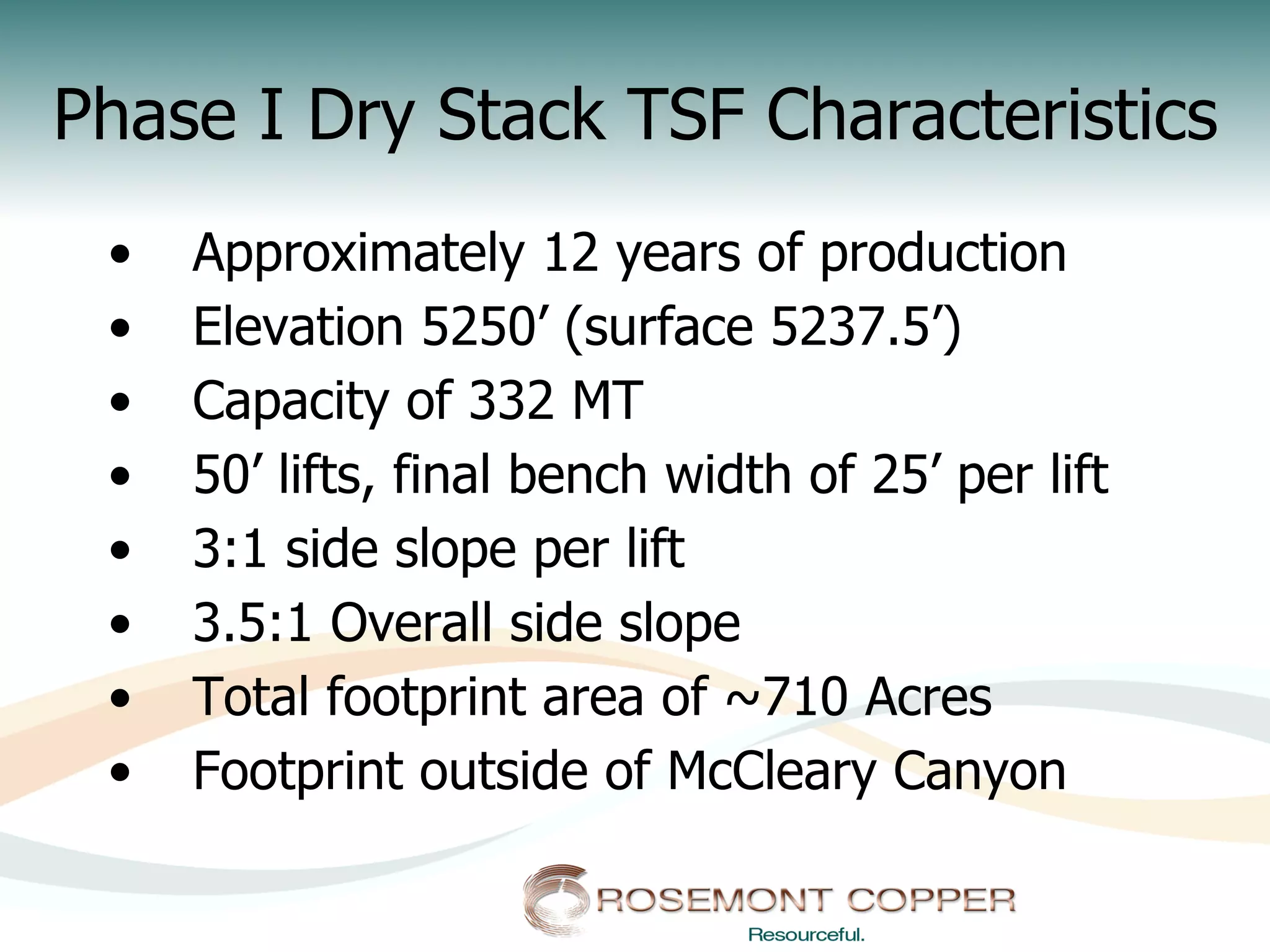

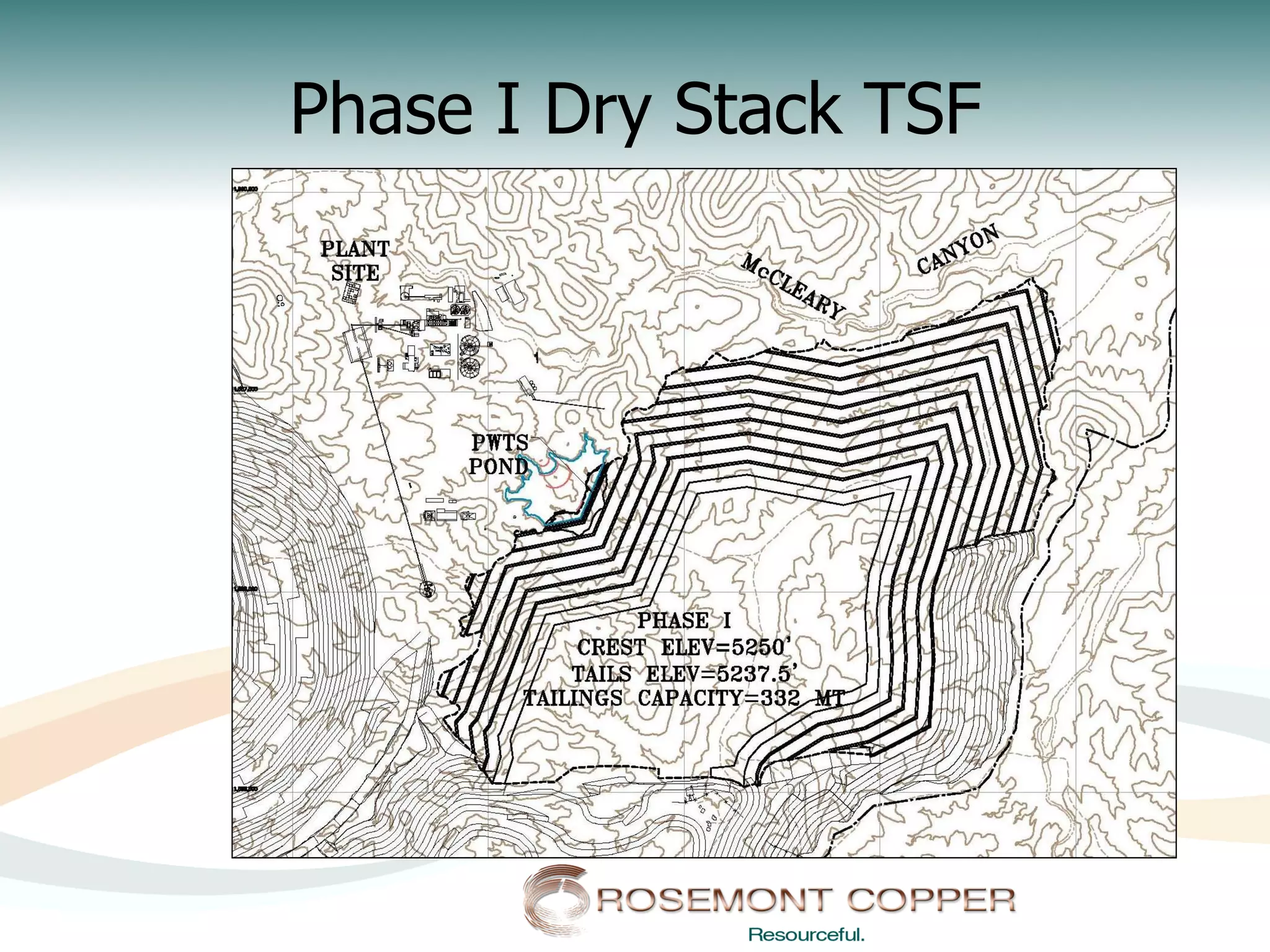

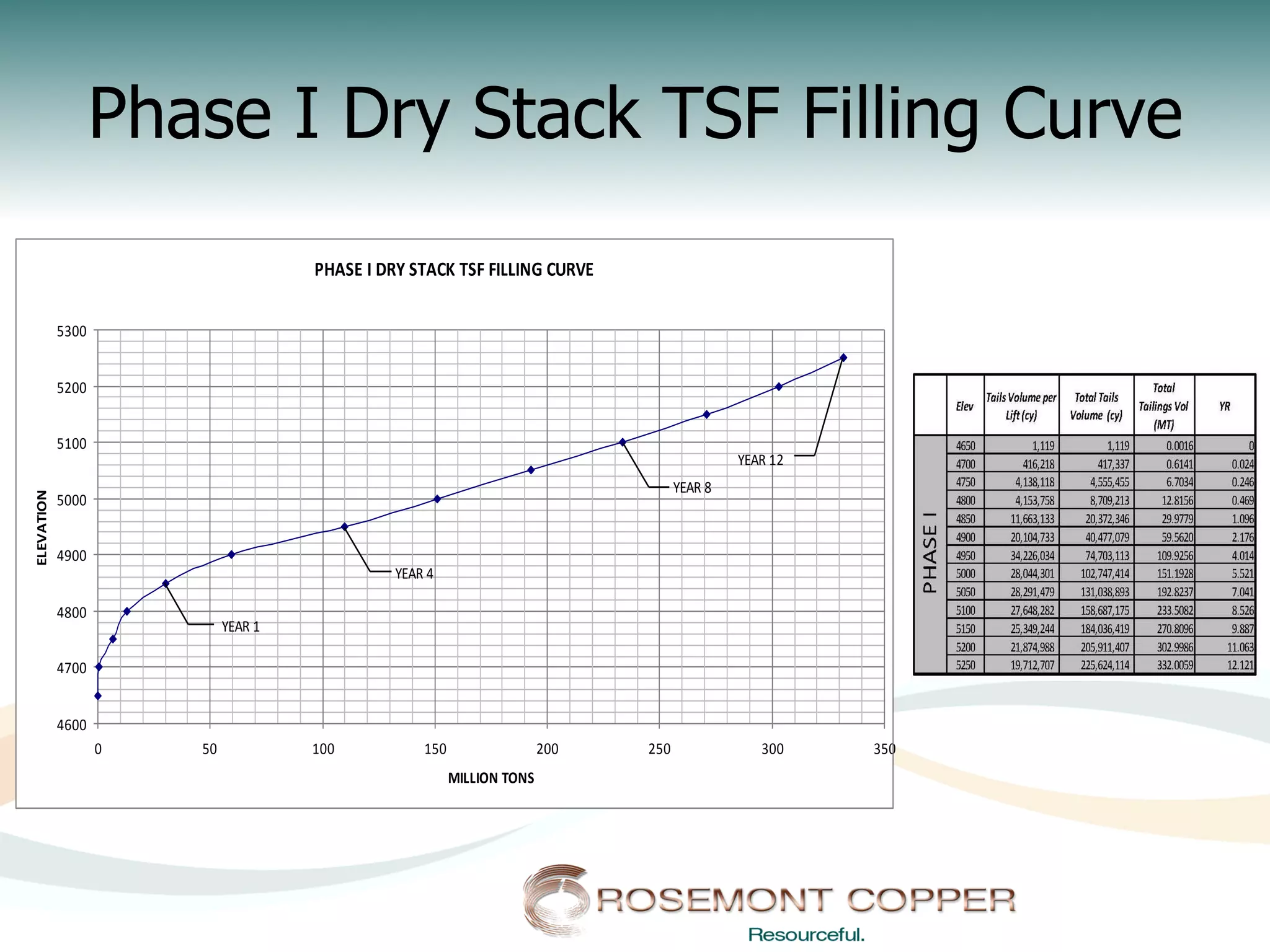

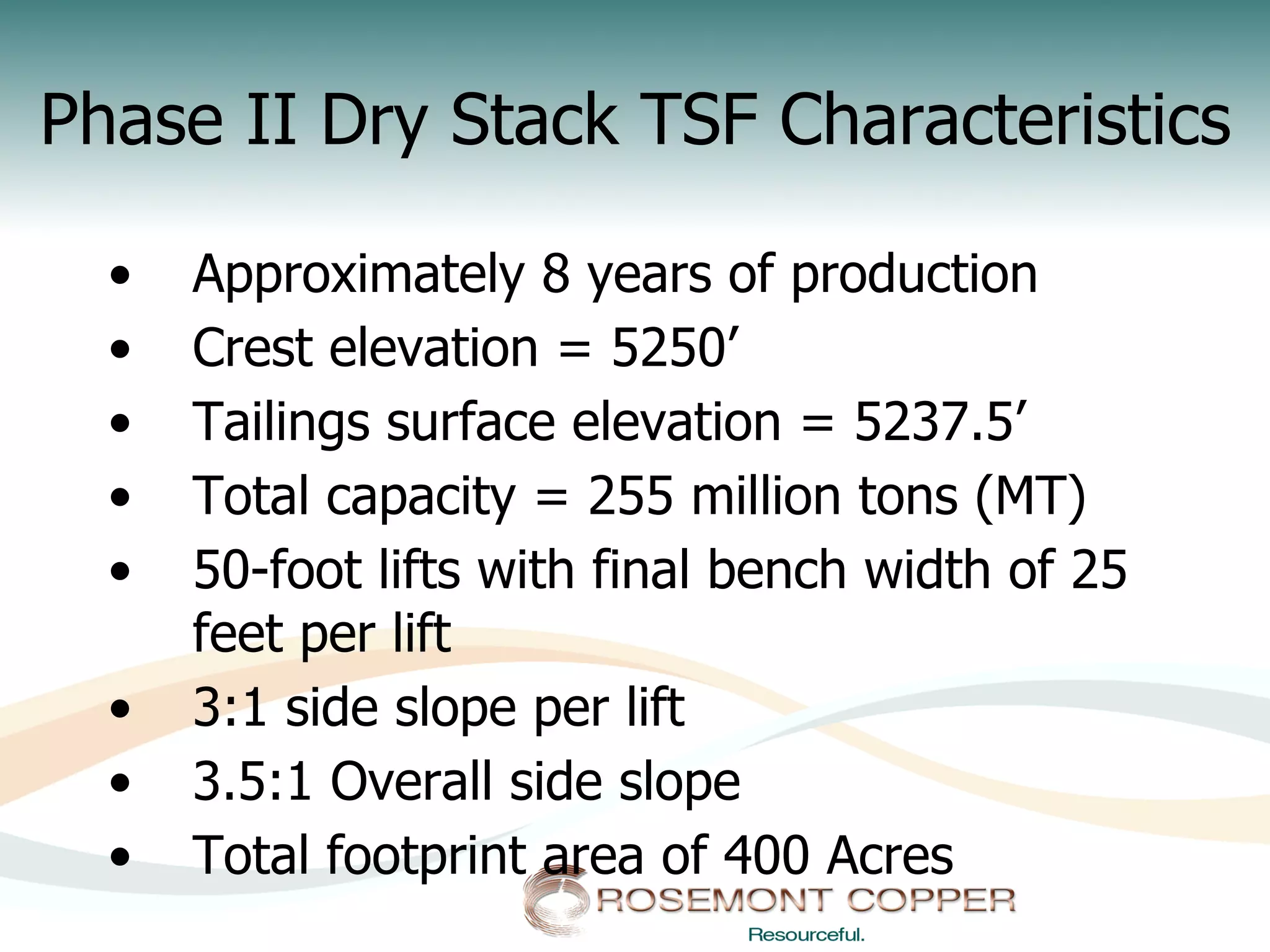

