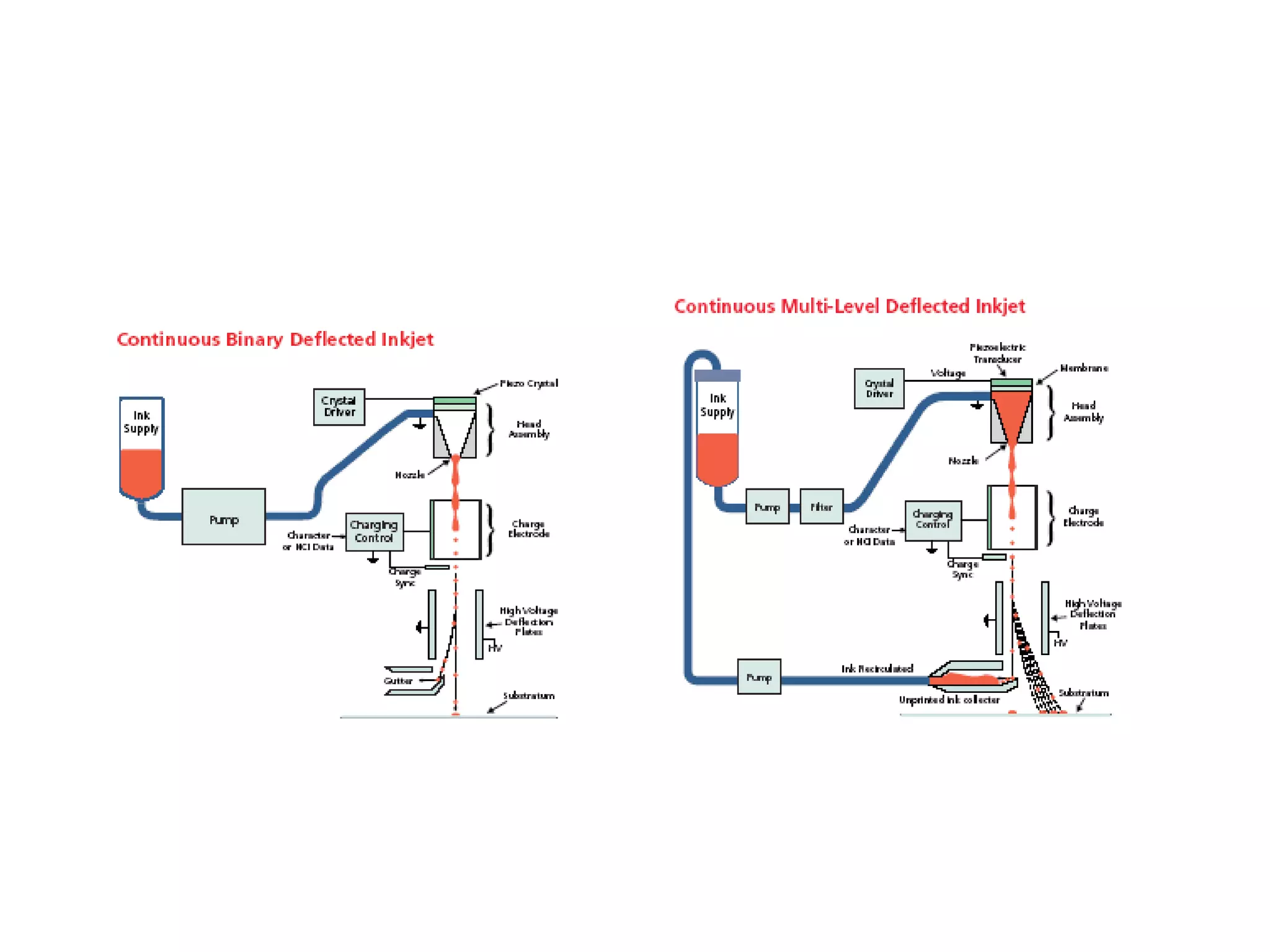

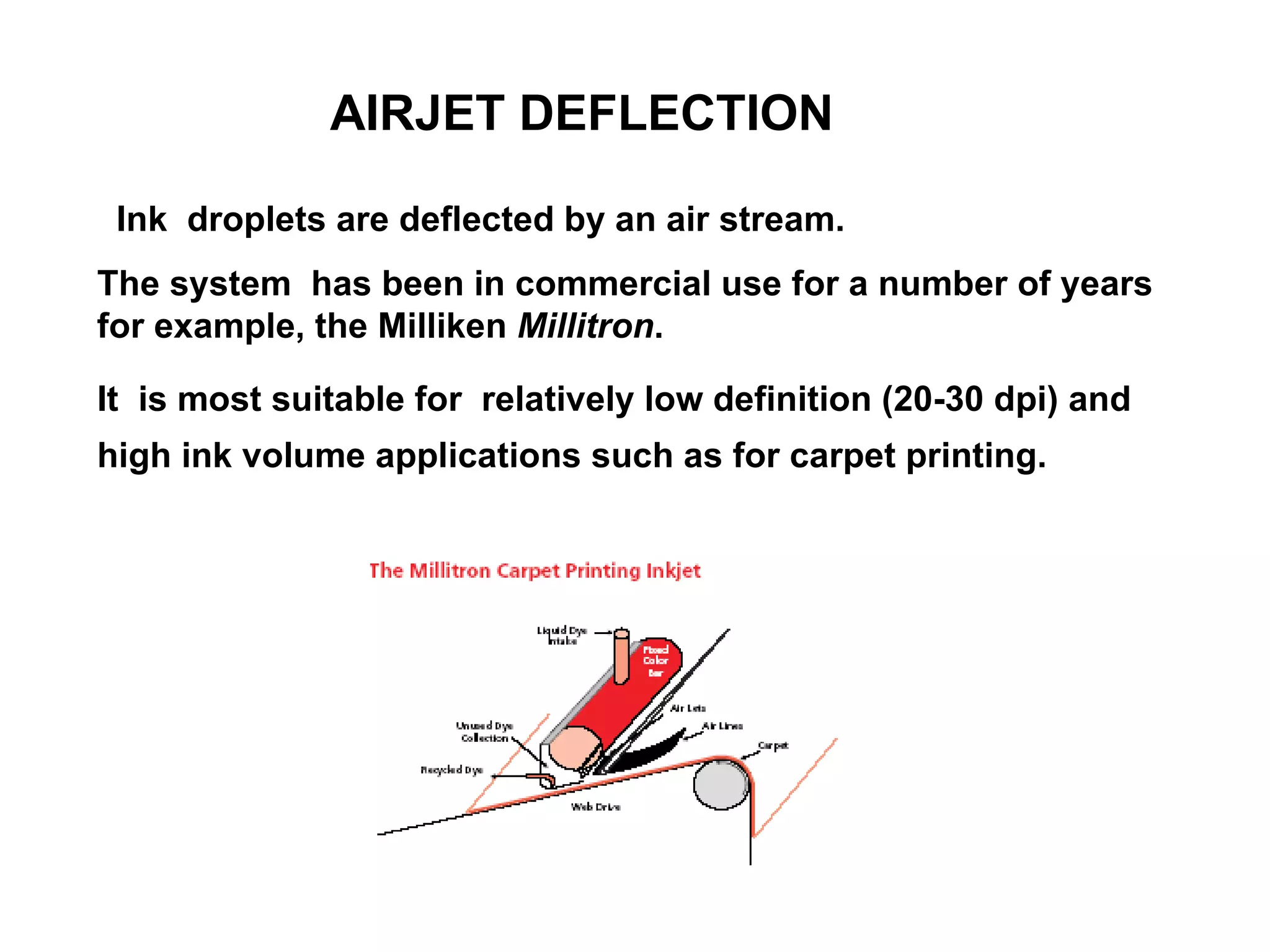

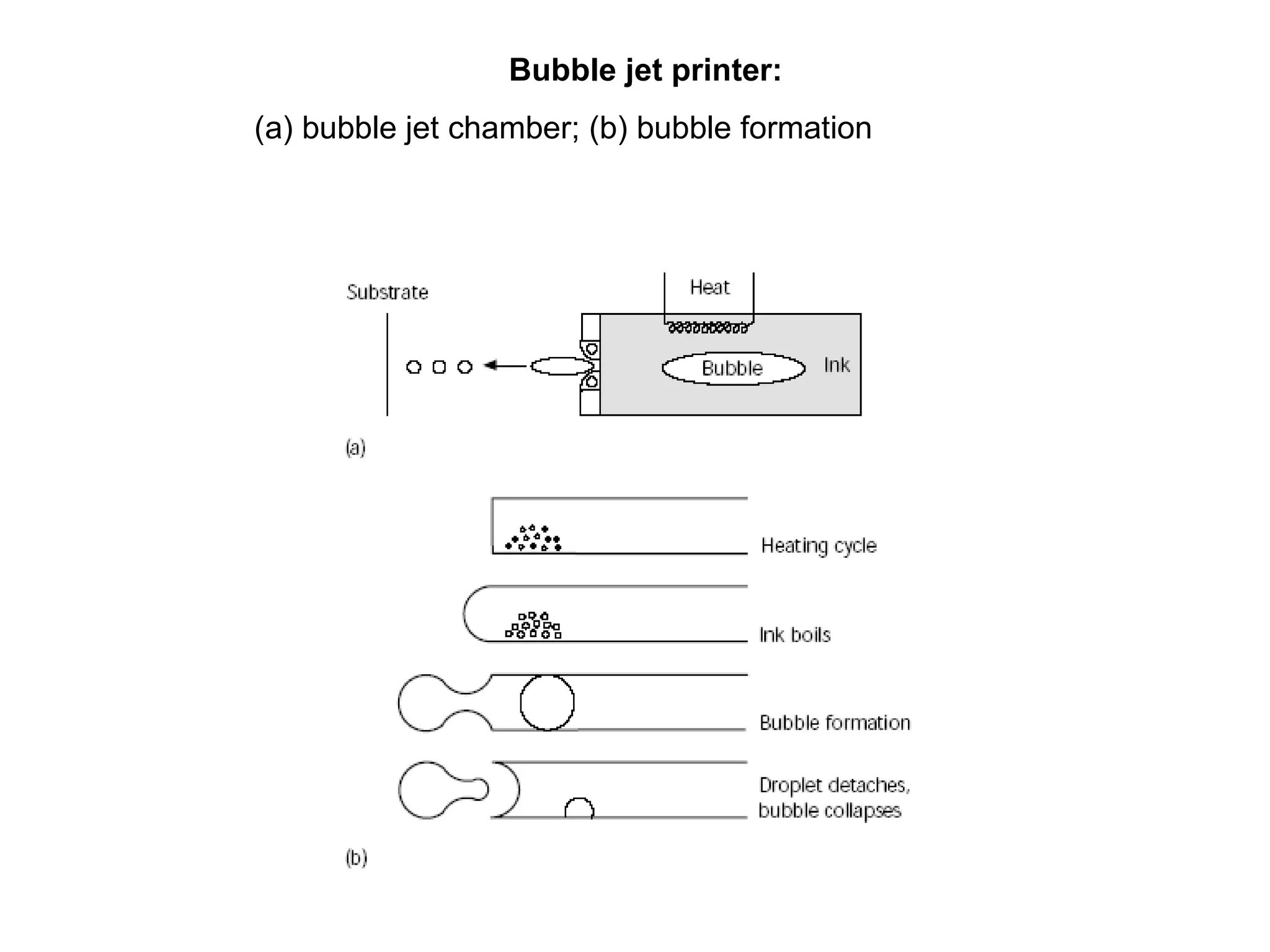