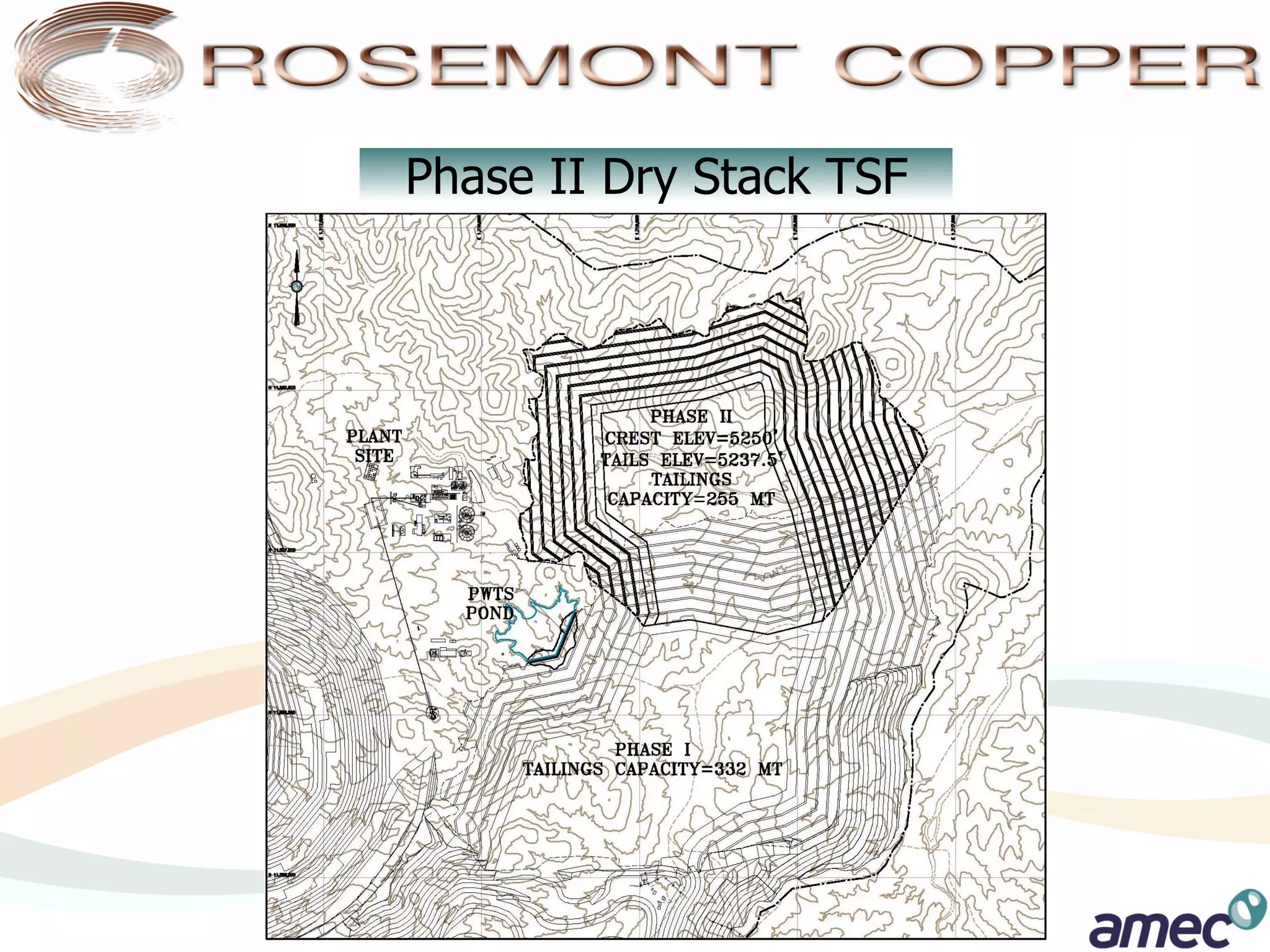

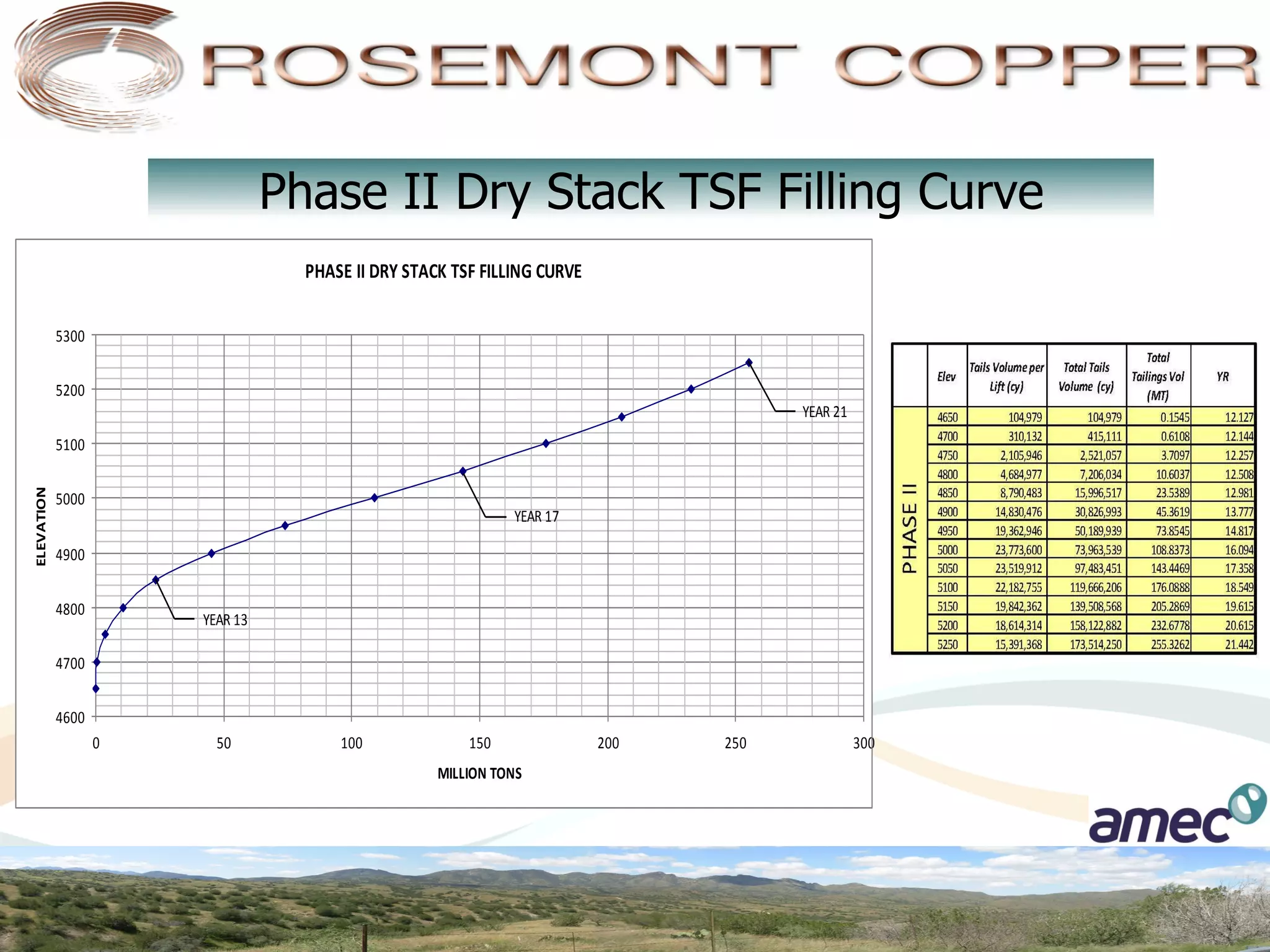

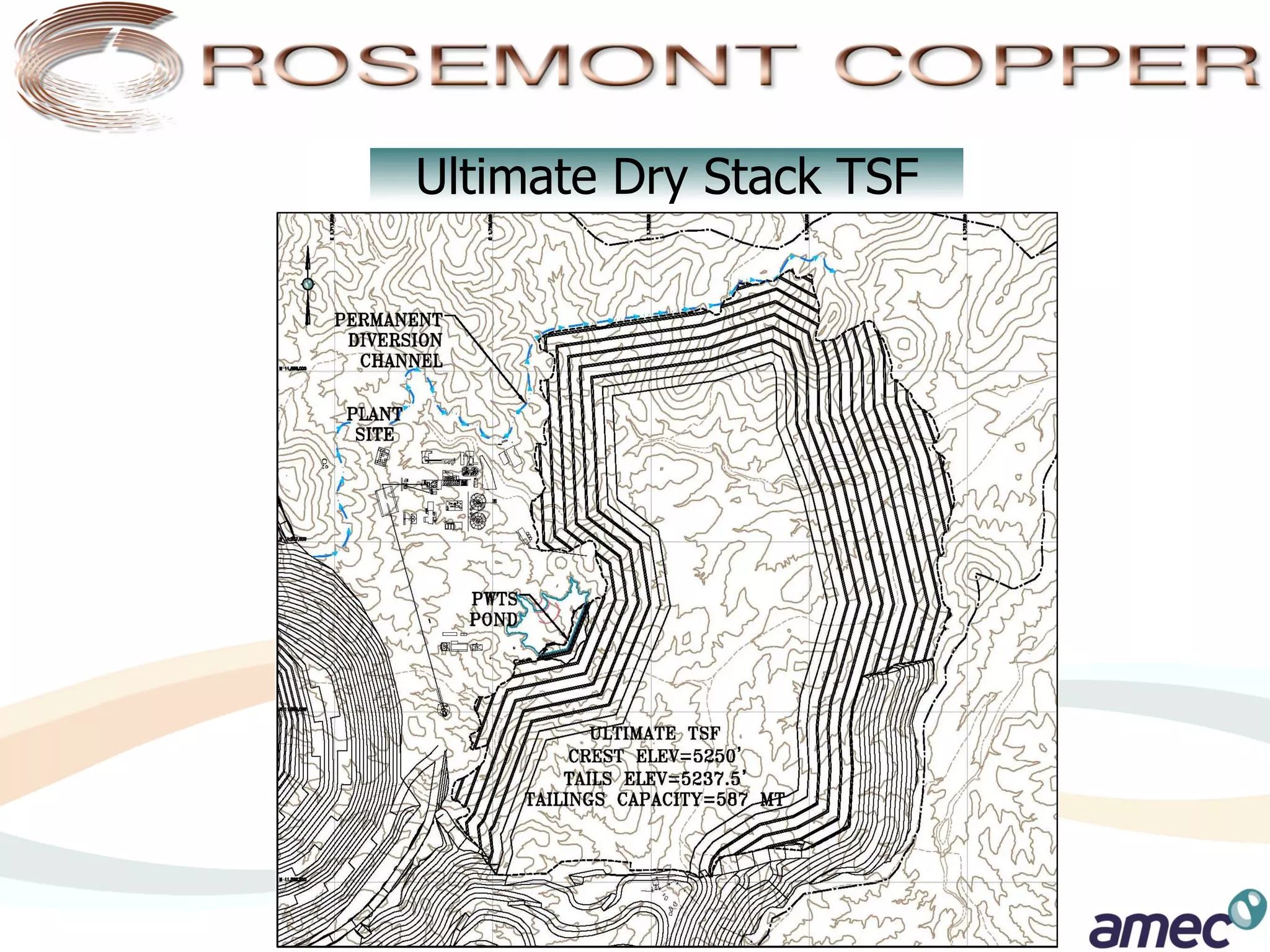

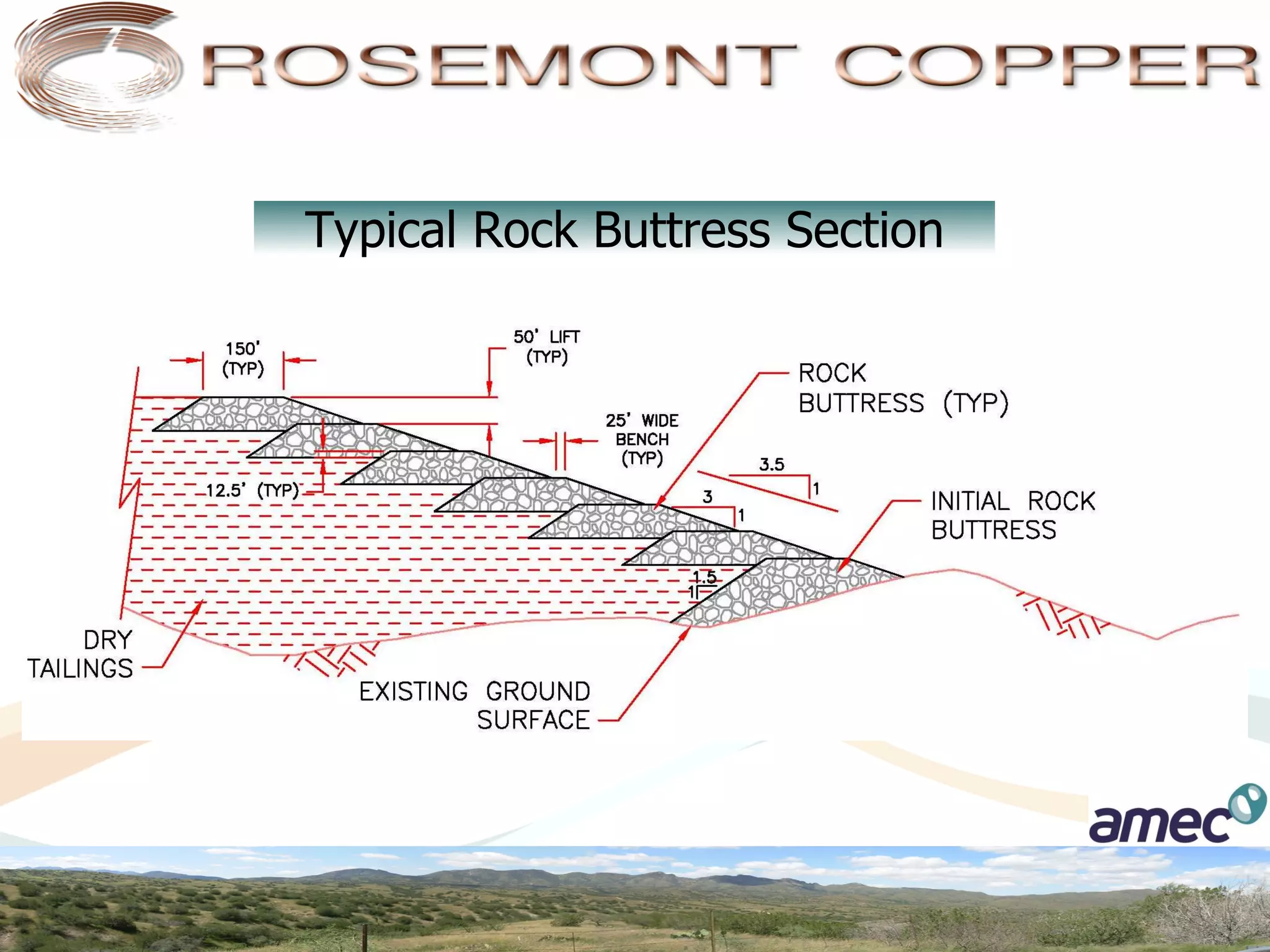

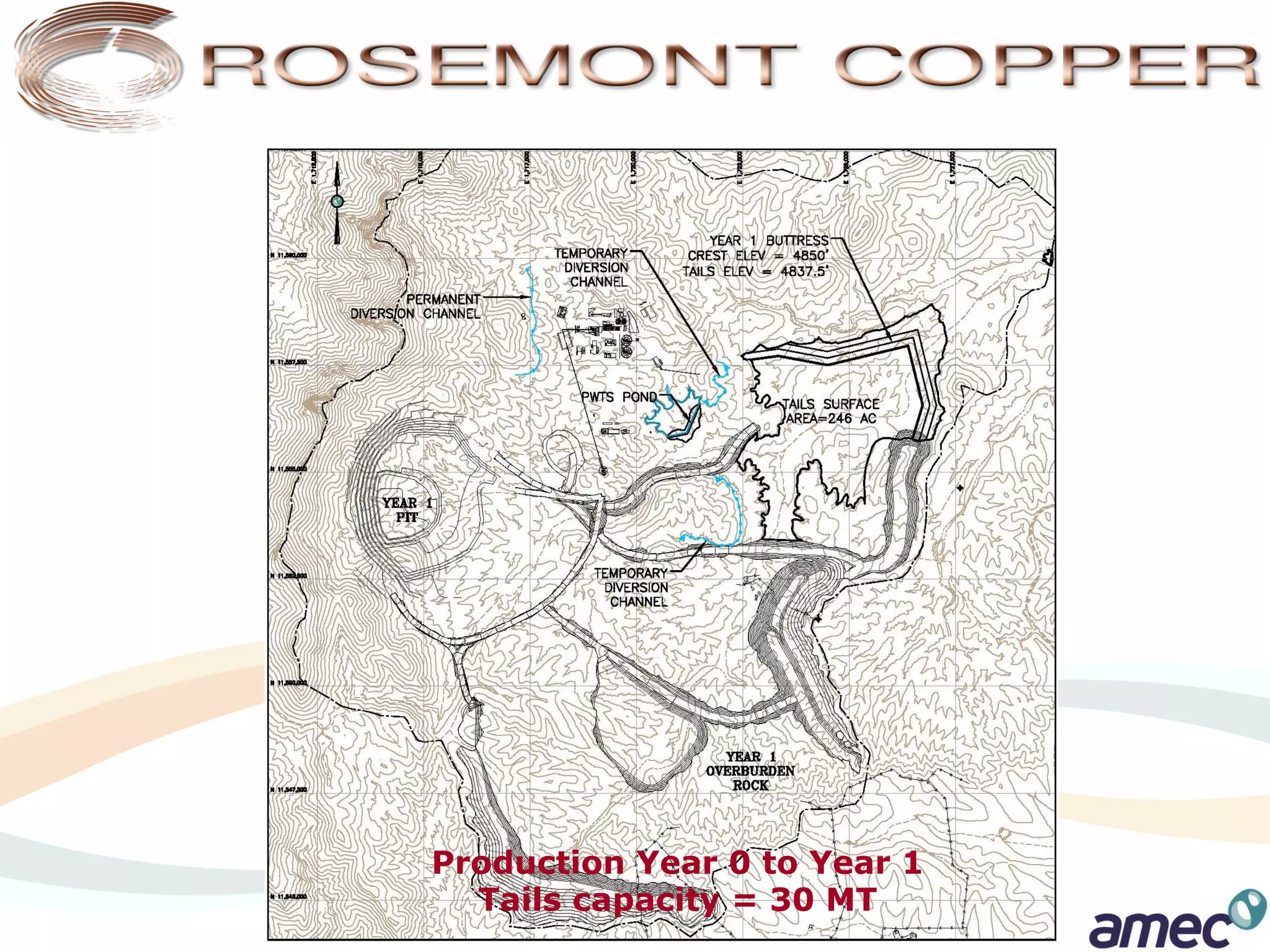

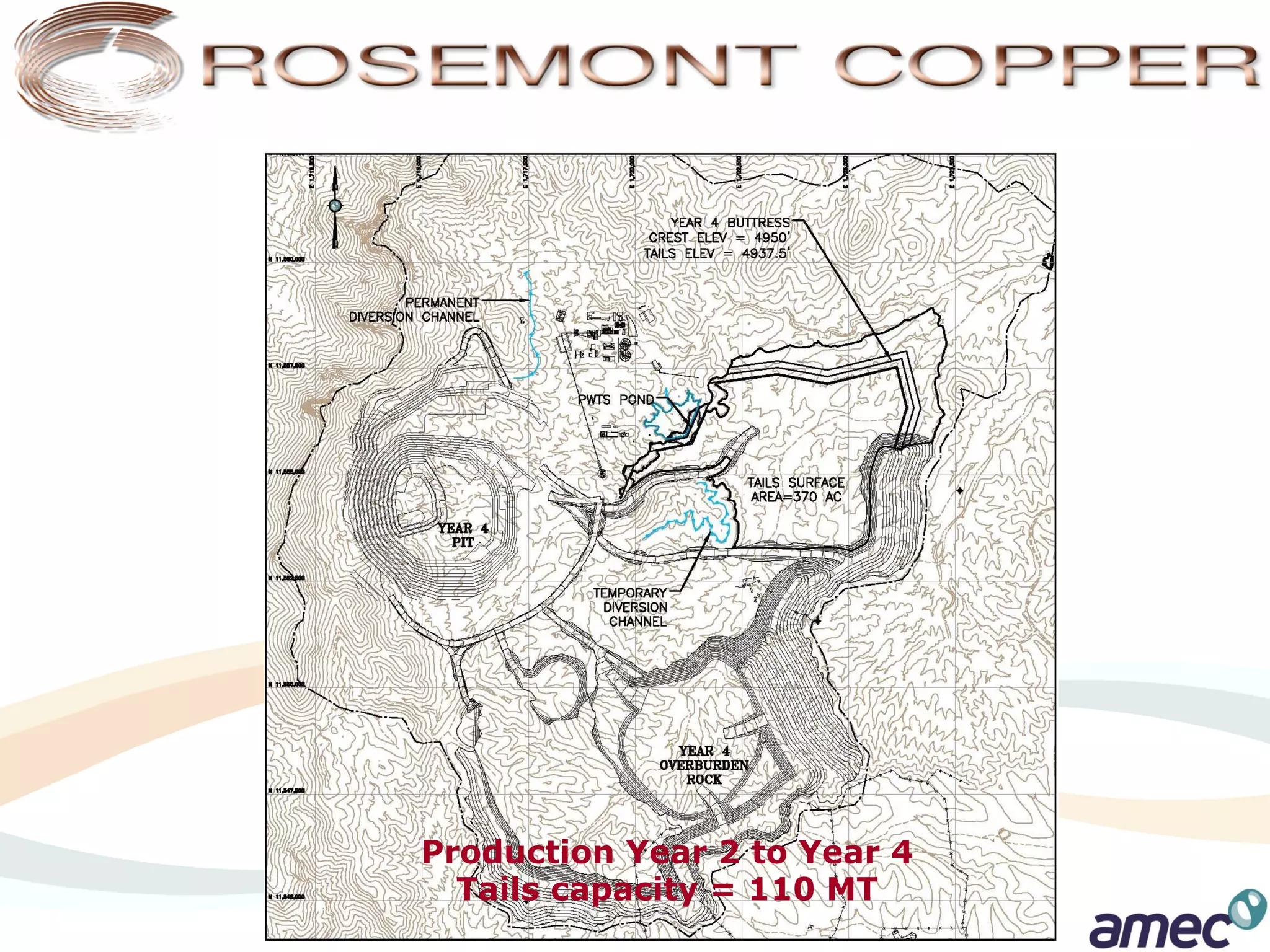

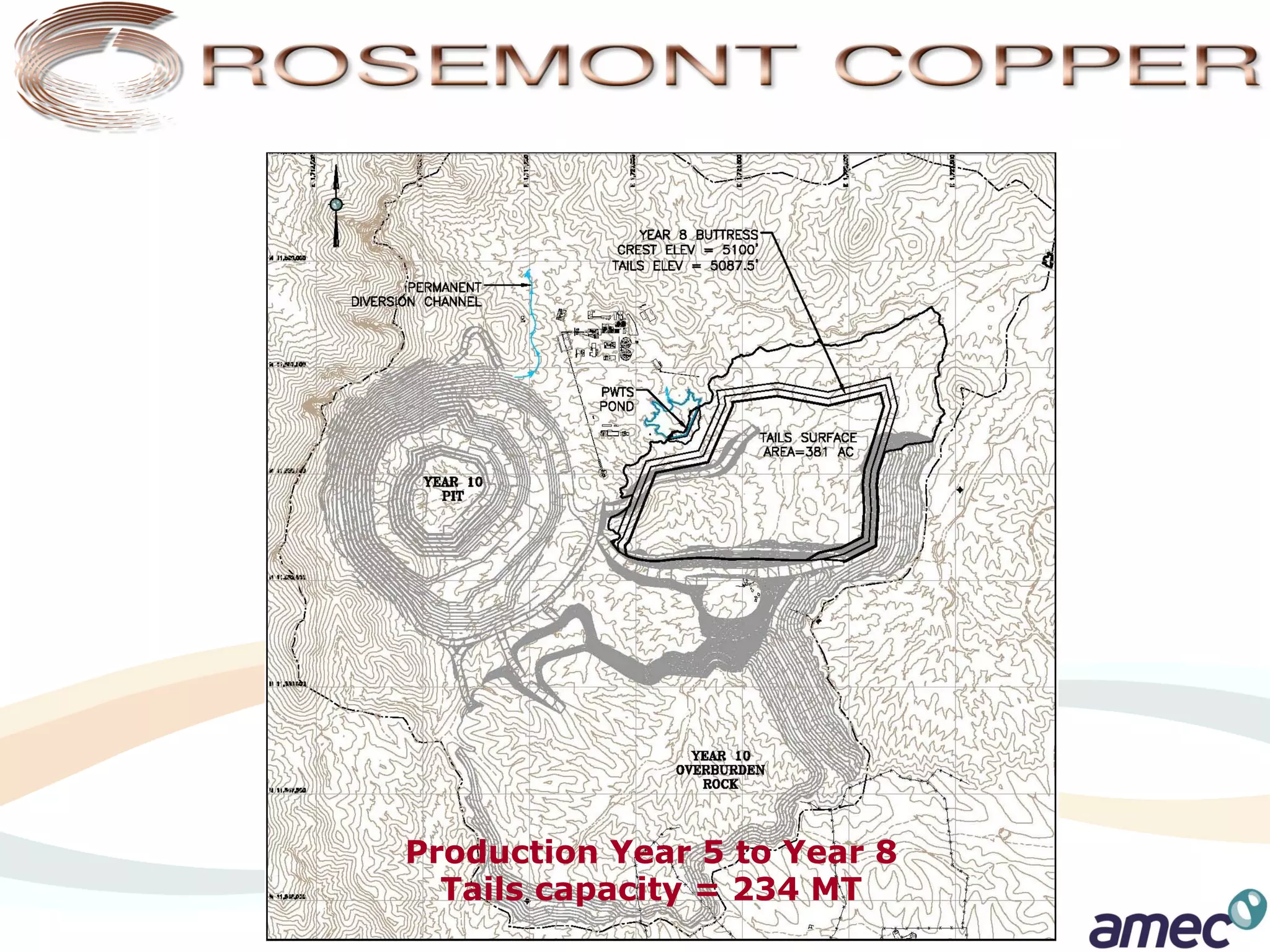

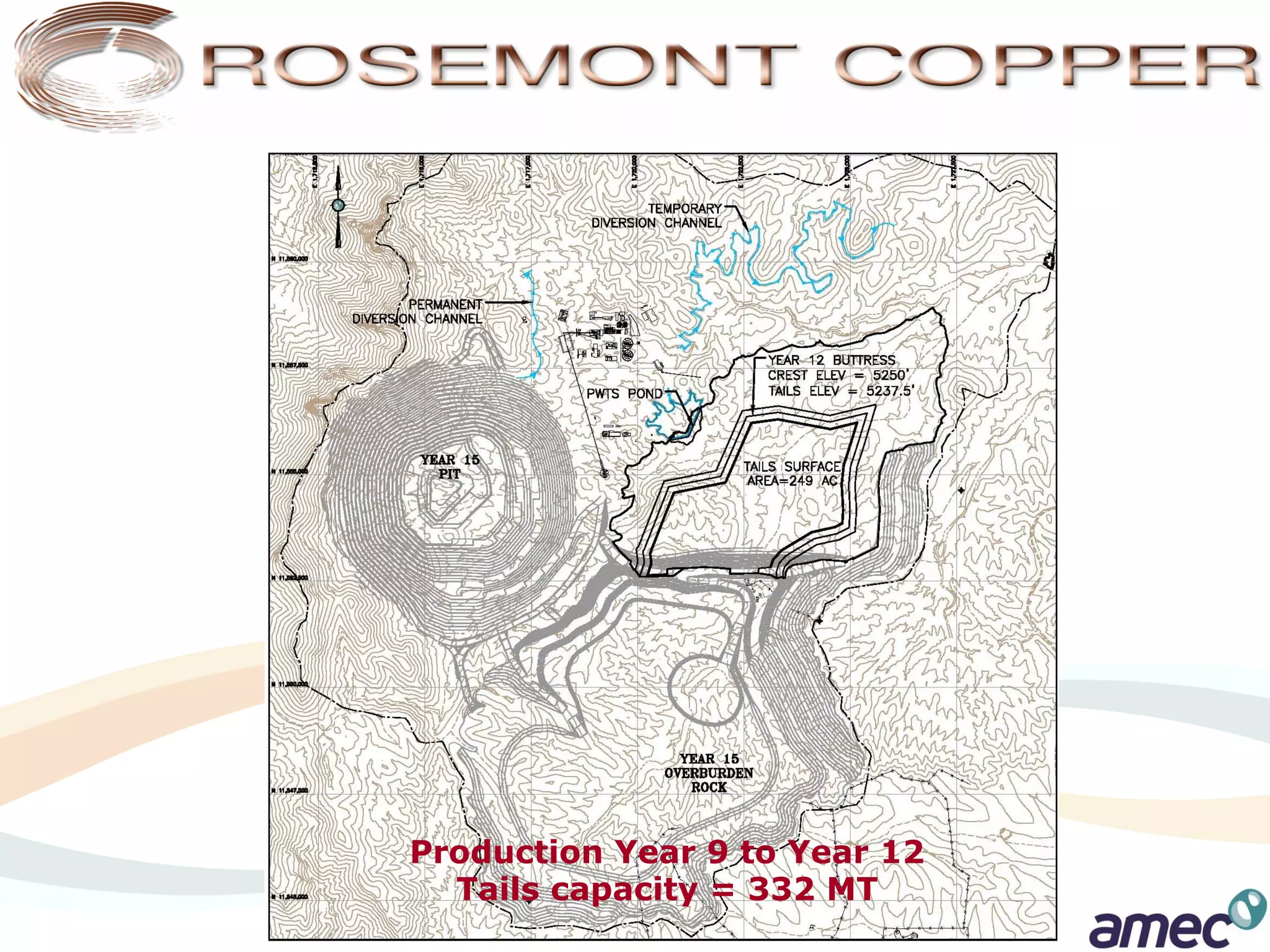

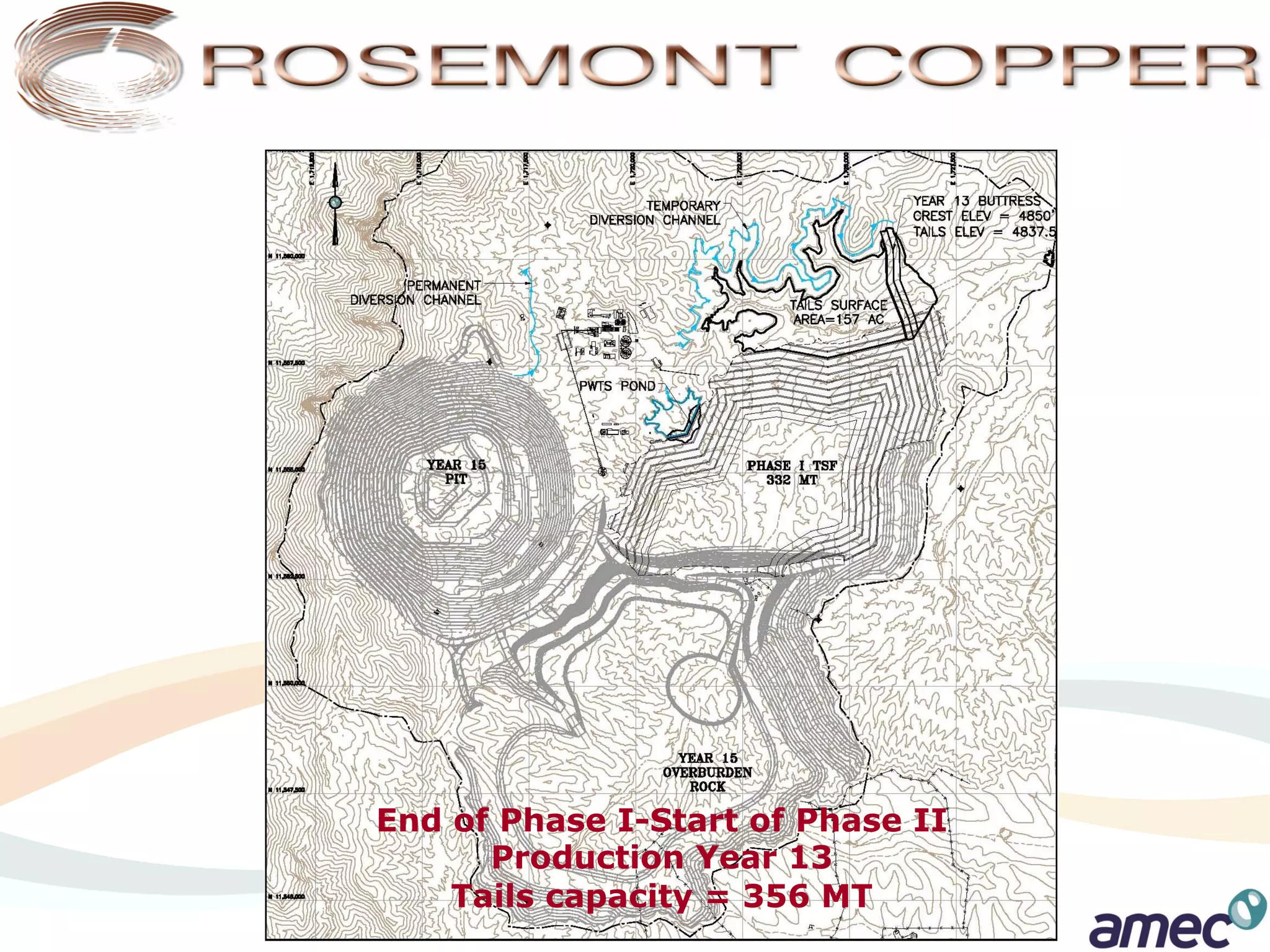