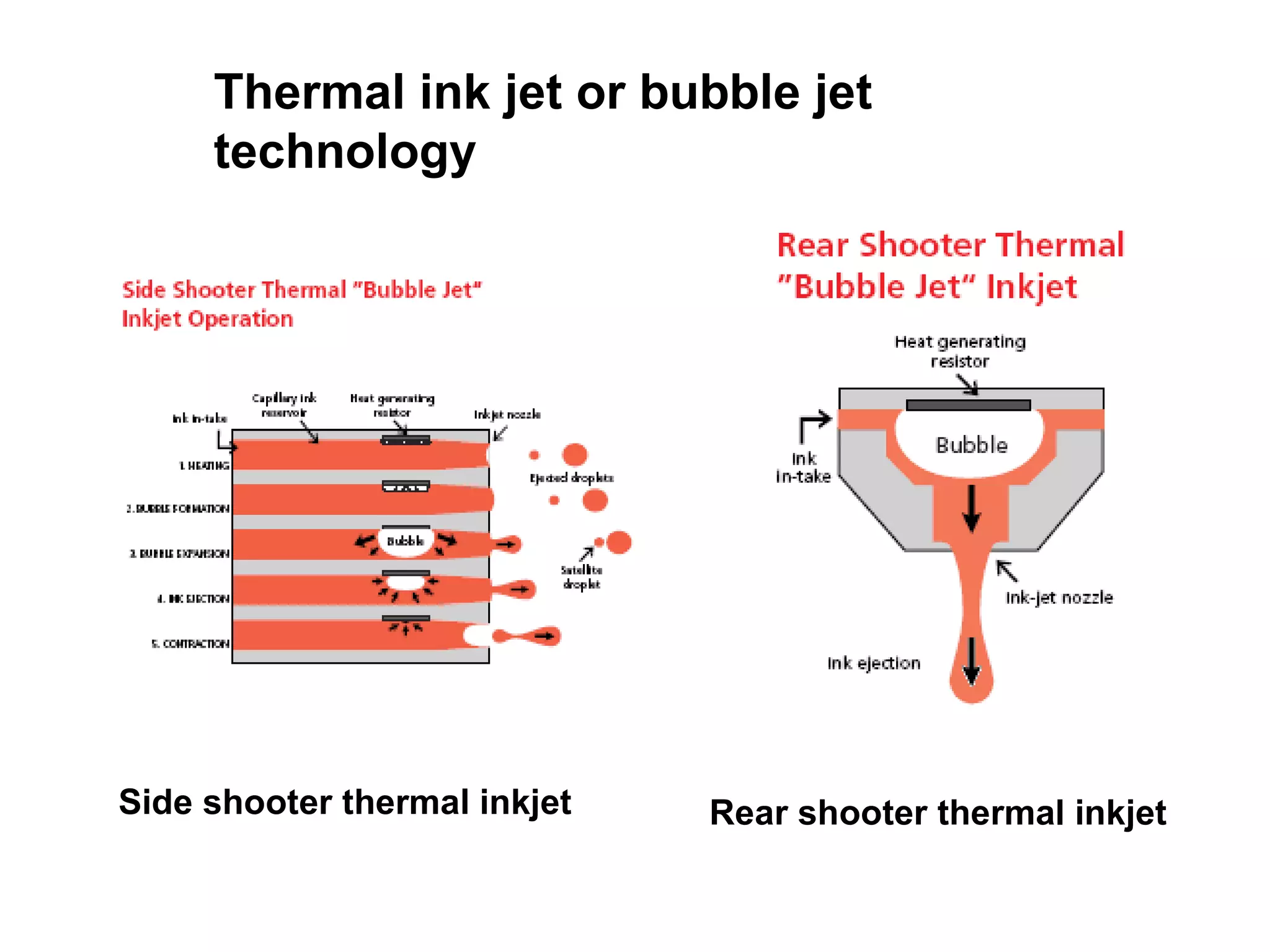

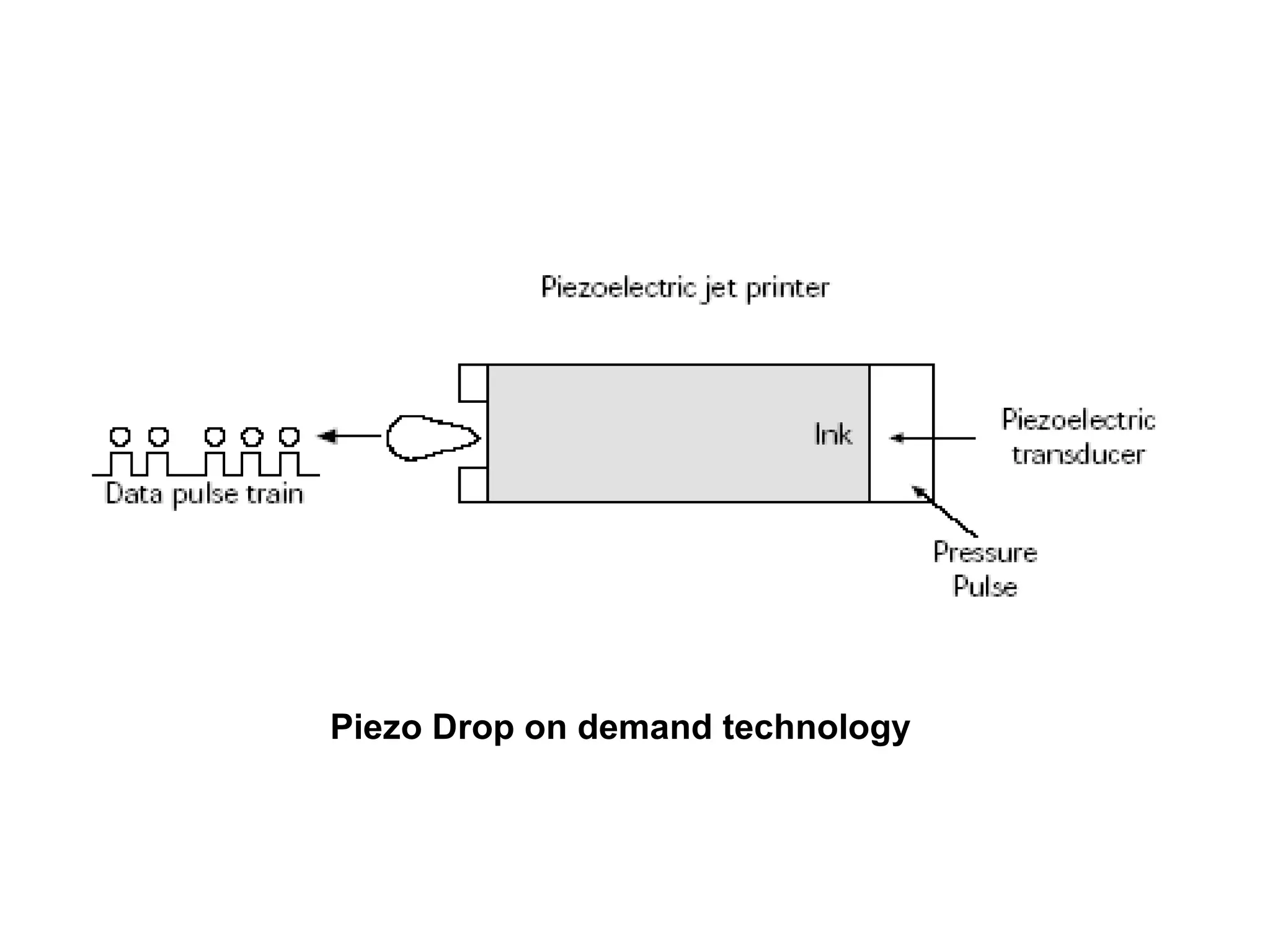