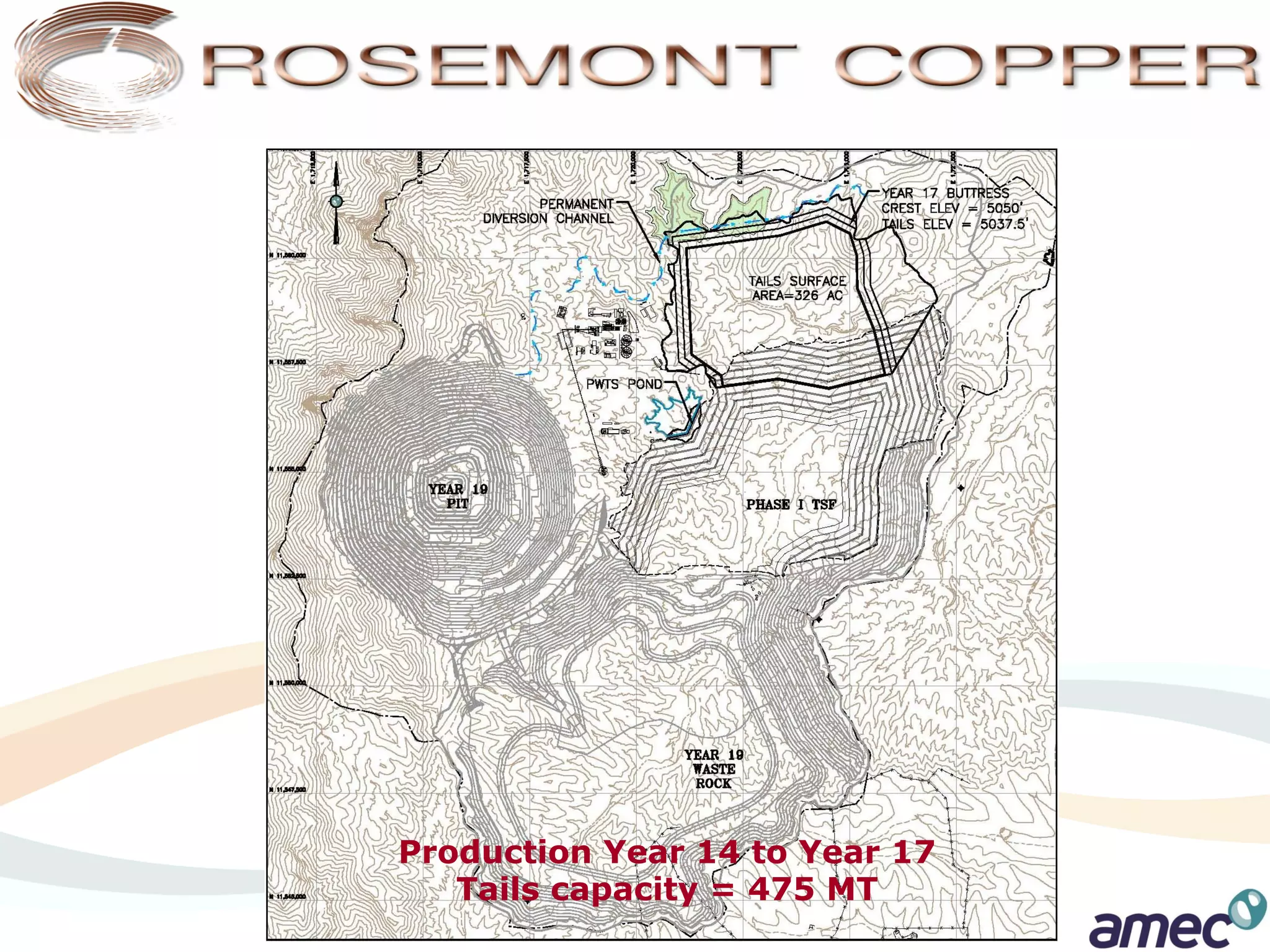

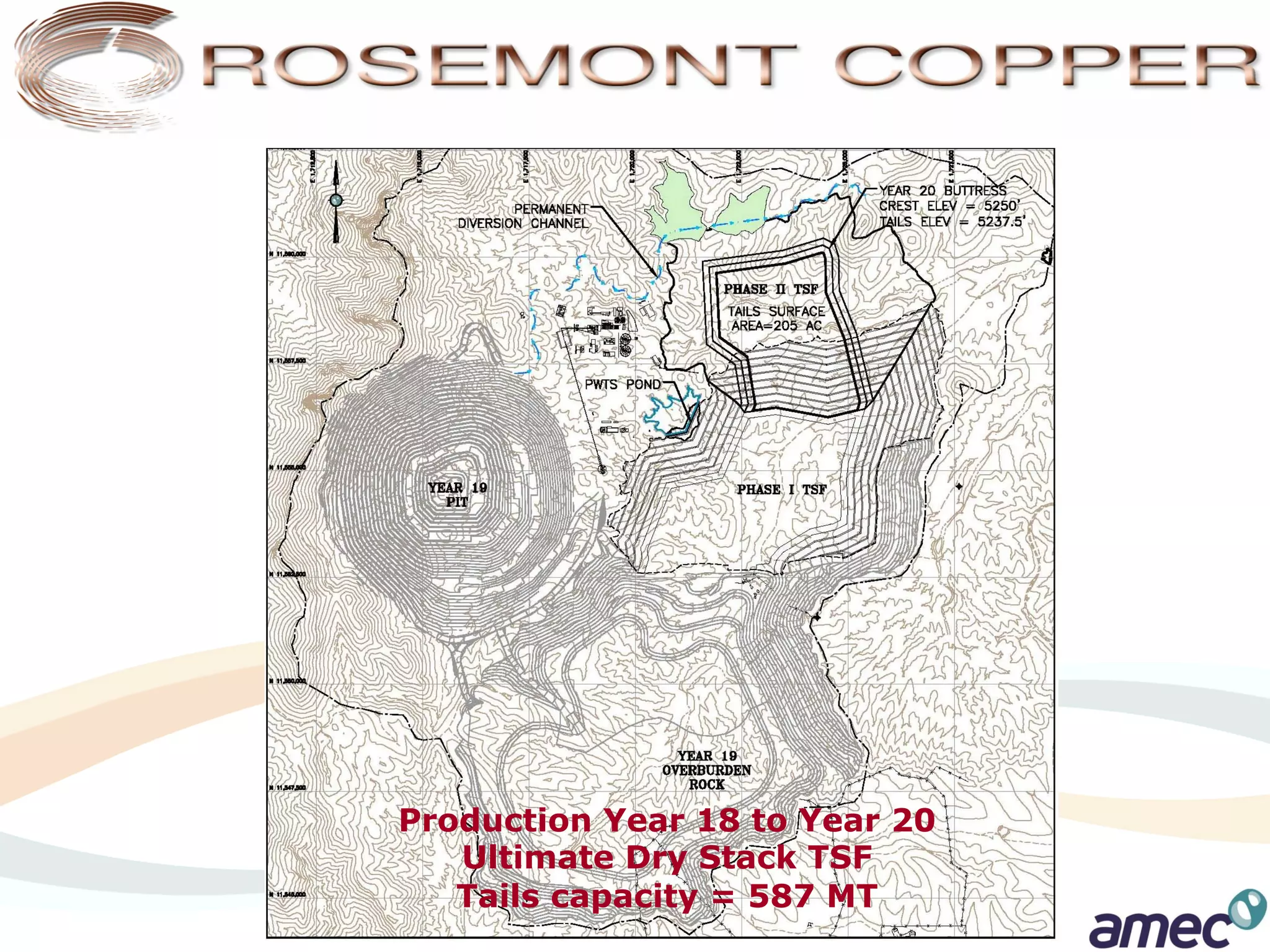

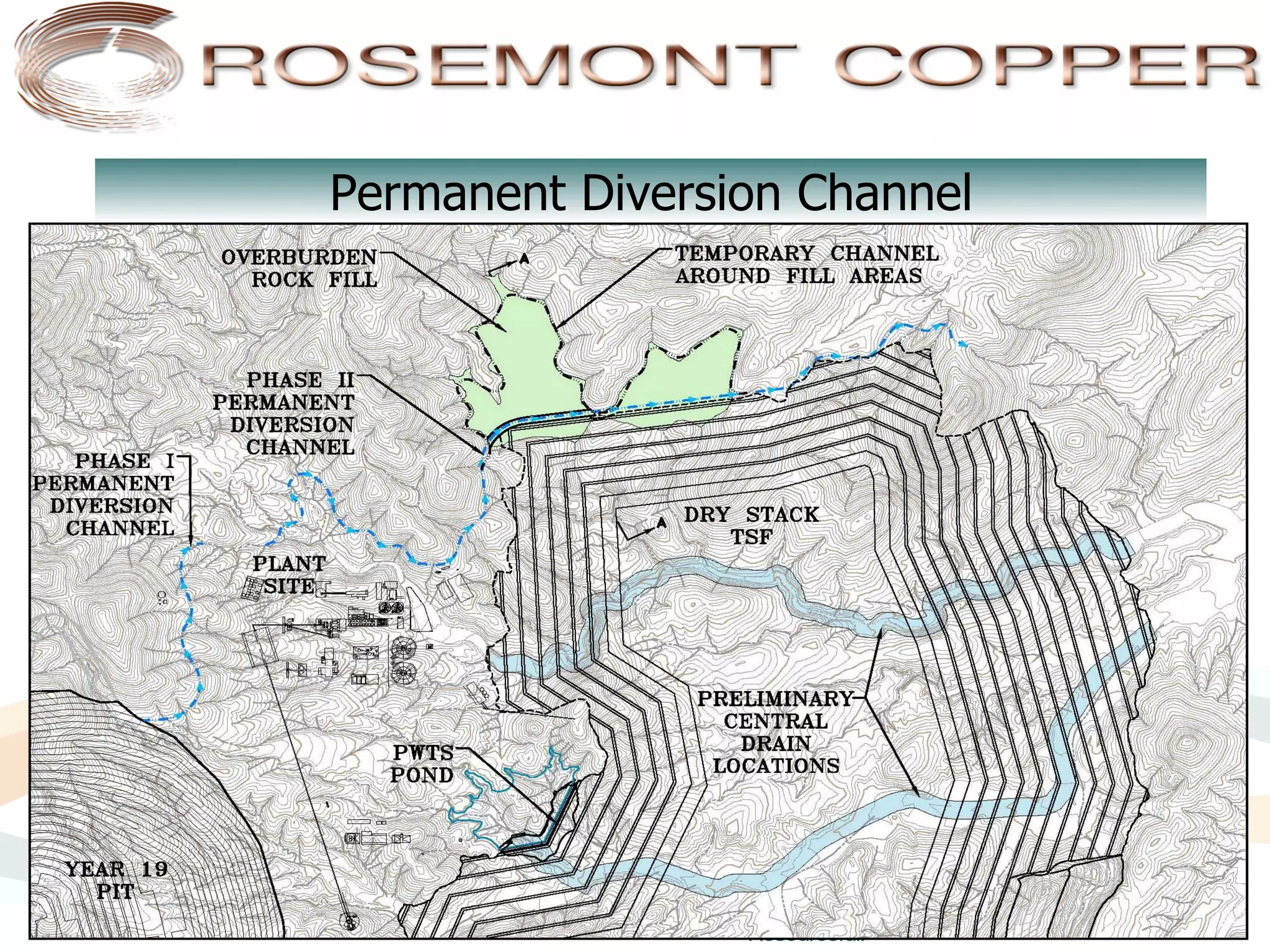

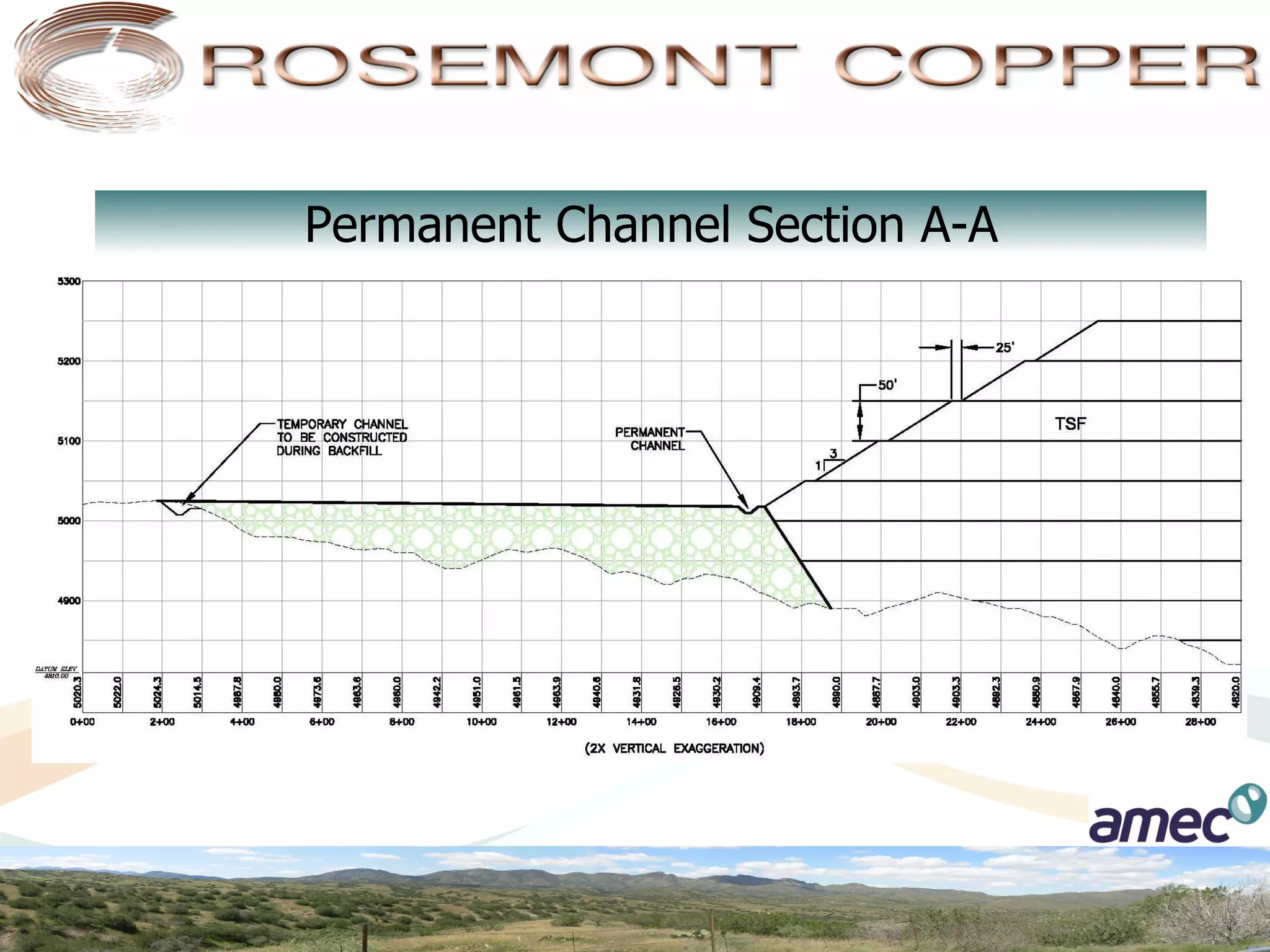