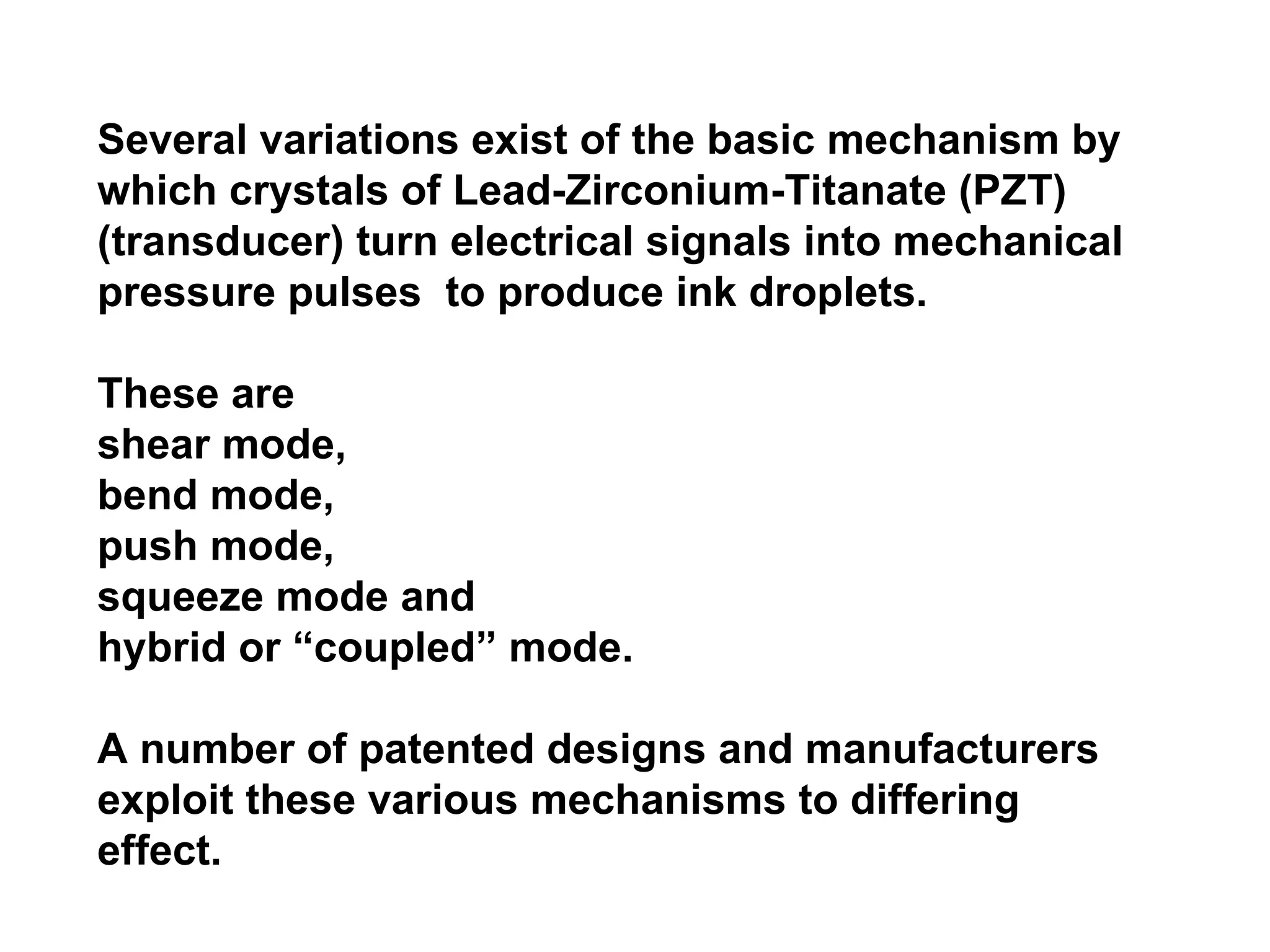

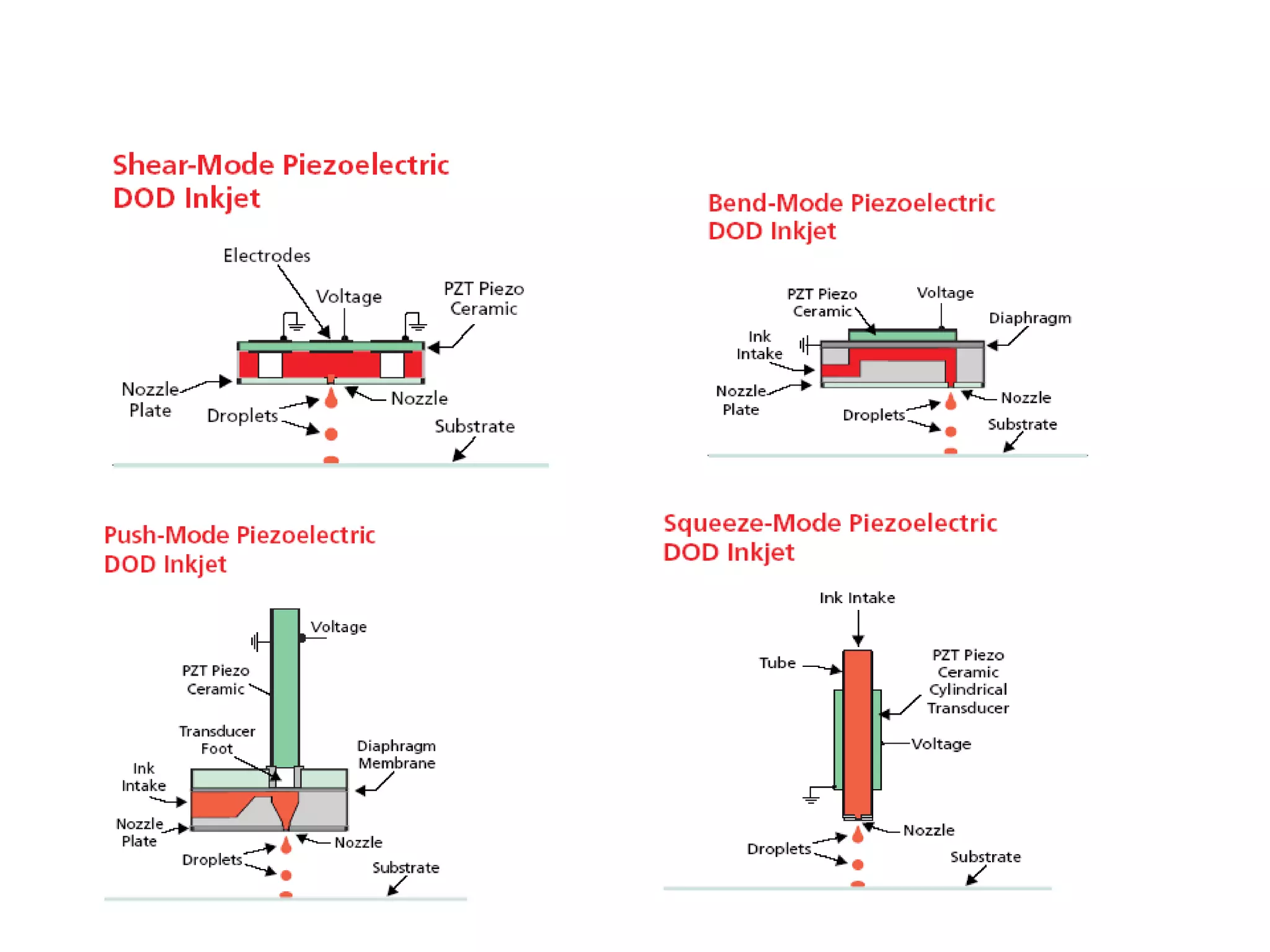

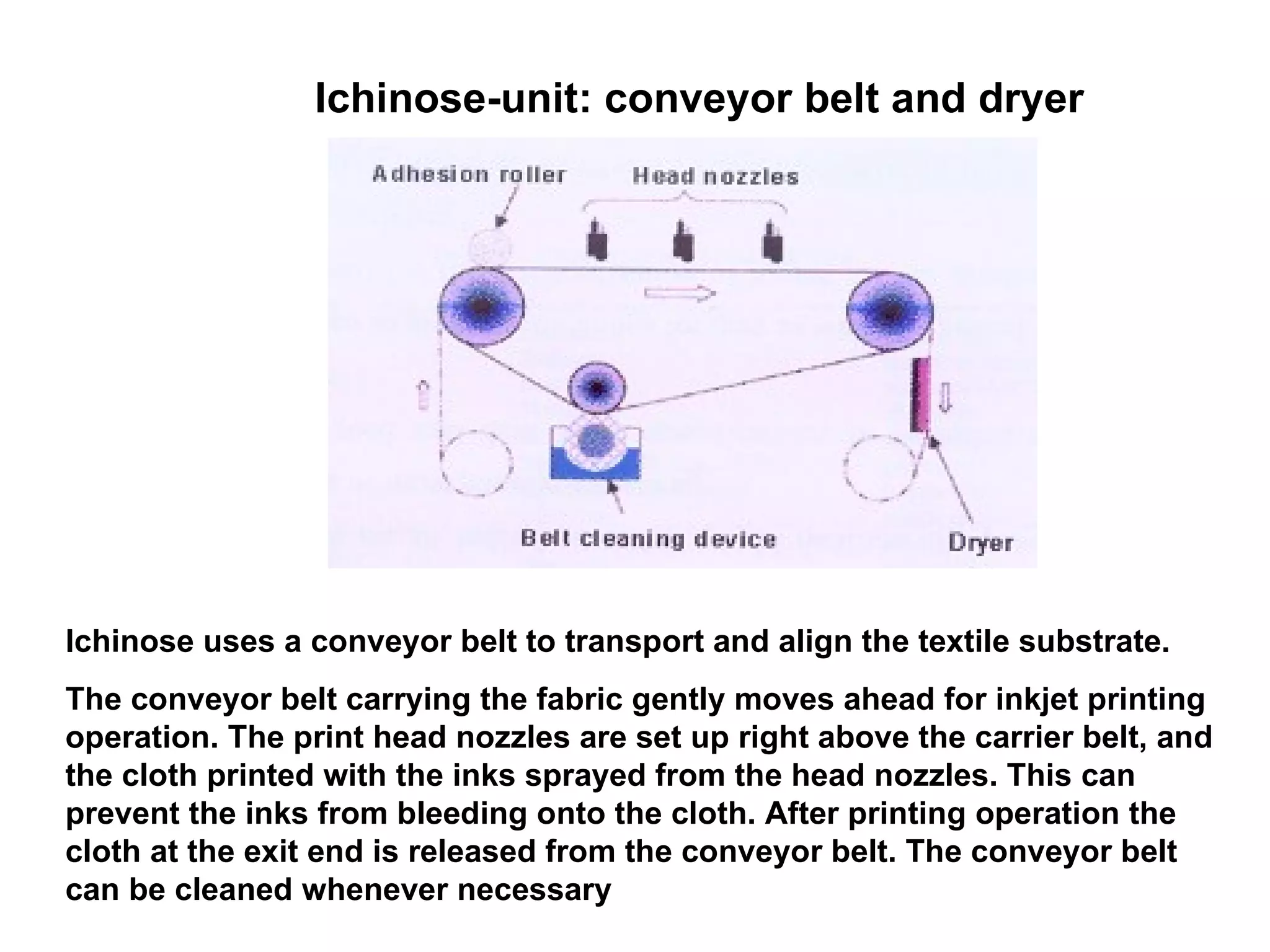

The document discusses digital printing of textiles compared to analog printing methods. Digital printing involves storing the design electronically and using an inkjet printer to apply the design to fabric without screens or plates. It has advantages over analog methods like quicker turnaround times, lower costs for short runs, and more design flexibility. The two main inkjet technologies discussed are continuous inkjet which uses electrically-charged droplets, and drop-on-demand inkjet which forms droplets only as needed using thermal or piezoelectric methods.