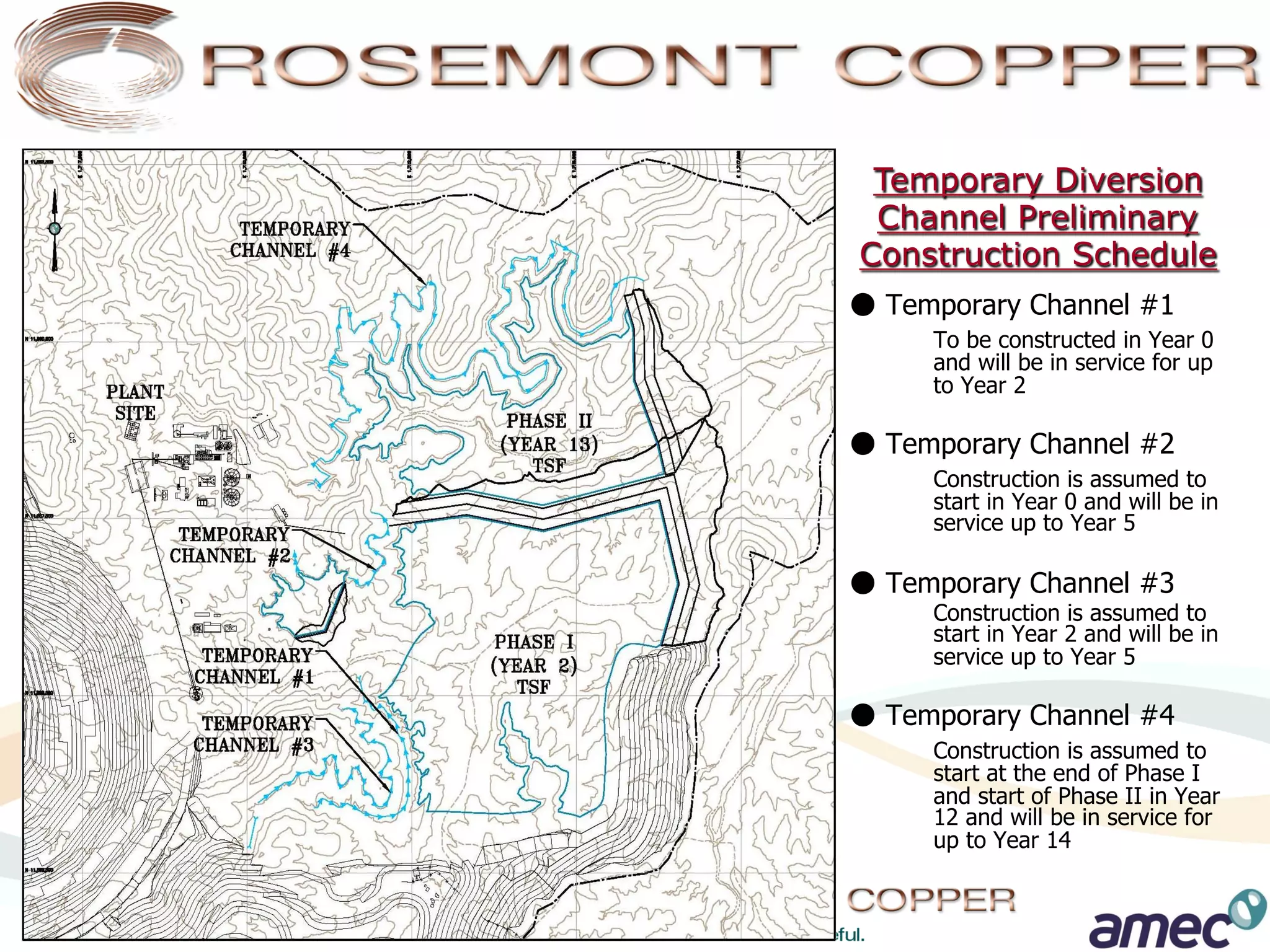

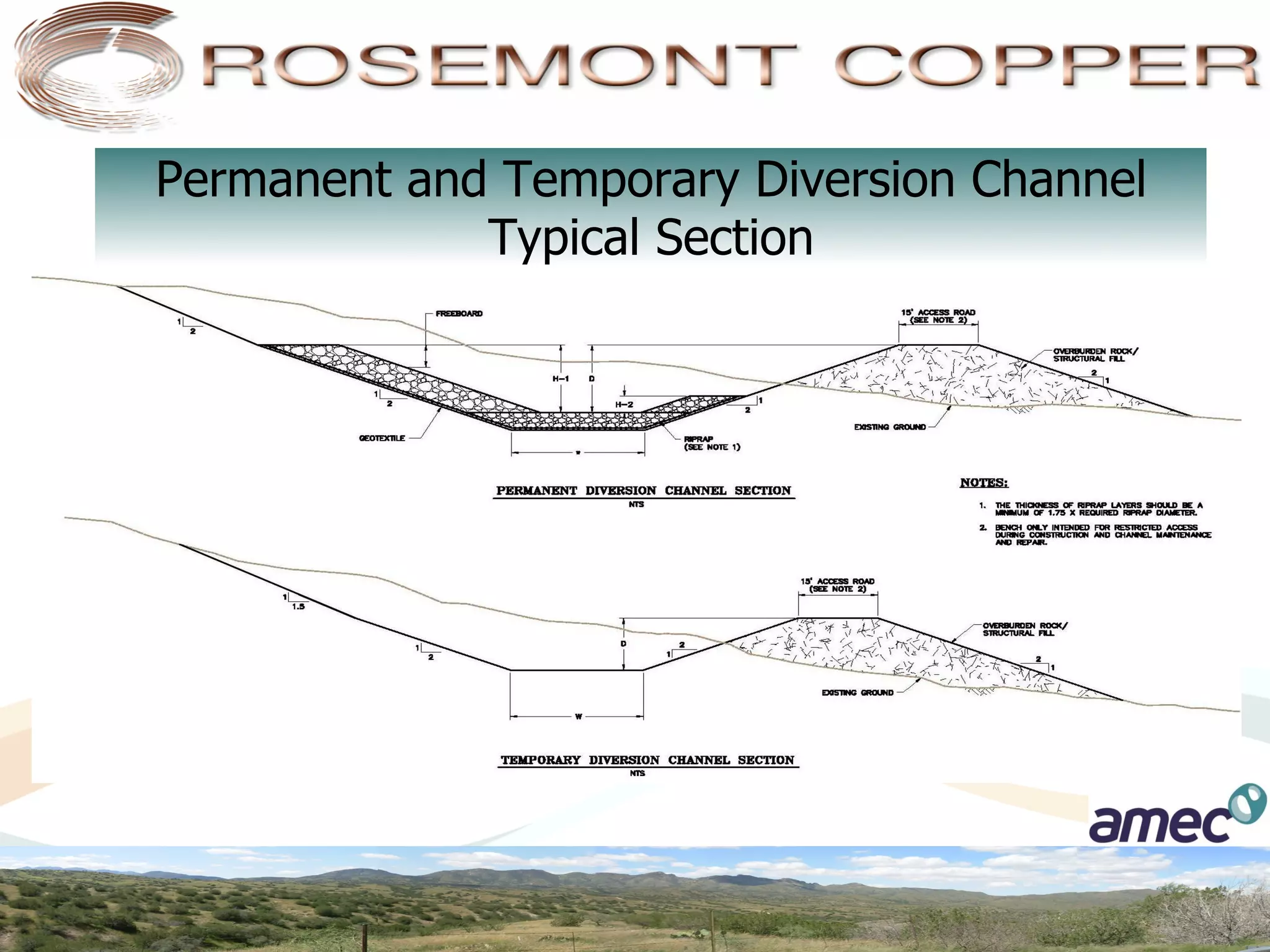

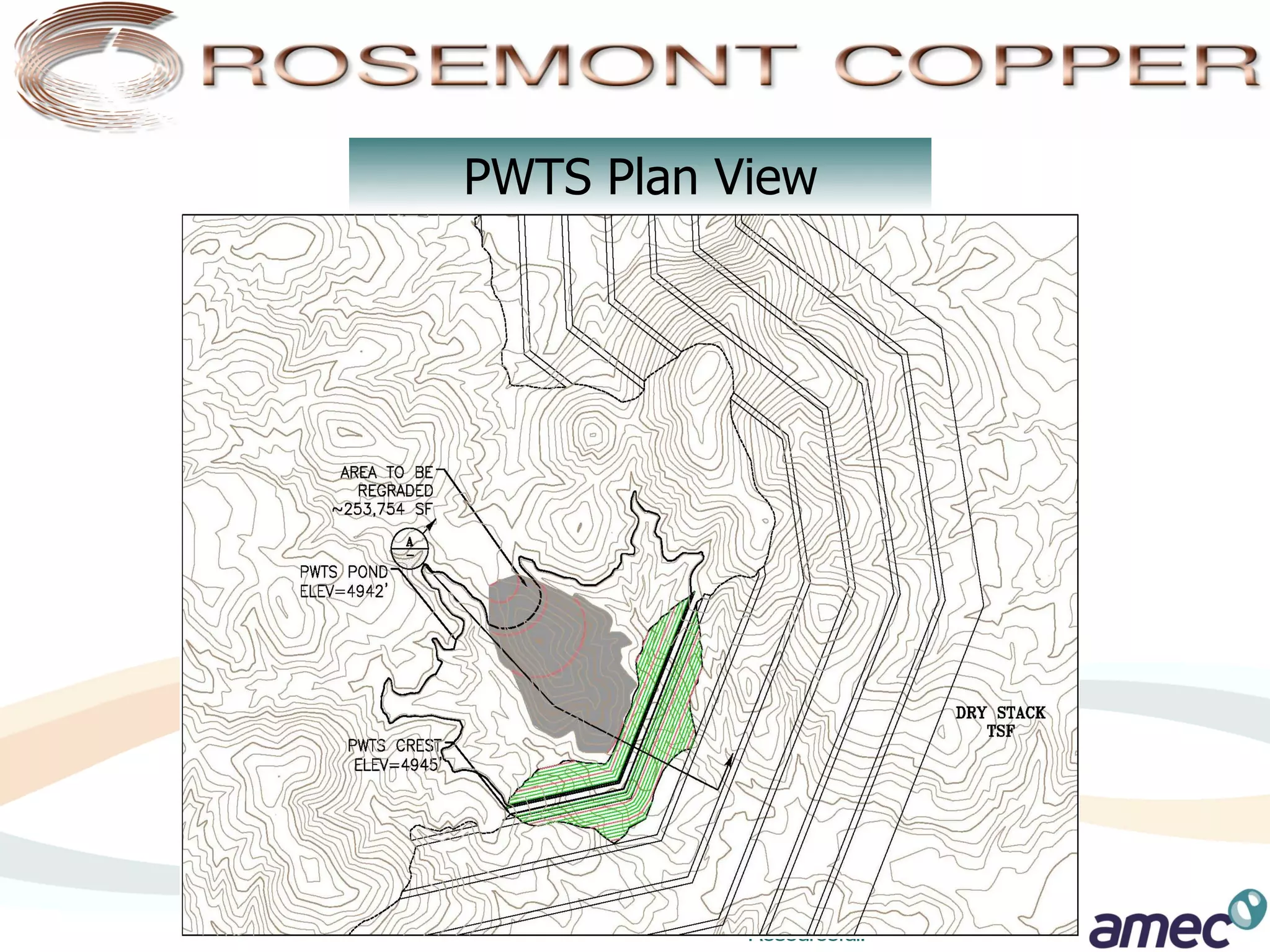

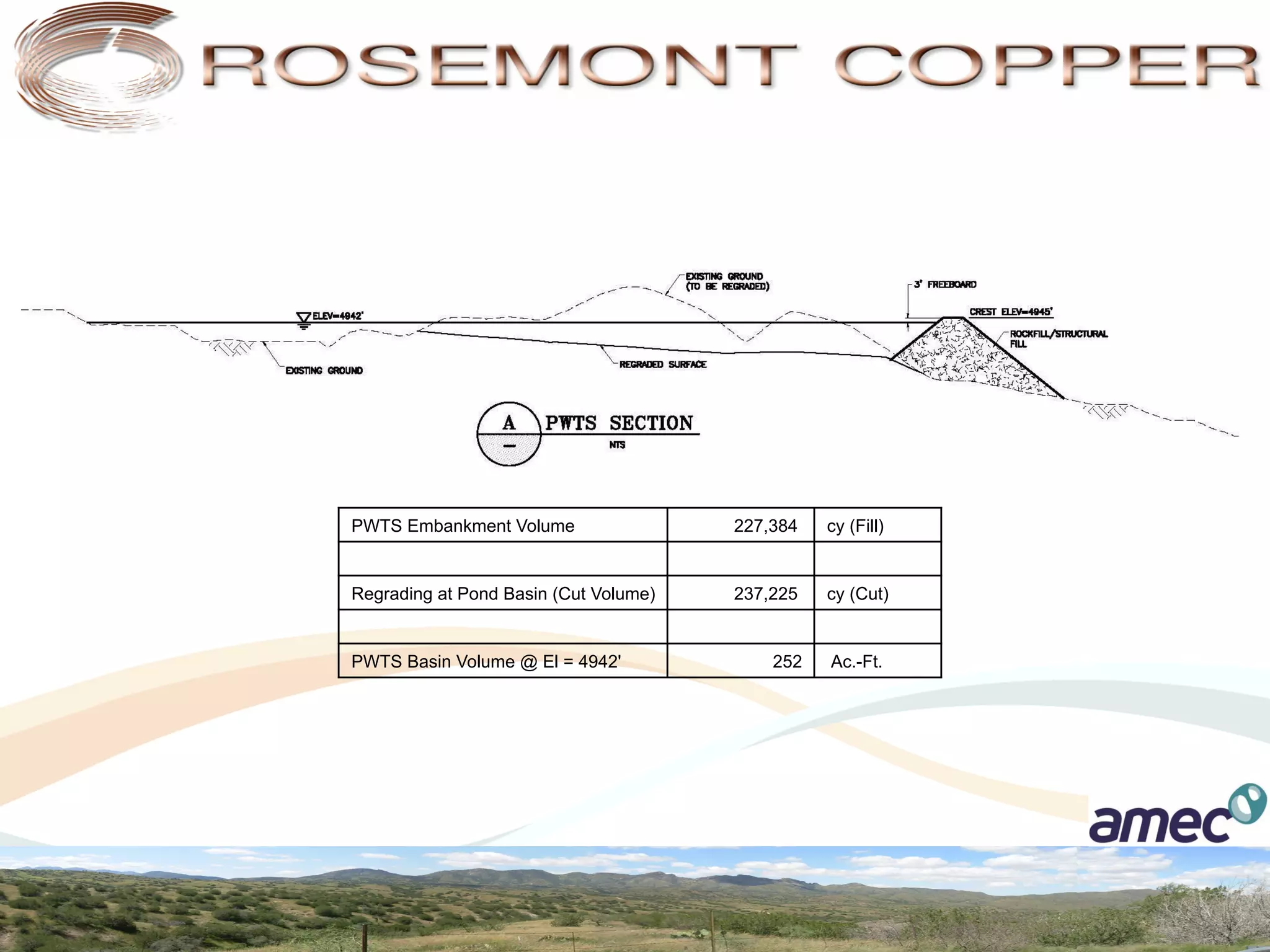

The document outlines the advantages and design criteria for a dry stack tailings storage facility (TSF), highlighting benefits such as water conservation, minimal disturbance, and concurrent reclamation. It details the storage capacities and characteristics of both Phase I and Phase II of the TSF, along with environmental compliance and construction specifications. Additionally, it describes the design and schedule for both permanent and temporary diversion channels and a process water temporary storage pond to manage stormwater and maintain operational integrity.